2014/12/8 Global Bioenergies

Direct biological production of Propylene - Third star on Global Bionergies' race to renewable olefins

Global Bioenergies announces having succeeded in the production of bio-sourced propylene by direct fermentation. It is the first time ever an entirely biological production procews - i.e. without any chemical step - is reported for propylene, a central building block for the manufacturing of plastics.

After isobutene in 2010 and

butadiene earlier this year, Global Bioenergies today announces having created a

proprietary strain able to convert glucose into propylene at laboratory scale.

This is the first time ever such a direct biological production of propylene has

been reported.

Over 80 million metric tons of propylene are produced yearly, corresponding to a market exceeding 100 billion dollars - the second largest of the petrochemical industry after ethylene. It is a key building block for the manufacturing of different plastics - polypropylene for example accounts for more than half of the plastics used in the car industry.

Propylene is so far only produced through fossil resources and principally obtained from naphtha cracking.

Tho,as Buhl, Head of Business Development at Global Bioenergies comments: "Because of the decrease in naphtha cracking capacities, there is a need for alternative routes to light olefins, and in particular to propylene. By developing this process to bio-propylene, we are contributing to building a better world, sustainable and environment friendly."

November 26th, 2014 GLOBAL BIOENERGIES announces break-through in direct biological production of butadiene

November 17th, 2014 GLOBAL BIOENERGIES: Successful first trial in its industrial pilot isobutene

グロバルバイオエネルギーは再生可能資源から軽質オレフィンを生物を持ちいてダイレクトに生産することを可能とする代謝経路を2008年に新たに開発しました。このダイレクトが意味するところは、細胞器官により分泌されたものがまさしく軽質オレフィン自身であり、アルコール類、例えばエタノール、イソブタノールやブタンジオールのような化学的な脱水や、その後数段階におよぶ化学反応を必要とするものではありません。

室温において軽質オレフィンは気体であり、それゆえ連続的に発酵中の液体培地より気化します。 よって通常の液体発酵と比べ2つの大きな利点があります:

− ガスは反応チャンバー内に蓄積されないため、生産物の濃度が微生物の活動を減速または阻害しません。

たとえば、エタノールの場合10%を少し超える濃度において酵母に対し毒性を持ち始めます。

−精製プロセスにおいては、例えば生成された最終産物までの段階において、蒸留または相分離等のエネルギーを消費する方法が必要ではなく、かなり簡単で安価に済みます。

グローバルバイオエネルギー社は第四四半期に、グルコースをプロピレンとブタジエンへ直接変換するために必要なすべての酵素群を実験により同定したと発表しました。

2011年6月、同社はイソブテンプロセスの工業化だけでなく、他の軽質オレフィンのプログラムを前倒しするための資金を調達するためにIPOを実施しました。

グローバルバイオエネルギー社は、Synthos、LanzaTech、ドイツ系自動車メーカー及び50の米国大手企業とバイオブタジエン合成ガス、ガソリンと互換なバイオ燃料及びイソブテンに関してパートナーシップを確立しています。

Using our innovative approach to produce

gaseous olefins identical to those currently produced massively from fossil

oil, ensures the sustainability of industries that rely on these products:

indeed, fuels derived from isobutene are fully miscible with fossil fuels.

Existing storage and distribution infrastructures will continue to be used

and thus allow a transition towards renewable fuels that will not require

additional investments or adaptive efforts from end users.

These gaseous olefins will also allow the production of materials (plastics,

rubbers, Plexiglas®…) in existing industrial infrastructures. Relying on

these infrastructures will facilitate the transition towards the use of

these biosourced products.

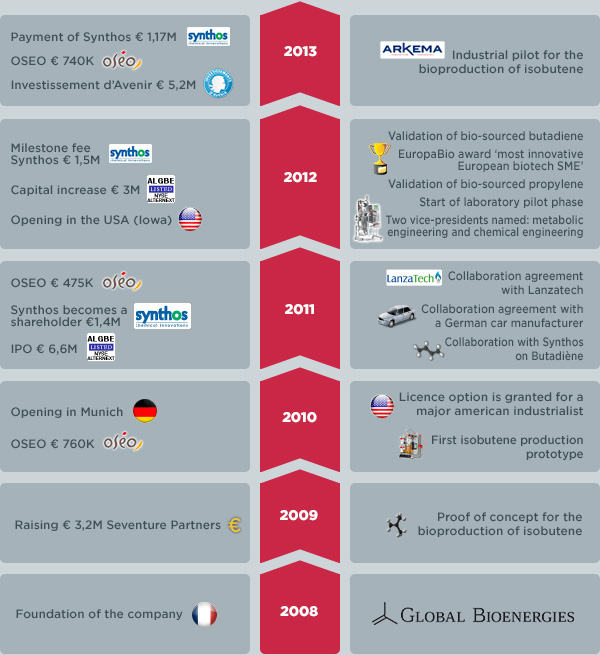

Global Bioenergies was founded in October 2008 by Marc Delcourt and Philippe

Marlière.

In February 2009, the company raised €3.2m ($4.6m) from Seventure Partners, the

VC subsidiary of BPCE, one of France’s main banks.

In 2009, a proof of concept was obtained for the process leading to the

bio-production of isobutene. A lab-scale prototype was built in 2010. Two

preliminary agreements have been signed on the isobutene process, one with an

American major and one with a German car manufacturer.

In July 2011, Global Bioenergies has performed its IPO to raise the capital

necessary to the development of its isobutene process. €6.6m have thus been

raised on the NYSE Alternext market in Paris.

In July 2011, the Company has announced the signature of a partnership with

Synthos to replicate to butadiene the success originally obtained on isobutene,

another member of the light olefins family. A milestone in this partnership has

been reached in December 2012 which has resulted in the payment of €2.7m by

Synthos to Global Bioenergies. The butadiene process is now in its development

phase.

In June 2013, the Company announced the beginning of the industrial pilot phase

of its isobutene process, in collaboration with Arkema and supported by a €5.2m

financing to be received from the French State (“Investissements d’Avenir”

program).

Global

Bioenergies development milestones