トップページ

CPChem (Chevron

Phillips Chemical Company LP )

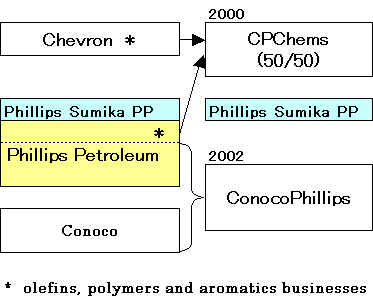

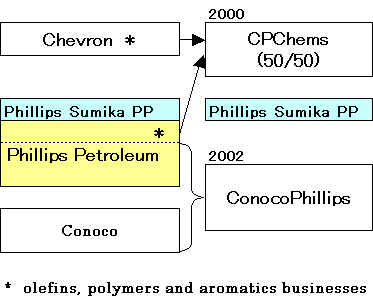

Phillips’chemicals and plastics businesses were combined into a 50/50 joint venture with Chevron Corporation's petrochemical and plastics

businesses on July 1, 2000,

except for Chevron's Oronite fuel and lubricants additives

business. CPChem is one of the world's top producers of olefins,

polyolefins, aromatics and styrenics.

Headquartered in Houston, Texas, CPChem uses fractionated natural

gas liquids purchased from Duke Energy Field Services and other

sources as one of the primary feedstocks for petrochemicals - an

intermediate chemical like ethylene, propylene, benzene or xylene

- and other petroleum products of higher value. The

petrochemicals are used to produce plastics, specialty chemicals

and synthetic fibers.

CPChem, with 34 production facilities and seven research and

technology centers in eight countries, has the people, assets and

technology to pursue chemical opportunities on a global scale.

Phillips/Chevron

石化統合発表文 添付

Chevron Phillips Chemical Announces Its

Intention To Build A New Ryton® PPS Plan

Chevron

Phillips sells Port Arthur Cumene unit to INEOS Americas

ConocoPhillips to Acquire

Burlington Resources in $35.6 Billion Transaction

Dow and Chevron Phillips Chemical

Announce Plans to Form Styrenics Joint Venture in the Americas

Chevron

Phillips, Plans to Build New Ryton(R) PPS Plant in Borger

CPChem Facts (June 30, 2001, average data unless

indicated)

Major Domestic Facilities:

Borger, Cedar Bayou,

Orange, Pasadena, Port Arthur and Sweeny, Texas; St.

James, La.; Pascagoula, Miss.; Marietta, Ohio; Drilling

Specialties in Conroe, Texas; Guayama, Puerto Rico; and

11 plastic pipe and two pipe fittings plants.

Major Overseas Facilities:

Kallo-Beveren and

Tessenderlo, Belgium; Shanghai, China; Zhandgjiagang,

China; Al Jubail, Saudi Arabia; Singapore; Yochon, South

Korea; and two plastic pipe plants in Mexico.

Assets: $7 billion.

Phillips' Interest: 50 percent.

Employees: 6,100

Petrochemicals Product

Capacities MMLB/Yr http://www.phillips66.com/FB01/CPCHEM.PDF

場所別能力は後記

| |

Gross |

Net |

| Olefins

and Polyolefins |

|

17,363 |

| Ethylene |

8,080 |

8,080 |

| HDPE |

4,970 |

4,408 |

| Propylene |

2,880 |

2,880 |

| LDPE |

620 |

620 |

| Plastic Pipe |

580 |

580 |

| LLDPE |

400 |

400 |

| Polypropylene |

790 |

395 |

| Aromatics |

|

8,718 |

| Benzene |

3,130 |

2,600 |

| Cyclohexane |

1,700 |

1,438 |

| Paraxylene |

1,880 |

1,880 |

| Styrene |

1,700 |

1,700 |

| Cumene |

1,100 |

1,100 |

| Specialty

Chemicals and Plastics |

|

3,174 |

| K-Resin |

450 |

404 |

| Polystyrene |

990 |

990 |

| Normal Alpha Olefins |

1,250 |

1,250 |

| Polyalpha Olefins

(PAO) |

104 |

104 |

| Ryton |

56 |

56

+22 |

| Misc. Specialty

Chemicals |

370 |

370 |

Growing International Presence

CPChem is moving to create

world-scale complexes in key overseas locations where

excellent feedstock resources allow competitive access to

markets in Asia, Europe, the Middle East and Africa.

The Qatar complex now under construction, Q-Chem I, is

designed to have an annual capacity of 1.1 billion pounds of

ethylene, 1 billion pounds of polyethylene and 100 million

pounds of hexene-1. The complex, located in Mesaieed, Qatar,

is expected to start up in the third quarter of 2002. CPChem

has a 49 percent share, and the state firm Qatar Petroleum

Corp. owns the remaining 51 percent.

CPChem has also signed an agreement for the development of a

world-scale petrochemical complex, Q-Chem II, to be built in

Ras Laffan, Qatar. The facility will have an ethylene cracker

with the capacity to produce up to 2.6 billion pounds per

year and a polyethylene plant capable of producing 1.6

billion pounds per year. The Ras Laffan complex is scheduled

for completion in 2006.

CPChem signed a letter of intent in August 2001 to conduct a

feasibility study for construction of a styrene monomer plant

in Paraguana, Venezuela. The capacity of the Paraguana

styrene plant would be approximately 1 billion pounds

annually, and the product would be marketed primarily in the

Americas region. The feasibility study is expected to be

completed by year-end with startup of the plant potentially

slated for 2007.

CPChem Plants Worldwide Gross MMLB/Yr

| Facility |

Product Line |

|

| Borger

Plant, Borger, Texas |

Methyl

mercaptan

Ryton polyphenylene sulfide (PPS)

Dimethyl sulfide

High-purity hydrocarbons and solvents

Mercaptans

Mining chemicals

Organosulfur chemicals

Performance and reference fuels |

100

28

10

*

*

*

*

*

|

| Cedar Bayou

Chemical Complex, Baytown, Texas |

Ethylene

Normal alpha olefins (NAO)

Propylene

Low-density polyethylene (LDPE)

High-density polyethylene (HDPE)

Linear low-density polyethylene (LLDPE)

Polyalpha olefins (PAO)

Acetylene black |

1,750

1,250

910

620

520

400

104

18

|

| Chevron Phillips

Chemicals Asia Pte Ltd., Singapore |

Ryton polyphenylene

sulfide (PPS) |

8 |

Chevron

Phillips Singapore Chemicals Pte Ltd.,

Singapore ーJoint

venture (50% interest) |

High-density

polyethylene (HDPE) |

860 |

| Drilling

Specialties Co., Conroe, Texas |

Soltex

drilling mud additives |

20

|

Houston

Chemical Complex, Pasadena, Texas

Phillips Sumika

Polypropylene

ーJoint

venture (50% interest) |

High-density

polyethylene (HDPE)

K-Resin styrene-butadiene copolymers (SBC)

Polypropylene |

2,200

335

790

|

Kallo

Compounding Plant, Kallo Beveren,

Belgium |

Ryton

polyphenylene sulfide (PPS) |

20

|

K R

Copolymer Co. Ltd., Yochon,

South Korea Joint venture (60% interest) |

K-Resin

styrene-butadiene copolymers (SBC) |

115

|

| Marietta

Plant, Marietta, Ohio |

Polystyrene |

770

|

| Orange

Chemical Plant, Orange, Texas |

High-density

polyethylene (HDPE) |

1,170

|

Pascagoula

Chemical Operations,

Pascagoula, Miss. |

Benzene

Paraxylene |

1,540

1,000

|

Performance

Pipe Division

Abilene, Texas

(fittings)

Abbeville, S.C.

Bloomfield, Iowa

(fittings)

Brownwood, Texas

Colton, Calif.

Fairfield, Iowa

Hagerstown, Md.

Knoxville, Tenn.

Pryor, Okla.

Reno, Nev.

Startex, S.C.

Waxahachie, Texas

Williamstown, Ky.

Queretado, Mexico

Tlaxcala, Puebla,

Mexico

−Joint

venture (49% interest) |

Polyethylene

pipe |

580

|

| Port Arthur

Plant, Port Arthur, Texas |

Ethylene

Cumene

Propylene

Benzene

Cyclohexane |

1,730

1,100

720

530

330

|

Puerto Rico

Core, Guayama, Puerto Rico

|

Paraxylene

Cyclohexane

Orthoxylene |

880

845

215

|

Saudi

Chevron Phillips Petrochemical, Al Jubail,

Saudi Arabia Joint venture (50% interest) |

Benzene

Cyclohexane |

1,060

525

|

Shanghai

Golden Phillips Petrochemical Co. Ltd.,

Shanghai, China ーJoint venture (40% interest) |

High-density

polyethylene (HDPE)

|

220

|

Specialty

Chemicals, Tessenderlo, Belgium

|

Organosulfur |

40

|

| St. James

Plant, St. James, La. |

Styrene |

1,700 |

Sweeny

Chemical & NGL Fractionation,

Old Ocean,

Texas |

Ethylene

Propylene |

4,600

1,250 |

| Chevron

Phillips Chemical (China) Co. Ltd., Zhangjiangang, China |

Polystyrene |

220

|

*Small volume specialty

chemicals

他に カタール(Q-Chem)計画

(Chevron/Phillips統合発表 2000/2/7)

Chevron and Phillips to Form Joint

Venture Creating World-Class Chemical Company

http://www.cpchem.com/news/pr/2000/0207.asp

Chevron and Phillips today

announced the signing of a letter of intent and exclusivity

agreement to combine their worldwide chemicals operations

into a 50/50 joint venture with more than $6 billion in

assets that will be a world-scale competitor in the

petrochemicals industry.

2004/11/1 Chevron Phillips

Chevron Phillips Chemical Announces Its Intention To Build A New

Ryton® PPS Plant

http://www.cpchem.com/press_releases_6952.asp

Chevron Phillips Chemical Company

LP (Chevron Phillips Chemical) announces its intention to build a

new 22

million pound-per-year capacity polyphenylene sulfide (PPS)

plant. Startup is anticipated

in early 2007. The location of the new plant has not yet been

chosen.

RubberWorld 2005/11/1

Chevron Phillips sells Port Arthur Cumene unit

Chevron Phillips Chemical Company LP has announced the sale of

its cumene production unit at its Port Arthur, Texas facility to INEOS Americas

LLC (INEOS),

where it will become part of INEOS’Phenol Division. The financial

terms of the sale were not disclosed. Chevron Phillips Chemical

will provide certain tank operations and maintenance services

related to the cumene unit according to terms of a separate

agreement.

Chevron Phillips Chemical will continue operation of its olefins

complex as well as the existing cyclohexane unit at the Port

Arthur facility. Chevron Phillips Chemical previously idled the

cumene unit in 2003 due to poor market conditions.

2005/12/12

ConocoPhillips

ConocoPhillips to Acquire

Burlington Resources in $35.6 Billion Transaction

http://www.conocophillips.com/newsroom/news_releases/121205_burlington.htm

Burlington Resources' Gas

Reserves and Production Provide Excellent Strategic Fit With

ConocoPhillips' Global Energy Portfolio

ConocoPhillips to Become a Leading Natural Gas Producer in North

America

ConocoPhillips (NYSE: COP) and Burlington Resources Inc. (NYSE:

BR) announced today they have signed a definitive agreement under

which ConocoPhillips will acquire

Burlington Resources in a transaction valued at $35.6 billion. The transaction, upon approval by

Burlington Resources shareholders, will provide ConocoPhillips

with extensive, high quality natural gas exploration and

production assets, primarily located in North America. The

Burlington Resources portfolio provides a strong complement to

ConocoPhillips’ global portfolio of integrated

exploration, production, refining and energy transportation

operations, thereby positioning the combined company for future

growth.

Burlington Resources is one of the world's leading independent

exploration and production companies, and holds one of the

industry's leading positions in North American natural gas

reserves and production. At December 31, 2004, Burlington

Resources had total reserves of 2,001 MMBOE (million barrels of

oil equivalent). In addition, Burlington Resources has estimated

2005 production of approximately 475 MBOE/d (thousand barrels of

oil equivalent per day), and access to significant conventional

and unconventional resources.

2007/3/29 Chevron

Phillips

Plans to Build New

Ryton(R) PPS Plant in Borger, Texas Finalized

Chevron Phillips Chemical

Company LP (Chevron Phillips Chemical) announced today that it

will proceed with plans to build a 22 million

pound-per-year polyphenylene sulfide (PPS) plant in Borger, Texas. Built next to Chevron Phillips

Chemical’s existing PPS plant in Borger,

the new facility will expand the company’s total PPS capacity at the site

to approximately 44 million pounds per year. The new plant will share some

infrastructure and operations with the existing Ryton(R) PPS

plant.

The construction process begins immediately, with project

completion anticipated in early 2009.

◎ Phillips (現 CPChem) Ryton®能力

Borger, Texas 12,700 t +10,000t→20,000t

Belgium 9,100

Singapore 3,600

合計 25,400

Chevron Phillips

Chemical Announces Its Intention To Build A New Ryton® PPS Plan +10,000t →+ 11,000

2014/6/12

Chevron Phillips Chemical Announces

Mechanical Completion and Start-up of World's Largest 1-Hexene Plant

Chevron Phillips Chemical Company LP announced today the successful

commissioning and start-up of the world’s largest on-purpose

1-hexene plant. With worldwide supply capabilities, the 1-hexene unit is

capable of producing 250,000 metric tons

(551,000,000 lbs.) per year and will enjoy significant advantages in

infrastructure, feedstock availability and operational knowledge by its

placement in the existing Cedar Bayou Chemical Complex in

Baytown, Texas.

Chevron Phillips is committed to being a consistent and reliable supplier for

our customers,” said Mitch Eichelberger, general manager of Normal Alpha Olefins

and Polyalphaolefins for Chevron Phillips Chemical. “With the start-up of this

plant, we will enable our customers to expand their businesses and meet the

growing worldwide demand for 1-hexene comonomers.”

"Our investment to expand 1-hexene production is due in part to Texas’ growth as

a major international hub for the petrochemical industry and the increased

supply of competitive feedstocks in the U.S. from the development of shale

resources,” said Pete Cella, CEO of Chevron Phillips Chemical. “Only five years

ago, the expectation was that the U.S. would become a significant net importer

of ethylene derivatives. Now the U.S. is expecting to become a major exporter of

ethylene derivatives, including 1-hexene, able to compete with any producing

region in the world.”

The new plant is the third plant to utilize Chevron Phillips Chemical’s

proprietary selective on-purpose 1-hexene technology, which produces

comonomer grade 1-hexene from ethylene with exceptional

product purity. 1-hexene is a critical component used in the manufacture

of polyethylene, a plastic resin commonly converted into film, plastic pipe,

detergent bottles, and food and beverage containers.

The proven technology is already successfully used at

Qatar Chemical Company Ltd.’s (Q-Chem) facility in Mesaieed, Qatar, and

at the Saudi Polymers Company plant in Al Jubail, Saudi

Arabia. Both of these facilities are joint ventures of wholly-owned

subsidiaries of Chevron Phillips Chemical Company LLC.

2014/6/17

Chevron Phillips Chemical Breaks Ground on

Two World-Scale Polyethylene Units for U.S. Gulf Coast Petrochemicals Project

Chevron Phillips Chemical Company LP held its second groundbreaking ceremony for

its U.S. Gulf Coast (USGC) Petrochemicals Project at the construction site in

Old Ocean, Texas. The construction includes two

world-scale polyethylene units that will each

produce 500,000 metric tons of plastic resin every year. With this

groundbreaking, Chevron Phillips Chemical maintains its first mover position

within the petrochemicals industry to engineer and build

world-scale ethylene and derivatives facilities in the U.S. based upon the

successful development of shale resources.

The groundbreaking ceremony included local officials from the Cities of Sweeny

and West Columbia, Brazoria county commissioners, Texas representative Dennis

Bonnen and other state and federal elected representatives. In addition,

officials from the owner companies of Chevron Phillips Chemical, Chevron

Corporation and Phillips 66 were in attendance at the ceremony.

The resin from the polyethylene units will be used for a variety of products,

including new flexible packaging options that extend the shelf life of fruits

and vegetables, as well as in the creation of plastic piping, merchandise bags,

and bottles. In addition to constructing the production facilities, 45 miles of

railroad track will be installed on-site to hold and transport the output of

these units.

The engineering, procurement and construction (EPC) phase of the two

polyethylene units is being executed through Gulf Coast Partners, a partnership

between Technip USA Inc. and Zachry Industrial.

"With the construction of this mega project, we will be in a position to better

serve the growing needs of our customers around the globe. This entire project

is made possible by advances in technology. First, through innovations within

the E&P industry to unlock oil and gas trapped in shale rock. Second, by the

research and brilliance within Chevron Phillips Chemical to develop

high-performance polyethylene resins,” said Peter L. Cella, president and chief

executive officer of Chevron Phillips Chemical.

“We want to thank our local community neighbors and government officials for

their support over the years. We value the trust you have in us and will

continue to do our best to maintain that trust by being a good neighbor and a

positive force in the community,” said Cella.

The economic impact generated from this endeavor is significant; over 400

long-term direct jobs and 10,000 engineering, construction and fabrication jobs

will be created as a result of the Chevron Phillips Chemical USGC Petrochemicals

Project.

Chevron Phillips Chemical

は2011年12月24日、テキサス州のメキシコ湾岸で大規模エタンクラッカーと誘導品設備を建設する計画のFSが完了したと発表した。

同社は2011年3月に、シェールガス開発で得られる有利な原料を利用する計画のFS実施を進めることを発表していた。

テキサス州BaytownのCedar

Bayou工場が新しいエチレンプラントの建設場所となる。年産150万トンのエタンクラッカーで、Shaw Energy and

Chemicals の技術を使用する。設計契約を締結している。

更に自社技術を使用して2基のポリエチレンプラントを建設する。同社のLoop

Slurry Technologyを使用する。

Sweenyのエチレン能力は1,860千トンだが、同社は2013年6月に、1炉増強して90千トン増やすと発表した。

2011/12/29 Chevron

Phillips Chemical、シェールガス利用で大規模石化計画