ExxonMobil, BASF to Partner on Methane Pyrolysis Demonstration Plant in Baytown, TX CO2でなく、固形炭素製品ができるため、カーボン補足・貯蔵処理が不要

ExxonMobil and BASF have agreed to co-develop methane pyrolysis technology, including plans to construct a demonstration plant, which would serve as a critical step toward delivering commercial-ready hydrogen solutions for industrial use, the companies said this week.The companies plan to build and operate a demonstration plant at ExxonMobil's Baytown, TX, complex using existing natural gas infrastructure, which would be capable of producing up to 2,000 tons/year of low-emission hydrogen and 6,000 tons/year of solid carbon product. (As we noted in Hard to Handle, hydrogen's unique properties can make using existing natural gas infrastructure a difficult task.) BASF has been developing methane pyrolysis technology over the past several years in a project funded by the German Federal Ministry of Research, Technology and Space, validated at its test plant in Germany, the companies said.

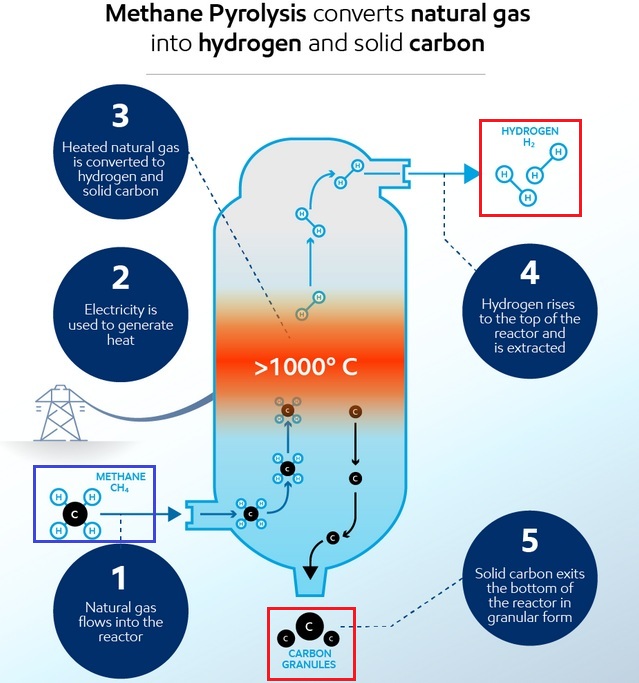

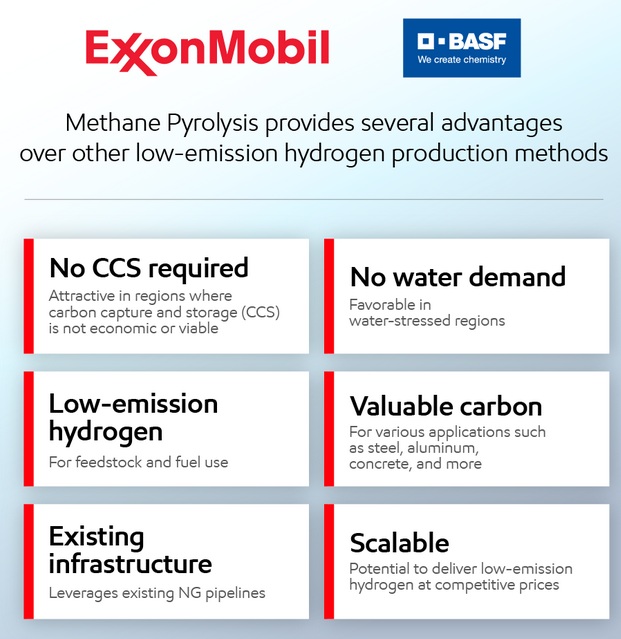

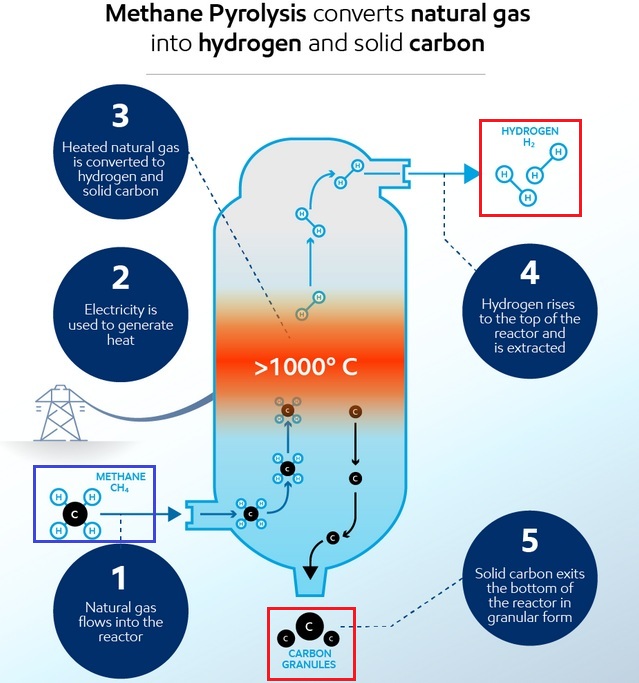

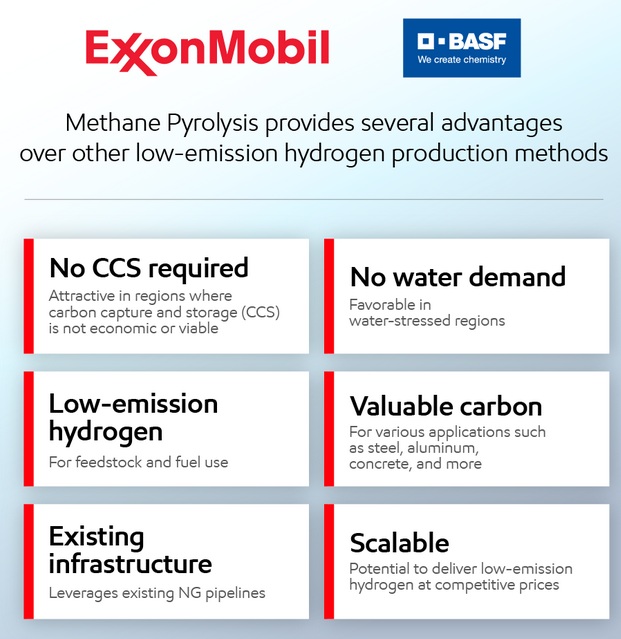

Methane pyrolysis (see graphic below) uses electricity to convert natural gas or other gases, like bio-methane, into hydrogen and solid carbon. The technology offers several potential advantages: it does not generate process-related carbon dioxide (CO2) emissions, unlike traditional methods such as steam-methane reforming; requires approximately 5X less electricity than water electrolysis; and does not require the use of water. The lack of process CO2 emissions could make it attractive for regions where carbon capture and sequestration (CCS) faces geologic, technical or policy-related challenges. (For more on the challenges of CCS, see The Longest Time.)

This process creates two products: low-emission hydrogen and high-purity solid carbon. The solid carbon has applications across multiple industries including steel, aluminum manufacturing, construction and advanced carbon products, like battery materials.