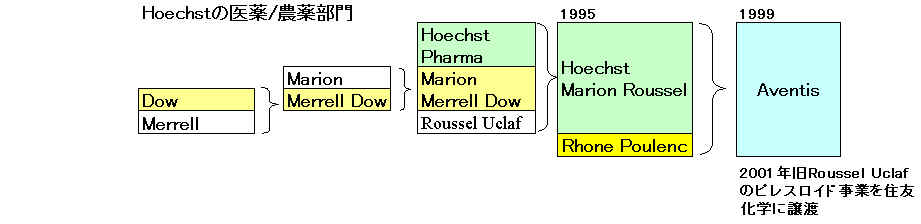

トップページ

Dow

Louisiana立地

Decades Later,

Toxic Sludge Torments Bhopal

2008/11/13 Dow

Announces Energy Plan for America

- Encourage

aggressive energy efficiency and conservation

- Increase

and diversify domestic energy supplies

- Accelerate

development of alternative and renewable

energy

- Reduce

greenhouse gas emissions

|

ダウーUCC合併 Cleaning

up After Bhopal Gas Tragedy - Not Begun U.S. Lawmakers

Back Bhopal Survivors

認可条件:Dow

Announces Plans to Sell Portions of Two Amine Businesses to

Huntsman, INEOS

Dow selects Seadrift, Texas, for new

ethylene plant site

Union

Carbide closed Texas City olefins plant in June and shutdown

Seadrift Plant in September

東独 BSL 買収

EVC took over the BSL PVC production

facility at the Schkopau

西豪州石化計画 2002/12 社長更迭

日本で医薬製造受託(野依「不斉触媒合成技術」取得)

Epoxy

Resin Plant in China

PIC and Dow Plan to Construct

Ethylene and Derivatives Complex and Ethylbenzene/Styrene Unit in

Kuwait

Dow and PIC Announce

Formation of Two New Joint Ventures

オマーン政府とダウ、石化コンプレックスJV設立で合意

2004/8 Dow & BASF to construct a world-scale

PO, using HPPO technology

米ダウ・ケミカル 中東の生産拠点増強

Dow

to build speciality PE plant in Spain

Dow

to reduce production at VCM Plant in Texas (Oyster Creek) in 2005

Shenhua and Dow Chemical agree to study

Coal-to-Olefins opportunity in China

2007/5 Shenhua

and Dow to Sign Co-operation Agreement on Coal-To-Chemicals

Project

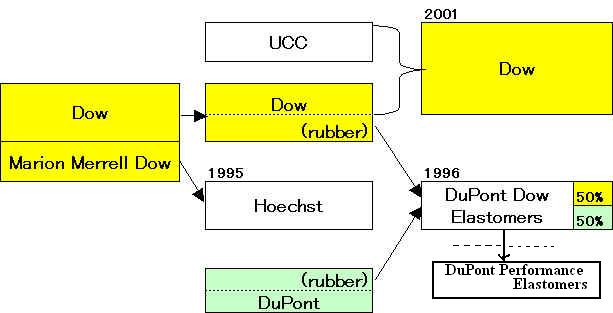

DuPont Dow

Elastomers 解散

DuPont Dow Elastomers、DuPont

Performance Elastomersに

ダウ・ケミカル 燃料電池事業を強化

セルロース 大幅増産 信越化学抜き再び首位

ダウ、エニと共同でエタンからのSM製造法開発

Dow Completes Acquisition of Korea’s Pacific Epoxy Co., Ltd.

LG-DOW Proceeds

with Project for Second Polycarbonate Train

Dow

Aligns Business Portfolios to Drive Strategy

Dow

to sell 50 percent interest in UOP

BASF とダウ・ケミカル、プロピレンオキサイドの新生産プロセスを共同開発

Dow Plans to Close Polystyrene

Plant at Barry, UK

Degussa Acquires Superabsorbent

Business from Dow

Zhejiang

Pacific Chemicals Corporation Celebrates 10th Anniversary

Milestone

Dow to Build a New Center in

Shanghai, China

2006/3 Dow Signs HPPO Joint Venture

Agreement with BASF

Dow

Moves Forward with Expansion Plans for Cellulosics

2006/4 Dow buys PE

production in Romania

2006/4 Dow

To Build New P-Series Glycol Ethers Plant in Zhangjiagang, China 張家港

2006/4 SINOPEC To Build

Two MEG Plants Based on EO/EG Process Technology Licensed Through

Dow

2006/5 Dow Signs LOI with Zhangjiagang

Government

張家港

2006/7

Dow acquires Zhejiang Omex

Environmental Engineering, increasing its Water Components

Portfolio

2006/8 Dow

Epoxy to Invest US$200 Million to Accelerate Growth in China

2007/3 Dow Epoxy Advances

Glycerine-To-Epichlorohydrin and Liquid Epoxy Resins Projects by

Choosing Shanghai Site

2006/8 Dow Corning And WACKER Receive

Government Approval to Build Siloxanes Facility in China

2006/8 Dow

and Izolan Form Joint Venture to Serve Growing Systems Business

in Russia

2006/9 Dow

Announces Plant Closures To Strengthen Competitive Position

2006/10 Dow

pursues Natural oil polyols derived from soya beans

Dow

Advances Strategy in Asia Pacific:to move ahead with a jv cracker in Thailand

Asset Light Investment to

Spur Performance Business Growth

Dow

to Significantly Enhance its Capabilities to Serve Asian

Customers Through Construction of a New Dow Center in China

2006/11 Dow Epoxy to boost allyl chloride

capacity in Texas by 20 kt/year

2006/11 BASF and Dow to Conduct Joint

Feasibility Study for World-Class TDI Facility in Europe

2006/12 Dow to Acquire Wolff Walsrode from

Bayer

2007/7 Dow Unveils Dow Wolff Cellulosics,

a $1 Billion Specialty Business

2007/1 Dow Starts Up First

Production Plant in Russia

2007/1 Dow Eyes PP, PS

JVs

Dow to Expand

MDI Production in North America

2007/3 Dow 買収説

Reliance-Dow

to set up $20bn venture

Dow

Announces Increased Global PO and PG Capacity

Dow invests more

in European polyurethanes

2007/4 Dow and Chevron

Phillips Chemical Announce Plans to Form Styrenics Joint Venture

in the Americas

The Dow Chemical Company

Announces Executive Terminations

Libya's NOCand Dow Announce JV

Plans To Expand Petrochemical Complex in Libya

2007/5 アラムコとダウ、世界最大級の石油化学コンプレックス建設

Shenhua

and Dow to Sign Co-operation Agreement on Coal-To-Chemicals

Project

Reliance selects Dow technology

for polypropylene

Investigation Is Said to Open

on Dow Chemical

Dow's CEO declines comment on

BASF, seeks growth elsewhere

Dow Chemical has talks on

Australian petrochemical project

ダウ・ケミカルCEOに聞く M&A、規模より技術志向 「川下」で投資機会探る

2007/6 Dow

to expand European SSBR (JSRが引取権)

2007/7 Dow Chem plans India plant, ties

up with GACL

Dow and Crystalsev Announce Plans

to Make Polyethylene from Sugar Cane in Brazil

Dow and Solvay Form Joint

Venture to Build Hydrogen Peroxide Plant in Thailand

2007/8 Dow Chemical seeking partner to

build plant in Russia

Shell And Dow Prepare $2.1 Billion

Iraqi Petro Plan

2007/9 Dow

Polyurethanes to Increase Specialty Polyols Capability in

Freeport, Texas

2007/10 Dow Releases White Paper on Joint

Ventures

A former Dow

Chemical executive sues JP Morgan

Dow moves closer to shuttering

Sarnia site

India, Dow Chemical may settle

Bhopal gas disaster claims

2007/11 Dow Announces Plans to Suspend

Production at Union Carbide Polypropylene Manufacturing Facility

in Louisiana

Dow to Exit Hydroxyalkyl

Acrylates Market

Dow to Acquire Remaining JV

Shares of Pacific Plastics (Thailand)

Gazprom Group and Dow sign

memorandum of intentions in gas processing sector

Dow to use Bayer's IMPACT technology to make polyols

2007/12 Dow Announces Further Moves to

Bolster Competitiveness

Dow Chemical's

Indian R&D centre plan faces social boycott

Dow Chemical to Exit ABS and SAN

Sales in the Americas for All Non-Automotive Markets

Dow, Chevron Phillips Chemical

Name Leadership Team for Styrenics Joint Venture 'Americas

Styrenics'

ダウとクウェートのPIC、グローバル石化JVを設立

Dow has US$5b fund for China

investment

2008/1 EPA quits dioxin talks with Dow

Aux Sable Canada and Dow Chemical

announce ethane deal, strategic alliance

Dow Plans Major chlor-alkali

Investment, Signs Long-Term VCM Agreement with Shintech

Dow Chemical

Awards “Methane

Challenge” Grants to

Cardiff and Northwestern Universities

2008/2 Petromont halts petrochemical

production in Quebec

PetroChina Fushun Selects Dow

and Aker Kvaerner for PP Project in China

Dow Sharpens Focus on

Portfolio Optimization

2008/3 Dow Chem board rejects call for

study on pesticide health effects

2008/4 Dow Europe and Gujarat Alkalies

and Chemicals Sign JV Agreement

Dow Corning Opens Silicone Rubber

Plant in China to Support Asia Growth

2008/5 Dow Chemical ordered to clean up

area in Michigan near its headquarters

2008/6 Boeing, Dow Chemical fined 926

million over nuclear pollution

SCG-ダウ、タイにPO年産39万トンの大型工場起工

2008/7 Dow Acquires

Rohm and Haas

2008/8 Dow Reichhold announces site

closures, plans to cease all business activities

Dow Reichhold sells synthetic

latex technology

2008/9 Dow Exploring Divestiture Options

for Acrylic Acid and Esters and other businesses

2008/10 Dow Epoxy and Shanghai Tian Yuan

Huasheng Sign Long Term Raw Materials Supply Agreements for Two

Proposed Plants in Shanghai

2008/11 Dow Chemical Must

Defend Bhopal Claims, Court Rules

Dow Announces Post

Close Organization for Rohm and Haas

2008/12 Dow and PIC of Kuwait Sign Binding

Joint Venture Agreement to Launch K-Dow Petrochemicals

Dow will cut production,

contract jobs at Freeport complex

Dow Accelerates Implementation

of its Transformational Strategy

Kuwai Cabinet reviews Dow JV

Kuwait scraps K-Dow deal

2009/1 Lubrizol Acquires Dow

Thermoplastic Polyurethane Business

Dow Chemical Confirms Commitment

to Transformational Corporate Strategy

EU approves Dow's acquisition of

Rohm and Haas

Dow Chemical

begins layoffs

FTC Intervenes in Dow

Chemical's $18.8 Billion Acquisition of Rohm & Haas

Dow Chemical Confirms Rohm and

Haas Acquisition Will Not Close On or Before January 27, 2009

2009/2 Dow postpones new chlor-alkali

facility at Freeport, Texas

2009/3 World's largest propylene oxide

plant of Dow and BASF finishes start-up phase

Dow Chemical,

Rohm & Haas Jump After Disclosing Talks

Dow AgroSciences

LLC 概要

Alstom and Dow Collaborate to Combat

Climate Change

2009/4 Dow Completes Acquisition of Rohm

and Haas

2009/5 Dow Takes

Action to Improve Capital Structure, Announces $1.625 Billion

Public Common Stock Offering

Dow Europe Exploring Divestiture

Options for Synthetic Rubber Business

Dow to Divest Calcium Chloride

Business and Interests in TRN Refinery

Dow Completes

MDI Expansion in Estarreja, Portugal

2009/6 DOW launches Shanghai Center and

Starts up Glycol Ethers Project in Zhangjiagang

DOW enters into strategic

relationship with King Abdullah

University of Science and Technology

Dow

Announces Plan to Build and Operate a Pilot-Scale Algae-based

Integrated Biorefinery with Algenol Biofuels

2009/7 Dow to Achieve More Than $100

Million in Annual Savings via Additional Portfolio Management

Actions to Streamline Manufacturing Footprint

Dow

shutters some US ethylene, derivative production

Dow to Close its Ethylene Oxide

& Glycol Plant in England

Dow to

Divest Ownership in OPTIMAL Group of Companies to PETRONAS for

$660 Million

2009/8 MEP, UNEP and Dow Join Forces to

Set Standards for Chemical Safety and Emergency Preparedness in

China

2009/9 Dow Announces Shutdown of Styrene

Monomer and Ethylbenzene Plants in Freeport, Texas

OMNOVA to Buy Hollow Sphere

Plastic Pigment Product Line from Dow

SCG-DOW Group Commemorates

Thailand HPPO Progress with Stone Laying Ceremony

2009/11 Dow Chemical, Shenhua revive $10

billion China project

2010/2 Dow's Styron unit

attracts private equity-sources

2010/3 Dow Announces Sale of Styron

Division to Bain Capital for $1.63 Billion

2010/6 Dow Closes Sale of Styron Division

to Bain Capital for $1.63 Billion

Styron Begins Operations as a

Leading Materials Company with Global Reach

2010/7 三井物産、ダウケミカルと合弁会社設立、テキサス州で電解事業に参入

2010/11 Dow Elastomers Completes EPDM

Expansion Project

2010/12 Dow Announces Plans to Increase

Ethane Cracking Capabilities; Reviews JV Options for NGL

Fractionator

Dow Announces Plans for New

Propylene Glycol Plant in Thailand

2011/4 Dow Announces Plans to Fully

Integrate and Grow North American Performance Businesses with

Shale Gas Liquids

2011/6

Dow, Aksa of Turkey in Talks to

Form Carbon Fiber Joint Venture

2011/7 ダウとアラムコ、石油化学JV設立で合意

Braskem to buy Dow's polypropylene

business

2011/8

Qinghai Salt Lake Industry Selects UNIPOL™ Polypropylene Technology for PP

Project

Dow,

Lehigh partner to develop sustainable tyre rubber

2011/9

Dow and K2 Pure Announce

Start-Up of Chlor-Alkali Facility at California Site

2011/10

Dow studying plan for EPDM

plant

Saudi Aramco, Dow Sign

Sadara JV Shareholders’ Agreement

2011/12 Dow

and Jilin Connell Sign LOI to Strengthen Integration of Dow’s Polyurethanes

Franchise

Dow and Aksa Sign Joint

Venture Agreement for Carbon Fiber and Derivatives

2012/6

Dow

and Aksa Announce Formation of Joint Venture for Carbon Fiber and

Derivatives

2012/3 Dow

Announces Coatings Manufacturing Investment in Saudi Arabia

2012/4

Dow Implements Cost-Reduction

Plans, Anticipates Annual Savings of Approximately $250 Million

2012/5

Dow Announces $2.16

Billion Award in PIC-Dow Arbitration

2012/8

Kuwait company to

pay compensation to Dow - paper

| Segment |

Business |

| |

| Performance Plastics |

Dow

Automotive

Engineering Plastics

Epoxy Products and Intermediates

Fabricated Products

Licensing

Polyurethanes and Polyurethanes Systems

Wire and Cable |

| Performance Chemicals |

Custom and Fine Chemicals

Emulsion Polymers

UCAR Emulsion Systems

Industrial Chemicals

Oxide Derivatives

Specialty Polymers

Water Soluble Polymers |

| Agricultural Products |

Dow AgroSciences LLC |

| Plastics |

Polyethylene

Polystyrene

Polypropylene |

| Chemicals |

Chemicals |

| Hydrocarbons and Energy |

Hydrocarbons and Energy |

| Unallocated and Other |

New Businesses |

Union Carbide Product Overview

Ethylene Oxide/Ethylene

Glycol

Coating Materials

Industrial Performance Chemicals

UCARTM Emulsion Systems

Specialty Polymers and Products

Solvents, Intermediates and Monomers

Polyolefin Resins and Compounds

Linear low

density polyethylene (LLDPE) resins are used for

such diverse applications as garment bags, trash bags,

container lids, housewares, stretch wrap, waste

containers, disposable diapers and shipping sacks.

TUFLINTM LLDPE high-strength film resins are used in

trash bags, packaging and stretch wrap, and shipping

sacks.

High density polyethylene (HDPE) resins

are used for pails, food tubs, housewares and toys. They

are also used to make drums and bottles for household and

industrial chemicals such as liquid detergents, bleach,

motor oil and antifreeze, and for food packaging,

merchandise bags and multi-wall liners. UNIVALTM HDPE

resins are used for milk, juice and water bottles because

of their excellent taste and odor properties.

FLEXOMERTM Resins are very low density,

extremely flexible olefin copolymers that bridge the gap

between plastics and rubber. They are used for hose and

tubing, ice and frozen food bags, food packaging and

stretch wrap, as well as impact modifiers when blended

with other polymers.

Wire and cable insulation and jacketing compounds

protect power distribution cables, industrial

power and control cables, and copper and fiberoptic

telecommunication cables. Union Carbide is the world's

leading supplier of polyethylene-based insulation,

semiconductive and jacketing compounds to the wire and

cable industry.

Ethylene copolymer resins, including

ethylene ethyl acrylate (EEA) and ethylene vinyl acetate

(EVA), are used in a variety of film, hose and tubing

applications and as an additive to other polymers.

Polypropylene resins are used to make a

variety of industrial and consumer products, including

textiles, many types of packaging, automotive parts,

appliance housings, toys, outdoor furniture and much

more.

Dow-Carbideの北アメリカにおけるLDPE/L・LDPEへの影響

(単位:千トン)

| 種 類 |

生産能力 |

合併後

の能力 |

構成比

(%) |

| Dow |

Carbide |

| LDPE |

612.2 |

226.7 |

838.9 |

20 |

| L・LDPE |

375.3 |

771.0 |

1,646.3 |

37 |

| 合 計 |

1,487.5 |

997.7 |

2,485.2 |

29 |

Dow

Chemicals

The Chemicals business is a

leading global producer of each of its basic chemical

products. These products are sold to many industries

worldwide and also serve as key raw materials in the

production of many of Dow's performance and plastics

products.

Products:

carbon tetrachloride, caustic

soda, chlorine, Dowper dry cleaning solvent, ethylene

dichloride (EDC), ethylene glycol (EG), ethylene oxide (EO),

Liquidow liquid calcium chloride, Maxistab stabilizers for

chlorinated solvents, methylene chloride, Peladow calcium

chloride pellets, perchloroethylene, propylene oxide (PO),

Safe-tainer closed loop delivery system, trichloroethylene,

and vinyl chloride monomer (VCM).

Polyethylene/PET

The Polyethylene

business supplies polyethylene-based solutions through

sustainable product differentiation. Dow is the world's

leading producer of polyethylene resins, one of the most

versatile plastic materials. Also included in the business

are polyethylene terephthalate (PET), purified terephthalic

acid (PTA), and several specialty resins.

Products:

Affinity polyolefin plastomers,

Aspun fiber grade resins, Attane ultra low density

polyethylene copolymers, Dowlex linear low density

polyethylene resins, Elite enhanced polyethylene resins, High

density polyethylene resins (HDPE), Lighter C PET, Low

density polyethylene resins (LDPE), Primacor copolymers, PTA,

and Saran PVDC resins and films.

Polypropylene

Polypropylene

(PP) is leveraging Dow's innovative manufacturing technology,

research and product development expertise to become a major

global PP supplier. Polypropylene is managed through the

Engineering Plastics business.

Products:

INSPiRE Performance Polymers and

DOW Polypropylene Resins

Polystyrene

The Polystyrene

business is the global leader in the production of

polystyrene resins, uniquely positioned with geographic

breadth and broad industry experience to meet a diverse range

of customer needs. By implementing breakthrough proprietary

technology, Dow continues to improve efficiencies and product

performance.

Products:

Aim advanced styrenic resins,

EcoPLA renewable biodegradable polymers, Styrenic alloys,

Styron general purpose polystyrene resins, Styron high impact

polystyrene resins, and Styron ignition resistant polystyrene

resins.

Insite Technology

Insite

Technology is a proprietary catalyst technology that enables

Dow and its customers to improve the performance of a variety

of plastics. Insite Technology is leveraged to develop new

products and strategic business opportunities through

licensing. A new Dow innovation, Index interpolymers, was

developed from Insite technology. DuPont Dow Elastomers

L.L.C., a 50:50 joint venture, leverages Insite technology

into elastomeric products.

Engineering Plastics

The Engineering

Plastics business offers one of the broadest ranges of

engineering plastics of any global plastics supplier. Dow's

Engineering Plastics portfolio is backed by technical

expertise and a commitment to delivering improved economics

and performance.

Products:

Calibre polycarbonate resins,

Isoplast engineering thermoplastic polyurethane resins,

Magnum ABS resins, Pellethane thermoplastic polyurethane

elastomers, Prevail engineering thermoplastic resins, Pulse

engineering resins, Questra crystalline polymers, Tyril SAN

resins, and Vydyne nylon.

(化学工業日報 2001/2/7)

ダウーUCC合併 米FTCが正式承認

一部PE売却など条件

ダウ・ケミカルは99年8月にUCCとの合併計画を発表。株式交換により実質的にはUCCを買収するもので、UCCはダウの100%子会社になる。

両社は類似事業が多いため、合併計画承認に当たって規制当局から条件が付いた。売却が必要なのは①欧州での一部ポリエチレン(PE)資産②ダウの世界でのエチレンアミン事業(オランダのタヌーゼンにある設備は除く)③ダウの世界でのエタノールアミン事業④ダウの北米でのガス処理事業となっており、そのほかPEの気相法技術の売却およびライセンス、UCCのPE技術「ユニポール」のライセンス権と従来のPE用触媒事業をユニべーション・テクノロジーズに供与することも求められた。

エチレンアミン ハンツマンに売却

石化再編、世界の頂点に 600億ドル企業へ戦略加速

世界の主要化学企業の連結売上高 (99年度ベース)(単位:億円)

1 デュポン(米) 29,340

2 BASF(独) 27,115

3 ダウ/UCC(米) 27,030

4 バイエル(独) 25,116

5 アトフィナ(仏) 19,007

6 住化+三井化学 18,345

7 エクソンモービル(化学部門)17,376

8 三菱化学 16,699

注 日本企業は2000年3月期

SCHKOPAU II - SOLUTION ELASTOMER FACILITY,

GERMANY

http://www.plastics-technology.com/projects/schkopau2/

In May 2000, Dow Chemical

Company completed the reconstruction programme of its newest

operation in Germany - Buna Sow Leuna Olefinverbund GmbH

(BSL).

BSL was created in 1995 when Buna GmbH in Schkopau,

Sachsische Olefinwerke in Bohlen and Leuna Polyolefine GmbH

merged to form Buna Sow Leuna Olefinverbund GmbH. The same

year Dow announced its intention to take an 80% stake in the

operation and to manage the reconstruction process of the

company. Dow also announced that from June 1, the BSL sites

will be known as Dow Central Germany, reflecting Dow's 100%

ownership of the operation from that date.

Platts 2002/9/16

Dow selects Seadrift, Texas, for new ethylene plant site

Dow began the site study last

fall when it announced Union Carbide Corp, a wholly owned subsidiary, plans to permanently shut down

its 975-mil lb/yr Seadrift and 1.5-bil lb/yr Texas City,

Texas, ethylene plants by 2005. Based on the site study analysis,

Carbide's site in Seadrift, Texas, has been selected as the

preferred location for a 900,000 mt/yr ethylene plant, which

will use ethane and propane as feedstocks, Dow said.

July 08, 2003 Dow

Union Carbide Finalizes Shutdown

Date for Seadrift Olefins Plant

Unit to Cease Operation in September

http://www.dow.com/dow_news/corporate/2003/20030708a.htm

The unit

will cease operation on September 12, 2003, in line with the overall timeframe

that was announced earlier this year.

The Texas City olefins

plant was safely taken out of operation on June 16, 2003.

2002/12/13 Dow

Stavropoulos Named Dow President and Chief Executive Officer

http://www.dow.com/dow_news/corporate/2002/20021213a.htm

2002/12/13 Platts

Dow's replacement of Parker surprises some analysts

2001/2/5 Dow

Dow Announces Plans to Sell

Portions of Two Amine Businesses to Huntsman, INEOS

http://www.dow.com/dow_news/prodbus/2001/20010205d.html

The Dow Chemical Company

today announced that it has signed agreements to sell

selected portions of two amines businesses as part of the

process to receive regulatory approval for Dow's merger

with Union Carbide.

The agreement with INEOS includes Dow's ethanolamines (EOA)

manufacturing assets in Plaquemine, Louisiana; Dow's global

EOA business including Dow's U.S. and Canadian GAS/SPEC

customer base, the associated technology, trade names and

access to one-hundred percent of the MDEA capacity of Dow's

Freeport plant which Dow will continue to own and operate.

The agreement with Huntsman includes Dow's global EA business;

and Dow's EA manufacturing assets in Freeport, Texas; and up

to fifty-percent of the Terneuzen EA asset capacity rights.

June 26, 2003 http://www.rubberworld.com/

Union Carbide Shuts Down Olefins

Plant

Union Carbide Corporation, a

wholly owned subsidiary of The Dow Chemical Company, has

announced the permanent shutdown of the Texas City Olefins plant. The company also announced the planned shutdown of its Seadrift

olefins plant no later than

the end of 2003. Environment, Health and Safety considerations

will remain a top priority during the shutdown and the cleaning

of the unit, reported the company.

2003/5/7 Dow

Dow Announces Successful Start-up of

Converted Epoxy Resin Plant in China

http://www.dow.com/epoxy/news/2003/20030507b.htm

The Dow Chemical Company

announced today that its 41,000 metric tons per annum converted

epoxy resin plant at the

Dow Zhangjiagang site in the People's Republic of China has

started up on schedule and with the first production within

specification. (Zhangjiagang : 張家港)

"It joins our epoxy

facilities in Kumi, Korea (30,000 metric tons per

annum) and Kinu Ura, Japan (40,000 metric tons per annum) to provide a superior network of epoxy

resin facilities in the largest global concentration of

demand," said Graham Daley, EP&I Commercial

Director, Pacific.

The new facility

joins a Dow styrene butadiene latex facility and a joint

venture polystyrene resin facility, which began operations in

2002. All three

facilities are world-scale and state of the art.

Platts 2003/9/12 Celanese release

Dow Chemical to acquire Celanese acrylics business

The acquisition would include

intellectual property, inventory and technology for crude acrylic acid,

glacial acrylic acid, ethyl acrylate, butyl acrylate, methyl

acrylate and 2-ethylhexyl acrylate, as well as acrylics production assets

at the Celanese Clear Lake, Texas facility.

Sep 12 2003 Celanese AG

Celanese to sell Acrylates Business to Dow

http://www.celanese.com/mr_news_fullpage?id=18818

Celanese AG and The Dow

Chemical Company announced today that they have reached an

agreement for Dow to purchase the acrylates business of

Celanese.

化学工業日報

2003年10月22日

米ダウ、スペインでポリオレフィン弾性繊維を自社生産へ

米ダウ・ケミカルは20日(米国時間)、スペイン・タラゴナにポリオレフィン系弾性繊維「ダウXLA」(一般名・ラストール)の量産工場を建設すると発表した。

同社初の繊維工場

December 11, 2003 Dow

Dow Global Business Groups

Re-aligned,

Liveris Names Three Senior Vice Presidents to Lead Business

Portfolios

http://www.dow.com/dow_news/corporate/2003/20031211a.htm

The three global business

portfolios - and their leaders who report to Liveris - include

the following:

Plastics, headed by Romeo Kreinberg, which includes

Polyethylene (PE), Polypropylene (PP), Polyethylene Terephthalate

(PET), Polystyrene, Engineering Thermoplastics (ETP), Fabricated

Products; Automotive, Wire and Cable; and Rubber and Elastomers.

Chemicals and

Intermediates, headed by

Michael R. Gambrell, which includes Organic Intermediates,

Solvents and Monomers (OISM), Oxide Derivatives, Chlor-Vinyls,

Chlorinated Organics, Cal/Mag, Propylene Oxide/Propylene Glycol

(PO/PG), and Acrylates.

Performance

Chemicals and Thermosets,

headed by Phillip H. Cook, which includes Polyurethanes,

Polyurethane Systems, Epoxy, Dow Latex (Emulsion Polymers &

UCAR Emulsion Systems), Industrial Chemicals, Specialty Polymers

(excludes Acrylates), Water Soluble Polymers, Custom and Fine

Chemicals, and Licensing.

The three senior vice presidents will be accountable for:

・Their portfolios’

profitability and related business

measurements;

・Working with Liveris and

the Office of the CEO on allocating resources based on the needs

of the overall company;

・Operating at the corporate

level on strategy and portfolio management.

2004/9/6 日本経済新聞夕刊

米ダウ・ケミカル 中東の生産拠点増強

30億ドル投資 石化合弁3社新設

化学最大手の米ダウ・ケミカルは中東で相次いで合弁事業を立ち上げる。

クウェート石油公社傘下のペトロケミカル・インダストリーズ(PIC)と折半出資で合弁2社を設立した。外販用モノエチレングリコール・ジエチレングリコールの製造を手がける「MEグローバル」と、ポリエチレンテレフタレート(PET)製造などを手がける「エクイポリマーズ」で、クウェートで10億ドルをかけて生産設備を建設する。

(注 実際には両社はクウェート国外の事業)

オマーンでもオマーン政府、オマーン石油との折半出資で合弁会社を設立する。

November 4, 2004 Financial Times

Information

Dow to build speciality PE plant in Spain.

Dow Chemical is to erect a speciality PE plant at Tarragona,

Spain. Completion is due in 2Q 2006. Production will comprise a

wide range of products from speciality LLDPE resins and ultra-low

density resins to polyolefins, plastomers and elastomers.

Capacity will be over 300,000 tonnes/y. Also at Tarragona, Dow

has completed the first commercial-scale production unit for the

company's XLA elastic fibre.

November 04, 2004 Dow

Dow to reduce production at VCM

Plant in Texas (Oyster Creek) in 2005

http://www.dow.com/dow_news/prodbus/2004/20041104c.htm

The Dow Chemical Company (Dow)

announced that it plans to reduce production at its vinyl

chloride monomer (VCM) facility and cease production of ethylene

dichloride (EDC) at the Unit 1 facility in Oyster Creek, Texas,

by the end of 2005.

The remaining chlor-alkali, Oxy EDC, and VCM plants in Unit 5 at

Oyster Creek will not be affected by this decision and will

continue to operate.

"Long-term operation of this

portion of the facility would require significant capital

investments which could not

be justified against other options within the Dow portfolio. In

addition, high

and volatile energy and feedstock costs on the U.S. Gulf Coast have increased the

cost of operating this facility. This decision maximizes Dow's

flexibility for long-term value creation."

Dow will honor its

current contract VCM commitments to its customers by supplying

from its other VCM plants and via commercial agreements.

日本経済新聞 2004/11/8

米ダウ・ケミカル、原料価格高騰で不採算事業撤退へ

米化学最大手のダウ・ケミカルは、2005年末までにテキサス工場で手がけている中間原料である二塩化エチレンの生産を取りやめ、塩化ビニール樹脂の原料となる塩化ビニルモニマーの生産も縮小すると発表した。エネルギー・原料価格の高騰に伴い、採算が合わなくなったためと説明している。

*Unit 5は生産継続

ダウの生産削減量は北米全体の塩ビモニマー生産能力の約4%にあたる。化学業界を取り巻く経営環境は悪化する一方で、同社は今回の撤退・縮小を採算性見直しの第一歩と位置づけ、今後もさらに見直しを進めるという。

December 20, 2004 Dow 神華石炭直接液化プロジェクト

Shenhua and Dow Chemical agree to

study Coal-to-Olefins opportunity in China

http://www.dow.com/dow_news/corporate/2004/20041220a.htm

The Shenhua Group and The Dow Chemical Company have signed

an agreement to jointly evaluate the feasibility of

coal-to-olefins projects in China.

A feasibility study which covers areas such as economics and

market analysis, logistics and technological applications will be

undertaken to evaluate the potential and value of building large

scale coal-to-olefins plants in China.

Areas around Yulin 楡林 city,

Shaanxi 陜西province, have

been identified as the location for the study which will start in

the first quarter of 2005. It is anticipated that the study will

be concluded by end of next year.

ダウは中国の国有石炭最大手・神華集団との間で、中国で石炭からオレフィンを生産する計画のFSを共同で実施する契約を結んだ。大規模なオレフィンプラント建設のための経済性、市場分析、物流、技術等を検討する。

立地は陜西省楡林市の近辺で、2005年第1四半期に検討を開始し、年末に終える予定。

神華集団は1995年に設立された国有企業で、

世界8大炭田の一つとされている神府東勝鉱区の開発・運営を担当しており、関連事業として鉄道、発電、貯炭設備、輸送設備を運営している。

中国国有石炭最大手 神華集団 http://ns.coalinfo.net.cn/shenhua/e1.htm

Shenhua Group Corp.is

responsible for the overall planning/development &

operation of the massive Shenfu Dongsheng coalfield as well

as the related railway, power station, coal terminal and

shipping fleet; pursuing the unified development of coalmine,

railway, electric power, coal terminal and shipping fleet;

undertaking the integrated operation of coal

production/transportation/marketing; developing domestic

& overseas investment & financing and trading

business in the aforeaid respect and unfolding industrial

development in the areas of finance, telecommunication and

high-tech etc.

* Shenfu Dongsheng 世界8大炭田の一つとされている神府東勝鉱区

神華計画(石炭輸送)

2005/3/7 日本経済新聞夕刊

ダウ・ケミカル 燃料電池事業を強化

VBと組む 携帯型を商品化へ

GMとは発電

総合化学最大手の米ダウ・ケミカルは提携先を広げ、燃料電池事業を強化する。水素エネルギー開発ベンチャーのミレニアム・セル(ニュージャージー州)と組み、家電・軍事向けの携帯型燃料電池の商品化に乗り出す。ゼネラル・モーターズ(GM)とも燃料電池による発電事業を始動。燃料電池分野を新たな主力事業に育成する。

ダウはミレニアム・セルに対し3%をまず出資、最終的にはミレニアム社の発行済み株の19.9%を取得する権利を握る見込み。

2005/3/28 日本経済新聞夕刊

建材添加剤セルロース ダウ・ケミカル大幅増産 信越化学抜き再び首位

総合化学最大手の米ダウ・ケミカルは、建材や自動車排ガス処理に使う主要添加剤のセルロースを米独で増産する。増産規模は2万トン。これにより同社の生産量は6万5千トンとなり、信越化学の計画する6万3千トンを上回り、再び世界首位に立つ。

ダウは米ミシガンとルイジアナの2工場で計1万7千トン増産するために生産設備の増強を計画中。ミシガン工場は2007年、ルイジアナ工場は07-08年にそれぞれ稼働する予定。

さらに、独工場でも3千トン増産する計画で、現在、生産設備を増強中。来年初旬の完成・稼働を予定している。

Midland, MI - March

21, 2005

Dow Announces Global

Expansion Plans For Cellulosics

The Dow Chemical

Company has announced a planned 20,000 metric ton global

expansion for the production of its METHOCEL* methylcellulose

(MC) and hydroxypropyl methylcellulose (HPMC) products. This

multi-phase expansion plan focuses on Dow's continued global

leadership and commitment to the industrial and premium

marketplace for water soluble polymers.

The first phase

involves increasing production by 3,000

metric tons at Dow's Stade, Germany facility. This project is currently

underway and will be completed in early 2006. This is the

second recent expansion at the Stade facility, with a full

new train brought on-stream in 2003.

In North America, Dow

intends to implement an additional 17,000 metric tons

of production between Dow's two facilities in Midland,

Michigan and Plaquemine, Louisiana. The overall building

materials industry continues to grow in excess of 6% per year

in North America, and these expansions will ensure continuous

support of this industry well into the future. In addition,

plans also include enhanced capabilities for manufacturing

premium and specialized grades of Dow products in support of

the pharmaceutical, food and industrial specialties

businesses. Dow is anticipating the Midland facility start-up

to be in 2007, while Plaquemine is planned for 2007/2008,

subject to state and local tax incentives.

Marty Kollmeyer,

global business director for METHOCEL cellulosics products at

Dow, comments, "This action is consistent with our

strategy to invest in our cellulosics business and grow our

position in all market segments on a global basis. A global

expansion of this magnitude is a significant investment to

ensure we can meet our customer's needs. This decision to

expand now is based on continued global demand strength

across all major industries, including building materials -

the largest. These expansions will also enhance our

capability to provide even more specialized and premium

products needed for the food and pharmaceutical businesses as

well as the ability to participate in emerging new

applications for these multi-functional polymers."

About METHOCEL

Dow MC and HPMC products, known as METHOCEL cellulose ethers,

are used in a wide variety of industries and applications,

including tile grouts and mortars, tape joint compounds,

plasters, paper coatings, resins and catalytic converters.

Specialized Food grades and Premium grades are used

respectively as functional food ingredients and in the

pharmaceutical industry as tablet coatings and in controlled

release formulations. For additional information about

METHOCEL cellulose ethers from Dow, please visit www.methocel.com.

About Water Soluble

Polymers

Dow's Water Soluble Polymers enhance the physical properties

and performance of essential consumer products including

foods, personal care products, pharmaceuticals, household

products, paint, and building materials, among others. Water

Soluble Polymers consist of Amerchol Corporation, a wholly

owned subsidiary of The Dow Chemical Company, CELLOSIZE™

hydroxyethyl

cellulose, ETHOCEL* ethylcellulose resins, METHOCEL cellulose

ethers, and POLYOX™ water-soluble resins. These

expansion projects for METHOCEL will continue to promote

Dow's global leadership in the markets served by this family

of specialty polymers.

Midland, MI - March

28, 2006

Dow Moves Forward

with Expansion Plans for Cellulosics

The Dow Chemical

Company continues to make progress with its plans to increase

cellulosics capacity at production facilities in Midland,

Michigan; Plaquemine, Louisiana and Stade, Germany. As

announced in March 2005, the expansions will enable an

additional 20,000 metric tons of METHOCEL™

cellulose

ethers to be produced. This multi-phase expansion plan

focuses on Dow's continued global leadership and commitment

to the industrial and premium marketplace for water soluble

polymers.

The first phase

involves de-bottlenecking of current production capabilities

at Dow's Stade, Germany facility. This phase is currently

underway and will be completed in 2006. This is the second

recent expansion at the Stade facility, with a full new train

brought on-stream in early 2003.

Dow's North American

facilities are the focus of the second phase of the project,

with the first expansion in Midland. The equivalent of a

full-train expansion will be achieved by installation of new

post reactor processing equipment through optimization of our

current assets. This project has received support for state

and local tax incentives to move forward on an aggressive

schedule for start-up in 2007. Expansion in Plaquemine will

follow the Midland project and will include the first North

American train capable of manufacturing hydroxyethyl methyl

cellulose (HEMC), a functional polymer supporting our

commitment to the construction industry. Dow is anticipating

the Plaquemine facility start-up to occur in 2008.

Marty Kollmeyer,

global business director for METHOCEL™

cellulosics

products at Dow, comments, "Dow's strategy is to invest

in opportunities that will strengthen the Company's position

in key growth economies around the globe and will enable us

to grow our business with strategic customers and in

strategic markets. Global demand for methyl cellulosics has

been growing at an average of about 6 percent per year. These

actions are consistent with our strategy to invest in our

cellulosics business and maintain our historical leadership

position by growing in all market segments on a global basis.

A global expansion of

this magnitude is a significant investment to ensure we can

meet our customers' needs. Based on continued demand strength

across all industries, including construction - the largest -

we feel it is critical to further develop our facilities and

leverage new technologies. These expansions will also enhance

our capability to provide even more specialized and premium

products needed for the food and pharmaceutical businesses as

well as the ability to participate in emerging new

applications for these multi-functional polymers."

Univation

http://www.univation.com/main.asp

Univation

Technologies is a 50/50 joint venture between ExxonMobil

Chemical Company and The Dow Chemical Company. Univation was

originally formed in 1997 as a joint venture between Exxon

Chemical Company and Union Carbide to license the UNIPOL PE

Process, metallocene catalyst technology, and to sell metallocene

catalysts.

In 1999, Exxon and Mobil merged to form ExxonMobil Corporation,

and in 2001, Dow acquired Union Carbide, leading to a

restructuring of Univation. As part of our restructuring, Univation took full responsibility

for

the UNIPOL PE licensing business and

the Ziegler-Natta and Chromium catalyst business. At the same time, Dow

and ExxonMobil granted all the resources necessary to make

Univation a world class PE licensing and catalyst company.

Over thirty years of PE

process innovation stand behind Univation Technologies. In the

late 1960s, a method using chromium and Ziegler-Natta catalysts

in the UNIPOL? PE gas-phase process was invented to produce

high-density PE. In the late 1970s, that knowledge extended to

the use of Ziegler-Nata catalysts to make linear or low-density

PE.

In the mid 1990s, ExxonMobil Chemical Company developed the first

commercial single-site metallocene catalysts for use in the

UNIPOL PE process. Under Univation stewardship, numerous catalyst

and process enhancements have taken place. These include the

development of bimodal catalysts, enabling the production of

bimodal film resins in a single reactor.

Dow 2005/4/5

Dow and Snamprogetti developing breakthrough technology for

styrene production

New Technology Would Realize Significant Cost Savings

http://www.dow.com/dow_news/corporate/2005/20050405d.htm

The Dow Chemical Company

and Snamprogetti, the engineering and main contracting company of

Italy's

Eni,

announced today that both companies are jointly developing a new

process for the production of styrene monomer

from ethane and benzene. The process, based on proprietary

technology, would enable significant cost savings.

"The significance of this new process would be that

producers can take advantage of a much lower cost feedstock in

ethane, eliminating the need for upstream

investment in ethylene production at a steam cracker or ethylene

purchases."

2005/6/21 Dow

Dow Completes Acquisition of Korea’s Pacific Epoxy Co., Ltd.

http://news.dow.com/dow_news/prodbus/2005/20050621b.htm

The Dow Chemical Company

announced today that it has completed the acquisition of Pacific Epoxy Co.,

Ltd., a

manufacturer of converted epoxy resins in Korea, from Saehan

Industries, Inc. (セハン)

Dow had previously

acquired 80 percent of Pacific Epoxy Co., Ltd. in January 2001.

The current agreement is for the remaining 20 percent of the

company. Terms of the agreement were not disclosed.

Effective today, Dow becomes 100 percent owner of the Pacific

Epoxy Co., Ltd. facility in Kumi, Korea. The 30,000 MT (66

million lbs) per year converted epoxy resin (CER) plant currently supplies brominated,

solid, and solid-solution epoxy resins for use in protective

coatings, electronics and specialties.

Dow is the world's largest global supplier of epoxy products and

intermediates and the most committed epoxy manufacturer in Asia

Pacific. The company currently operates three epoxy manufacturing

facilities in the region, including a 40,000 MT/year

(88 million lbs) facility in Kinu Ura, Japan, a 41,000 MT/year

(90 million lbs) facility in Zhangjiagang, China, and the Pacific Epoxy

Co., Ltd. Kumi facility in Korea. Earlier this year, Dow announced

its plan to build a state-of-the-art R&D Center in China to

better serve its customers.

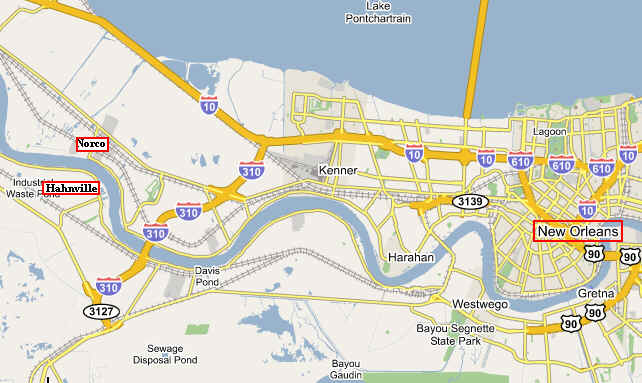

| St.

Charles, Louisiana ・Started operations in 1966

as Union Carbide Corporation. Union Carbide was acquired

as a wholly-owned subsidiary of The Dow Chemical Company

in February 2001.

・ 2,000-acre site just

upriver from Hahnville and 40-acre site in Norco.

|

|

| |

|

Plaquemine,

Louisiana

|

|

2005/9/15 Dow

Dow Aligns Business

Portfolios to Drive Strategy; Executive Management Changes

Announced

http://news.dow.com/corporate/2005/20050915a.htm

To further accelerate

implementation of the company's long-term strategy, The Dow

Chemical Company will realign its current three portfolios of

businesses into two: Basic Plastics & Chemicals, and Performance

Plastics & Chemicals, according to Andrew N. Liveris,

president and CEO. Several executive changes have been announced

as a result.

(注 従来:

Performance

Chemicals and Thermosets, Chemicals and Intermediates, and

Plastics. セグメント

)

"Our strategy for the past decade has been to move to a

basics- and performance-based business model," Liveris

stated. "Dow is accelerating the implementation of that

strategy, capitalizing on our historical

strengths in low-cost production, as well as our growth and success

in innovative, market-driven businesses. This alignment will drive

independent strategies and actions based on the needs of each

type of business within these portfolios, with the ultimate goal

of maximizing Dow's earnings and extracting the full value of our

company's strengths in diversification, integration, global

reach, and technology."

2005/10/3 UOP

Honeywell to acquire remaining stake in UOP LLC Joint Venture

Acquisition Will Enhance Product and Service Offerings Of

Honeywell’s Specialty Materials Portfolio

http://www.uop.com/overview/8000.html

Honeywell announced today

it has entered into a definitive agreement to acquire the 50 percent

interest in UOP LLC currently owned

by Union Carbide Corp.,

a wholly owned subsidiary of The Dow Chemical Company, giving Honeywell

full ownership of the entity.

UOP is a leading international supplier

and licensor of process technology, catalysts, process plants and

consulting services to the petroleum refining, petrochemical and

gas processing industries. UOP, which had 2004 annual

revenues of $1.2 billion, will become part of Honeywell’s Specialty Materials portfolio of

businesses.

UOP was founded as

the National Hydrocarbon Company in 1914 by California

inventor Jesse A. Dubbs and Chicago industrialist J. Ogden

Armour, with the goal of developing and licensing technology

to the petroleum refining industry. In 1915 the name was

changed to Universal Oil Products. Four years later, the

company introduced its Dubbs thermal cracking process, a

continuous process to convert crude oil into more useable

products.

To learn the history of other UOP products and services, http://www.uop.com/overview/8061.html

Announcing the sale,

Dow Chief Executive Officer, Andrew Liveris, explained that

despite the success of the joint venture with Honeywell, UOP

is not considered strategic to Dow's future growth agenda.

2005/11/2 Dow

The Dow Chemical Company Plans to Close Polystyrene Plant at

Barry, UK

The Dow Chemical Company announced today the decision to close

its polystyrene production facility at Barry, South Wales, in the

United Kingdom, by the end of 2005.

Dow produces STRYON* and STYRON A-TECH* Polystyrene Resins at six

sites in Europe: Tessenderlo, Belgium; Schkopau, Germany;

Lavrion, Greece; Terneuzen, The Netherlands; Bilbao, Spain; and

Barry. The plant in Barry has a capacity to produce 75,000 MT annually of polystyrene

but has operated historically below capacity.

March 28, 2006 Dow

Dow Moves Forward with Expansion Plans for Cellulosics

http://news.dow.com/dow_news/prodbus/2006/20060328a.htm

The Dow Chemical Company

continues to make progress with its plans to increase cellulosics

capacity at production facilities in Midland, Michigan;

Plaquemine, Louisiana and Stade, Germany. As announced in March

2005, the expansions will enable an additional 20,000 metric tons

of METHOCELTM cellulose ethers to be produced.

This multi-phase expansion plan focuses on Dow's continued global

leadership and commitment to the industrial and premium

marketplace for water soluble polymers.

About METHOCEL

Dow MC and HPMC products, known as METHOCELTM cellulose ethers, are used in a

wide variety of industries and applications, including tile

grouts and mortars, tape joint compounds, plasters, paper

coatings, resins and catalytic converters. Specialized Food

grades and Premium grades are used respectively as functional

food ingredients and in the pharmaceutical industry as tablet

coatings and in controlled release formulations. For additional

information about METHOCEL? cellulose ethers from Dow, please

visit www.methocel.com.

METHOCEL cellulose

ethers are water-soluble methylcellulose and hydroxypropyl

methylcellulose polymers that bind, retain water, thicken,

form films, lubricate, and much more. They add unique

physical properties and outstanding performance to a huge

array of products, including building materials, food,

personal care products, and pharmaceuticals.

ヒドロキシプロピルメチルセルロース(HPMC)は、食品添加物公定書に収載されているメチルセルロース(MC)にヒドロキシプロポキシル基を導入したセルロースエーテルであり、同じく食品添加物公定書に収載されているカルボキシメチルセルロースナトリウム(CMC・Na)やカルボシキメチルセルロースカルシウム(CMC・Ca)と同じ範疇にあるセルロースの誘導体(セルロースエーテル類)である。

HPMC は、わが国では、平成15 年(2003 年)6

月に食品添加物として指定され、現在、「保健機能食品たるカプセル剤及び錠剤以外の食品に使用してはならない」との使用基準が定められている。

米国においては、GMP(Good Manufacturing Practice)のもと、直接食品添加物として、乳化剤、フィルム形成剤、保護コロイド、安定剤、分散剤及び粘稠化剤としての使用が認められている。また、欧州連合(EU)では、一部の食品を除き、一般食品にGMP

のもとで使用することができる食品添加物とされ、広い範囲の食品に使用することが認められている。

British Plastics &

rubber 2006/4/4

Dow buys PE

production in Romania

Dow Chemical is

pitching for lower cost business in Eastern Europe by appointing

a Romanian polypropylene company to make polyethylene on its

behalf. It has done a deal with Rompetrol

Chemicals,

part of the Rompetrol Group, for Rompetrol to make LD and HDPE using

Dow technology and feedstock - Dow will supply ethylene to

Rompetrol Petrochemicals until the Romanian company starts up its

own pyrolysis installation. Initial production is expected at the

rate of 60,000 tonnes a year, with a target of an annual 100,000

tonnes.

In addition to the

toll manufacturing agreement, the two companies expect marketing

benefits through Rompetrol's position in Eastern Europe which

will benefit Dow, and Dow's technology and market presence which

Rompetrol expects will enhance its domestic market position, and

its position in markets to which it currently sells polypropylene

- Rompetrol is Romania's leading polypropylene producer with 64

per cent of the domestic market and 80,000 tonnes annual

capacity.

2006/4/19 Dow

Dow To Build New

P-Series Glycol Ethers Plant in Zhangjiagang, China 張家港

http://news.dow.com/dow_news/prodbus/2006/20060419a.htm

The Dow Chemical Company

("Dow"), the leading producer of glycol ethers, today

announced that it will proceed with construction of a new propylene

oxide-based glycol ethers facility at Zhangjiagang, Jiangsu

Province,

the People's Republic of China. This state-of-the-art facility is

scheduled to come on line in late 2008, with an annual nameplate

capacity of 120,000 metric tons.

About Dow Glycol Ethers

The Glycol Ethers

business, a member of the Specialty Chemicals Business Unit, is

the industry leader in glycol ether products used in paints and

coatings, cleaning products, inks, and electronics. Dow offers a

full range of ethylene-based and propylene-based glycol ether

products, including DOWANOL glycol ethers, and CELLOSOLVE and

CARBITOL solvents. Production locations are in Seadrift, Texas;

Hahnville, La.; Plaquemine, La.; Midland, Mich.; Stade, Germany;

San Lorenzo, Argentina; and Kerteh, Malaysia (OPTIMAL Group of

Companies).

2006/4/19 Dow

SINOPEC To Build

Two Monoethylene Glycol Plants Based on METEORTM EO/EG Process Technology Licensed

Through Dow

http://news.dow.com/dow_news/prodbus/2006/20060419d.htm

Dow Technology Licensing,

a business group of The Dow Chemical Company and its consolidated

affiliates (Dow), today announced that China Petrochemical

International Company Limited (a fully owned subsidiary of

SINOPEC) has agreed to license METEOR LEC EO/EG process

technology

from Union Carbide Chemicals & Plastics Technology

Corporation, a subsidiary of The Dow Chemical Company, to build

plants for SINOPEC Tianjin Branch and Zhenhai Refining &

Chemical Company, Ltd.

SINOPEC

Tianjin Branch will

build a 420 KTA monoethylene glycol (MEG)

plant as part of its 1 million MTPA ethylene cracker facility located in the Bohai Gulf, the

closest seaport to Beijing. Zhenhai Refining & Chemical

Company, Ltd. will build a 650 KTA MEG plant located in the southern region of

mainland China.

2006/5/31 Dow

Signing a Letter of

Intent with Zhangjiagang Free Trade Zone Dow Intends to

Significantly Step Up Investment in China 張家港

http://news.dow.com/dow_news/prodbus/2006/20060531a.htm

The Dow Chemical Company,

a world leader in the chemical industry, today signed a Letter of

Intent (LOI) with the Administrative Committee of Zhangjiagang

Free Trade Zone in Jiangsu Province and expressed its intention

to significantly step up investment in China.

Located on the Yangtze River approximately 200 kilometers (125

miles) upstream from Shanghai, Zhangjiagang is uniquely

positioned to supply domestic customers as well as export

markets. The LOI covers products in three downstream Performance

businesses of Dow - DOWANOL(TM) PM glycol ethers in Specialty Chemicals, styrene butadience

latex in Dow

Latex, and STYROFOAM(TM) brand insulation in Dow Building

Solutions.

Dow currently operates three world-scale, state-of-the-art

facilities in the Yangtze River International Chemical Park in

Zhangjiagang Free Trade Zone: a converted epoxy resin plant, a tyrene butadiene

latex

facility, as well as a polystyrene resin plant. Total investment so far is

about US$300 million. The facilities under the LOI would bring an

additional US$200 million investment to this strategic site in

China.

2006/6/29 Dow 浙江省湖州市

Dow Signs Agreement

to Acquire Zhejiang Omex Environmental Engineering Co. Ltd.,

Increasing Its Water Components Portfolio

http://news.dow.com/prodbus/2006/20060629a.htm

The Dow Chemical Company

and Zhejiang Omex Environmental

Engineering Co. Ltd. (OEE) today announced that Dow has agreed to

acquire OEE. This acquisition establishes Dow as a leader in

advanced component offerings for water purification.

OEE will bring new

critical components that, together with Dow’s existing technology offerings,

will create the framework for a new Dow Water Solutions business.

Terms of the agreement have not been disclosed.

The acquisition of OEE will allow Dow to expand into three

critical, enabling component technologies for water treatment: Ultrafiltration

(UF), Membrane Bio-Reactor (MBR) membranes, and

Electrodeionization (EDI). With these technologies, Dow can

now provide an enhanced component offering for its global

customer base.

アメリカのダウ・ケミカルは29日、浙江省の欧美環境工程有限公司(OEE)の株を買収したことを発表した。これによりダウ・ケミカルの中国での傘下企業に、強力なシステムメーカー1社が加わった。ダウ・ケミカルの話では、欧美環境を世界、特にアジア地域の水処理プロジェクトの設備プロバイダーとし、世界での競争力を強化するという。

欧美環境の買収で、ダウ・ケミカルは中国市場でシステム製造分野を開拓することになる。欧美環境は浙江省湖州市に位置する。今回の買収により、ダウ・ケミカルは、水処理の部品分野で発展が最も早い地域のに進出した。

Ultrafiltration

(限外ろ過:微孔を有する高分子膜を

用い、コロイド状粒子や有機性物質を加圧ろ過する方法)

Membrane Bio-Reactor (MBR) membranes 膜分離活性汚泥処理

Electrodeionization

(EDI 電気再生式脱イオン装置)

ダウ事業

・FILMTEC

Membranes 逆浸透膜

・DOWEX

Ion Exchange Resins イオン交換樹脂

・ADSORBSIA

GTO Media for removing

arsenic in drinking water

a granular titanium oxide with

strong affinity for arsenic, lead, and other heavy metals.

2006/7/13 Dow

Dow Completes

Acquisition of Zhejiang Omex Environmental Engineering;

Further Strengthens Water Solutions Portfolio

Newly expanded

portfolio addresses rapidly growing need for environmentally

sustainable water treatment in China and globally

http://news.dow.com/dow_news/prodbus/2006/20060713a.htm

The Dow Chemical

Company today announced completion of its acquisition of

Zhejiang Omex Environmental Engineering (OEE). The

acquisition of the water treatment company further

strengthens Dow’s leading position in advanced

solutions for water purification at a time of increasing

efforts to address the world’s water scarcity and

environmental sustainability challenges.

June 29, 2006 Dow

Zhejiang Omex

Environmental Engineering Co. Ltd.

http://www.dow.com/liquidseps/backgrounder/oee.htm

Zhejiang Omex

Environmental Engineering Co. Ltd. (OEE) is an innovative

company that has been providing design engineering and

installations for high-purity water facilities since 1995.

Located in Huzhou, Zhejiang, China, it has become a premier

water treatment and design company, specializing in pure and

ultra pure water applications.

OEE’s specialties include research

and development, design, engineering, manufacturing,

installation, and service of Integrated Membrane Technology

(IMT) equipment used in the process of water treatment.

IMT consists of three major membrane-based water treatment

components sold under the OMEXELLTM brand. They are:

Ultrafiltration (UF), Reverse Osmosis (RO) and

Electrodeionization (EDI). OEE manufactures both UF and EDI

components. OEE has emerged as a leader in IMT with its

patented spiral wound EDI and unique hollow fiber UF

technologies. OMEXELL component manufacturing is proudly

certified as compliant with ISO 9001.

The primary systems manufacturing is done in a new,

custom-built 20,000 square meter facility. The complex in

Huzhou also has a 4,700 square meter membrane manufacturing

center and a 5,600 square meter membrane R&D center

complete with the latest technology in testing and analytical

equipment.

Industry proven UF and EDI systems, together with RO, make

IMT a cost-effective alternative for total high-purity water

treatment. There are many equipment options and

configurations that these systems can be used in to provide

specific water purification objectives.

UF-RO-EDI systems can be used in tandem for complete water

treatment applications, independently for specialized

applications, or in paired configurations such as UF-RO and

RO-EDI for alternate water treatment requirements.

OEE currently employs over 500 people involved in

manufacturing, design, engineering and fabrication.

2006/8/9 Dow

Dow Epoxy to Invest US$200 Million to Accelerate Growth in China

Construction of new plants, capacity expansion and new Global

Application Development Center support epoxy market growth in

China

http://www.dow.com/facilities/asiapac/greaterchina/en/news/20060809a.htm

Dow Epoxy, a business

unit of The Dow Chemical Company (“Dow”), today announced plans to

invest more than US$200 million over the next five years in

manufacturing and R&D facilities in China. Dow Epoxy is a

leading global supplier of epoxy resins and related feedstock

products with 10 manufacturing facilities worldwide,

including plants in Zhangjiagang, Jiangsu Province, China;

Gumi, Korea; and Kinu Ura, Japan.

To support continued growth in China and the broader Asian

region, Dow Epoxy plans to build a 100,000 MTPA

world-scale liquid epoxy resins (LER) plant at its existing

site in Zhangjiagang, and a 150,000 MTPA

epichlorohydrin (ECH) plant in a soon-to-be-announced site

also in China. Both units are expected to start up in the

2009-2010 timeframe. At the same time, Dow Epoxy plans to

expand the capacity of its converted epoxy resins (CER) plant

in Zhangjiagang from its current 41,000 MTPA

to 75,000 MTPA.

In another related move, Dow Epoxy will also establish a Global

Application Development Center in China, further

strengthening customer support in China and across the

region.

Dow Epoxy is one of the largest ECH suppliers in the world.

The new 150,000 MTPA world-scale ECH plant in China, which is

expected to start up in 2010, would be the first to use a new

Dow

proprietary glycerine-to-epichlorohydrin technology. Glycerine is a bio-renewable

product generated during bio-diesel production. The use of

glycerine as the primary feedstock in Dow’s ECH manufacturing represents

a major technology breakthrough, providing significant cost

and environmental advantages versus the conventional process

technologies.

About Dow Epoxy

Dow Epoxy is one of the world’s largest producers of epoxy

resins and intermediates, with strong positions in a number

of major applications including coatings, electrical

laminates and civil engineering. Three of the company’s 10 epoxy plants are in the

Asia Pacific region, including a 41,000 MTPA

facility in Zhangjiagang, China; a 40,000 MTPA

facility in Kinu Ura, Japan; and a 30,000 MTPA

facility in Gumi, Korea. Dow Epoxy is also the global

market leader in epichlorohydrin, with more than one-third of

global capacity share and manufacturing facilities in all

major regions. More information about Dow Epoxy is available

at www.dowepoxy.com and www.epoxyavenue.com.

March 26, 2007 Dow

Dow Epoxy Advances

Glycerine-To-Epichlorohydrin and Liquid Epoxy Resins Projects

by Choosing Shanghai Site

Innovative Technology Provides

Significant Environmental & Cost Advantages

Dow Epoxy, a business

group of The Dow Chemical Company and a leading global

supplier of epoxy resins and related feedstock products,

today announced Shanghai Chemical Industry

Park (SCIP)

as the selected site for its world-scale 150,000-MTPA

glycerine-to-epichlorohydrin (GTE) plant and 100,000-MTPA

liquid epoxy resins (LER) plant.

Both plants are

slated to start up in the 2009-2010 timeframe.

Today's announcement

follows the signing of a Letter of Intent (LOI) by Dow Epoxy

with SCIP, and an additional LOI with Shanghai Chlor-Alkali

Chemical Co., Ltd. (SCAC) and its subsidiary Shanghai Tianyuan Group

Huasheng Chemical Co., Ltd. (TYHSC 上海天原華勝化工) for the supply of critical

raw materials for both the GTE and LER plants. SCIP is

located in Caojing on the north coast of Hangzhou Bay,

approximately 50 kilometers (31 miles) from Shanghai city,

China.

The announcement

directly underscores Dow's growth strategy, and marks another

major step forward in the Company's quest for sustainable

chemistries. The world-scale GTE facility

will be the first to use Dow's innovative and proprietary

GTE technology,

which uses a renewable resource - glycerine from

bio-diesel - to produce epichlorohydrin.

At the cutting

edge of innovation, this breakthrough technology provides

significant cost and environmental advantages versus the

conventional process technologies. In 2006 Dow launched a

stand alone, full-process GTE demonstration unit at its Stade

site in Germany.

January 31, 2006 Solvay

Solvay builds new Epichlorohydrin plant to meet growing

demand with innovative production process

A strategic outlet for booming‘green’biodiesel industry

http://www.solvay.com/services/newsfrompo/0,,38696-2-0,00.htm

Solvay announces

today that it will build a new epichlorohydrin plant on its

industrial site of Tavaux, France, implementing a novel

process with greatly enhanced environmental performance. The

process, called Epicerol, was successfully developed

by Solvay’s R&D and is based on the transformation

of glycerine, a by-product of the biodiesel industry. The new plant, which is

scheduled to be operational by the first half of 2007, will

be fed with glycerine derived from rapeseed oil and fits

perfectly with the development of the Biodiesel industry

actively supported by the French government.

2006/8/6 Dow

Dow and Izolan Form Joint

Venture to Serve Growing Systems Business in Russia

http://news.dow.com/dow_news/corporate/2006/20060808d.htm

The Dow Chemical Company

and Izolan

announced

today the formation of a joint venture company that will provide customer-tailored,

polyurethane systems products to a growing customer base in

Russia. Subject to regulatory and other customary approvals, the

new company, Dow Izolan, will be based in Vladimir, a

city 170km north east of Moscow.

About

Isolan

Located in Vladimir (Russia), Izolan was established in 1991 by

recognized Russian specialists in the polyurethanes science and

chemistry applications. Izolan main activity is the production

and sales of Polyurethane Systems for rigid and flexible foams.

Izolan employs about 100 employees and has more than 400

customers in Russia and the CIS (Commonwealth of Independent

States). In 2005, Izolan Systems sales in Russia reached more

than 20,000 MT, making Izolan the market leader in the

Polyurethane Systems in Russia and the CIS. More information

about Izolan can be found at www.izolan.ru.

September 27, 2004 Dow

Zhejiang Pacific

Chemicals Corporation Celebrates 10th Anniversary Milestone

Zhejiang Pacific

Chemicals Corporation (ZPCC), a wholly owned

subsidiary of The Dow Chemical Company, has celebrated the 10th

anniversary of its production plant in Ningbo, Zhejiang province,

with outstanding business results and environmental and safety

records.

With an annual capacity

of 48,000

metric tons of basic flexible and rigid polyol and 24,000 metric

tons of formulated polyol, the Ningbo plant has doubled its

capacity in the past decade.

Widely used in foam

cushioning and rigid insulations, these products are also used in

other end user markets such as beddings, fabric and textile

linings, automotive seating, and footwear in-sole padding.

The past decade has also

seen tremendous achievement of ZPCC's Ningbo site in its

environmental, health and safety performances. Since 2000, the

site has been injury-free. And, for more than 7 years, there has

been no reportable leaking or spilling incident in the site.

"This is an

absolutely world class performance and puts the Ningbo site on a

par with - if not better than - the best Dow sites anywhere in

the world," said Jim McIlvenny, President of Dow Greater

China who officiated at the site's 10th anniversary celebration.

Joining McIlvenny at the occasion was Mr. Yao Li, Vice Mayor of

Ningbo and other senior officials of Ningbo City Government.

Dow is a leader in

science and technology, providing innovative chemical, plastic

and agricultural products and services to many essential consumer

markets. With annual sales of US$33 billion, Dow serves customers

in more than 180 countries and a wide range of markets that are

vital to human progress, including food, transportation, health

and medicine, personal and home care, and building and

construction, among others. Committed to the principles of

sustainable development, Dow and its approximately 46,000

employees seek to balance economic, environmental and social

responsibilities. References to "Dow" or the

"Company" mean The Dow Chemical Company and its

consolidated subsidiaries unless otherwise expressly noted.

April 5, 1989

The Dow Chemical

Company entered a joint venture with China's

Zhejiang Chemical Factory to build a $50 million

chemical plant in Ningbo, China. The new company, the

Zhejiang Pacific Chemical Corporation, in Zhejiang Province

on the East China Sea, will produce 20,000 metric tons a year

of polyether polyol, Dow said.

The Dow Chemical

Company entered a joint venture with China's Zhejiang 浙江 Chemical Factory to build a

$50 million chemical plant in Ningbo, China. The new company,

the Zhejiang Pacific Chemical Corporation, in Zhejiang

Province on the East China Sea, will produce 20,000 metric

tons a year of polyether polyol, Dow said. Polyether polyol

is used to make foam for furniture, seat cushions,

mattresses, automobile parts, laminated fabrics and building

insulation.

August 31, 2005 Dow

Dow to Build a New Center

in Shanghai, China

Underscoring its commitment and positioning for long term growth

The Dow Chemical Company

today announces that it will build a new Dow Center in China at

the Zhangjiang Hi-Tech Park in Shanghai which can house more than

1,000 employees.

The new Dow Center will

be comprised of a state-of-the-art research and development

(R&D) facility as well as a global information technology

(IT) center, with other service and support facilities as well.

The Center which takes up more than 65,000 square meters will

have created 600 new jobs when it is completed in 2007.

2006/8/31 Dow

Dow Announces Plant

Closures To Strengthen Competitive Position

In its ongoing drive to

improve the competitiveness of its global operations, The Dow

Chemical Company announced today that it will shut down a number

of assets around the world.

As a consequence of these

shutdowns, and other optimization activities, the Company expects

to

incur a charge in the range of $550 million to $650 million, which includes costs such as

severance and asset write-downs. This charge will be reflected in

Dow’s third quarter of 2006 results.

In Sarnia, all production activity will

cease by the end of 2008, reflecting the outcome of individual

assessments by each of the four businesses located at the Ontario

facility. The assessments, which were triggered by the recent

suspension of ethylene shipments through the Cochin Pipeline,

highlighted a variety of issues related to the effectiveness,

efficiency and long-term sustainability of the Sarnia-based

assets. As a consequence:

- The low

density polyethylene plant will be shut down

over the coming weeks;

- Polystyrene

production

will cease before the end of this year;

- Latex

production

from the UES facility will shut down by year-end 2008;

and

- The polyols plant will also shut down

by year-end 2008.

http://www.canplastics.com/issues/ISArticle.asp?id=59660&issue=08312006

"The closing of

our LDPE facility in Sarnia was a difficult decision, but due

to the suspension of ethylene shipments through the Cochin

Pipeline and not being able to secure an alternate source of

economically sustainable ethylene, it was unavoidable,"

Glenn Wright, Dow global director for LDPE, said.

Ethylene shipments to Sarnia through the Cochin Pipeline were

suspended for safety reasons in March 2006.

Closure of Dow's PS facility in Sarnia will begin in fourth

quarter 2006 and will be concluded by the year's end.

"A number of factors, including the significant cost

increase of doing business at Sarnia due to the closing of

[Dow's] LDPE facility, the need for capital improvements to

the aging PS plant to maintain Dow standards, and the

difficult long-term market conditions facing the PS industry

made it necessary to shut down the Sarnia PS plant,"

Jeff Denton, Dow product director for polystyrene in North

America, said.

Also in Sarnia, latex production from Dow's UCAR emulsion

systems (UES) facility, as well as production from a polyols

plant, will shut down by year-end 2008.

http://www.jobwerx.com/news/dow_biz-id=948401_791.html

Beyond that

timeframe, Dow's focus will be to generate as much capacity

as possible from its LDPE plant in Freeport, Texas to service

customer demand. Dow will fulfill contractual obligations

appropriately, but may not be able to maintain the current

level of supply to all customers.

In March 2006,

ethylene shipments to Sarnia through the Cochin Pipeline were

unexpectedly suspended by the pipeline's owner, BP, for

safety reasons. Since then identifying an alternate

economically sustainable source of ethylene has been a top

priority for Dow. Multiple options were looked at, including

imports and other sources in the area, but none could meet

Dow's needs.

The LDPE plant at Sarnia has a capacity of 220 MM/lbs

annually and employs 33 people.

In Fort Saskatchewan, the Company will shut down its chlor-alkali and

direct chlorination ethylene dichloride plants by the end of October 2006. This

decision was driven by the substantial capital costs required to

maintain long-term operations at the 27 year-old facilities - an

investment that could not be justified based on expected rates of

return.

In Porto Marghera,

Italy, the

Company has made the decision to not restart production of the toluene

diisocyanate (TDI)

facility, which was shut down for planned maintenance in early

August. Fundamentals in the TDI business remain weak due to

excess global production capacity.

Ontario

The Sarnia site in Ontario was the first Dow

manufacturing operation in Canada. Having been invited in 1942

by the Canadian government to build a plant in Sarnia to

produce styrene (an essential raw material used to make

synthetic rubber), Dow then built a polystyrene plant in

1947.

This site's Polystyrene unit produces two types of

polystyrene plastic for a variety of applications from

refrigerator linings to foam meat trays to insulation used in

home construction. As a founding member of the Canadian

Polystyrene Recycling Association in Mississauga, Ontario,

Dow is involved in initiatives to collect, process and market

recycled polystyrene.

Another unit produces

low-density

polyethylene (LDPE) plastic for flexible

packaging and clear films such as those used for bread bags

and plastic wrap. Polyols are produced at our Propylene

Oxide Derivatives unit as the basic building blocks for a

wide variety of polyurethane foam products, such as

automotive car seats. The next time you paint your house, you

may be using a product which began its life at the Acrylate

Latex

plant. Using styrene and butyl acrylate, the unit produces

the raw material for many adhesives and architectural and

protective coatings - including latex paints. Using styrene

and butyl acrylate, the unit produces the raw material for

many adhesives and architectural and protective coatings -

including latex paints.

Alberta

The Fort Saskatchewan site began manufacturing

products for the agricultural, oil, gas, transportation, and

pulp and paper industries in 1961. Dow moved into the area

because of the availability and low cost of natural resources

to make its products.

Fort Saskatchewan's

2,128 acre manufacturing site uses natural gas and salt to

produce basic chemicals and plastics. Natural gas liquids are

brought into the site's Fractionator plant by pipeline and

separated into five hydrocarbon products: ethane,

propane-plus, propane, butane and pentane-plus. The Fractionator plant

delivers four products to customers outside Dow and sends the

ethane to the Ethylene plant to make

ethylene,

which is used internally on site to make a number of other

chemicals, including polyethylene and ethylene

dichloride.

The salt found below

the Fort Saskatchewan site is used to make brine, which is

then used in the Chlor-Alkali process to make chlorine,

caustic soda and hydrochloric acid. The site also receives

shipments of polystyrene, which is used to make STYROFOAM*

brand insulation.

In the past, Dow

often looked for new market opportunities and developed the

technology and customer base on its own. Today, with greater

competitiveness and an increased awareness of the need to

more quickly create value, Dow explores joint ventures as a

key means to do what it previously did on its own. On July 1,

2004, a new 50/50 joint venture between Petrochemical

Industries Company (PIC) of Kuwait, a wholly owned subsidiary

of Kuwait Petroleum Corporation, and The Dow Chemical Company

was formed for the manufacture, marketing and supply of

ethylene glycol, worldwide. Dow Canada's former Ethylene

Glycol (EG) unit

located at Fort Saskatchewan is now part of MEGlobal.

Cochin Pipeline

- Owned by

ConocoPhillips, Kinder Morgan and BP (who also

operates the line)