トップページ

SABIC

Europe

SABIC ACQUIRES DSM's POLYOLEFINS Capacity

Aiming

For Number One

SABIC

Europe starts production of bio - ETBE in the Netherlands

SABIC Europe Cracker Project in

Geleen on hold

SABIC Europe signs contract to

build new HDPE plant in Gelsenkirchen

SABIC opens new high density

polyethylene plant in Germany

SABIC Europe announces plans to

streamline its aromatics operations

Start date nears at £200m SABIC plant at Wilton

SABIC Announces Restructuring

Plans for its European Operations

Saudi chemical giant to invest

nearly £1bn in Teesside plant

http://www.sabic-europe.com/europe/_en/index.pl

SABIC Europe is a 100

percent affiliate of SABIC, the largest petrochemical player in

the Middle East and the number 4 global player in polyolefins

worldwide, producing more than 5 million tons of polyethylene and

polypropylene per year.

In Europe SABIC is

a major polymer producer. The European SABIC business also

harbors the sales organization for all SABIC products

manufactured elsewhere in the world. SABIC sales in Europe amount

to almost 6 million tons of polymers, base chemicals and

intermediates.

The European head

office is located in Sittard (The Netherlands) and integrated

world-scale production facilities are based in Geleen (The

Netherlands) and Gelsenkirchen (Germany) with a total yearly production of

4.0 million tons of petrochemicals. In Europe, apart from

polyethylenes and polypropylenes, SABIC also produces chemical

products like benzene, acetylene and MBTE.

Geleen is also the

hometown of a state-of-the-art R&D center and a highly

qualified Technical Marketing team for expert technical support.

Sales offices operate from The Netherlands, the United Kingdom,

France, Germany, Italy, Spain, Denmark, Poland, Czech Republic

and Turkey.

The European branch

forms part of SABIC, the largest Middle East petrochemicals

player and the number 4 player in polyolefins worldwide,

producing more than 5 million tons of polyethylene and

polypropylene per year. Apart from this SABIC is also active in

chemicals, fertilizers and metals.

| Located in

Geleen (The Netherlands), SABIC Europe operates two steam

crackers capable of producing over 1,250,000

tonnes of ethylene and approximately 675,000

tonnes of propylene each year. It also

operates advanced downstream plants for acetylene, MTBE,

butadiene, benzene, gasoline components, styrene, C9

resinfeed, cracked distillate and carbon black

feedstocks. |

Polyethylenes

SABIC markets over

2 million tons of HDPE, LDPE and LLDPE in Europe. The product

range is fit to serve all major PE markets, with extrusion, blow

moulding, injection moulding and extrusion coating as the main

processing techniques. Applications are flexible packaging, such

as stretch film, shrink film, food packaging, carrier bags and

photo-coating, and rigid applications such as bottles & cans,

pipes, sheets, crates & boxes and dustbins. Around 1.3

million tons of the total volume marketed is produced in Europe.

Polypropylenes

SABIC markets 1.2

million tons of polypropylene as well as a wide range of

compounds based on this polymer. Most of these materials are

produced in our European production facilities. The product range

is fit to serve all major PP markets with injection moulding and

extrusion as most important processing techniques. Applications

are flexible and rigid packaging, fibers, housewares &

appliances, caps & closures, automotive parts (e.g. bumper

systems) and pipes.

Melamine,

polyvinylchloride, polyester and polystyrene

Melamine,

polyvinylchloride, polyester and polystyrene products are

manufactured by SABIC affiliates in Saudi Arabia: National

Plastics Company (Ibn Hayyan), Arabian Petrochemical Company

(Petrokemya), Arabian Industrial Fibers Company (Ibn Rushd) and

Saudi Arabian Fertilizer Company (SAFCO).

These polymers are

used in applications such as components in paints, adhesives and

powders (melamine), wall covering, laminated fabrics, cell foam

and pipes (PVC), fibers, yarns and bottles for drinks (polyester)

and building & roof insulation, packaging for household

appliances and containers (polystyrene).

SABIC’s polyolefins position in Europe

(production in Europe in kt)

Chemical

Engineering News December 7, 2005

Aiming For Number One

http://pubs.acs.org/cen/news/83/i50/8350SABIC.html

Since Saudi

Basic Industries Corp. (SABIC) acquired DSM's petrochemical

operations in mid-2002, it has been busy coming to grips with

this European-based petrochemical business. Now, its European

management team has laid out how it intends to build its business

in the region.

And the answer is clear: SABIC Europe is aiming to be one

of the top two marketers of polyolefins in Europe.

The company currently is the fourth largest seller of polyolefins

in Europe. It also occupies the same position worldwide, selling roughly 4.9 million tons

of polyolefins

per year, behind ExxonMobil at roughly 6.5 million

metric tons, Dow Chemical at about 7.5 million metric tons, and

Basell at nearly 9.0 million metric tons.

SABIC is now finalizing plans for the big project it will rely on

to fulfill its European goal: its fifth

ethylene cracker, envisaged for its site in Geleen, the

Netherlands.

That cracker and a series of new plants and expansions are part

of the company's Europe 1 project to expand Geleen and its site

in Gelsenkirchen, Germany.

Between Geleen and Gelsenkirchen, SABIC Europe has a total polyethylene

capacity of 1.48 million metric tons per year - 47% of SABIC's global

polyethylene capacity - and 1.09 million metric tons of

polypropylene,

65% of total SABIC polypropylene capacity. The feedstock at

Geleen is from the company's own naphtha crackers - crackers No.

3 and 4 are its current workhorses, supplying a total of 1.25 million

metric tons of ethylene and 675,000 metric tons of propylene. Production in Gelsenkirchen

depends upon feedstock secured under a long-term contract from

the neighboring BP cracker.

The

Europe 1 project - budgeted at nearly $1.8 billion - is set to start up in 2009, says

Frans Noteborn, chief executive officer of SABIC Europe.

The Europe 1

project will add another 400,000 metric tons of ethylene capacity to the company's European

slate. But even more important, Noteborn says, the proposed

cracker will be a “propylene machine” that will use metathesis

technology to produce up to 620,000 metric tons of propylene. It will also make benzene and

ethyl tert-butyl ether.

Looking five years ahead, “propylene will not be tight - it

will be very tight,” Kostering says. The industry is

predicting a global demand increase over that

time of 14 million metric tons of propylene, he points out. But current

industry plans call for only 5 million more

metric tons from new crackers and cracker expansions, and another 4 million

metric tons through propane dehydrogenation and metathesis. Projected cracker propylene

output is modest because, unlike the proposed Geleen project,

most new crackers are based on ethane and don’t turn out propylene.

The company acknowledges the two other announced European

ethylene additions - Ineos’ plan for an 800,000-metric-ton

facility in Wilhelmshaven, Germany, by 2008 or 2009; and BASF's

300,000-metric-ton expansion in Antwerp by 2007. But Noteborn and his

team are not worried by the competitive threat.

June 9, 2006 SABIC Europe

SABIC Europe Cracker

Project in Geleen on hold

SABIC Europe has decided to put the development of

the cracker project on the Geleen-site (the Netherlands) on hold. The

investment costs and financial risks are too high to realize a

financially sound project on the Geleen site today.

“The

main cause for the high investment costs is the current

overstrained market situation in the global contracting and

construction market due to the many investments projects in the

oil, gas and energy market worldwide. “

explains Frans

Noteborn, CEO of SABIC Europe.

SABIC remains committed to its strategy of growth for the

important European market. To realize this strategy, all options

such as the upgrading of the current asset base and supply from

the global SABIC system to strengthen the existing portfolio will

be reviewed in the coming months.

The investment would have seen the building of a

third, 520,000 mt/year cracker at Geleen, and further polymer

plants at Gelsenkirchen.

2006/4/28 Global Insight Daily Analysis

Dutch Government Approves Installation of Third Cracker at

SABIC Refinery

The Dutch government has cleared the way for refiner SABIC to

build a third naphtha cracker at Geleen in the Netherlands,

after resolving issues over fiscal regulations and emissions.

'The problems connected with the plant from the side of the

government have now been resolved, and it is now up to SABIC

whether to go ahead', a Ministry of Economic Affairs

spokesperson told Platts.

Significance: Plans to build the 520,000-million-tpa

cracker

at Geleen had been held up by SABIC's concerns about carbon-dioxide

emission payments before and after 2012, fiscal

rulings and infrastructural issues. A decision on whether to

proceed with 1.5-billion-euro (US$1.86-billion) expansion is

now up to SABIC, which originally expected the cracker to

start up in the first quarter of 2006. Late last year, SABIC

said that the ongoing risk evaluation would last longer than

expected. and approval was delayed for an unspecified period.

March 22, 2006 SABIC

Europe

SABIC Europe starts production of bio - ETBE in the Netherlands

SABIC Europe announced today the start of production of bio -

ETBE [ethyl-tertiary butyl ether] at its Geleen site in the

Netherlands. First commercial deliveries to customers are

expected at the beginning of April. This investment in Geleen

enables SABIC to enter the bio-fuel market and is in support of

the EU’s implementation of the European

Bio-Fuels Directive within its member states. This plant is the

first of its kind in the Netherlands.

SABIC’s ETBE production plant in Geleen,

with an annual capacity of 140kt, converts bio-ethanol and

iso-butylene into ETBE which is recognised as a valuable

high octane gasoline blending component. ETBE in gasoline

contributes to a better air quality by reducing emissions of,

amongst others, carbon monoxide and volatile organic compounds.

July 31, 2006 SABIC

Europe

SABIC Europe signs

contract to build new HDPE plant in Gelsenkirchen

SABIC signed today

a contract with the German contractor, Uhde, for the construction

of a new bimodal HDPE (high density polyethylene) plant at its

production site in Gelsenkirchen, Germany.

The new 250 kt/y plant will come on stream in Q4 2008

and will replace the current 100 kt/y PE

plant in Gelsenkirchen. The investment in the new

project, including the infrastructural improvements at the site,

is around Euro 200 million.

“I am pleased

that after more than two years of dedicated work, we have decided

to start with the construction of the plant,”

says Abdullah

Bazid, Managing Director Chemicals & Intermediates. “The investment in the

Gelsenkirchen site is a positive signal for the site to become

even more competitive as against other petrochemical sites in

Europe. We will be able to enhance our cost position in Europe

and satisfy our customers.”

This investment is

in line with SABIC’s growth strategy in Europe. Koos

van Haasteren, Managing Director Polymers says: “This project will further

strengthen SABIC’s leading position in the fast

growing market for the bimodal pipe business.”

Gelsenkirchen site

The Gelsenkirchen

production site - formerly Vestolen Hulsの子会社- was acquired in 1997. (* DSM acquired Vestolen in November 1997)

The site has since

undergone continuous modernization and expansion. After

completion of the new plant more than Euro 500 million has been

invested in the Gelsenkirchen facilities. The production has gone

up from 250 to 1100 kilo tons per year since 1998.

“A lot of effort

has been successfully made in the past years to optimize the

site. This investment will further strengthen Gelsenkirchen’s competitiveness,”

says Jan van den

Berg, Managing Director at Gelsenkirchen. “The investment of Euro 200 million

will further secure the future of the site and will be a positive

contribution to the regional economy of Nord-Rhein Westfalen.”

2009/4/4

SABIC opens new high

density polyethylene plant in Germany

SABIC's new High

Density Polyethylene (HDPE) bi-modal slurry plant the LD6 in

Gelsenkirchen, Germany is up and running and meets the high

expectations. The first produced SABIC Vestolen A pipe grades

are commercially available from now.

The SABIC Vestolen A family is well-known for its high

quality; offering properties such as easy processability as

well as excellent pipe performance with regards to

reliability and safety. With the LD6 SABIC is ready for the

future HDPE market: The LD6 secures future product supply,

enables high-end product innovations and ensures a more

environmental friendly production process.

SABIC's LD6 is

equipped with a leading production technology that secures a

reliable and high quality product supply. The new plant will

cover a production of 250kt per annum.

Vestolen

Huls AG inherited the

polymer sector from the firms that succeeded I.G.

Farbenindustrie AG - Bayer AG, BASF AG and Hoechst AG dye

works.

They were created from the demerger of I.G. Farben after

1945.

Via the mining company Hibernia AG, which held 25%

of the shares in Huls, the company acquired the

highly productive Ziegler patents which made possible

non-pressurized, oil-based manufacture of polyethelene. In

order to manufacture and market VESTOLEN, Hibernia AG and

Huls AG entered into a joint venture, VESTOLEN GmbH, in the mid-1950s.

VESTOLEN

GmbH was dissolved when Huls became the Chemicals Division of

VEBA in

1979. Production and marketing were combined in one Huls

business unit. In the course of a portfolio consolidation,

the VESTOLEN product range was hived off again and in 1993 it

was launched as the newly-founded VESTOLEN GmbH, which today belongs to SABIC

(Saudi Arabian Basic Industries Corporation).

Capacity SABIC ACQUIRES DSM's POLYOLEFINS

DSM HYDROCARBONS B.V.

The heart of DSM’s European polyolefins business

lies in the ethylene crackers that feed the polyethylene,

polypropylene, and EP elastomers plants as well as other

production facilities.

Two steam crackers with a

combined ethylene capacity of ca. 2.8 billion pounds

are situated in Geleen and operated by DSM Hydrocarbons.

Located in Geleen

(The Netherlands), SABIC Europe operates two steam crackers

capable of producing over 1,250,000

tonnes of ethylene and approximately 675,000

tonnes of propylene each year. It also operates

advanced downstream plants for acetylene, MTBE, butadiene,

benzene, gasoline components, styrene, C9 resinfeed, cracked

distillate and carbon black feedstocks.

The Europe 1 project

will add another 400,000 metric tons of

ethylene capacity

to the company's European slate. But even more important,

Noteborn says, the proposed cracker will be a “propylene

machine” that will use

metathesis technology to produce up to 620,000 metric tons of

propylene.

It will also make benzene and ethyl tert-butyl ether. →

on hold

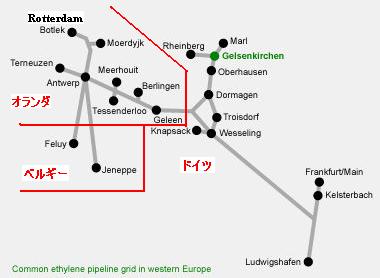

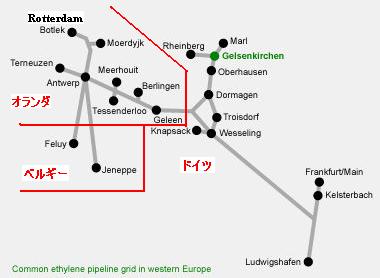

Two other steam crackers,

owned by Ruhr Oel, or ROG, a 50/50 joint venture between Veba Oel

GmbH and Petroleos de Venezuela SA, supply ethylene and propylene

to the polyethylene and polypropylene plants in Gelsenkirchen.

The Gelsenkirchen crackers are connected to the Geleen site by

the ARG ethylene pipeline.

Due

to BP's acquisition of Veba Oel, Ruhr Oel is now operated

jointly by Deutsche BP and the Venezuelan oil company PdVSA

As a large supplier

of olefins in north-west Europe BP Refining

& Petrochemicals has the operatorship of the

petrochemicals plants in Gelsenkirchen and Münchsmünster, which are operated

jointly by Deutsche BP and its partner, the Venezuelan oil

company PdVSA. Supplies come predominantly from the

oil-refining facilities of Ruhr Oel.

There are further petrochemicals plants at

Erdoel-Raffinerie-Emsland (ERE) in Lingen, a 100%

shareholding of Deutsche BP.

The total annual capacity of the petrochemicals plants

amounts to 4.9 million tonnes. BP RP is the biggest supplier

of ethylene in the merchant market. It is also market leader

in sales of cyclohexane. In its core business of olefins BP

RP will expand its market position by means of stategic

expansion and increases in capacities.

DSM POLYETHYLENE

DSM Polyethylenes presently has a total capacity approaching 3.4

billion pounds, divided as follows:

(1) LDPE - 1,342 million pounds,

(2) HDPE - 1,100 million pounds, and

(3) LLDPE - 924 million pounds.

Included in the LLDPE numbers are the pounds of EXACT(R) octene-1

based plastomers produced by Dex-Plastomers

V.O.F, the

50/50 joint venture with ExxonMobil.

Dex-Plastomers

V.O.F

A 50 / 50 joint

venture between DSM and ExxonMobil Chemical.

Established in

1996.

Two product

families, Exact® Plastomers and

Stamylex® octene linear

polyethylenes.

120 kTpa

solution PE capacity.

DSM's Compact®

solution

polymerisation process, which has a proven history of

manufacturing high performance octene copolymers.

ExxonMobil

Chemical's Exxpol® metallocene catalyst

technology, allowing the production of Exact

plastomers.

The Gelsenkirchen

production site - formerly Vestolen - was acquired in 1997.

(* Towards the end of 1997, the

Dutch company DSM bought Vestolen, the polyolefins business

of Veba, Germany, giving DSM an additional 150,000 t pa HDPE

and 200,000 t pa PP.)

The site has since undergone continuous modernization and

expansion. After completion of the new plant more than Euro

500 million has been invested in the Gelsenkirchen

facilities. The production has gone up from 250 to 1100 kilo

tons per year since 1998.

The new bimodal HDPE 250 kt/y plant will come on stream in Q4

2008 and will replace the current 100 kt/y

HDPE plant in Gelsenkirchen. The investment in the new

project, including the infrastructural improvements at the

site, is around Euro 200 million.

Exhibit 3 lists

polyethylene and polypropylene plant locations and production

technologies for DSM. The Vestolen acquisition in 1997 brought DSM 3 HDPE lines each

having a capacity of 110 million pounds per year. Since then DSM

has expanded one of the lines by 50% to produce HDPEs with

bimodal MWDs for use in pipe and sheet applications.

Geleen has 3 tubular reactors with a total capacity of 1,100

million pounds of LDPE within excess the largest line, which was

installed in 1993, having a capacity of 440 million pounds. DSM

produces a small amount of ultrahigh-molecular-weight

polyethylene, UHMWPE, used primarily to produce its Dyneema(R) fibers. Dyneema is produced by

DSM High Performance Fibers.

DSM POLYPROPYLENE

Total annual polypropylene production capacity is in excess of

2.4 billion pounds. DSM expanded its polypropylene capacity as

well in 1997 when it picked up the Vestolen assets. Vestolen was

a relatively small player in polypropylene that focused on niche

applications such as film and fibers. The Vestolen polypropylene

assets comprised a 220 million pound UNIPOL plant and 2 slurry

lines, each having a capacity of 110 million pounds per year. The

UNIPOL plant is slated for expansion to 330 million pounds per

year. DSM has added a 517-million-pound plant at Geleen and a 750-million

pound plant at Gelsenkirchen, using BP Amoco’s (horizontal) gas-phase process

technology (Innovene PP) to produce polypropylene homopolymers

and random copolymers. A third Innovene PP plant with a capacity

of 660 million pounds is slated for construction at Geleen.

DSM

Hydrocarbons Americas, Inc.

is a sales office whose primary business focus is on the sales

and procurement of products for DSM Hydrocarbons in The

Netherlands.

DSM Hydrocarbons

Americas' geographical focus is the USA, Canada, Mexico,

Venezuela and Colombia. For the Latin American market DSM

Hydrocarbons Americas also sells caprolactam, cyclohexanone and

specialty chemicals.

Exhibit 3

DSM - PE & PP Capacities, Western Europe, 2001→2005

| |

|

Process

Tech./Type |

Capacity |

| (MM Lbs) |

千トン |

| Ethylene |

Geleen |

|

|

1,250 |

HDPE

|

Geleen,

Gelsenkirchen

|

Slurry

Slurry ***

|

(1,100)

|

350

150→100

(500)→(450)

|

LDPE

|

Geleen

|

Tubular, autoclave

|

1,342

|

610

|

LLDPE

|

Geleen

|

Unipol, gas

|

660

|

300

|

Compact, solution *

|

264

|

120

|

Total

|

(924)

|

(420)

|

Polyethylenes

|

3,366

|

1,530

→1,480

|

Polypropylene

|

Geleen

|

Innovene, gas

|

517

|

235

|

Mitsubishi-Yuka, slurry

|

704

|

320

|

Gelsenkirchen

|

Innovene, gas

|

750

|

340

|

Huls, slurry**

|

220

|

100

|

Unipol, gas**

|

220

|

100

|

Total

|

2,411

|

1,095

|

DSM, TOTAL

|

5,777

|

2,625

→2,575

|

*

Dex-Plastomers

V.O.F

** former

Vestolen GmbH

***

By

1st January 2004 SABIC Europe closed two out-dated polyethylene

slurry lines in Gelsenkirchen (120 tpy). Production has been

transferred to a modern gas phase plant on the same site and

plants in Saudi Arabia, resulting in substantial cost savings.

50+50+50

→50+50+75

→60+60+100

→0+0+100→(250+0)

Sep 17 2007

Evening Gazette

SABIC, planning 3rd PP

plant in Europe

A Teeside, Wilton chemical company, which earlier this

year said it may invest £200m locally in a new plant, has

applied for planning permission for the project.

A spokesman for SABIC

said while no decision had yet been made on whether the

investment would come to Wilton, the move would help speed up

development if the region is successful.

Paul Booth, president of

SABIC UK Petrochemicals, revealed earlier this year that the

company was hoping to secure construction of a new polypropylene

plant at Wilton.

He said Teesside was one

of two locations the company was looking at for a third European

polypropylene plant.

SABIC has now applied to Redcar and Cleveland Council for

planning permission to build a new plant.

オランダのGeleen工場にエチレン、HDPE、LDPE、LLDPE、PPプラント、

ドイツのGelsenkirchen工場にHDPEとPPプラントをもつ。

エチレン能力は125万トン、PEは148万トン、PPは109.5万トン。

The company is currently

building a £200m polyethylene

plant at Wilton.

July 16, 2008 SABIC Europe

SABIC Europe announces

plans to streamline its aromatics operations

SABIC Europe today

announced plans to re-structure its Aromatics

operations based on Teesside, UK following a wide-ranging review

of the long-term viability of the business.

The plans involve closure

of the Aromatics 2 unit at the SABIC UK

Petrochemicals North Tees Site near Seal Sands and the Paraxylene plant

at the Wilton Site

near Redcar. The plans also include an upgrade of the

remaining Aromatics 1 plant at North Tees.

"On Teesside, SABIC

UK Petrochemicals remains fully committed to its Olefins Cracker

operations at Wilton

and Cyclohexane

production at North Tees. The current construction of the

new world scale Low Density Polyethylene (LDPE)

plant and a

possible upgrading of the Aromatics 1 plant are important factors in helping

to underpin this." concludes Hughes. In addition, SABIC

Europe continues to operate its ongoing Aromatics business in the

Netherlands.

Aug 21 2009

Start date nears at £200m SABIC plant at Wilton

A NEW multi-million-pound chemical plant on Teesside could come

on stream within weeks.

The £200m Low Density

Polyethylene (LDPE)

facility is being developed by SABIC at Wilton.

Today the company said it hoped to bring the plant on stream

during September.

The facility will create around 120 permanent jobs and help

underpin the future of the company’s Cracker facility at Wilton.

A spokesman said: “The LDPE is nearing completion.

“Commissioning

is well advanced and we hope to be able to bring the plant on

stream during September.”

When the new LDPE

plant reaches full production of well in excess of 400,000 tonnes per

annum, it

will make it the biggest plant of its type in the world.

The spokesman added: “We hope to be running at full

capacity during 2010.

“We

hope the plant will provide a boost for Sabic and the industry in

general.”

Plans for the £200m plant were originally

announced in 2004 when industrial giant Huntsman said it wanted to build

the world’s largest

polyethylene plant at the Wilton International site.

In

2006 Huntsman signed a £372m deal with

SABIC for the sale of a major part of its Teesside operations.

The sale comprised Huntsman’s petrochemicals assets at Wilton

- the cracker and paraxylene plants and the £200m polyethylene plant, and the

aromatics complex at North Tees.

The new plant reached a major milestone on June 22 when ethylene

feedstock was introduced to the complex for the first time.

April 19, 2013 SABIC Europe

SABIC Announces Restructuring Plans for its

European Operations

SABIC today announced a restructuring program in Europe designed to strengthen

its European businesses for the competitive challenges ahead, whilst maintaining

the highest environmental, health and safety standards.

Following a full review of its European business, SABIC will restructure its

European assets and organizational footprint. The planned restructuring includes

the shutdown of certain assets and a net reduction of approximately 1,050

positions, while there will also be continued investments in plant improvements,

new technologies and innovation. SABIC has initiated consultations with the

relevant Works Councils and trade unions regarding the planned restructuring.

Strategic Overview

“Our strategy in Europe is to be the preferred leader in chemicals by delivering

‘Chemistry that matters’™ demonstrating excellent performance in environment,

health and safety, cost competitiveness, customer value and sustainable profit

levels”, said Koos van Haasteren, Vice President SABIC in Europe. “Furthermore,

we have stronger ambitions in terms of revenue, market position and innovation.

Once the restructuring process has been completed, I am confident that SABIC

will be in an even stronger position to meet customer needs, support its

employees and contribute to the communities and environments within which we

operate.” Van Haasteren continued, “We remain committed to building a company

that provides our employees the opportunity to grow and develop.”.

Challenging Market Context

The European market is facing structural changes that are likely to set a new

course for future competitive challenges. Our industry continues to face slow

growth, as consumers’ spending on houses, cars and appliances and investments in

infrastructure projects are down. These developments have led to structurally

reduced demand and squeezed margins. At the same time, competition has

intensified from other regions, especially from the United States, which has the

advantage of shale gas development, and Asia, which has increased local

production capacity and consumption.

Organizational changes

All of SABIC’s European assets have been reviewed and as a result SABIC plans to

close certain assets and reorganize the supply of products from these affected

assets through other plants.

The planned organization has been redesigned to be more focused and efficient at

delivering to customers’ needs at the highest environmental, health and safety

standards. It is expected that a reduction of

approximately 1,050 positions will take place across Europe, including

1/3 contracting staff and 2/3 SABIC employees.

These changes will enable SABIC to continue to deliver Chemistry that matters to

its customers and all its stakeholders.

----

Rubberworld

The company said it had started consultations

with the relevant works councils and trades unions on the planned restructuring.

A company source said

two smaller polypropylene lines in Gelsenkirchen, Germany, including PP 2.3 and

PP 2.4, would be closed, while another line would be consolidated. SABIC

operates two gas-phase PP plants at Gelsenkirchen, with a capacity to produce

200,000 metric tons/year and 330,000 mt/year of PP resins, respectively. The

first plant uses Unipol PP technology, while the second uses Amoco technology.

At Bergen op Zoom, the Netherlands, SABIC will close a small asset operated by

SABIC Innovative Plastics, the company source said. The asset is used to

manufacture the raw material for one of SABIC's brands, Noryl.

This raw material is used to make polyphenylene ether (PPO) resins, which are

used as an additive or building block in a variety of thermoplastics used in the

insulation, cable and automotive sectors, among others. The production of this

raw material will be moved to the U.S., where the company intends to expand its

capacity, the source said. The source did not give the capacity of this unit or

the expansion plans in the U.S.

"All of SABIC's European assets have been reviewed and as a result SABIC

plans to close certain assets and reorganize the supply of products from these

affected assets through other plants," the company statement said. It attributed

the restructuring to the structural changes in Europe. The source did not give

details of the use of the PP resins coming from these two lines.

| |

立地 |

製法 |

能力(千トン) |

| 2001 |

2005 |

| エチレン |

Geleen |

(2系列) |

1,250 |

→ |

|

PE

|

HDPE |

Geleen |

slurry |

350 |

→ |

|

Gelsenkirchen |

slurry * |

150 |

100 |

|

LDPE |

Geleen |

Tubular, autoclave |

610 |

→ |

|

LLDPE |

Geleen |

Unipol, gas |

300 |

→ |

|

Compact, solution ** |

120 |

→ |

| 合計 |

1,530 |

1,480 |

|

PP |

Geleen |

Innovene, gas |

235 |

→ |

|

Mitsubishi-Yuka, slurry |

320 |

→ |

|

Gelsenkirchen |

Innovene, gas |

340 |

→ |

|

Huls, slurry * |

100 |

→ |

|

Unipol, gas * |

100 |

→ |

| 合計 |

1,095 |

→ |

| ポリオレフィン合計 |

2,625 |

2,575 |

-----

ICIS

The company said two

older polypropylene (PP) lines in Gelsenkirchen have been earmarked for

closure, while a polyphenylene ether (PPO) asset in

Bergen op Zoom (of

SABIC Innovative Plastics) will be shut down.

SABIC said business from the PPO asset would be transferred to its site in

Selkirk, NY (of

SABIC Innovative Plastics).

Business from the two units in Gelsenkirchen will be transferred to another PP

facility at the same site, the company added.

SABIC also confirmed jobs will be cut in Raamsdonkveer, Geleen, Bergen op Zoom

and Sittard in the Netherlands, Teesside in the UK, Cartagena, Spain and in

Gelsenkirchen.

The restructuring programme is expected to be completed by the end of 2014,

however SABIC will start implementing the changes as soon as possible.

“We have started the consultation process with the respective works councils and

employee representatives this week. The timing of the outcome of this

consultation process may differ per location but we are hoping to provide

clarity as from mid-July,” SABIC said.

Around two thirds of the planned job cuts across Europe will involve SABIC

employees. The remainder of the cuts will come from contracting staff. SABIC

said the job cuts will take place across all business units, operations and

staff functions. Information about cuts at a departmental or individual level

are subject to the consultation process, it added.

The company did not disclose the cost of the restructuring.

On Thursday, SABIC announced a planned restructuring programme designed to

strengthen its European businesses. The company said at the time the planned

organisation has been redesigned “to be more focused and efficient at delivering

to customers’ needs at the highest environmental, health and safety standards.”

SABIC added that lower consumer spending in the European market has led to

slower growth, which has “structurally reduced demand and squeezed margins”,

while competition has intensified from other regions, especially from the US and

Asia.

2021/10/28

Saudi chemical giant to invest

nearly £1bn in Teesside plant

Saudi Arabian manufacturing and

chemicals giant Sabic is to invest almost £1bn at its Teesside plant.

The company, one of the world's

largest petrochemical manufacturers, told Reuters the cash injection was part of

its plans to reduce its carbon footprint by up to 60%

initially.

Boris Johnson said the investment was a "huge vote of confidence" in the UK's

chemicals industry.

The prime minister said the deal would create and safeguard 1,000 jobs.

Sabic said the investment would include strengthening operations at Teesside and

making its site "one of the world's lowest carbon-emitting crackers".

A cracker is a facility that processes and heats hydrocarbons to make building

blocks for all sorts of products.

The company produces chemicals, fertilisers, plastics and metals at its plant

in Wilton, near Redcar, but also has storages and logistics facilities in

North Tees and Teesport.

The announcement comes as Britain is set to host the COP26 climate talks in

Glasgow in November.

The summit is seen as crucial if climate change is to be brought under control.

For this conference, 200 countries are being asked for their plans to cut

emissions by 2030.

----------------

SABIC Europe

2006/8/22

SABIC Europe とその前身

2006/10/3

SABIC、Huntsmanから英国の石化子会社を買収

SABIC’s Teesside site has manufacturing,

storage and logistics facilities spread over three sites, at Wilton

International, North Tees and Teesport. The import and export facilities

make the Teesside site an integral part of SABIC’s European-manufacturing

operations.

The Olefins 6 facility at Wilton has

been closed for over a year and the investment will secure its future,

creating and protect 1,000 jobs in the process.

The firm announced on Wednesday that

investment in the Teesside site is one of a series of actions the

company is taking as part of its carbon neutrality strategy.

The first phase will reduce its

carbon footprint by up to 60 per cent, making it one of the world’s

lowest carbon-emitting crackers.

In the second phase, a carbon

neutrality feasibility study will be undertaken with

the use of hydrogen as a fuel source.

Wilton

International site is one of the UK’s leading process

manufacturing sites based on the outskirts of Redcar, in the North

East of England.The

site boasts a number of major international companies in a variety

of fields including energy generation, recycled plastic, biofuel

products as well as the manufacture of chemicals and petrochemicals.

SABIC own several assets based

here, which manufacture some of the major chemicals for our company.

Olefins 6

The Olefins 6 plant, also known

as the ‘cracker’, was commissioned by ICI in 1979 as a liquid

naphtha cracker and is now the second largest cracker in Europe. The

plant also includes the Gasoline Treatment Unit and Butadiene 3

plant, in addition to the main cracker unit.

The world-scale cracker produces

ethylene, propylene and butadiene, which are the chemical buildi

blocks for items that we use in our everyday lives such as car

interiors, tyres, electrical goods, clothing and detergents.

The cracker was recently modified

to handle both liquid and gas feedstock, including ethane, naphtha,

propane and butane, making it one of the most flexible crackers in

Europe.

System 18, LDPE

Commissioned in October 2009, the

System 18, LDPE plant is the largest single stream tubular

low-density polyethylene (LDPE) plant in the world. The plant

processes approximately half of the ethylene output from SABIC’s

Olefins 6 ‘Cracker’. The technology for System 18 is licensed from

Exxon Mobil.

Approximately fifteen grades of

LDPE, in the form of polymer pellets, are produced at System 18,

which can be tailored to our customers’ requirements. The pellets

are stored in the Logistics facility adjacent to our plant until

they are ready to be shipped to our customers. Our pellets are used

to manufacture products that are commonly found in everyday life,

such as packaging for food and agriculture and in medical

equipment.

Wilton Logistics

Wilton Ethylene Control (WEC)

forms the hub of the UK ethylene system, moving product from the

Olefins 6 plant to customers around the UK; including the System 18

plant, North Tees Liquefaction, the Ineos Grangemouth site and the

Inovyn site at Runcorn, via cross-country pipelines (CCPL).

Our Central Control facility,

manages the feedstock for the Butadiene Plant and products from

Olefins 6 and the Gasoline Treatment Unit.

Finally, our Teesport operation

is responsible for the safe and reliable import and export of all

feedstocks and products via our two jetties on the River Tees.

North Tees

Site

The North Tees Logistics (NTL) area

supports the major feedstock and product import, export, storage and

distribution logistics for SABIC on Teesside. Our operations cover an

extensive land area, which includes storage facilities, operation of

three jetties on the River Tees, an ethylene liquefaction terminal,

brine extraction and an ethane import terminal.

The storage and distribution of all Olefins

6 feedstocks, naphtha, ethane, propane and butane, is managed by NTL; as

well as the export of the two main products from Olefins 6, ethylene and

propylene, to customers outside the UK mainland by ship. NTL also

operate an Effluent Treatment Plant which processes all water on SABIC’s

North Tees site.

Wilton

Centre

SABIC’s UK headquarters is based in The Wilton Centre,

which is adjacent to the Wilton International Site.

Staff from our UK

manufacturing operations team are based in the offices

here, working in disciplines such as HR, procurement,

EHSS, finance, legal, communications, IT and

administration along with employees from our European

and Global teams and our Senior Management Team.