The Williams Companies, Inc

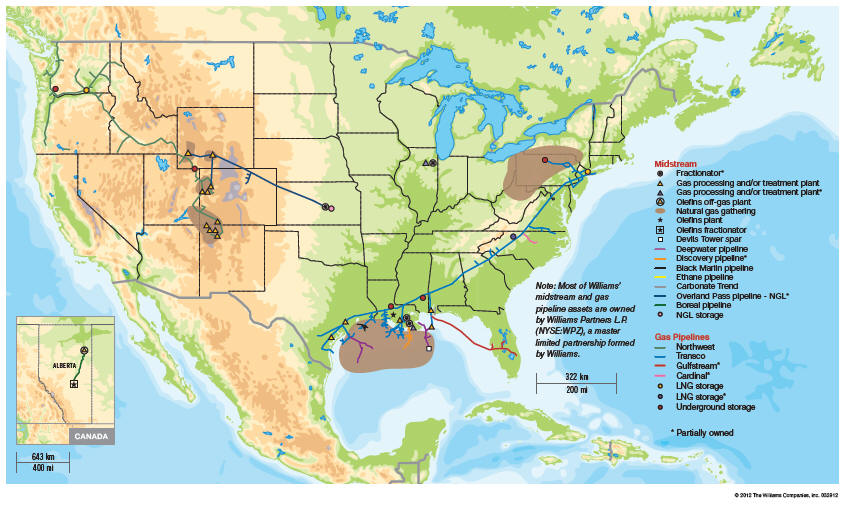

Williams, including its assets held

through Williams Partners L.P., is an energy infrastructure company focused

on connecting North Americafs significant hydrocarbon resource plays to

growing markets for natural gas, natural gas liquids (NGLs) and olefins.

Williamsf operations span from the deepwater Gulf of Mexico to the Canadian

oil sands.

Williamsf interstate gas pipeline and

midstream operations span the deepwater Gulf of Mexico to the Canadian oil

sands.

The companyfs gas pipeline and domestic midstream interests are largely held

through its significant investment in Williams Partners L.P., one of the

largest energy master limited partnerships. Williams owns a 68-percent

interest in Williams Partners.

@

Sep 13, 2012 (Datamonitor via COMTEX)

Williams to build new PDH facility in Canada

The Williams Companies, Inc., an energy infrastructure company, has announced

that it is exploring building a propane dehydrogenation, or PDH, facility in

Alberta, Canada.

A new PDH facility, which would be the first in Canada, would allow Williams to

significantly increase its production of polymer-grade propylene from its

Canadian operations. Williams is the only company in Canada producing

polymer-grade propylene, a valuable petrochemical feedstock used in plastics

manufacturing.

Williams would primarily use the propane it recovers at its Redwater facility

near Edmonton, Alberta, as feedstock for the new PDH facility, which would

convert the propane into higher-value propylene that will be transported to the

US Gulf Coast. The associated hydrogen by-product would be sold locally in the

Alberta market.

"Building a PDH facility would further build on the value and expertise that

we've built in Canada and serve the booming North American petrochemical

market," said David Chappell, president of Williams Energy Canada. "Besides our

expertise in extracting and marketing these products, we have the infrastructure

in place with fractionation, distribution and storage to fully realize the value

from a new PDH facility.

"Because of our existing facilities, we would be able to capture value from PDH

production byproducts butane/butylene and ethane/ethylene that another PDH

operator would have to burn," Chappell said. "We've built a unique business in

Canada and we're continuing to explore ways to capture more of the off-gas

available from existing and planned upgraders, and to add more value to the

products we produce."

Williams' proposed PDH facility in Canada would have an annual capacity of

approximately 1 billion pounds. The company estimates capital expenditures of

approximately $600 million to $800 million that would be funded primarily with

international cash on hand.

@

2013/3/18@Williams@

Williams to Build and Operate PDH Facility in

Alberta, Canada, to Produce Polymer-Grade Propylene From Propane

New Propane Dehydrogenation Facility Will

Convert Alberta Propane Into Higher-Value Propylene

Uses Propane Feedstock Primarily from Williams' Expanding Canadian Upgrader

Offgas Processing Operations as well as Expected Abundant and Low-Cost

Alberta Propane

Adds to Williams' Expanding Canadian Propylene Supply; Expect to Expand

Distribution and Sales to U.S. Gulf Coast Markets as well as Explore

Development of New Alberta Markets

Builds on Williams' Unique Business in Canada, Creates Natural Hedge for

Williams' Propane Position

Company Cites Environmental Advantages in Selected Processing Technology

Williams announced today that it has

sanctioned construction of a propane dehydrogenation (PDH)

facility in Alberta, Canada. The new PDH facility, the first and only in

Canada, will allow Williams to significantly increase production of

polymer-grade propylene from its Canadian operations. Williams is the only

company in Canada currently producing polymer-grade propylene, a valuable

petrochemical feedstock used in plastics manufacturing.

Williams' PDH facility in Canada will have the capability to initially produce

up to approximately 1.1 billion pounds (500 kilotonnes)

annually of polymer-grade propylene, with the opportunity

to double capacity with a future expansion. The

company estimates capital expenditures of up to $900

million CAD to be funded with expected cash flow from its Canadian

operation and international cash on hand. Pending appropriate permitting

approvals, the PDH facility is scheduled to go into service in the second

quarter of 2016.

Williams has selected Honeywell's UOP as the vendor to provide the UOP Oleflex™

process technology for the dehydrogenation process. The technology is

environmentally superior because it uses a platinum-based catalyst system, as

well as less energy and water than competing PDH technologies. Williams' PDH

facility will be sited in close proximity to its existing

Redwater fractionation plant near Edmonton, Alberta.

Williams plans to primarily use propane recovered from its

expanding oil sands offgas processing operations along with local propane

purchases as feedstock for the new PDH facility. It will convert the propane

into higher-value propylene that will be transported to

the U.S. Gulf Coast and sold to petrochemical producers. Plans are to

sell the associated hydrogen byproduct in the Alberta market. Williams is also

exploring development of new propylene markets for its production in Alberta.

The Redwater complex includes fractionation, storage and distribution facilities

and is currently being expanded to produce approximately 5 million barrels of

propane and 280 million pounds of polymer-grade propylene annually from offgas,

in addition to other NGLs and olefins. The addition of the new PDH facility will

vastly increase Williams' production of polymer-grade propylene. The company

expects the new facility to produce one of the lowest-cost, PDH-sourced

propylene feedstocks in North America.

"We're thrilled to be moving full-speed ahead on Canada's first and only PDH

facility. The project fits strategically within Williams' operations in Alberta,

leverages our expertise in propylene and adds further value to a byproduct of

oil sands upgraders," said David Chappell, president of Williams Energy Canada.

"Once operational, this new propane dehydrogenation facility will expand market

opportunities for Canada, feed the demands of North America's growing

petrochemical industry and allow for the creation of a new value chain in

Alberta."

"We are extremely excited about this project on many levels," said Alan

Armstrong, president and chief executive officer of Williams. "We expect the PDH

facility to deliver a very attractive return on investment as well as provide a

long-term natural hedge of the propane volumes we control in our Canadian offgas

processing business. Our planned PDH facility will enable Williams to capture

the full value between natural gas and polymer-grade propylene rather than just

the value between natural gas and propane."

Williams' Operations in Canada: Innovative Business, Emissions Reducer

When producers convert the Canadian oil sands into usable oil, the process

produces an offgas byproduct that includes a rich mixture of natural gas, NGLs

and olefins. Williams pioneered the process of extracting the mixture from the

offgas at its Fort McMurray, Alberta, liquids extraction plant.

After it extracts the offgas mixture, Williams returns the clean-burning natural

gas to the third-party oil sands producer for its operations. It then transports

the remaining NGL/olefins mixture, via Williams' Boreal Pipeline, to its

Redwater fractionation facility for further separation.

Williams' offgas processing reduces emissions of carbon dioxide (CO2) – a

greenhouse gas – in Alberta by approximately 200,000 tonnes each year and cuts

emissions of sulphur dioxide (SO2) – a contributor to acid rain – by an average

of 1,700 tonnes each year. The new offgas expansions will further reduce both

carbon dioxide and sulphur dioxide emissions in Alberta.

@