Capital investment is expected to be approximately SAR 40.5 billion ($US 10.8 billion), subject to the completion of detailed feasibility studies and environmental impact assessments. Ma’aden will own 60 percent of the joint venture. Alcoa will control the remaining 40 percent of the joint venture through an investment partnership in which it will own 20 percent and its partners will participate through financing that represents the other 20 percent economic interest. Each of Alcoa and the partners will invest $900 million over a four-year period and will be responsible for their pro rata share of the project financing, in addition to specific completion commitments.

In welcoming the new venture, Dr. Abdallah Dabbagh, President and CEO of Ma’aden, said, “Alcoa’s partnership in all aspects of this integrated industry brings with it enormous value not only in terms of technology, resources and experience but also a proven commitment to sustainability.” He added, “A focus on quality alongside the robust economics of the project will ensure its leading role in advancing Saudi Arabia and the region as a major hub for the aluminum and downstream sectors.”

Alcoa President and CEO Klaus Kleinfeld said, “This joint venture is a once-in-a-generation opportunity for Alcoa, for Ma’aden and for the Kingdom of Saudi Arabia. We are creating a fully integrated aluminum complex that will be the most technologically advanced and cost efficient in the world. By changing the operating dynamics and cost base within our industry, the complex will be a model for the growth of aluminum in competition with other metals and is designed with the potential for future expansion. The joint venture leverages the unique strengths of both Alcoa and Ma’aden to create substantial value for our investors, customers and partners.”

Alcoa will provide know how, management expertise and support during the design, construction and operation of the mine, refinery, smelter and rolling mill. Alcoa will also arrange the supply of alumina feedstock to the smelter from outside the Kingdom until the project refinery comes on stream. Alcoa and Ma’aden will work with leading international and local firms on the design and construction of the complex.

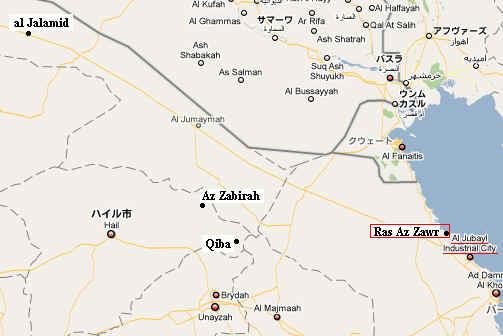

Ma’aden’s Chairman, Engineer Abdullah Saif Al-Saif, added that the Saudi government’s investment in critical national infrastructure is proving to be a catalyst for this and other projects. “The positive impact of the government’s vision in developing the Kingdom’s infrastructure including the new railway network and deepwater port at Ras Az Zawr is clearly demonstrated by the realization of this industry and others such as phosphate. Collaboration in clean efficient power generation also ensures that it is both highly competitive and sustainable.”

About Alcoa

Alcoa is the world leader in the production and management of primary aluminum, fabricated aluminum and alumina combined, through its active and growing participation in all major aspects of the industry. Alcoa serves the aerospace, automotive, packaging, building and construction, commercial transportation and industrial markets, bringing design, engineering, production and other capabilities of Alcoa's businesses to customers. In addition to aluminum products and components including flat-rolled products, hard alloy extrusions, and forgings, Alcoa also markets Alcoa® wheels, fastening systems, precision and investment castings, and building systems. The Company has been named one of the top most sustainable corporations in the world at the World Economic Forum in Davos, Switzerland, and has been a member of the Dow Jones Sustainability Index for eight consecutive years. Alcoa employs approximately 63,000 people in 31 countries across the world. More information can be found at www.alcoa.com

About Ma’aden

Ma'aden was established as a Saudi Arabian joint stock company in March 1997 to facilitate the development of Saudi Arabia’s non-petroleum mineral resources and to diversify the Kingdom’s economy away from the petroleum and petrochemical sectors.

Ma’aden is engaged in the development, advancement and improvement of all aspects of the mineral industry, mineral products and by-products and related industries in Saudi Arabia. In July 2008 Ma’aden offered 50 percent of the company’s shares for subscription in a successful SAR 9.25 billion IPO.

Ma’aden has progressed towards realizing its vision of building a world class mineral enterprise and its mission of being a profitable, publicly owned, international mining company, while maintaining the utmost concern for human resources, health and safety, environmental and social issues.

About Ras Az Zawr

Ras Az Zawr is the location for Ma’aden’s minerals industry complex, a 77 square km site, 90km north of Al Jubail on the Arabian Gulf coast of Saudi Arabia. In addition to housing the alumina refinery, aluminum smelter and rolling mill for the Ma’aden Alcoa joint venture aluminium industry, it is also the site for Ma’aden Phosphate Company’s integrated chemical and fertilizer facility, due to begin operation in 2010. The phosphate complex consists of a phosphoric acid plant, a sulphuric acid plant, an ammonia plant, a DAP granulation plant, a co-generation plant and desalination plant, as well as related infrastructure. It will process phosphate concentrate brought by rail from Al Jalamid. This will produce about 2.92 million mtpy of granular DAP, plus approximately 400,000 mtpy of excess ammonia and about 200,000 mtpy of excess phosphoric acid. Ras Az Zawr also has 25 square kilometers of land set aside for industrial expansion and downstream industry.