↓

Yeochun NCC (Joint Venture between Hanwha Chemical and Daelim, 50:50)

大林産業

The Daelim Group

started in 1939 as a lumber

operation named Boolim Company. In 1947, the company was renamed

Daelim industrial Co., Ltd. which completed Korea's first-ever

overseas construction project in the 1960s. In additon, the group

has been involved in many construction projects of historical

proportions in Korea, including petrochemical plants in Yosu and

Ulsan, fertilizer plants, the Seoul-Pusan Expressway, power

plants, and harbors. Daelim acquired Honam Ethylene Co., Ltd. in 1979, and that operation was merged

with Daelim industrial Co., Ltd. in 1987, setting the stage for a

new round of growth. On the 50th anniversary of the group

foundation (1987), the Daelim Group proclaimed a second

foundation and embarked on an ambitious plan for leadership.

↓

Yeochun NCC (Joint Venture between Hanwha Chemical and Daelim,

50:50)

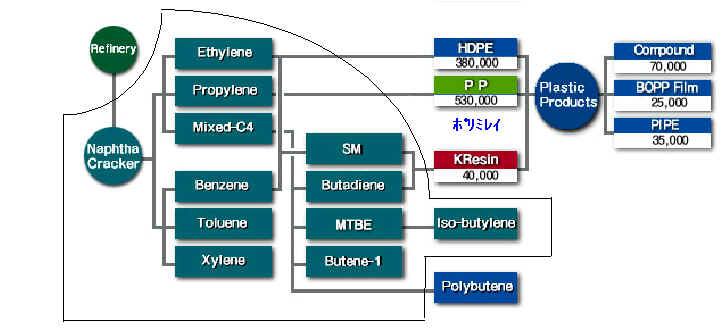

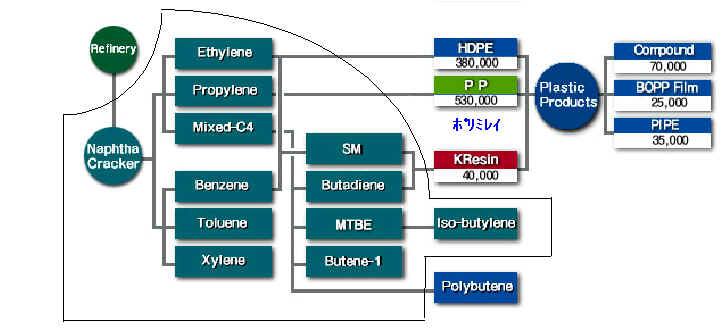

大林産業 扱い製品:HDPE、ポリブテン、加工製品

ナフサクラッカー ハンファのクラッカーと統合 → Yeochun

NCC

LDPE

ハンファに譲渡

PP ポリミレイに譲渡

ポリミレイ資本構成

大林産業㈱ 50%

モンテル・エスディーケイ・サンライズ㈱

30%

バセル・インターナショナル・ホールディングス社

8%

台湾ポリプロピレン㈱ 12%

HDPE

HDPE is manufactured using two kinds of process.

One is the Supported Chrome Catalyst-Slurry Process, which was developed by Phillips 66 in U.S.A., a world renowed company in the field of catalyst technology. By this Process, the control of molecular weight and its distribution is easily made and products may be modified according to customer's requirements. The use of a chrome catalyst eliminates the risk of corrosion of processing machinery due to residual chlorine.

The Other is the Spherilene Process that was first developed by Montell, the largest Polyolefin Manufacturer in the world, which Daelim has commercialized first time in the world.

POLYBUTENE

- Daelim undertook the development of polybutene synthesis process as a research project to enhance the value of C4-raffinate-1

- Daelim became the first Korean company to succeed in the synthesis of Polybutene in 1986.

- To commercialize this thchnology, Daelim built a pilot plant in 1989 and engaged in operation and sales of sample product.

- After quilty improvement and process evaluation were achieved, Daelim constructed plant in 1993.

| 1939 | Lumber production company & civil engineering and construction company established(Bulim company) | |

| 1947 | Trade name changed to Daelim Industrial Co., Ltd. | |

| 1979 | Participated to petrochemical industry (Honam Ethylene Co., Ltd.), Operates Naphtha Cracking Center No.1 | |

| 1986 | R&D center established, Operates SM plant | |

| 1987 | Honam Ethylene Co., Ltd. changes its name to Petrochemical Division Daelim Industrial Co.,Ltd., Starts PIPE processing business | |

| 1991 | Research center at Daeduk established. | |

| 1992 | Starts operations for high-value products (CctComplex plant, BD plant), Research center at Daeduk established, plastics processing plant newly expanded (Chochiwon plant) | |

| 1993 | Polymer business expanded (PP、LDPE plant), PB own process developed & commercial plant started up (PB plant) | |

| 1994 | Commercial production started of all companies in the world(L-LDPE), ISO 9002 Certificate acquired, Sales company (Daelim Corporation) established | |

| 1996 | Operates another PP & L-LDPE plant (Yong-song Complex), Starts BOPP film processing business (Chon-ju plant), ISO 14001 Certificate acquired | |

| 1997 | Operates KResin plant | |

| 1999 | LDPE, L-LDPE business withdrew (Big-deal with Hanwha petrochemical co.,). NCC Business is separated as an independent company (Yeochon NCC co.,) | |

| 2000 | K-Resin Business is separated as an independent company (KR Copolymer co.,) PP Business is separated as an independent company (PolyMirae co.,) |

Asia Chemical Weekly 2003/8/20

Korean Daelim mulls divesting hdPE

plant to Basell

South Korea’s Daelim Industrial is considering

inviting Basell to take a majority stake in its 380 000 tonne/year high

density polyethylene (hdPE) plant at Yeochun. The plant would subsequently

be converted to a polypropylene (PP) plant, a source close to

Daelim sail.

Basell and Daelim are already equal

partners in PolyMirae, a 530 000 tonne/year PP player also sited

at Yeochun. Basell was not immediately available for comment.

The other option for Daelim if

Basell is not interested would be to sell off the hdPE plant to

an interested party.

The company hopes to go through with

the hdPE divestment or sale some time next year.

Daelim hopes to divest most of its

petrochemical assets in the next couple of years, keeping a

minority interest for itself. The assets include a 70 000 tonne/year polymer

compounding plant, a 35 000 tonne/year pipe-processing plant and

a 25 000 tonne/ year biaxially oriented PP (BOPP) film plant in addition to the hdPE and PP plants.

This marks another shift in Daelim’s strategy. The company said in June that

it was frustrated by its inability to divest its petrochemicals

assets, and was considering realigning its petrochemicals

business to bring it closer to its core engineering and

construction operations.

At the time, the company said it was

not considering attracting a partner to consolidate its PP and PE

businesses. Nor would it sell its stake in its cracker joint

venture with Hanwha Chemical-Yeochun National Cracker Centre

(YNCC).

The company claimed at the time that

it had been on the lookout for a partner to consolidate its

business in South Korea, but had been unable to find a deal that

was attractive to all parties involved. It had therefore decided

to produce more speciality-grade polymers for the construction

business, as opposed to commodity-grade general-purpose polymers.

The company said at the time that it

aimed to change the speciality-to-commodity ratio to 55:45 from

30:70 by retooling its plants at Yeochun.