|

2006/7/27 Repsol YPF Repsol

presentation (企業概況、計画)

Repsol YPF invests

over Eur 600 million to double production at its Petrochemical

complex in Portugal

The Sines complex among the most advanced in Europe

・Three

new plants to be built and cracker capacity to be increased by

more than 40%.

・The

complex will have a production capacity of one million tonnes of

olefins and another million tonnes of polyolefins.

・Over

1,500 jobs will be created in the construction phase of the new

facilities.

・Sines

will enhance its added value by using all current production as

feedstock for the new polyolefin plants.

・Repsol

YPF consolidates growth in its natural markets in the Iberian

Peninsula and Southern Europe and complements its product

portfolio.

Antonio Brufau, Executive Chairman of Repsol YPF, accompanied by

Pedro Fernandez Frial, Executive Director of Downstream, will

meet today in Lisbon with the Portuguese Ministry of Economy and

Innovation, Manuel Antonio Gomes de Almeida de Pinho, to present

the company’s growth project for the Sines

Petrochemical Complex

in the 2006-2010 period, involving an investment of

over EUR600 million.

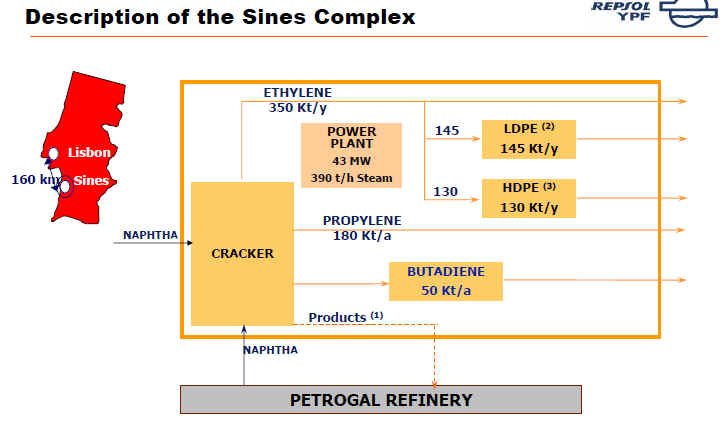

This project contemplates the construction of three new plants,

including a power station and two plants for the production of

new plastic products (linear polyethylene and

polypropylene)

at the current installations, as well as increasing the

capacity of the cracker currently in operation by more than 40%

to 570,000 tonnes/year. Current production at the

complex will increase twofold, boosting oleofin production to

nearly one million tonnes and polyolefin production to a similar

amount.

This investment will

accomplish full integration of feedstock consumption (ethylene,

propylene) at the Sines Complex, and optimise costs, as well as

complement the product portfolio and increase production of

higher added value products. As a result of all of this, the

Sines Complex will increase its efficiency, making it one of the

most technologically advanced of its kind in the European

petrochemical industry.

This project offers high returns since total investment per

tonnes of installed polyolefin production (including acquisition

costs), represents 60% of the cost required to build a new

complex.

A project of international dimension in Southern Europe

Repsol YPF’s Executive Chairman, Antonio

Brufau, highlighted the importance of this investment in “an internationally competitive

project that is very beneficial for Portugal in that, apart from

taking advantage of a large part of the existing infrastructure

in the area not fully exploited to date, it will create jobs,

double the current size of the complex, and benefit the country’s economy and balance of payments

by using the new capacity for export.”

Antonio Brufau

underscored the strategic importance of this investment for

Repsol YPF since it would be spent on “a profitable growth project aimed

at strengthening the company’s presence in a natural market,

such as the Iberian Peninsula/Southern Europe, and increasing

core businesses in the chemicals division.”

Enhances added

value of the Sines petrochemical complex

Following the construction of two new polyolefin plants, the

complex will cease to be a mere exporter of raw materials (over

30% of ethylene and 100% of propylene produced at the complex is

currently exported outside Portugal), and will significantly

enhance its added value by using all the cracker’s ethylene and propylene

production in the new polyolefin plants.

Linear polyethylene and propylene are plastics with numerous

applications and constantly expanding markets. Demand for these

products is showing very attractive annual growth rates (6% and

5%, respectively), greatly outpacing the economic growth rates of

Western European countries.

The linear polyethylene plant will complement the range of

products currently manufactured at the company’s facilities in Sines, as well as

in the Puertollano and Tarragona complexes, where Repsol YPF is

now producing low and high-density polyethylene (LDPE and HDPE).

With respect to polypropylene, the future range of products will

complement that currently produced at the company’s Puertollano and Tarragona

plants, using the most advanced technology currently existing in

the market.

Creates a significant number of jobs

The investment project will create a considerable number of jobs

over the next four years:

Construction phase 2007-2010:

・Over

eight million working hours

・An

average of 1,200 employees

・1,500

employees at peak periods

Operations:

・120

direct jobs

・250

indirect jobs

Supplementary information

Repsol YPF is one of the leading industrial groups in Portugal,

with a turnover of EUR2.1 billion in 2005. The company is present

in several areas of activity in the petroleum chain and has a

workforce of over 1,500 employees.

In the liquefied petroleum gas (LPG) business, the company

operates two bottling plants and enjoys a 20% market share in

Portugal. The company’s over 400 service stations

flagged under the Repsol brand sell more than 1.1 million cubic

metres of oil products and have an 18% market share.

Additionally, Repsol YPF sells more than 0.9 million m3 of fuel

as direct sales (to distributors), representing 17% of the

Portuguese market. Repsol YPF also operates in the aviation

business, lubricants, special products, and asphalt segments, in

the latter with a 30% market share.

In Chemicals, since 30 September 2004 when Repsol YPF acquired the Sines

petrochemical complex from Borealis, the company has invested

approximately EUR50 million to increase production capacity at

the cracker and high-density polyethylene plant and to improve

the environmental and safety conditions of this facility.

The cracker is a base petrochemical plant that produces basic

feedstock, mainly ethylene and propylene, to feed the derivative

petrochemical plants, from raw materials produced at the

refineries.

Polyolefin is a type of plastic divided into two main products:

polyethylene and propylene (PP). There are several classes of

polyethylene: high density (HDPE), low density (LDPE), and low

linear density LLDPE Polyethylene and polypropylene have many

applications in different sectors and day-to-day use.

Polyethylene is a flexible material, resistant, easy to handle,

impermeable, and reusable. Its use is becoming increasingly

widespread. Its applications include: film for food products,

agriculture and industrial use; water and gas pipes; cables and

covering for other materials.

Polypropylene is used in textiles (fibres), hygiene and

sanitation, construction, household appliances, and toy sectors.

It is also used in the manufacture of automobile components,

packaging, and piping.

One of the biggest

investments realized in the history of Portugal

Repsol has initiated the expansion of its Petrochemical Complex

in Sinex, Portugal

Today, Repsol's CEO,

Antonio Brufau, Portugal's Prime Minister, and Minister of

Economy José Socrates and Manuel Pinho, have

announced the initiation of the Sines Petrochemical Complex

expansion project. This important project is one of company's

main worldwide growth projects to be carried out in the Iberian

Peninsula and represents an investment of more than 1 billion

euros, one of the biggest investments ever to be realized in the

history of Portugal.

The expansion of

the Repsol Sines Complex contemplates building new lineal

polyethylene and polypropylene units that will triplicate the current petrochemical

complex, and will increase the current cracker capacity by

40%, until reaching a production of 570.000 tons of ethylene a year. In addition, a cogeneration plant

of 45 megawatts (Mw)

will be built, by this, the Sines Petrochemical Complex will

increase its efficiency and become one of Europe's most advanced

technological centres.

With this important

investment, around 500 jobs will be created, and during the

building process, more than 1.500 specialists will be employed.

The production of

this new Complex will be mainly destined for export and will

exceed more than 1.2 billion euros per year, which will have a

positive impact when exporting petrochemical products from

Portugal. The future capacity of the polyethylene and

polypropylene factories will be equally 300 Kt/y, while the new cracker production

capacity will be 570 Kt/y. The Repsol Sines Petrochemical Complex

will end up with a production of almost a million tons of olefins

and polyolefin’s.

With the new

polyethylene and polypropylene factories the Sines complex will

no longer be a mere exporter of raw materials, (at the moment,

near to 30% of ethylene and 100% of the propylene produced is

exported) and it will significantly increase its added value by

using the entire ethylene and polypropylene production of the

cracker in the new polyolefin factories.

Repsol’s CEO, Antonio Brufau, pointed out

that: "without a doubt Portugal is one of the high-priority

markets for our company, which is made evident by the billion

euro investment. Consequently the Sines petrochemical complex is

an extremely important project for Repsol which is included in

the company’s main worldwide strategic growth

projects for the coming years."