トップページ

NOVA Chemicals

Corporation 歴史

NOVA Chemicals Corporation,

headquartered in Calgary, Alberta, Canada is a focused

commodity chemical company, producing styrenics and

olefins/polyolefins at 18

locations in the United States, Canada, France, the

Netherlands and the United Kingdom.

As of January 2000, we are the:

largest producer of

styrene and polystyrene in North America

2nd largest producer

of styrenic polymers in Europe

5th largest producer

of ethylene in North America

5th largest producer

of polyethylene in North America

We operate two businesses -

olefins/polyolefins and styrenic polymers. From plants in

Canada, the U.S., and Europe, we produce:

Olefins/polyolefins

ethylene

polyethylene

chemical and energy co-products, including all the olefin

and aromatic petrochemical building blocks

Styrene and styrenic

polymers

specialty polystyrene

including DYLARK®

engineering resins

expandable polystyrene (EPS)

solid polystyrene

NOVA Chemicals selected as partner for

proposed world-scale ethylene/polyethylene complex in Mexico

NOVA Chemicals announces intent to form

European Styrenics Joint Venture with BP

BP、NOVAとの提携でLLDPE生産性アップ

BP and NOVA Chemicals sign binding

agreements for European Styrenics JV:NOVA Innovene

NOVA

Chemicals announces agreement with Taiwan's Loyal to manufacture

ARCEL(R) resin in Shanghai

NOVA Chemicals restructuring to

create separate STYRENIX unit and cut costs

US styrenics sector in need of

further consolidation

NOVA Chemicals announces start-up

of ARCEL(R) resin manufacturing facility to support growing Asian

markets

NOVA

Innovene announces intention to close its Polystyrene site in

Carrington, UK

Nova still weighing options for

Styrenix unit: spokeswoman

NOVA

Chemicals、北米のSM、PS事業をINEOSとのJVに移管

INEOS NOVA joint venture

approved by Federal Trade Commission

INEOS NOVA joint venture will

acquire rights to Sterling styrene production

Nova to shut Sterling's 1.7B

lbs/yr SM unit at Texas City, TX

INEOS

NOVA announces Montréal polystyrene production to shut

down

Nova Chemicals envisions big

expansion of Alberta petrochemical industry

NOVA

Chemicals and Williams announce letter of intent for project to

extract ethane from Alberta oil sands

Ineos

Nova to shut US polystyrene facility at Belpre, Ohio

NOVA Chemicals announces plans for

Ontario polyethylene asset modernization and expansion

IPIC of Abu Dhabi acquires NOVA

Chemicals

Borealis acquires

24.9% of Nova from IPIC

NOVA Chemicals Announces MOU with Statoil for Ethane

Supply from Marcellus Shale

Nova Chemicals sells Performance Styrenics business

歴史

| 1993 |

NOVA

exchanges its methanol assets for common shares of

Methanex and becomes the largest shareholder in Methanex. |

| 1994 |

the company

purchases DuPont Canada's polyethylene resin business

(St. Clair River site plant) including the SCLAIRTECH

technology and licensing business. |

| 1995 |

the

polymers production site in Marysville, Michigan is sold

to Huntsman. |

| 1996 |

NOVA

acquires Arco Chemical Company's plastics business. |

| 1997 |

the

construction of a third ethylene plant at Joffre, Alberta

- a joint venture with Union Carbide - begins. With this

plant's completion, Joffre will be the largest ethylene

production site in the world.

NOVA also announces plans to construct a second

polyethylene plant based on the company's Advanced

SCLAIRTECH- technology at the Joffre site. |

| 1998 |

NOVA

Chemicals is launched as an independent, publicly traded

company - one of the few publicly traded companies

focused on commodity chemicals.

NOVA Chemicals becomes North America's largest producer

of styrene and polystyrene with U.S. $637 million

acquisition of most of the styrenics business of Huntsman

Corporation. |

| 1999 |

"NOVA

Chemicals Corporation" adopted as parent company

name. |

| 2000 |

NOVA

Chemicals completes acquisition of Shell's European

polystyrene business, becoming Europe's largest producer

of EPS and the continent's second-largest producer of

styrenic polymers.

The start up of a 2.8-billion lb./year (1275 kilotonne)

ethylene facility, jointly owned with Union Carbide

Corporation, becomes the world's largest ethylene cracker

located in Alberta, Canada. |

| 2001 |

NOVA

Chemicals opens the lowest-cost ethylene/polyethylene

production site in North America. The Advanced SCLAIRTECH

polyethylene facility located in Joffre, Alberta, Canada

produces 850-million lb./year (380-kilotonne). |

| 2001 |

Due to weak

industry margins and high plant costs NOVA Chemicals

closes its Joliet, IL solid polystyrene plant. |

| 2003 |

NOVA Chemicals shuts down

high-cost polyethylene capacity |

| NOVA

CHEMICALS BUSINESS SNAPSHOT Capacity -

Millions of Pounds |

| Manufacturing

Sites |

ETHYLENE |

POLYETHYLENE |

STYRENE |

STYRENIC POLYMERS |

| Corunna,

Ontario, Canada |

1,600 |

|

|

|

| Joffre, Alberta, Canada(1) |

4,800 |

1,600 |

|

|

| Montréal, Quebec, Canada |

|

|

|

120 |

| Moore Township, Ontario,

Canada |

|

830 |

|

|

| Sarnia, Ontario, Canada |

|

|

950 |

|

| St. Clair River, Ontario,

Canada |

|

395 |

|

|

| Bayport, Texas, USA |

|

|

1,250 |

|

| Belpre, Ohio, USA |

|

|

|

320* |

| Channelview, Texas, USA(2) |

|

|

400 |

|

| Chesapeake, Virginia, USA |

|

|

|

300* closed |

| Decatur, Alabama, USA |

|

|

|

425 |

| Monaca, Pennsylvania, USA |

|

|

|

435* |

| Painesville, Ohio, USA |

|

|

|

85 |

| Indian Orchard,

Massachusetts, USA |

|

|

|

330* |

| Quilicura, Chile |

|

|

|

7 |

| El Tepual, Chile |

|

|

|

Converter |

| Total

Site Capacities |

6,400 |

3,385 |

2,600 |

2,022 |

* Includes production of select Performance

Products.

(1) Excludes Dow portion of ethylene capacity

(2) This represents the equity position in the

Lyondell Chemical Company, Channelview, Texas facility and does

not include a short-term tolling arrangement

for an additional 400 million pounds.

October 20, 2003

NOVA Chemicals shuts down high-cost polyethylene capacity

http://www.nova.ca/08_news/a_line_1003.html

NOVA

Chemicals Corporation today announced the shutdown of a 275

million pound linear low-density polyethylene line at its St.

Clair River Site, in Corunna, Ontario. This shutdown will

occur during the second quarter of 2004.

October 21, 2004 NOVA Chemicals

NOVA Chemicals selected as partner for proposed world-scale

ethylene/polyethylene complex in Mexico

http://www.novachem.com/08_news/phoenix_1004.html

NOVA Chemicals

Corporation today confirmed it has been selected by Pemex

Petroquimica (Pemex) as a partner in a feasibility study for a

potential world-scale ethylene and polyethylene complex in

Mexico.

This confirmation follows today’s announcement by Pemex, which has named NOVA Chemicals and two

Mexican companies - Grupo Idesa and Indelpro - as its strategic

joint-venture partners in the proposed ethylene-based petrochemicals and

plastics complex known as Project Phoenix. The partners have

committed to a feasibility study that aims to confirm the project

will deliver a globally competitive ethylene cracker and key

derivatives, initially including two world-class polyethylene

plants.

November 16, 2004 NOVA

Chemicals

NOVA Chemicals announces intent to form European Styrenics Joint

Venture with BP

http://www.novachem.com/08_news/bpjv_1104.html

NOVA Chemicals

Corporation today announced it has reached an agreement in

principle to merge its European styrenic polymers business

into a new 50:50 Joint Venture with BP plc (BP). The planned Joint Venture

is expected to be a leading manufacturer and marketer of styrenic

polymers in Europe and will be headquartered in Fribourg,

Switzerland.

September 6, 2005

NOVA Chemicals

NOVA Chemicals announces agreement to manufacture ARCEL(R) resin

in Asia to meet demand growth

http://www.novachem.com/appl/prelease/news.cfm?ID=301

NOVA

Chemicals Corporation today announced that it has entered into a

long-term agreement with Loyal Chemical Industrial

Corporation to manufacture ARCEL(R)

moldable foam resin near Shanghai, China. This

agreement is a component of NOVA Chemicals´ plan to expand manufacturing

capacity for ARCEL, a one-of-a-kind expandable inter-polymer, to

100 million pounds (45 kilotonnes) annually by the end of 2006.

Construction of the ARCEL resin manufacturing facility is

underway and production is expected to commence

in early 2006.

ARCEL(R)

http://www.novachem.com/ARCEL/index.cfm

ARCEL

is a high-performance, moldable foam resin consisting of 70%

polystyrene (PS) and 30% polyethylene (PE). ARCEL

provides the best of both polymers with its exceptional

toughness, flexibility and durability in a lightweight foam.

The strength and flexibility of ARCEL creates a resilient

resin able to be molded into numerous complex and intricate

forms. Its lightweight construction is resistant to puncture,

flaking, tearing and breaking. In addition, packaging molded

with ARCEL provides superb cushioning and easy handling,

while its lightweight properties help lower freight and other

packaging costs.

NOVA

Chemicals June 26, 2006

NOVA Chemicals restructuring to create separate STYRENIX unit and

cut costs

NOVA Chemicals Corporation today announced it plans to

restructure in order to better align resources and reduce costs.

NOVA Chemicals' styrene monomer and solid

polystyrene assets in North America and the company's interest in the

European 50:50 Joint Venture with INEOS will operate as a

separate unit that will be known as STYRENIX.

Companywide costs will be reduced by a total of at least U.S. $65

million per year, which represents an additional $50 million in

annual cost savings beyond the previously announced savings of

$15 million per year from the Chesapeake, Virginia, site closure.

In total, approximately 375 positions will be eliminated.

"By removing a minimum of $65 million per year of current

costs, we believe STYRENIX will be able to run as the lowest-cost

operator of its type in the industry," said Jeffrey M.

Lipton, President and CEO of NOVA Chemicals. "By taking

these actions, not only will STYRENIX be more competitive, but

the core of our company will also reduce costs and be able to

focus on our advantaged ethylene and polyethylene position, as

well as expandable polystyrene and related Performance

Products."

| The STYRENIX unit will

include: |

| ・ |

The Bayport, Texas, and

Sarnia, Ontario, styrene monomer production facilities |

| ・ |

Solid polystyrene

manufacturing facilities at Decatur, Alabama;

Springfield, Massachusetts; and Montreal, Quebec |

| ・ |

NOVA Chemicals’ interest

in the European Joint Venture with INEOS, NOVA

Innovene. |

NOVA

Chemicals’ Earnings Release

for the second quarter, to be issued July 20, 2006, will reflect

the new structure.

NOVA Chemicals produces plastics and chemicals that are essential

to everyday life. Our employees develop and manufacture materials

for customers worldwide that produce consumer, industrial and

packaging products. NOVA Chemicals works with a commitment to

Responsible CareR to ensure effective health, safety, security

and environmental stewardship. Company shares are traded on the

Toronto and New York stock exchanges as NCX.

Platts

2006/7/20

US

styrenics sector in need of further consolidation: Lipton

Nova Chemical CEO Jeff Lipton said in a Thursday conference

call he feels it is necessary for the US

styrenics industry to keep shutting down facilities, consider

consolidation and start moving on to stop bleeding profits in

the weak sector.

His statements come on the heels of Nova's

company restructure, which placed the recently

reopened Bayport plant in the non-core Styrenix division.

The said division lost $45 million in the quarter ending June

30. Lipton said Styrenix will not be considered part of the

core business "no matter what happens in the

short-term."

On June 26, Nova reported that it was separating its North

American styrenics businesses and its interest in the

European 50:50 joint venture with Ineos into Styrenix.

Nova said it will keep its ethylene, polyethylene and

expandable polystyrene businesses. Nova will separate its

businesses into three separate units, according to a company

spokesman -- ethylene and polyethylene, EPS and

performance products, and Styrenix.

Performance

Products:

ARCEL(R)

- high-performance, moldable foam resin

DYLARK(R) - automotive engineering resins

DYLARK(R) FG - high-heat styrenic copolymer

SURPASS(R) - performance film, rotational molding &

thin-wall injection molding resins

ZYLAR(R) EX - low-temperature, clear acrylic copolymer

http://www.theglobeandmail.com/servlet/story/RTGAM.20060720.wnova0720/BNStory/Business/home

Nova Chemicals sees

strong future (2006/7/20)

Nova Chemicals Corp.

is predicting continued strong markets for its key plastics

after reporting second-quarter net income of $108-million

(U.S.), up from a year-ago loss of $5-million.

The chemical

producer, headquartered in Pittsburgh but with extensive

operations in Canada and its shares inter-listed on the

Toronto Stock Exchange, said Thursday its April-June revenue

was up 22 per cent to $1.62-billion from $1.33-billion.

The latest quarter's

net earnings ? substantially boosted by reduced Alberta and

federal tax rates ? were worth $1.30 per share, up from a

year-ago loss of 29 cents per share, and represented a return

on equity of 31.8 per cent.

Nova stock was up

four per cent near midday, gaining $1.39 (Canadian) to $34.78

on the Toronto Stock Exchange.

"Global growth

keeps on looking stronger and Mid-eastern capacity expansion

looks more and more uncertain," president and CEO Jeff

Lipton said during a conference call with analysts.

"It's hard to

see anything but global recession stopping what should be not

a mere peak but a long plateau of very strong conditions for

our industry."

In the meantime, Nova

has "taken aggressive action to change our company from

a pure commodity one to one focused on advantaged olefins and

polyolefins and unique performance products," Mr. Lipton

said.

During the quarter,

Nova rearranged itself into three business units, and its

olefins/polyolefins and expandable polystyrene/styrenic

divisions generated net income of $147-million or $1.77 per

share.

But the Styrenix

business, being separated from the rest of the company with

hopes it can be sold or spun off, lost $45-million or 54 cents

per share on revenue of $510-million.

Styrenix - producing

thermoplastics used in an array of processes including

compounding, extrusion and injection moulding - includes a

styrene facility in Sarnia and solid polystyrene production

in Montreal, as well as four U.S. plants and a half-interest

in a European joint venture.

Nova, which

originated half a century ago in the old Alberta Gas Trunk

Line Co. and became an independent company in 1998, is closing its Chesapeake, Va.,

polystyrene plant with the loss of 125 jobs and

a saving of $15 million a year.

A wider restructuring

will save an additional $50 million, involving 250 other jobs

cuts "including a significant number of very senior

positions," Lipton told analysts.

Of the $65-million in

total savings, $45 million will be at Styrenix.

"We believe we

have a controllable plan in place to stop the new Styrenix

from bleeding dollars in no longer than 1½

years,"

Mr. Lipton added.

"The new

Styrenix will soon be able to stand on its own, and will be a

very clean and attractive set of assets for the industry to

think about consolidating," he said.

"Our goal is to

have an ultimate solution to this business unit sooner rather

than later."

Nova's Canadian

operations include the world's largest ethylene and

polyethylene complex in Joffre, near Red Deer,

Alta., as well as four plants in the Sarnia, Ont., area and

the Montreal polyethylene facility.

The company also has

seven plants in the United States and two in Chile, but

Lipton stressed the "Alberta advantage" of low-cost

natural gas - currently worth 20 cents per pound of plastic-

and predicted strong markets for Joffre's polyethylene amid

low inventories.

Additionally, the

April 1 reduction in the Alberta corporate tax rate and

promised future federal tax cuts added $60 million to

second-quarter net earnings by reducing deferred tax

liabilities.

"We see the

short-term fundamentals for the olefins and polyolefins as

very positive, with very low inventories and very strong

demand," Mr. Lipton said.

"For Nova, the

Alberta advantage is giving us excellent margins at today's

polyethylene price levels, and any movement up will be icing

on our cake."

January 19, 2006

NOVA

Chemicals announces closure of Chesapeake, Virginia, site

NOVA

Chemicals Corporation (NYSE, TSX: NCX) today announced it

plans to close its Chesapeake, Virginia, site in 2006.

The plant has solid polystyrene production capacity of

300 million pounds (136 kilotonnes) per year and

compounding capability of 170 million pounds (77

kilotonnes) per year.

"We

continue to drive cost improvements in our Styrenics

business as aggressively as possible. We were able to

take this step because upgrades to the Performance

Products operations at our Belpre, Ohio, site freed up

capacity at other locations,"said Chris Pappas,

President of NOVA Chemicals' Styrenics business."We

remain firmly committed to ZYLAR® and our other

compounded products and plan to identify production

alternatives in 2006. We will also work to make this

transition seamless for our customers and as successful

as possible for our affected employees."

July 18, 2006 NOVA

NOVA Chemicals announces start-up of ARCEL(R) resin manufacturing

facility to support growing Asian markets

NOVA Chemicals Corporation today announced the successful

start-up of an ARCEL(R) moldable foam

resin manufacturing facility in Ningbo, China, near Shanghai.

The new facility, Ningbo Chang-Qiao

Engineering Plastics Co., Ltd., ensures local

sourcing of ARCEL in Asia and is operated under a long-term

manufacturing agreement with Loyal Chemical Industrial

Corporation, the largest expandable polystyrene

producer in the world.

ARCEL is

a high-performance, moldable foam resin consisting of 70%

polystyrene (PS) and 30% polyethylene (PE). ARCEL provides

the best of both polymers with its exceptional toughness,

flexibility and durability in a lightweight foam.

Loyal

Chemical Industrial Corporation was founded in

1976 and specializes in a full range of EPS products, using the

brand name King Pearl. Within 14 years of entering the Chinese

market, Loyal Chemical has become the largest EPS manufacturer in

the world, with an annual capacity of more than 1.9 billion

pounds (880 kilotonnes). The company’s newest, preeminent plant in

Tianjin began operation in June 2006 with a capacity of 180

kilotonnes. Loyal Chemical (www.loyalgroup.com) is a reliable and

respected private organization in Taiwan and China.

July 25, 2006 Nova

Chemicals 米国

NOVA

Chemicals announces reduction of solid polystyrene capacity and

fixed costs in Europe

NOVA Chemicals Corporation today announced continued progress

toward a target of $60 million per year in joint venture

synergies by the end of 2007, with the announced closure of NOVA Innovene's

Carrington, UK, solid polystyrene facility. NOVA Chemicals

will receive 50 percent of the benefit of total joint venture

synergies.

The Carrington facility closure, announced today in a news

release issued by NOVA Innovene, will remove approximately six percent of

European solid polystyrene capacity and reduce NOVA

Innovene's fixed costs by approximately U.S. $14 million per

year. Production at the Carrington solid polystyrene facility,

which has rated capacity of 396 million pounds (180 kilotonnes)

annually, is scheduled to cease in October 2006.

The plant has a capacity of 180,000 tonnes

and currently employs 82 people.

The Carrington plant, formerly operated by Shell, made both

expanded polystyrene and general moulding grades. The EPS

plant was shut down by Nova last year after being idle for

three years.

NOVA

Innovene http://www.nova-innovene.com/

Headquartered

in Fribourg, Switzerland, NOVA Innovene is a 50:50 joint

venture between NOVA Chemicals and INEOS, who acquired BP's

Innovene in December 2005. With a turnover of Euro 1 billion

per annum, NOVA Innovene is a European leader in styrenic

polymers, supplying customers in a wide range of market

segments. NOVA Innovene employees develop, manufacture and

market commodity and performance styrenic polymers that are

essential to everyday life.

July 25 th 2006 NOVA Innovene

NOVA Innovene announces intention to close its Polystyrene site

in Carrington, UK

Fribourg, Switzerland, NOVA Innovene announced today its

intention to close its Carrington, UK, site in October 2006. The

plant has solid polystyrene production capacity of 180 kilotonnes

per year and currently employs 82 people.

“We have

significant overcapacity in our PS business” said Martin Pugh, Managing

Director of NOVA Innovene. “This, combined

with significant feedstock volatility, has depressed margins,

making our PS business unprofitable. In making this change, we

intend to address our overcapacity and improve our cost

structure, a key objective for NOVA Innovene.”

2006/9/8 Platts

Nova

still weighing options for Styrenix unit: spokeswoman

A Nova

Chemicals' spokeswoman said Thursday the company was still

studying various options regarding the future of its Styrenix

business unit, but did not deny that a sale or joint venture

agreement was being considered.

In the news articles, Credit Suisse analyst William Young was

cited as saying that Nova likely will receive $500 million for

the sale of the Styrenix business. That figure is a fraction of

the purported value of the Styrenix asset, market sources said.

Young would not comment on any aspect of the story when contacted

by Platts on Thursday.

2007/3/23

NOVA Chemicals、北米のSM、PS事業をINEOSとのJVに移管

NOVA ChemicalsとINEOS は22日、NOVAの北米のSM、PS事業を両社の欧州の50/50JVのNOVA

Innovene に移管することで合意したと発表した。今後手続きを経て、第3四半期に拡大JVが発足する。

移管するのはNOVAの子会社STYRENIXで、テキサスとカナダのオンタリオにあるSM事業、米国とカナダのPS事業のほか、PS系のポリマー、NAS(R)(Styrene Methylmethacrylate copolymer)、ZYLAR(R)(NASの 耐衝撃性改質グレード)、DYLARK(R)( スチレン-無水マレイン酸共重合体)を含む。

NOVAのCEOは「米国のスチレン業界は設備を廃棄し、統合を検討し、赤字垂れ流しを止めるために動き出す必要がある」と述べており、2006年1月にはバージニア州のチェサピーク工場を閉鎖すると発表し、6月にStyrenix事業部を別会社にすると発表した。

NOVAは事業を「エチレン &

PE」、「発泡PS & 機能製品」、及び「Styrenix」の3つに区分しているが、Styrenixはコア事業ではなく、将来、売却するか、スピンオフすると見られていた。

2006/7/27 「欧米でもPS事業は苦境」

今回の移管により新しいNOVA Innovene

の北米、欧州、全世界でのシェアは以下の通りとなる。

| |

North America |

Europe |

Global |

| Styrene |

No.1 |

ー |

No.5 |

| Solid Polystyrene |

No.1 |

No.2 |

No.2 |

| Expandable Polystyrene |

ー |

No.1 |

No.4 |

INEOSは欧州のSM事業を、NOVAは北米の発泡PS事業を、JVには出さず自社で運営する。

NOVA Innoveneは2005年にNOVAが欧州のPS事業を出してBPとの50/50JVとして設立した。その後、BPが分離したInnoveneをIneosが買収した。

March 22,

2007 Nova Chemicals

NOVA Chemicals

announces plan to expand joint venture with INEOS to North

America

NOVA Chemicals

Corporation today announced it has signed a letter of intent with

INEOS to expand the two companies' existing European joint

venture to include North American assets. Under the terms of the

proposed agreement, the newly expanded 50:50 joint venture will

include NOVA Chemicals' STYRENIX unit and

other styrenic polymer assets. The STYRENIX unit includes NOVA

Chemicals' North American styrene and solid polystyrene assets,

as well as the company's interest in the existing European joint

venture with INEOS, called NOVA Innovene. INEOS will contribute

its North American styrene and polystyrene assets, as well as its

interest in the existing NOVA Innovene European joint venture.

The expanded

joint venture will also include solid polystyrene-based NAS®, ZYLAR® and DYLARK® polymers from NOVA

Chemicals and the AVANTRA®

specialty

products of INEOS.

| |

North

America |

Europe |

Global |

| Styrene |

#1 |

ー |

#5 |

| Solid

Polystyrene |

#1 |

#2 |

#2 |

| Expandable

Polystyrene |

ー |

#1 |

#4 |

March 22 2007 INEOS

INEOS

announces expansion of styrenics joint venture with NOVA

Chemicals

INEOS

announced today that it has signed a letter of intent with

NOVA Chemicals Corporation to expand on the parties' existing

styrenics European joint venture so as to include North

American assets of both companies. Under the terms of the

proposed agreement, INEOS will contribute its

North American styrene and polystyrene assets and NOVA Chemicals

will contribute its STYRENIX unit and other styrenics polymer

assets

to a 50:50 joint venture arrangement. The STYRENIX unit

includes NOVA Chemicals North American styrene and solid

polystyrene assets.

INEOS

will retain full ownership of its styrene business in Europe with a styrene manufacturing

plant in Marl, Germany.

2007/4/13 Canadian

Press

Nova Chemicals

envisions big expansion of Alberta petrochemical industry

Nova Chemicals said

Thursday it plans to build a world-class polyethylene plant in

Alberta by the end of the decade, pending approval of an

associated ethane extraction plant.

The petrochemical

facility would produce up to 800 million pounds of

polyethylene a

year, using feedstock from gas processor Aux

Sable Canada

Ltd.'s planned ethane plant in

Fort Saskatchewan.

"If we're going to make full use of it, we're going to have

to build a polyethylene plant here," CEO Jeff Lipton said at

Nova's annual meeting in Calgary. Lipton would not speculate on

costs.

March 21, 2007 NOVA Chemicals

NOVA Chemicals

and Aux Sable reach agreement on Alberta ethane extraction

plant

NOVA Chemicals Corporation (“NOVA Chemicals”) today announced that the

company has signed a letter of intent with Aux Sable Canada

Ltd. (“ASC”) to develop an ethane

extraction plant in Fort Saskatchewan, Alberta that would process natural

gas from the Alliance Pipeline. ASC and NOVA Chemicals will

work together to develop the project, which will be owned and

operated by ASC and is expected to begin operating in

mid-2010.

The extraction

plant will have the capacity to process as much as 1.2

billion cubic feet of natural gas per day and will produce

approximately 40,000 barrels per day of ethane. The

extraction plant will be located on land owned by ASC in Fort

Saskatchewan, adjacent to the site of ASC’s Heartland Offgas Plant.

Ethane will be delivered via pipeline to NOVA Chemicals’

Joffre,

Alberta, petrochemical complex for use as a feedstock in the

production of ethylene.

ASC and its

U.S. affiliate, Aux Sable Liquid Products L.P. (“Aux Sable”), are owned by Enbridge Inc.

(ENB), Fort Chicago Energy Partners L.P. (FCE-UN) and

Williams (WMB). Aux Sable intends to leverage its position as

a significant player in the natural gas processing and

natural gas liquids businesses through fee-based

infrastructure investments. ASC is headquartered in Calgary,

Alberta.

Aux

Sable Liquid Products http://www.auxsable.com/

Aux

Sable Liquid Products is a US$400 million (C$550 million),

world-scale natural gas liquids (NGL) extraction and

fractionation facility constructed to initially process up to

2.1 billion cubic feet of natural gas per day. It is designed

to initially recover 70,000 barrels per day of NGL (ethane,

propane, normal butane, iso-butane and natural gasoline).

Aux Sable is

the largest facility of its kind in the U.S. It has become a

significant propane supplier for the Midwest, particularly

for the state of Illinois. The facilities are connected with

existing product pipelines that also make NGL available

elsewhere in the United States and Canada.

July 23,

2007 Nova

NOVA Chemicals

and Williams announce letter of intent for project to extract

ethane from Alberta oil sands

NOVA Chemicals

Corporation today announced it has reached an agreement with

Williams to evaluate processing current and future off-gas

streams from the Alberta oil sands to extract ethane. This feedstock would be

delivered to NOVA Chemicals' Joffre, Alberta, manufacturing

facility, utilizing the existing Joffre Feedstock Pipeline.

September

10, 2007

INEOS NOVA joint

venture approved by Federal Trade Commission

NOVA Chemicals

Corporation today announced that the U.S. Federal Trade

Commission has approved the previously announced INEOS NOVA joint

venture. The joint venture is expected to commence operations on

October 1, 2007.

INEOS

NOVA Joint Venture http://www.novachem.com/investorcenter/docs/INEOS_NCX_ConfCall_09_19_07.pdf

September

18, 2007

INEOS NOVA joint

venture will acquire rights to Sterling styrene production

NOVA Chemicals

Corporation today announced that it has secured exclusive

rights to the styrene production from Sterling

Chemicals Inc.'s Texas City, Texas, manufacturing facility on behalf of its pending

joint venture with INEOS. The INEOS NOVA joint venture has

received U.S. regulatory approval and will be assigned the rights

when the joint venture is operational, which is expected to be

October 1, 2007. The $60 million cost of the transaction will be

fully funded by the INEOS NOVA joint venture from cash on hand.

Sterling's Texas

City facility has 1.7 billion pounds of annual

styrene production capacity, which represents approximately

11% of North American capacity and 3% of global capacity.

SEPTEMBER 18,

2007

STERLING CHEMICALS ANNOUNCES LONG-TERM STYRENE SUPPLY

AGREEMENT

Under these

agreements, Nova will have the exclusive right to the entire

production capacity of Sterling’s Texas City, Texas styrene

plant, the amount of any styrene supplied being at Nova’s option based on a full-cost

formula,

and will purchase Sterling’s styrene monomer rail car

fleet. In exchange, Nova has agreed to pay Sterling $60 million within ten business days

after the agreements become effective. Alternatively, if the

FTC does not approve the supply agreement, Nova will be

required to pay Sterling a break-up fee

of $6 million.

Sterling Chemicals, Inc. is a leading North American producer

of selected petrochemicals used to manufacture a wide array

of consumer goods and industrial products throughout the

world. Its primary products are

acetic acid Percent of Total North

American Capacity 17% North American Market Position by

Capacity 3

styrene Percent of Total North

American Capacity 11% North American Market Position

by Capacity 4

and

plasticizers.Percent

of Total North American Capacity 9% North American Market Position

By Capacity 3

Platts 2007/9/17

Nova to shut Sterling's

1.7B lbs/yr SM unit at Texas City, TX

Following its

announcement to acquire Sterling's 1.7 billion lbs/year styrene

monomer asset at Texas City, Texas, Nova Chemicals President and

Chief Executive Officer Jeff Lipton said Wednesday that it intended to

close the facility and shift production to more efficient sites.

After the shutdown of

Sterling, operational rates will be much stronger -- an estimated

91%, up 3% from previous levels, he explained. In addition,

October

10, 2007 Nova Chemicals

INEOS NOVA

announces Montréal polystyrene production

to shut down

INEOS NOVA

announced today that it plans to shut down its Montréal, PQ

polystyrene production by the end of 2007. The site has

annual production capacity of 120 million pounds (55

kilotons) of polystyrene.

Platts

2007/10/10

Market eyes more PS

closures after Ineos Nova's Montreal decision

During an analyst call September 19, Nova President and CEO

Jeff Lipton said, "We expect the (Ineos

Nova) JV to take out another 300 to 400 million pounds of

solid polystyrene capacity and to have a significant

impact on that part of the business, and, as you know, we are

not alone. We think the Dow-Chevron Phillips JV, which the

FTC has now stated they have no objection to, will follow our

start-up quickly. While the partners have not made any

specific statements about their plans, we expect to see more

consolidation as part of their cost reduction efforts."

One producer Wednesday added, "The market is just

consolidating in light of shrinking

demand for PS and poor profitability...This will help them

streamline. Will be interesting to see what Dow/Chevron will

do."

Platts 2007/11/29

Ineos Nova to shut US

polystyrene facility at Belpre, Ohio

UK-Canada styrenics joint venture Ineos Nova plans to permanently

shut down its US polystyrene facility at Belpre, Ohio, by January 31, 2008, the company

announced Thursday.

The site has production capacity of 220 million lbs/year (100,320

mt/year) of crystal polystyrene.

January

9, 2008 NOVA Chemicals

NOVA Chemicals

announces plans for Ontario polyethylene asset modernization and

expansion

NOVA Chemicals

Corporation today announced plans for a series of polyethylene

plant modernization and expansion projects in the Sarnia,

Ontario, region. The projects will add a total of up to 250

million pounds per year of new polyethylene

capacity in stages over the next two years.

"These

projects should have about a two year pay-back and will generate

meaningful earnings growth for our shareholders in every part of

the industry business cycle," said Jeffrey M. Lipton, Chief

Executive Officer. "The upgrades include technology that

will enable us to produce higher value products that our

customers are hungry for."

The projects

include:

・Upgrading products,

improving reliability and expanding the low density polyethylene

unit at Mooretown, Ontario

・Optimizing the high

density polyethylene unit at Mooretown to increase throughput

rates and improve product quality

・Debottlenecking high

density polyethylene and linear low density polyethylene

production at the St. Clair River site at Corunna, Ontario

The projects are

now feasible because the Corunna flexi-cracker modernization

completed in 2007 has successfully delivered: greater ethylene

capacity, increased energy efficiency, improved plant reliability

and global cost competitiveness. The total cost of the projects

will be approximately $80 million, which will not result in a

material change in the company’s overall capital

program. The projects will require appropriate Board of Directors

approvals as they proceed.

July 26, 2011NOVA

Chemicals

NOVA Chemicals Announces Memorandum of Understanding with Statoil for Ethane

Supply from Marcellus Shale

NOVA Chemicals Corporation (NOVA Chemicals) today

announced that it signed a memorandum of understanding with Statoil Marketing

and Trading Inc. (Statoil) for a long-term supply of ethane from the Marcellus

Shale Basin.

“We are very pleased to be

working with Statoil for the supply of additional ethane to our Corunna, Ontario

cracker. Their supply will help to diversify our supply base for our

Corunna

cracker revamp project and support our growth plans in the future,” said Randy Woelfel, Chief Executive Officer.

“Statoil is pleased to have reached a framework agreement with NOVA Chemicals

for the sale of ethane from the Marcellus Shale Basin. Statoil has over the

years had other supply agreements with NOVA Chemicals and looks forward to

furthering this commercial relationship,” said Martin Jones – President of

Statoil Marketing and Trading (US) Inc.

In addition to finalizing a

definitive purchase and sale agreement with Statoil, and customary reviews and

approvals, the arrangement is subject to NOVA Chemicals concluding a pipeline

transportation agreement to transport ethane from the Marcellus Shale Basin into

the Sarnia, Ontario petrochemical market.

2012/5/10 Nova Chemicals

売却取り止め

NOVA Chemicals and PFB Corporation sign

letter of intent for acquisition of NOVA Chemicals’ Performance Styrenics

business

NOVA Chemicals Corporation and PFB Corporation, announced today that they have

signed a letter of intent for PFB, through its subsidiary PFB International

Corporation, to acquire NOVA Chemicals Performance

Styrenics business, including the expandable polystyrene (EPS) and ARCEL®

resin products. NOVA Chemicals will acquire an equity

stake in PFB and hold two seats on PFBs Board of Directors following

closing. In addition, at closing, Robert Snyder, Vice President, Performance

Styrenics for NOVA Chemicals will join PFB as Chief Operating Officer, PFB

International Corporation.

NovaとIneos

は2007年3月に、Novaの北米のSM、PS事業を両社の欧州の50/50JVのNOVA

Innovene に移管することで合意し、新しいJV、Ineos

Novaが2007年10月に発足した。

2007/9/24 INEOS

NOVA

スタートへ

Nova Chemicalsは2010年11月12日の第3四半期決算発表で、Ineosとの間で、両社の50/50JVであるIneos

NovaのNova持分をIneosに売却する交渉に入ったことを明らかにした。

新株主の

IPICの方針変更と思われる。

2010/11/22

Nova

Chemicals、Ineos

Novaから撤退

Nova Chemicalsの現在の事業は以下の通り。(単位:千トン)

| |

エチレン |

PE |

SM |

スチレン

ポリマー |

|

|

Corunna, Ontario |

820 |

|

|

|

|

|

Joffre, Alberta |

1,545 |

910 |

|

|

|

635

(1,270) |

190

(380) |

|

|

Nova/Dowの50/50JV

上はNova持分、(

)はJV合計能力 |

|

Moore Township, Ontario |

|

340 |

|

|

|

| St. Clair

River, Ontario |

|

205 |

|

|

|

|

Channelview, Texas |

|

|

180 |

|

Lyondell Chemical のSM工場のNova持分

他に短期の製造委託180がある。 |

| Monaca,

Pennsylvania |

|

|

|

155 |

Styrenic Performance Polymers含む |

| Painesville,

Ohio |

|

|

|

45 |

|

| Quilicura,

Chile |

|

|

|

3 |

|

| El Tepual,

Chile |

|

|

|

Converter |

|

| |

|

|

|

|

|

| Total

|

3,000 |

1,645 |

180 |

203 |

|

スチレン、スチレンポリマーはIneosNovaに供出していないもの。

スチレンポリマーはEPSが中心だが、下記の特殊品を含む。

ARCEL樹脂(PS/EVA)、DYLARK、UPESレジン |

NOVA Chemicals and PFB expect definitive

agreements to be executed during the second quarter, and closing to occur during

the second half of 2012. The acquisition is subject to the definitive agreement

being entered into, regulatory approval, and other customary conditions,

including NOVA Chemicals Board of Directors approval, and PFBs Board of

Directors and shareholder approval

We are extremely excited to have NOVA Chemicals experience and quality EPS

resins become a part of our business. NOVA Chemicals has long been a leading

North American producer of moldable foam resins with a diverse product portfolio

serving the construction, packaging, and global cup and container markets.

Together we have the opportunity to better serve customers - providing

outstanding products to the market, commented C. Alan Smith, CEO of PFB.

The acquisition of NOVA Chemicals Performance Styrenics business by PFB

International Corporation will underpin a

vertically-integrated, construction materials focused product offering in

the United States that parallels the Plasti-Fab Canadian operations. Bruce

Carruthers, Chief Operating Officer of Plasti-Fab, stated, With the world now

focusing on sustainable building products, it is the time for our industry to

provide vertically-integrated EPS product solutions that provide environmentally

friendly alternatives to the construction industry. This is our mission.

We are excited about the combined companys dedicated focus on the growth and

development of EPS resins, and their use in building insulation, protective

packaging, and cup and container applications, said Robert Snyder, Vice

President, Performance Styrenics for NOVA Chemicals.

About NOVA Chemicals

NOVA Chemicals develops and manufactures chemicals, plastic resins and

end-products that make everyday life safer, healthier and easier. Our employees

work to ensure health, safety, security and environmental stewardship through

our commitment to sustainability and Responsible Care®. NOVA Chemicals,

headquartered in Calgary, Alberta, Canada, is a wholly

owned subsidiary of the International Petroleum Investment Company (IPIC) of the

Emirate of Abu Dhabi, United Arab Emirates.

About PFB Corporation

PFB Corporation controls two operating subsidiaries,

Plasti-Fab Ltd. that operates in Canada and PFB

America Corporation that operates in the United States. The group is

vertically integrated in manufacturing insulating building

products that are marketed across North America under five brands.

Plasti-Fab, EPS Product Solutions® are products, manufactured using expanded

polystyrene (EPS) as base raw materials, that are delivered to customers in five

segmented markets. Advantage ICF Systems® are insulating concrete forming

systems that are employed to build insulated foundations and walls from concrete

in both residential and commercial markets. Insulspan® Structural Insulating

Panels Systems (SIPS) are used to create a high performance, energy-efficient

structural envelope. Precision Craft® and Riverbend® Timber Framing manufactures

timber frame and log structures that are designed by Mountain Architects LLC,

and installed by PC Design Build LLC.that combine our vertically integrated

products.

------------------

2012/11/16 Nova

NOVA Chemicals and PFB Corporation

terminate letter of intent for acquisition of NOVA Chemicals’ Performance

Styrenics business

NOVA Chemicals Corporation announced today that it and PFB Corporation mutually

agreed to terminate their letter of intent for PFB to acquire NOVA Chemicals’

Performance Styrenics business.

NOVA Chemicals will retain and continue to operate its Performance Styrenics

business, which includes its expandable polystyrene and ARCEL® resin products.

It had become apparent to both NOVA Chemicals and PFB that PFB would be unable

to complete certain steps necessary to consummate its planned expansion of PFB’s

vertically integrated, construction materials focused products offering in the

United States. As a result, both parties decided to terminate the letter of

intent.

“We are disappointed that this transaction with PFB was not successful, but will

move forward, focusing on performance and continuous improvement for the

Performance Styrenics business,” stated Randy Woelfel, CEO, NOVA Chemicals.

June 11, 2013 NOVA Chemicals

NOVA Chemicals Officially Begins Alberta

Polyethylene Expansion Project

NOVA Chemicals Corporation held a ground-breaking celebration on Friday, June 7,

2013 to celebrate a growth milestone at its Joffre, Alberta complex. This event

marked the official start of the construction phase of the Polyethylene 1

Expansion Project – a key component of the NOVA 2020 growth strategy of adding

value to emerging cost-competitive feedstocks and to support growing North

American polyethylene demand.

The PE1 Expansion Project at the Joffre, Alberta

Site will include a world-scale polyethylene reactor (R3) and associated

infrastructure. The project is designed to produce between

950 and 1,100 million pounds per year of linear-low density polyethylene

(“LLDPE”), enabling the company to increase polyethylene production at the site

by approximately 40% to meet growing customer needs.

The project is expected to be commissioned in the fall of 2015 and is expected

to cost approximately $1 billion including capital and startup costs.

| June 29, 2011 NOVA

Chemicals

NOVA Chemicals commits to growth

in North America: NOVA 2020

NOVA Chemicals Corporation today announced plans for growth of its

proprietary polyethylene technology to serve North American markets,

which the company is calling “NOVA 2020.”

As a part of the company’s strategy to capitalize on emerging

feedstock opportunities and growing North American demand, NOVA

Chemicals has begun feasibility and engineering work for the

construction of two new polyethylene assets

to be located at its sites in Alberta

and Ontario. NOVA Chemicals will also complete studies for a

further debottleneck of its low-density polyethylene line located at

its Mooretown, Ontario facility.

The new polyethylene assets consist of:

- a world-scale Advanced SCLAIRTECH™ technology based line; and

- a world-scale NOVAPOL® technology-based linear-low density line.

“As an integral part of International Petroleum Investment Company’s

(IPIC’s) global growth plans, we are very excited about the planned

expansion of NOVA Chemicals’ position in North America,” said His

Excellency Khadem Al Qubaisi, Managing Director of IPIC and Chairman

of NOVA Chemicals. “IPIC fully supports these plans that will

enhance NOVA Chemicals’ leading technology and market position.”

The completion of all engineering and feasibility studies is

expected by mid-2012, and start-up of the debottleneck project and

polymer expansions is targeted between late 2014 and 2017.

“We are committed to leadership in the markets we serve. Our ability

to meet our customers’ needs for higher performance polyethylene

products is fundamental to this commitment. Growing our Advanced

SCLAIRTECH technology capability - the core of our technology base -

together with our proprietary gas-phase capacity, will deliver real

value for our customers,” stated Randy Woelfel, NOVA Chemicals’

Chief Executive Officer.

In support of the polyethylene expansions, ethylene supply growth

will be derived from the increased utilization of existing Joffre

cracker capacity, along with expansion of the Corunna cracker. This

planned increase in ethylene production will be supported by

emerging, cost- competitive feedstock supply from a diverse

portfolio of new feedstock sources, linked to both shale oil and

shale gas development, oil sand upgrading off-gases and expansion in

supply from conventional ethane extraction capacity.

As an update for the conversion of the Corunna, Ontario olefins

cracker, detailed engineering and field tie-in preparation work is

progressing well, in line with the goal of reaching

full NGL feed

capability by the end of 2013.

Nova 2020 Projects Overview

In 2011, NOVA Chemicals announced a 10-year asset strategy referred

to as “NOVA 2020” to capitalize on emerging feedstock

opportunities and growing North American polyethylene demand.

Feasibility and engineering study

work is underway now with results anticipated later this year. We

are proposing to undertake the following project phases between 2012

and 2017. NOVA 2020 –

Phase 1 involves the conversion of the existing Corunna Site

ethylene facility to utilize up to 100% Natural Gas Liquids (NGL)

feedstock. The

Corunna Revamp Project proposed for 2013/2014 includes modifications

to site facilities, including the feed systems, fuel gas, cracking

heaters, and the addition of a second fractionation column.ne

emissions reduction program.

Phase 1 also involves, subject to regulatory approval, the Genesis

Pipeline Extension Project which will enable the delivery of

economically viable NGL, specifically ethane, from the liquids-rich

Marcellus Shale processing and fractionation areas of western

Pennsylvania and West Virginia. Utilization of this emerging

feedstock provides an important opportunity to ensure our economic

viability today and into the future.

NOVA 2020 – Phase 2 comprises engineering and feasibility study work on

additional proposed projects, including:

・Corunna

Site ethylene facility capacity expansion;

・A new polyethylene facility in the region;

・Moore Site

increase in polyethylene production; and,

・Moore Site ethylene emissions reduction program.

|

Polyethylene 1 Expansion Project

Currently, PE1 has two identical

polyethylene reactors referred to as production “trains”. R3 has been

designed to produce between 950 to 1,100 million pounds of Linear Low

Density Polyethylene (LLDPE). This will be an approximate 40% increase in

our overall site polyethylene capacity and will use existing Joffre Site

ethylene capacity.

---

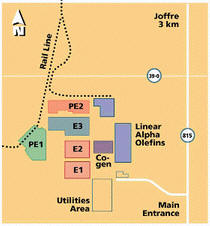

At our Joffre site we produce

ethylene and polyethylene.

Each year our three ethylene facilities produce more than six billion

pounds of ethylene and the two polyethylene facilities produce more than

two billion pounds of polyethylene.

Every year, we ship our polyethylene

resins to customers around the world who use them as the building blocks

for countless consumer products that enhance the quality and convenience

of daily life. Co-products result from the

production of our primary products (ethylene and polyethylene) and

Innovene produces Linear Alpha Olefins right

here on site.

From humble beginnings in 1979 with the

start-up of the first ethylene facility (called Ethylene 1), production and

site facilities have grown along with the worlds' demand for our products.

Manufacturing facilities (E1, E2, E3 and Polyethylene 1, PE2), together with

a massive supporting infrastructure (feedstock/product pipelines, water

treatment, rail storage/handling, cogeneration power plant) result in a

large-scale, integrated petrochemical complex.

E1

1988 Debottlenecked E1 to increase

capacity from 1.2 to 1.4 billion pounds

1993 Debottlenecked E1 to increase capacity to 1,542.2 million

pounds/year.

E2

1984 E2 brought into operation on

June 29

1987 Debottlenecked E2 to increase capacity from 1.5 to 1.7 billion

pounds

E3

2001 E3 officially achieves

commercial operations in July, demonstrating operation at an average of

100% of

nameplate over three months

Production capacity 2.8B pounds / 1.3M metric tonnes per year.

PE1

1984 PE1 started up on June 22

1988 Debottlenecked PE1 to increase capacity from 600 to 850 million

pounds

1992 PE1 increased nameplate capacity to one billion pounds per year.

1994 Polyethylene increased nameplate capacity to 1.2 billion

pounds/year.

PE2

2001 PE2 achieves initial start-up in

April, successfully producing polymer product.

Production capacity is 950 M pounds / 430,000 metric tonnes per year

(all sold in a pelleted form).

-----

Sarnia-Lambton Plant Facilities

Corunna, our largest site, is capable

of producing in excess of 3 billion pounds of petrochemicals annually.

Originally devoted entirely to processing crude-oil-based liquids, the

facility now has the flexibility to process a much

broader variety of feedstocks, producing a full range of primary

petrochemicals.

Crude oil, condensate and natural gas

liquids are delivered to the site by pipeline for processing.

Co-products are derived during petrochemical production at the site,

including synthetic natural gas, gasoline components, diesel fuel and

home heating oil. Another co-product, heavy residual fuel oil, is sold

as industrial fuel.

The resin from both Mooretown and St.

Clair River polyethylene sites is transported to end-product

manufacturers via rail and truck in the form of small pellets.

End-products produced from our polyethylene resin include grocery bags,

film wrap, household bottles and foam for packaging.

Corunna Site - Corunna, Ontario

Corunna also produces a variety of

specialty chemicals for the North American market. These include

products for the rubber and hydrocarbon resin industries, as well as

resin oils used in the manufacture of printing inks and adhesives.

The Corunna site processes crude

oil, condensate and natural gas liquids (NGLs) that are delivered to

the site by pipeline from western Canada. These products are the

feedstocks used to manufacture ethylene, propylene, butadiene,

iso-butylene, n-butylene, benzene, toluene and xylene.

Moore Site - Mooretown, Ontario

Moore Site converts ethylene,

supplied by Corunna, to manufacture both

low-density and high-density polyethylene resins.

about 840 million pounds of polyethylene per year.

St. Clair River Site - Corunna, Ontario

The St. Clair River

polyethylene facility is also home to NOVA Chemicals'

SCLAIRTECH™ polyethylene licensing and international ventures

business. SCLAIRTECH technology is used to manufacture high-density

and linear-low-density polyethylene resin.

Annual production capacity at St. Clair is 395 million pounds (180

kilotonnes) of polyethylene.

December 18, 2013

NOVA Chemicals announces plans for multiple

projects in Sarnia region

- Company will continue to evaluate options for a second Advanced SCLAIRTECH

technology facility

NOVA Chemicals Corporation today announced its decision to move forward with

the second phase of its NOVA 2020 growth strategy in Ontario, Canada, and to

continue to evaluate options for a second Advanced

SCLAIRTECHTM technology (AST) facility.

This next phase of the NOVA 2020 growth strategy, anticipated to take place over

the 2014 to 2018 timeframe, will concentrate on several cost-effective

expansions and upgrades to NOVA Chemicals’ existing facilities in the Sarnia, ON

region, including:

· Expanding the Corunna cracker ethylene manufacturing capacity by approximately

20%;

· Pursuing a debottleneck at the Moore low-density polyethylene (PE) line; and

· Pursuing a retrofit of the Moore high-density PE line.

These projects are intended to build on the impact of the Corunna cracker

conversion to utilize up to 100% natural gas liquids (NGLs)

to enhance NOVA Chemicals’ capabilities to meet growing and more sophisticated

customer demands.

During this period, NOVA Chemicals will continue to investigate options for a

second AST facility, which could be located in Ontario, the U.S. Gulf Coast or

elsewhere in the world, and which would be implemented in the final phase of the

NOVA 2020 growth strategy.

“We are excited to move forward with the next phase of growth for our Eastern

Canadian Olefins and PE assets, building on the imminent completion of our

Corunna feedstock conversion project. In parallel with the planned

implementation of these projects, which could represent investment exceeding

$300 million, we will continue to investigate options for a second AST

facility,” stated NOVA Chemicals CEO Randy Woelfel. “We believe phasing of

implementation of the NOVA 2020 projects is the optimal path forward to maintain

NOVA Chemicals’ financial strength and optionality while recognizing the market

challenges for project implementation.”

Work continues to progress on other projects within the first phase of the NOVA

2020 portfolio, including:

· Revamping the Corunna, Ontario cracker facility to utilize cost-competitive

NGL feedstocks with project completion targeted for Q1 2014. Ethane from the

Marcellus Shale Basin is currently accumulating in local Sarnia storage for

introduction as a Corunna feedstock shortly; and

· Building a world-scale gas-phase PE reactor at the Joffre, Alberta facility,

to provide customers with a complete set of LLDPE offerings, which is expected

to be mechanically complete in Q1 2016.

About NOVA 2020

NOVA 2020 is NOVA Chemicals long-term

asset strategy to capitalize on emerging feedstock opportunities and growing

North American demand.

NOVA 2020 lays out the strategic direction and vision of our organization.

As we evolve our asset base to support leadership in the markets we serve,

this endeavor will not only help deliver more capacity to our customers, but

also maximize the value generated by our business.

Corunna, Ontario – Eastern Canada

In 2011, NOVA Chemicals began a project to switch our Corunna, Ontario site

from consuming a mix of heavy and light feed to utilizing up to

100% natural gas liquid (NGL) feedstock.

We expect to begin consuming ethane from the Marcellus

Shale basin beginning in Q3 2013, with completion of the project in

early 2014.

Joffre, Alberta – Western Canada

NOVA Chemicals is expanding our PE1 facility to have a third gas-phase

reactor and associated equipment. This world-scale reactor allows us to

bring additional value to our customers – providing more linear-low density

polyethylene (NOVAPOL® resins) to the marketplace to meet the growing demand

for products such as: trashbags, heavy duty sack, etc.

We expect to commission and start-up the new unit in the fall of 2015.

Advanced SCLAIRTECH™ Technology Facility Update

We have decided to move forward with the second phase of our announced NOVA

2020 slate of projects in Ontario, while continuing to evaluate options for

a second Advanced SCLAIRTECH™ technology (AST) facility, which could be

located in Ontario, the U.S. Gulf Coast or elsewhere in the world. We will

first invest in smaller, more cost-effective projects, allowing us to better

manage cash flow, move beyond the construction peak and further develop our

technologies, solidifying our commitment to investing and working in the

Sarnia, Ontario region.

January 16, 2014 NOVA Chemicals

NOVA Chemicals announces utilization of

Marcellus Shale sourced ethane at its Ontario cracker

NOVA Chemicals Corporation today celebrated its commitment to the Sarnia,

Ontario region during a ceremony to commemorate the first barrels of

ethane sourced from the Marcellus Shale Basin being

utilized at its Corunna, Ontario cracker.

NOVA Chemicals began consuming this new feedstock in late December 2013 as part

of a project to revamp its Corunna, Ontario cracker to utilize up to 100%

natural gas liquid feedstock in line with its strategy to ensure the long-term

economic viability of its Ontario assets.

ポリエチレン拡大計画NOVA 2020

計画では、JoffreとMooreにそれぞれポリエチレン工場を建設する。更にMoore工場の既存プラントのデボトルネッキングを検討する。

Mooreの新工場は、同社が開発したポリエチレン技術 Advanced SCLAIRTECH 法を使用する第二のワールドクラスのプラントとなる。

原料のエチレンについては、既存のJoffreのエチレン利用増とCorunna のエチレンの増強で賄う。

エチレンの生産増には、シェールオイル・ガス、オイルサンドからのオフガスや、既存のエタンなど、多様化した原料ソースを使用する。

Corunnaのエチレンは原料を天然ガス100%利用できるよう改造する。2013年第3四半期からはMarcellus

Shaleのエタンの使用を開始する。

2013/6/14 カナダのNOVA

Chemicals、ポリエチレン拡大計画NOVA 2020 をスタート

June 13, 2014

NOVA Chemicals announces first utilization of

ethane supplied from Bakken Shale

NOVA Chemicals Corporation today announced

that the first barrels of ethane supplied from natural gas associated with oil

production from Bakken Shale are being utilized at

its Joffre, Alberta complex.

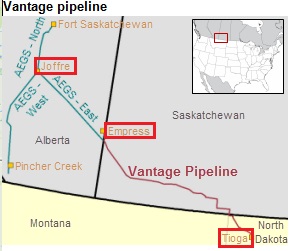

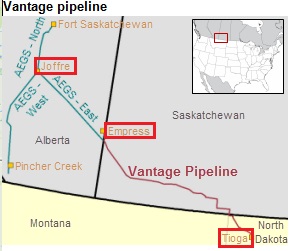

The ethane was produced at Hess Corporation’s Tioga, North

Dakota plant and transported across the border into Alberta via the

Vantage Pipeline. The Vantage Pipeline connects to

the Alberta Ethane Gathering System (AEGS) in

Empress, Alberta for the final journey to Joffre. NOVA Chemicals is the contract

operator of both AEGS and the Vantage Pipeline.

The Vantage Pipeline has an initial design capacity of 40,000 bpd but is

expandable to greater than 60,000 bpd, a volume that reflects more than 20% of

Alberta’s existing installed ethylene production capacity. Ethane extracted from

associated gas produced from Bakken Shale is expected to be a growing and stable

feedstock supply source for the Alberta petrochemical industry.

“The introduction of Bakken Shale-based ethane into the feedstock diet at Joffre

marks an important milestone in the diversification of our ethane sources for

the region and our NOVA 2020 strategy to capitalize on North American demand,”

stated Todd Karran, NOVA Chemicals Acting CEO and CFO. “The new supply sources

we recently began to use, together with those currently in development, should

enable us to run our existing polyethylene plants at full capacity, as well as

support our PE1 Expansion project in Joffre and position us well for potential

further growth.”

The

Vantage Pipeline is a high vapour pressure (HVP) pipeline

carrying ethane from a source near Tioga, North Dakota, U.S.A., extending

northwest, through Saskatchewan, Canada, and terminating near Empress,

Alberta, Canada. The pipeline links a growing supply of ethane from North

Dakota to markets in Alberta.

The Vantage Pipeline

is 712 km long (445 miles) steel pipeline, with an outside diameter of 273

mm (10 inch).

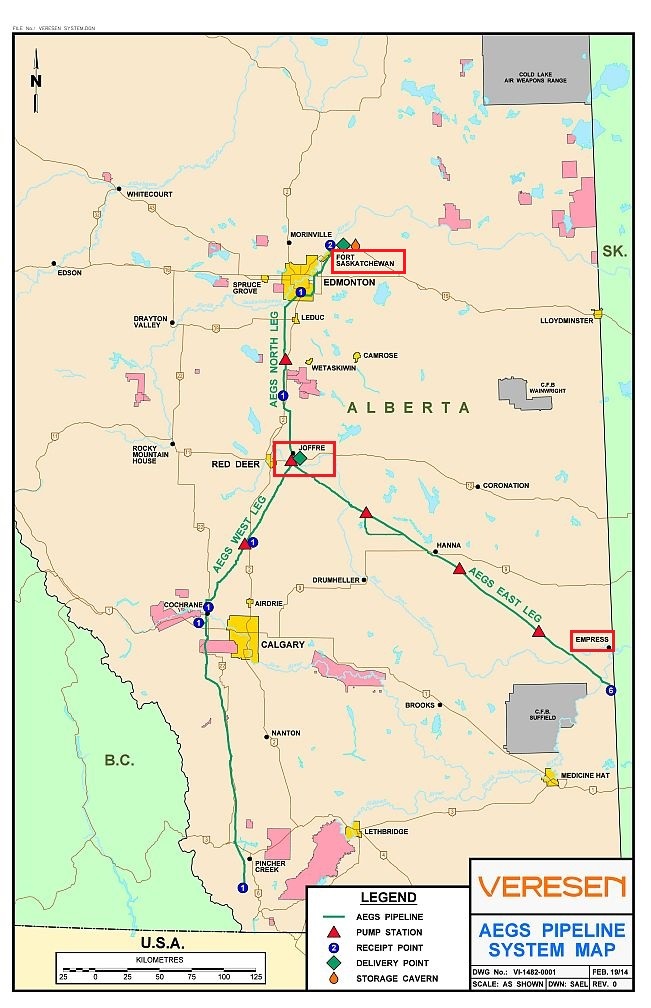

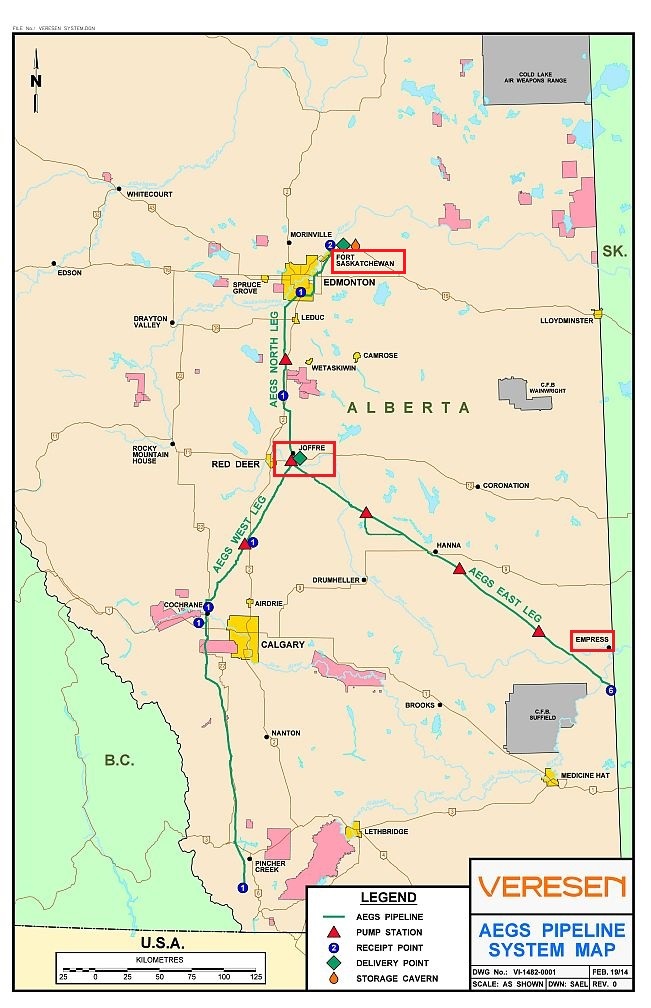

The Alberta Ethane Gathering System ("AEGS")

is the exclusive long-distance transporter of pure or "specification" ethane

in Alberta and, as such, fully integrates Alberta's world scale

petrochemical industry with the province's major natural gas liquids

extraction facilities.

AEGS is the only pipeline system that

transports specification ethane to Alberta’s

petrochemical complexes at Joffre and Fort Saskatchewan, which are

among the largest petrochemical plants in the world.

AEGS is comprised of several integrated

pipeline legs that currently span the southern and central portions of

Alberta, areas that funnel the flow of virtually all of Alberta's natural

gas production. The AEGS network is currently 1,330km in total length and

has an approximate aggregate design capability of 330,000 barrels per day.

Through this pipeline network, AEGS delivers substantively all of the

specification ethane feedstock requirements for NOVA

Chemicals' petrochemical complex near Joffre, Alberta, as well as a

majority of Dow Chemical's specification ethane

feedstock requirements at Fort Saskatchewan and Joffre, Alberta. AEGS

is also connected to a large underground storage facility near Fort

Saskatchewan, Alberta.

The AEGS system, as shown on the following map, consists of three legs:

(i)

the East Leg which extends from ethane extraction plants near Empress to

Joffre;

(ii) the West Leg which extends from near Waterton through Cochrane

to Joffre; and

(iii) the North Leg which extends from Joffre past Edmonton

to Fort Saskatchewan.

-------------

May 19, 2014

Hess Corporation, North Dakota Officials

Gather to Celebrate Expansion of Tioga Gas Plant

Hess Corporation was joined today by Governor Jack Dalrymple, Senator John

Hoeven and a host of other government officials to commemorate the recently

completed expansion of the Tioga Gas Plant, which

more than doubles the operational capacity of the facility.

The project is part of a more than $1.5 billion infrastructure investment made

by Hess between 2012 and 2014 in North Dakota that has significantly increased

production of propane, methane, butane and natural gasoline, and of ethane, a

vital industrial product never before produced in the state. The expansion also

brings a substantial improvement in efficiency and significantly reduces the

amount of natural gas flared at Hess’s operations, from about 25 percent before

the plant was shut down for the expansion project to 15 to 20 percent today.

“The Tioga Gas Plant was built in 1954, just three years after we drilled the

very first oil well in the state of North Dakota,” said John Hess, Chief

Executive Officer of Hess Corporation. “Today, as one of the largest oil and gas

producers in the Bakken, we are committed to responsible long-term growth in

North Dakota and proud to contribute to the state’s infrastructure.”

The plant is fully operational and is currently processing about 120 million

standard cubic feet of gas per day (MMSCFD), with the expectation that through

the combination of Hess and third-party gas it will soon process at least 250

MMSCFD with the potential to increase beyond 300 MMSCFD. Prior to expansion, the

plant processed about 100 MMSCFD.

“North Dakota leads the oil and gas industry because it is an attractive place

to invest, with strong public-private partnerships, responsible regulation and a

firm commitment to work hand-in-hand with the business community,” Hess said.

“Since 2010, we have invested more than $10 billion in North Dakota, we

currently have a 17 rig drilling program with 2014 net production expected to

average 80,000 to 90,000 barrels of oil equivalent per day, and are proud to

contribute to the state’s economic success. I would like to personally thank

Governor Dalrymple, Senators Hoeven and Heitkamp, Rep. Cramer, and the state

regulatory agencies that made these investments possible.”

“I’m very excited about the opening of Hess Corporation’s expanded gas plant in

Tioga,” Governor Jack Dalrymple said. “It means leadership for other companies

that are taking advantage of the Bakken oil boom. It’s an example of what we

need to see, which is more capturing of natural gas and more added value to the

product. We are very grateful to Hess for showing the way.”

“We appreciate the tremendous investment Hess is making in North Dakota, which

amounts to $1.5 billion not only for this expansion, but also for four new gas

gathering projects the company expects to complete by the end of the year,” U.S.

Senator John Hoeven said. “This new expansion more than doubles the plant’s

capacity to produce natural gas, more than triples the amount of propane

available to North Dakota and the region, and at the same time significantly

reduces flaring in the oil patch. That’s a huge win for our state and our

country.”

“Hess has a long history in North Dakota, and it’s great news the company is

continuing to invest in our state and build on its current facilities,” said

U.S. Senator Heidi Heitkamp. “With natural gas, North Dakota has an excellent

opportunity to greatly expand its already incredible energy production and move

toward fully using our vast natural resources. To make this a reality, we need

to make significant infrastructure investments, which is why the Tioga Gas Plant

expansion is so important. For years, we have wasted valuable natural gas

through flaring, but with critical investments in processing capacity, like we

are celebrating today, we can move closer toward energy independence.”

“The legacy of Hess in North Dakota is inseparable from the story of our booming

economy. This expansion grows our portfolio of hydrocarbon and natural gas

exports while reducing flaring, continuing their rich tradition of responsibly

developing our state’s energy capabilities,” said Congressman Kevin Cramer.

Hess Corporation has a world-class acreage position, with 640,000 net acres in

the Bakken. The company’s full year 2014 production forecast for the Bakken is

80,000 to 90,000 barrels of oil equivalent per day. The gas plant expansion, as

well as other recent infrastructure improvements made in North Dakota, is part

of the company’s growth strategy.

“As a leading operator in one of the best shale plays in the world, the Bakken

will be the single biggest contributor to our production growth over the next

five years,” said Greg Hill, President and Chief Operating Officer of

Exploration and Production for Hess. “We expect that by 2018, we’ll be producing

150,000 barrels of oil equivalent per day from the Bakken.”

Hill was proud to credit employees for the successful expansion project. “Our

successes here are made possible by the incredibly talented employees and

contractors we have in place, who have worked tirelessly to bring this plant

online safely,” Hill said.

At the peak of plant expansion, there were about 1,400 people working at the

site, with more than 5 million total man-hours accumulated over about a 2 1/2

year period. During the final 9 months to complete the project and commission

the plant, these crews worked 2.3 million man hours without a single recordable

injury.

March 27, 2017

NOVA Chemicals and Borealis enter Preliminary

Agreement with Total to meet growing global demand for polyethylene

NOVA Chemicals Corporation and

Borealis AG signed a preliminary agreement to form

a joint venture (JV) with Total Petrochemicals and

Refining USA, Inc. that will develop and own a

new light feed cracker and a new

Borstar® polyethylene (PE) facility in

Bayport, Texas.

Key aspects of the JV will include:

Building a new 2.2 b lb (1000 ktpa) ethylene cracker in Port Arthur,

Texas

Building a new 1.35 b lb (625 ktpa) Borstar PE plant in Bayport, Texas

Total’s existing Bayport PE facility, total capacity 880 m lb (400 ktpa)

The ethylene cracker and Borstar PE unit are expected to start-up in late 2020.

A final investment decision is expected in late 2017, pending NOVA Chemicals’

Board and regulatory approvals and execution of definitive agreements.

The JV is expected to create significant synergies by enabling strong

integration of the value chain and the first-time use of the proprietary Borstar

PE process technology in the Americas. It is also expected to provide

competitive export access to markets outside of North America to help meet the

growing global demand for PE.

“This opportunity will complement NOVA Chemicals’ existing asset structure in

Canada and broaden our PE product slate as we continue to grow our business in

the Americas to deliver products that make everyday life healthier, safer and

easier,” stated Todd Karran, President and CEO, NOVA Chemicals. “It also paves

the way for NOVA Chemicals to collaborate further with Borealis as part of the

IPIC family of companies,” continued Karran.

“Working in a JV with NOVA Chemicals and Total on a cost effective brownfield

investment project, integrated with a cracker is an attractive opportunity. We

can also leverage our proven technology and benefit from large scale experience

gained in other projects (e.g., Borouge) and develop the project together with

NOVA Chemicals,” said Borealis CEO Mark Garrett.

February 23, 2026

Nova to pay Dow more than $1B in ethylene

dispute

A Canadian court has denied Nova Chemicals’ request to stay a

June 2025 judgment in favor of Dow Inc. involving Nova’s operation of the

companies’ jointly owned ethylene facility in Joffre, Alberta.

June 12, 2025

Nova ordered to pay

US$1.2B to Dow in feedstock case

A Canadian court has issued a

judgment requiring Nova Chemicals Corp. to pay Dow Inc.

another C$1.6 billion (US$1.2 billion) in damages related to

an ethylene feedstock unit operated by the two firms in

Joffre, Alberta.

Dow Chemical、エチレンJVに関するNova

Chemicals への訴訟で追加賠償取得

ブログ 2018/6/29 Dow

Chemical、エチレンJVに関するNova

Chemicals への訴訟で勝訴 付記

Dow 主張は以下の通り:

NovaはDowの持分のエチレン及び副産品の一部を取り込んだ。契約違反である。

JV契約での義務に違反し、設備をフル稼働しなかった。

エタンの不足はなかった。JVプラントをフルに動かすエタンはあり、Novaは追加のエタンを取得する能力も自由も持っている。

当初賠償命令 10億6千万米ドルの支払い

今回追加 12億米ドルの支払い