BP Refining &

Petrochemicals GmbH

http://www.bprp.de/index_en.html

As a large supplier of

olefins in north-west Europe BP RP has the operatorship of the

petrochemicals plants in Gelsenkirchen and Münchsmünster, which are operated jointly

by Deutsche BP and its partner, the Venezuelan oil company PdVSA. Supplies come predominantly from

the oil-refining facilities of Ruhr Oel.

There are further petrochemicals plants at

Erdoel-Raffinerie-Emsland (ERE) in Lingen, a 100% shareholding of

Deutsche BP.

The total annual capacity of the petrochemicals plants amounts to

4.9

million tonnes.

BP RP is the biggest supplier of ethylene in the merchant market.

It is also market leader in sales of cyclohexane. In its core

business of olefins BP RP will expand its market position by

means of stategic expansion and increases in capacities.

BPRP operates two cracker lines at Gelsenkirchen, the stricken 440,000mt line and another 515,00 mt/yr ethylene line which continues to run as normal.

| The sale of two of the three shareholdings in ARG held by BP and Veba Oel to BASF Aktiengesellschaft and Sasol Germany GmbH. was one of the conditions attached to the European Commission's clearance of BP's acquisition of Veba Oel. The sales of the shareholdings have been approved by the other ARG shareholders and the European Commission. |

The beginnings

As early as 1913 Friedrich Bergius carried out successful

experiments in coal hydrogenation. The large-scale industrial

application of the results of his research did not, however,

follow until 1927 - through the chemist Mathias Pier.

The first hydrogenation plant capable of producing gasoline on an

industrial scale went into operation in 1927. The process was

based on lignite as the raw material and Pier conducted research

on the hydrogenation of bituminous coal. In 1935 he achieved the

breakthrough. His process was so far advanced that it was decided

to set up a large-scale plant for the hydrogenation of bituminous

coal (瀝青炭).

Scholven - situated in Gelsenkirchen, in the mining region known

in Germany as the "coal pot" - was the ideal location

for the project, with plenty of the necessary raw material

available locally. All that was needed in addition was hydrogen,

and this was extracted from the coke furnace gas produced in the

cokeries of the Hibernia nitrogen works already there.

It was for these reasons that the first large-scale plant for the

hydrogenation of bituminous coal was built in

Gelsenkirchen-Scholven, where the first gasoline was produced on

3rd August 1936. A milestone in the history of petrochemicals -

and the birthdate of our company.

Petrochemicals

To be precise, petrochemicals already existed at the Scholven

location before gasoline was produced from coal. Pure hydrogen is

needed for the hydrogenation of coal and this was not available

as such. There was, admittedly, so-called coke furnace gas from

the cokeries of the Hibernia nitrogen works, but this gas - with

its 60% hydrogen content - could not be used for hydrogenation

because of its other components. This marked the birth of

petrochemicals in Scholven: the impurities which impaired the

hydrogenation process are in fact valuable raw materials for the

petrochemicals industry. The products which arise in the course

of coke-gas purification - hydrogen sulphide, raw benzene, carbon

dioxide and ethylene - are processed in a further step to

sulphuric acid, pure benzene and (together with the ammonia

likewise produced from pure hydrogen) fertilizers, while ethylene

was sold in those days in steel bottles. In those days the plants

were still very small - polyethylene plants had a normal capacity

of around 10,000 tonnes per year, whereas today 300,000 tonnes

and more per year are the rule - but nevertheless the basis for

petrochemicals in Scholven had been established.

In the last months of the war the hydrogenation plants were

completely destroyed in massive Allied air-raids, and

petrochemicals production also came to a halt.

After the end of the war it became clear very quickly that

petrochemicals, once started up again, would no longer be based

on coal and coke gas but on crude oil, which was far easier to

process.

At the beginning of the 1950s crude oil began to be refined in

Scholven and Horst, at first with the aim of producing heating

oil. During the distillation process naphtha was produced in

quantities that could not be sold on the as yet still small motor

fuel market. Therefore it was decided to process this naphtha

further by cracking, into ethylene, in an olefin plant with a

capacity of 40,000-60,000 tonnes per year. For purposes of

comparison: the quantity of ethylene produced from coke

processing in the early days in Scholven amounted to a maximum of

10,000 tonnes per year.

Veba

Oil Refining & Petrochemicals GmbH

The origins of VORP and its petrochemicals segment date back to

the establishment of the Scholven Hydrogenation Plant on the Hibernia site in 1935.

This represents a milestone in the history of the company, as it

was here that the first gasoline in the world was produced from

bituminous coal and hydrogen. The Hibernia nitrogen works

provided the hydrogen needed for hydrogenation.

In 1939 in Gelsenkirchen-Horst Gelsenberg Benzin

AG started

the production of gasoline from bituminous coal by the

Bergius-Pier process.

After the total destruction of both plants - Scholven and Horst -

in the Second World War, the next milestone came in the early

50s: the beginning of oil refining. In the early 60s the question

arose of what to do with the surplus naphtha production from the

oil refining process. The solution found in Scholven was to build an olefin

plant, which

marked the birth of our petrochemicals activities. At the same

time Gelsenberg started producing crude oil from its own

production sites.

In 1975 both companies came together under the umbrella of Veba Chemie, which was superseded in 1978 by Veba Oel AG. The setting up of Ruhr Oel GmbH in

1983 by Veba Oel AG and Petroleos de Venezuela S.A. was a further important step,

especially for the petrochemicals segment. Ruhr Oel operates the

plants at the Scholven and Munchsmunster (Bavaria) sites. After

numerous restructurings and new shareholdings in the 80s and 90s,

Veba Oel AG became the integrated oil company that is today among

the leaders in Europe.

With the establishment of Veba Oil Refining &

Petrochemicals GmbH with

effect from January 1st, 2000, all of Veba Oel's supply, refining

and petrochemicals activities were brought together under one

roof. VORP has transferred the operatorship of Ruhr Oel's

Gelsenkirchen and Munchsmunster plants to its subsidiary Veba Oel

Verarbeitungs GmbH.

The October 1, 2002 acquisition of Veba Oel AG by BP (from E.ON) did not change the

business goals or activities of VORP. VORP's Joint Venture Assets

with the ROG system were transferred to Deutsche BP on January 1, 2003. VORP is since

then the contractual operator for BP and PdVSA in the ROG system.

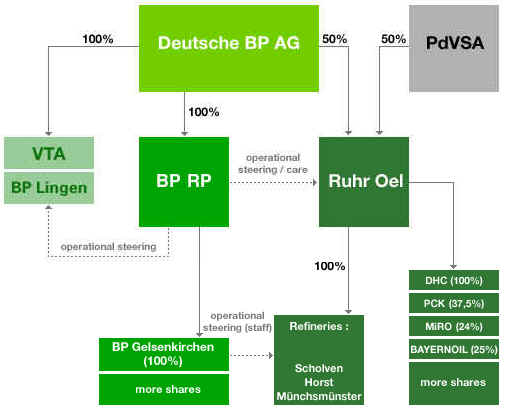

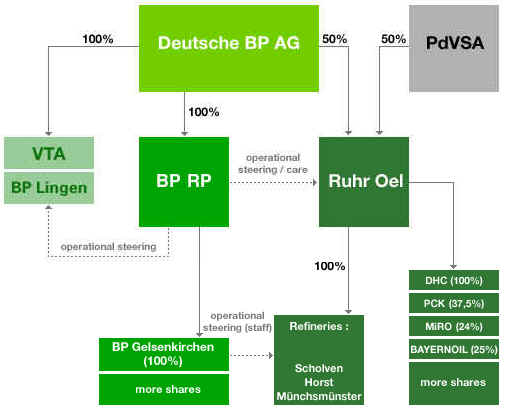

BP Refining & Petrochemicals GmbH

Effective September 1, 2003, the company name Veba Oil Refining

and Petrochemicals GmbH has been changed to BP Refining and

Petrochemicals GmbH to underscore ownership by Deutsche BP AG.

BP Refining &

Petrochemicals, BP RP for short, is a wholly owned subsidiary of

Deutsche BP, on whose behalf it operates of one of the biggest

refinery and petrochemicals systems in Europe. This system, known

as Ruhr Oel, is a joint venture between BP and Venezuela’s PdVSA. Each partner has a 50%

stake in Ruhr Oel and the products are marketed through the

outlets of BP/Aral and partly by BP RP itself.

The BP RP oil refining and petrochemicals production

activities are grouped mainly under the umbrella of Ruhr Oel

GmbH, a 50:50 joint venture with the Venezuelan state-run oil

company Petróleos

de Venezuela S.A. (PdVSA). The Ruhr Oel

companies include the

Scholven and Horst refineries in Gelsenkirchen and the Münchsmünster

petrochemicals plant near Ingolstadt. BP

RP operates all three locations on behalf of Ruhr Oel through its

subsidiary BP Gelsenkirchen GmbH.

Via Ruhr Oel, BP RP also cooperates with other national and

international oil companies such as DEA, Agip, TotalFinaElf,

Esso, Mobil and Conoco. BP RP looks after the operational side of

BP's

shareholding in the

Mineraloelraffinerie Oberrhein GmbH & Co. KG Karlsruhe, the

BAYERNOIL Raffinerie Gesellschaft mbH, Vohburg/Danube and the PCK

Schwedt GmbH, Schwedt/Brandenburg.

Ruhr Oel's Capacities in the BP RP Group 2004

| Location | Segment | Crude oil distillation capacity (Mill. t) |

Production capacity (Mill. t) |

Ruhr Oel share |

| Gelsenkirchen | Min* | 12.9 | 12.9 | |

| Gelsenkirchen/Mülheim | PTC** | 3,9 | 3,9 | |

| Münchsmünster | PTC | 0.5 | 0.5 | |

| Karlsruhe (MiRO) | Min | 14.9 | 3.6 | |

| Vohburg/Ingolstadt/ Neustadt (BAYERNOIL) |

Min | 12.0 | 3.0 | |

| Schwedt (PCK) | Min | 10.5 | 3.9 | |

| Schwedt (PCK) | PTC | 0.5 | 0.2 | |

| BP Lingen | Min | 4.0 |

* Min = Oil refining, ** PTC = Petrochemicals

PCK Raffinerie GmbH

Ruhr Oel has a 37.5% interest in PCK Raffinerie in Schwedt/Oder. PCK mainly refines Russian crude and has an annual crude distillation capacity of 10.5 million tonnes. The affiliated petrochemical plants have a total capacity of nearly 0.5 m tonnes per year.BAYERNOIL Raffineriegesellschaft mbH

Ruhr Oel has a 25% share in BAYERNOIL Raffineriegesellschaft in Vohburg (BO). BP RP's task is also the operational care of BP's 10% interest in BO. The refinery is mainly supplied with crudes from Africa, Venezuela, Norway and Saudi Arabia through the Transalpine Pipeline (TAL). BAYERNOIL has an annual crude distillation capacity of 12 million tonnes.

Mineraloelraffinerie Oberrhein GmbH & Co. KG (MiRO)

Ruhr Oel holds a 24% share in MiRO, Karlsruhe. MiRO processes crudes from Africa, the Persian Gulf, Russia, Venezuela and the North Sea. These crudes are transported from Marseilles and Triest via pipeline to Karlsruhe. The annual crude distillation capacity of MiRO is 14.9 million tonnes.DHC Solvent Chemie GmbH

DHC Solvent Chemie GmbH, a wholly-owned subsidiary of Ruhr Oel GmbH, is one of the leading European producers of solvents and other oil-based specialties. The company is supplied with feedstocks mainly from the Gelsenkirchen refineries and petrochemical plants.

The DHC product range includes special gasolines, white spirits (standard and aromatic-free), solvent naphtha and numerous other products such as printing ink oils and rolling oils.There are further petrochemicals plants at Erdoel-Raffinerie-Emsland (ERE) in Lingen, a 100% shareholding of Deutsche BP.

Veba Oel AG purchased Erdöl-Raffinerie-Emsland GmbH & Co. KG, Lingen from Wintershall AG, Kassel, in 1999.

History

In the petrochemicals industry,

scientific research and indsutrial applications are very closely

connected - more so than in almost any other branch of industry.

This symbiosis is rooted in the history of petrochemicals. If we

consider the early years of this branch of science - or industry

- the fruitful interaction between the two, from the start,

becomes clear.

The roots of petrochemicals lie on the one hand in organic

chemistry as a branch of science, on the other hand in the desire

of the coal industry to optimise the usefulness of its raw

material. Developments were accelerated by considerations at the

time of self-sufficiency, which had a high economic status.

The beginnings

As early as 1913 Friedrich Bergius carried out successful

experiments in coal hydrogenation. The large-scale industrial

application of the results of his research did not, however,

follow until 1927 - through the chemist Mathias Pier.

The first hydrogenation plant capable of producing gasoline on an

industrial scale went into operation in 1927. The process was

based on lignite as the raw material and Pier conducted research

on the hydrogenation of bituminous coal. In 1935 he achieved the

breakthrough. His process was so far advanced that it was decided

to set up a large-scale plant for the hydrogenation of bituminous

coal.

Scholven - situated in Gelsenkirchen, in the mining region known

in Germany as the "coal pot" - was the ideal location

for the project, with plenty of the necessary raw material

available locally. All that was needed in addition was hydrogen,

and this was extracted from the coke furnace gas produced in the

cokeries of the Hibernia nitrogen works already there.

It was for these reasons that the first large-scale plant for the

hydrogenation of bituminous coal was built in

Gelsenkirchen-Scholven, where the first gasoline was produced on

3rd August 1936. A milestone in the history of petrochemicals -

and the birthdate of our company.

Petrochemicals

To be precise, petrochemicals already existed at the Scholven

location before gasoline was produced from coal. Pure hydrogen is

needed for the hydrogenation of coal and this was not available

as such. There was, admittedly, so-called coke furnace gas from

the cokeries of the Hibernia nitrogen works, but this gas - with

its 60% hydrogen content - could not be used for hydrogenation

because of its other components. This marked the birth of

petrochemicals in Scholven: the impurities which impaired the

hydrogenation process are in fact valuable raw materials for the

petrochemicals industry. The products which arise in the course

of coke-gas purification - hydrogen sulphide, raw benzene, carbon

dioxide and ethylene - are processed in a further step to

sulphuric acid, pure benzene and (together with the ammonia

likewise produced from pure hydrogen) fertilizers, while ethylene

was sold in those days in steel bottles. In those days the plants

were still very small - polyethylene plants had a normal capacity

of around 10,000 tonnes per year, whereas today 300,000 tonnes

and more per year are the rule - but nevertheless the basis for

petrochemicals in Scholven had been established.

In the last months of the war the hydrogenation plants were

completely destroyed in massive Allied air-raids, and

petrochemicals production also came to a halt.

After the end of the war it became clear very quickly that

petrochemicals, once started up again, would no longer be based

on coal and coke gas but on crude oil, which was far easier to

process.

At the beginning of the 1950s crude oil began to be refined in

Scholven and Horst, at first with the aim of producing heating

oil. During the distillation process naphtha was produced

in quantities that could not be sold on the as yet still small

motor fuel market. Therefore it was decided to process this

naphtha further by cracking, into ethylene, in an olefin plant

with a capacity of 40,000-60,000 tonnes per year. For purposes of

comparison: the quantity of ethylene produced from coke

processing in the early days in Scholven amounted to a maximum of

10,000 tonnes per year.

Veba Oil Refining & Petrochemicals GmbH

The origins of VORP and its petrochemicals segment date back to

the establishment of the Scholven Hydrogenation Plant on the

Hibernia site in 1935. This represents a milestone in the history

of the company, as it was here that the first gasoline in the

world was produced from bituminous coal and hydrogen. The

Hibernia nitrogen works provided the hydrogen needed for

hydrogenation.

In 1939 in Gelsenkirchen-Horst Gelsenberg Benzin AG started the

production of gasoline from bituminous coal by the Bergius-Pier

process.

After the total destruction of both plants - Scholven and Horst -

in the Second World War, the next milestone came in the early

50s: the beginning of oil refining. In the early 60s the question

arose of what to do with the surplus naphtha production from the

oil refining process. The solution found in Scholven was to build

an olefin plant, which marked the birth of our petrochemicals

activities. At the same time Gelsenberg started producing crude

oil from its own production sites.

In 1975 both companies came together under the umbrella of Veba

Chemie, which was superseded in 1978 by Veba Oel AG. The setting up of Ruhr Oel GmbH in 1983

by Veba Oel AG and Petróleos de Venezuela S.A.

was a further important step, especially for the petrochemicals

segment. Ruhr Oel operates the plants at the Scholven and Münchsmünster

(Bavaria) sites. After numerous restructurings and new

shareholdings in the 80s and 90s, Veba Oel AG became the

integrated oil company that is today among the leaders in Europe.

With the establishment of Veba

Oil Refining & Petrochemicals GmbH with effect from January

1st, 2000, all of Veba Oel's supply, refining and petrochemicals

activities were brought together under one roof. VORP has

transferred the operatorship of Ruhr Oel's Gelsenkirchen and Münchsmünster

plants to its subsidiary Veba Oel Verarbeitungs GmbH.

The October 1, 2002 acquisition of Veba Oel AG by BP did not

change the business goals or activities of VORP. VORP's Joint

Venture Assets with the ROG system were transferred to Deutsche

BP on January 1, 2003. VORP is since then the contractual

operator for BP and PdVSA in the ROG system.

BP Refining & Petrochemicals GmbH

Effective September 1, 2003, the company name Veba Oil Refining

and Petrochemicals GmbH has been changed to BP Refining and

Petrochemicals GmbH to underscore ownership by Deutsche BP AG.