Libya's

National Oil Corporation and The Dow Chemical Company Announce

Joint Venture Plans To Expand Petrochemical Complex in Libya

The JV project represents Libya's commitment to developing

downstream industry

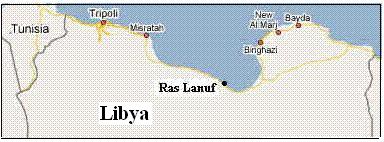

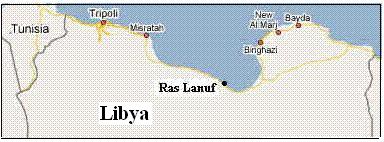

National Oil Corporation of Libya (NOC) and The Dow Chemical Company (DOW) have announced plans to participate in a joint venture to operate and expand the Ras Lanuf petrochemical complex in Libya.

The joint venture agreement encompasses the Ras Lanuf site's existing naphtha cracker, two polyethylene production facilities and associated infrastructure. The project will include refurbishment and expansion of the existing units, followed by construction of an ethane cracker and additional polyethylene and polypropylene facilities. Later phases will include construction of additional hydrocarbon, plastics and chemical production facilities based on natural gas.

The Ras Lanuf

petrochemical complex is on the Mediterranean coast of Libya and

was built in the 1980s. More information about the complex

is available at http://www.raslanuf.com/.

About NOC

NOC was established in 1970 to implement the strategy of the

Country's policy in upstream and downstream oil and gas

activities. NOC, through wholly and partially

owned subsidiaries, runs a network of onshore/offshore oil, gas,

and product facilities for domestic and export markets.

Presently NOC

produces about 1.7 million bls/day of crude oil and about 2.7

TSCFD of raw gas. NOC 5 petroleum refineries having

a total refining capacity of 380,000 lbs/day of methanol, ammonia,

urea plants, producing 2000 t/day, 2200 t/day and 2750 t/day respectively as well as

petrochemical facilities at Ras Lanuf based on Naphtha cracking

producing about 330 kt/year Ethylene, 170 kt/year

Propylene, 130 kt/year mixed C4's and 325 kt/year Pyrolysis

Gasoline. Part of Ethylene is used to

produce about 80 kt/year LLDPE and 80 kt/year of

HDPE.

Also affiliated to

NOC is a petroleum research center which carries out research and

technical studies related to the oil industry and conducts

technical analysis and tests for the various stages of

exploration and production of oil and petroleum products to

ensure quality control.

America resumed full diplomatic relations with Libya in May 2006.

能力

1.7

million bls/day of crude oil

2.7

TSCFD of raw gas

NOC

5 petroleum refineries at Ras Lanuf

a total refining capacity of

380,000 lbs/day

methanol 2000 t/day

ammonia 2200 t/day

urea 2750 t/day

Ras Lanuf Oil and

Gas Processing Company (RASCO)

LPG 105 850 MTA

naphtha 1,811,130 MTA

kerosene 525,230 MTA

Ethylene 330 kt/year

Propylene 170

kt/year

mixed C4's 130 kt/year

Pyrolysis Gasoline 325 kt/year

LLDPE 80 kt/year

HDPE 80 kt/year

Shenhua Group and The Dow

Chemical Company to Sign Co-operation Agreement on

Coal-To-Chemicals Project

Project

represents win-win economic partnership between leading U.S. and

China companies

The Shenhua Group (Shenhua) and The Dow Chemical Company (Dow) today will sign a cooperation agreement and announce plans for a detailed feasibility study, bringing the two parties one step closer to building a world-scale coal-to-chemicals complex in Shaanxi Province, People's Republic of China.

The project will use "clean coal" technologies that convert coal to methanol to produce ethylene and propylene, the building blocks to make various plastics and chemical products. The complex will include a chlor-alkali unit, enabling the production of products such as caustic soda, vinyl chloride monomer and chlorinated organics. Other derivative products being planned for the complex include glycols, amines, solvents, surfactants, acrylic acid and derivatives and propylene derivatives.

Benefits for China and U.S.

About Shenhua Group

2006/8/23 中国でのダウの活動

Nov 5, 2009 Reuters

Dow Chemical, Shenhua revive $10 billion China project

Dow Chemical Co and Shenhua Group, China's largest coal miner, will reportedly move ahead with their planned $10 billion coal-to-chemical project in Shaanxi province after a delay of at least one year.

Top executives from the companies, senior officials in Shaanxi province and representatives from the U.S. Embassy in China attended a cornerstone laying ceremony on November 3, the China Chemical Industry News reported on Thursday.

The Yulin project in northern Shaanxi aimed to install 23 units that include a 3.32 million tonne-per-year methanol facility for ethylene and propylene, which are used for making various plastics and chemical products.

"The feasibility study of the project has entered the stage of applying for an approval from the central government," the newspaper said, citing an unnamed local government official.

The feasibility study was previously planned to be completed in 2008.

An assistant president with Shenhua who is based in Beijing declined any knowledge of the project, and officials at Dow Chemical in China could not immediately be reached.

Dow sold off $3.4 billion in assets this year to boost its bottom line and reduce debt. The chemical firm also cut costs by laying off thousands of workers and shutting several plants.

Shenhua is the parent of Hong Kong-listed China Shenhua Energy.----

2009/11/8 Shanghai

Dow and Shenhua held groundbreaking ceremony for Coal Chemical JV Project in Shaanxi

On Nov. 3, 2009, Dow Chemical and Shenhua Group held a groundbreaking ceremony for their JV mega coal chemical complex in Yulin, Shaanxi Province.

According to the industrial sources, this JV will be invested by Dow Chemical (China) Holding Co. (Dow China), China Shenhua Coal to Liquids and Chemicals Co. (CSCLC) and the local Government. CSCLC is a subsidiary of Shenhua Group the largest coal producer in China. Dow and Shenhua will have the major shares with in the JV, but the financial details have not been revealed yet.

With the investment around USD 10 billion, the project will include 23 chemical units which will be based on coal and salt resources in Yulin, Shaanxi, and the coal chemical and chlor-alkali process will be used in the complex. The feasibility study of the project is applying the approval from the central government.

The preliminary main products proposal as follows:

Methanol 3.32 Mt/a

Olefins 1.22 Mt/a (Methanol to Olefins)

Chlor-Alkali 500 kt/a

MEG 400 kt/a

Ethanol Amines/ Ethylene Amine 210 kt/a

Polyether Polyols 340 kt/a

Acrylic Acid 150 kt/a

Acrylates 200 kt/a

EDC 510 kt/a

PVC 500 kt/aダウは2008年7月にRohm and Haas を188億ドル(借入金引継ぎを含む)で買収する契約を締結した。

ダウはこの資金の多くを、石油化学事業をクウェートのPICとの50/50JVにすることで入る資金で充てることにしていたが、2008年12月25日にこれが破談になった。

このため、ダウはRohm and Haas の買収を一時延期したが、裁判になり、結局本年4月1日に買収を完了した。

買収資金のつなぎ融資は1年間の契約のため、 K-Dow 破談によって資金繰りが危うくなり、このままでは格付会社が投資基準以下への格下げを行うことが確実なため、ダウは増資や史上初めての減配を行うとともに、R&H子会社のMorton Salt、塩化カルシウム事業、Total とのJVのTotal Raffinaderij Nederland、マレーシアのPetronas とのJVのOptimal グループなどの売却を進めた。

また、多くのプラントを停止している。ダウ自身は今回なにも発表はしておらず、着工時期などは不明である。

Investigation Is Said to Open on Dow Chemical

The Securities and Exchange Commission has begun an inquiry into whether two senior executives at Dow Chemical secretly tried to put the company into play as well as into the unusual trading in its stock that may have resulted, according to people briefed on the matter.

But the inquiry, still in the informal stage, may also look at a deal that the company actually pursued. Last fall, Dow made an overture to acquire DuPont in a deal worth more than $40 billion, according to people involved in the talks. If the approach had ultimately led to a deal, it would have combined the largest and third-largest chemical companies in the United States. ExxonMobil is No. 2.

Shares of Dow and DuPont traded somewhat erratically at the time, though neither company disclosed the approach. From September to December, shares of DuPont climbed 15 percent.

DuPont rebuffed Dow’s advances and never engaged in negotiations, these people said. Dow’s chief executive, Andrew N. Liveris, sits on the board of Citigroup with Alain J. P. Belda, the chief executive of Alcoa, who at the time of the overture was also a director of DuPont; Mr. Belda stepped down from DuPont’s board in March.

Dow's CEO declines comment on BASF, seeks growth elsewhere

Andrew Liveris, chief executive of Dow Chemical Co., declined on Friday to comment on recent rumors Dow is interested in buying BASF AG , while adding the deals that interest him are the ones that fit gaps the company has identified.

"We'll never comment on a rumor like that, but I will say that between Dow and BASF you are looking at two of the world's leading chemical companies and reality has to set in on do-ability," Liveris said in an interview with Reuters Television.

But Liveris said he would like to grow the company's water solutions and coatings businesses.

June 01, 2007 The Detroit News

Dow Chemical has talks on Australian project

Dow Chemical Co., the biggest U.S. chemical maker, has held initial talks with owners of natural gas fields off northern Australia for the supply of fuel to a possible petrochemicals project, according to a report today from Bloomberg News.

"We'd be interested in looking at an opportunity for petrochemical production" in northern Australia, Jim McIlvenny, Dow's president for Asia Pacific and China, told reporters today in Darwin. "They are exploratory talks only. It's too early until we get gas" ashore in northern Australia that's available for domestic use, he said.

Australia's Northern Territory government aims to develop a natural gas-based chemical industry to increase returns from gas reserves that either go into liquefied natural gas or are lying unused, Bloomberg News reported. ConocoPhillips, Santos Ltd., Nexus Ltd. and Eni SpA are among companies that own gas reserves off the northern coast.

Dow to expand European SSBR

Dow

Chemical has started building a 60,000 tonnes

solution styrene butadiene rubber plant at Schkopau in Germany. It

already has SSBR and PBR plants in Germany and France and is

back-integrated into butadiene and styrene. Off-take from the new

plant will be aimed at the tyre sector.

Dow says SSBR is the fastest growing segment of the rubber market

with an anticipated annual growth rate of 5 - 6 per cent

over the next few years.

The new facility will include a

capacity rights agreement with JSR Corporation of Japan though Dow will own and

operate the plant. .

2007/06/11 JSR

欧州におけるS-SBR(溶液重合SBR)引取権の取得について

JSR株式会社 (本社:東京都中央区、社長:吉田淑則) は、DOW

Europe GmbH (本社:スイス チューリッヒ、 社長:Markus

Wildi) が同社のSchkopau(シュコパウ)工場 (ドイツ、ザクセン

アンハルト州)で建設に着手した年産6万トンのS-SBR(溶液重合SBR)製造ラインにおいて、50%にあたる3万トンの引取権を取得することで合意し、同社と契約を締結しました。

DOW社が建設中の新設S-SBRラインは2008年下期中の完成を目指しております。

JSRは、2003年以降、欧州にてDOWとの間でS-SBRの生産委託を行なっておりますが、今回、さらに引取権を取得することにより、JSRの先端技術による高品質の製品の供給を拡大し、S-SBR市場におけるJSRのポジションをグローバルに強化できることとなります。

S-SBRは、主にタイヤや工業用品用途に使用されています。近年、世界的な環境に対する意識の高まりを背景に、省燃費タイヤ用への需要が拡大しています。JSRの高性能S-SBRは、タイヤの省燃費特性だけでなく、高性能タイヤに求められる操縦安定性等の特性についても高く評価されています。JSRは、今後、日・欧の生産拠点をベースにグローバル展開をさらに強化し、S-SBR事業の拡大を積極的に進めていきます。

欧州における溶液重合SBR(S-SBR)商業生産開始について

JSR株式会社は、DOW Europe GmbH (本社:スイス チューリッヒ、 社長:Markus Wildi) が同社のSchkopau(シュコパウ)工場 (ドイツ、ザクセン アンハルト州) で建設を進めていた6万トン/年の生産能力となる溶液重合SBR (S-SBR)製造ラインがこのたび完成したことを受け、50%にあたる3万トンの引取権に関する契約に基づき、3月に商業生産を開始することとなりまし た。

今回の引取権の実施により、当社の先端技術による高品質の製品の供給を拡大し、S-SBR市場における当社のポジションをグローバルに強化できることとなります。

S-SBRは、主にタイヤや工業用品用途に使用されています。 近年、世界的な環境に対する意識の高まりを背景に、省燃費タイヤ用への需要が拡大してい ます。 JSRの高性能S-SBRは、タイヤの省燃費特性だけでなく、高性能タイヤに求められる操縦安定性等の特性についても高く評価されています。

特にEUでは、2012年には、自動車の二酸化炭素排出規制が強化される予定であり、さらなる低燃費化の必要から、省燃費タイヤ用途でS-SBRへの ニーズが一層高まると見込まれています。新プラントで生産するS-SBRは、基本的に欧州での需要増にあてる方針です。従来、日本から欧州へ輸出していた 分は、日本およびアジア地区での需要拡大に充当する計画であり、今後、日・欧の生産拠点をベースにグローバル展開を図り、S-SBR事業の拡大を積極的に 進めていきます。

Dow Unveils Dow Wolff

Cellulosics, a $1 Billion Specialty Business

Wolff Acquisition

Creates World-class Team to Deliver Expanded Portfolio, Increased

Application Expertise and Innovations Across Market Segments

Underscoring its

transformational growth strategy, The Dow Chemical Company today

unveiled the creation of a new specialty business unit operating

under the name of Dow Wolff Cellulosics. It encompasses all activities

and interests of what were previously Wolff Walsrode AG and The Dow

Chemical Company’s Water Soluble

Polymers business.

The newly combined business will encompass cellulosics and

related chemistries,

providing application formulation expertise and other technical

services to a broad range of strategic industry sectors,

including construction, paint, personal care, pharmaceuticals,

food and a number of specialty industrial applications.

JULY 03, 2007 economictimes.indiatimes.com

Dow Chem plans India

plant, ties up with GACL

The $ 49-billion

Dow Chemicals, the world’s second-largest chemical

manufacturer, has signed an agreement with Gujarat Alkalies

and Chemicals (GACL), a Gujarat government company, to set up a chemicals plant in

the state.

Confirming the

development, a Gujarat government source told ET, “This new chemical plant is

proposed to be set up in a 50:50 JV between GACL and Dow. GACL is

already leader in manufacturing caustic chlorine with a basket of

26 diversified products.” He refused to divulge any

information on the investment and size of the proposed plant.

GACL, with annual

sales of Rs 1,000 crore, said in a notification to the stock

exchanges on Monday the company and Dow Europe have signed a

memorandum of understanding (MoU) for exploring a long-term and

strategic business relationship in the area of chlorinated

organics based

on the inherent strength of both the companies.

Dow’s move comes at a time when the

issue of compensation to the victims of the 1984 Bhopal gas

tragedy continues

to simmer. India has clarified that Dow Chemicals’ investments in the country will

not be affected

as a result of the Bhopal gas tragedy even as the government

would like to see the court processes resolved and the issue

addressed.

Dow Chemical plans India plant; ties up with India's GACL - report

Dow Chemical Co's European unit has signed a joint venture agreement with India's Gujarat Alkalies and Chemicals Ltd to manufacture chlorine-based products at the latter's Dahej project site in the western state of Gujarat, local dailies Business Standard and The Economic Times reported.

Dow and Crystalsev

Announce Plans to Make Polyethylene from Sugar Cane in Brazil

Renewable Resource Used in Production Process Will Significantly

Reduce Carbon Footprint

The Dow Chemical Company, the world's largest producer of polyethylene, and Crystalsev, one of Brazil's largest ethanol players have announced plans for a world-scale facility to manufacture polyethylene from sugar cane.

Under the terms of a memorandum of understanding agreed by the two companies, Dow and Crystalsev will form a joint venture in Brazil to design and build the first integrated facility of its scale in the world. It is expected to start production in 2011 and will have a capacity of 350,000 metric tons. The venture will combine Dow's leading position in polyethylene with Crystalsev's know-how and experience in ethanol to meet the needs of Dow's customers in Brazil and what will likely be international interest.

The new facility will use ethanol derived from sugar cane, an annually renewable resource, to produce ethylene - the raw material required to make polyethylene, the world's most widely-used plastic.

Dow and Solvay Form Joint

Venture to Build Hydrogen Peroxide Plant in Thailand;

Dow and BASF Continue to Pursue

Plans for Thailand HPPO Plant

The Dow Chemical Company and Solvay S.A. announced today an

agreement to create a joint venture for the construction of a

hydrogen peroxide (HP) plant in Thailand. Scheduled to be

operational in 2010, the new HP plant will serve as a raw

material source for the manufacture of propylene oxide (PO). The

HP plant will be the largest in the world, with a capacity of

over

330 kilotons per annum (KTA) of hydrogen peroxide at 100% concentration. The

hydrogen peroxide supplying the process is based on Solvay’s proprietary, high-yield hydrogen

peroxide technology.

In addition, Dow and BASF Aktiengesellschaft are advancing

negotiations for the construction of a world-scale, 390 KTA propylene

oxide (PO) manufacturing

facility in Map Ta Phut, Thailand. The new plant would use the

innovative hydrogen peroxide to propylene oxide (HPPO) technology

jointly developed by Dow and BASF. “This project would expand our

successful cooperation with Dow and Solvay to deploy this

innovative HPPO technology in Asia,” said Jacques Delmoitiez, president

of BASF’s Polyurethanes division.

2006/3/24 ダウとBASF、POを新製法で生産

The Dow and BASF

Thailand facility would be the second world-scale plant to use

HPPO technology. The first, a 300 KTA Dow and BASF HPPO plant, also

supplied by an HP plant based on Solvay’s high yield technology, is

currently under construction in Antwerp,

Belgium, and

is scheduled for start-up in early 2008. Propylene oxide is used

to produce propylene glycol, polyurethanes and glycol ethers.

Propylene

for the

proposed HPPO facility in Thailand would be supplied from the

liquids cracker that Dow announced it was building jointly with

The Siam Cement Group (SCG) in Thailand in October of 2006. The

liquids cracker facility is expected be fully operational in

2010.

2006/10/24 ダウ、アジア進出を促進

Dow Chemical seeking partner to build plant in Russia

Dow

Chemical, the world’s second largest chemicals

company, is looking for a partner to build its own petrochemicals

plant in Russia, the head of the company’s Russia and CIS division, Andrian

van den Berge told Interfax.

He named Gazprom as

a potential partner for construction of the plant. Gazprom is the

leading gas producer, while Dow Chemical is the leading

processor, so they could form a successful alliance in the energy

sector, he said, adding that negotiations are already underway

with the Russian gas giant.

Dow Polyurethanes to

Increase Specialty Polyols Capability in Freeport, Texas

Investment solidifies commitment to North American polyurethanes

industry

Dow Polyurethanes, a business group of The Dow Chemical Company, announced today it will add 130 million pounds or approximately 59 kilotons per annum (KTA) of specialty mix polyols capability at its manufacturing facility in Freeport, Texas. Scheduled to come on stream in early 2009, the additional capability will support growing demand for end-use polyurethanes products and polyurethane systems formulations in North America.

2007/10/17 financialnews-us.com

Dow Chemical sues JP Morgan as 'Judas'

A former Dow Chemical executive has alleged that JP Morgan, one of the top banks in private equity deals, secretly planned a leveraged buyout of his company and then blamed him for it.

Romeo Kreinberg, a former officer of Dow Chemical’s executive leadership committee, filed the lawsuit in the Eastern District of Michigan on Friday in a matter that has raged for over 10 months. The complaint is Kreinberg's retort to Dow Chemical’s suit earlier this year alleging that he held “unauthorized discussions” with JP Morgan bankers about a takeover of the company, behind the back of CEO Andrew Liveris.

A JP Morgan spokesman said: “These claims are legally and factually unfounded and we are confident they will be dismissed.”

Kreinberg's complaint alleged that JP Morgan started working with Omani and Kuwaiti investors on a buyout of Dow Chemical as far back as late 2006, then when rumors leaked into the marketplace in 2007 and Liveris became angry, the bank turned around and blamed Kreinberg for working on a buyout.

October 20, 2007

canplastics.com

Dow moves closer to shuttering Sarnia site

Dow Chemical Canada Inc. took another step towards shutting down

its Sarnia, Ont. facility this week when representatives

presented a closure plan to community representatives with the

assurance that environmental and property ownership

responsibilities would be met during the process.

Dow will proceed with its closure plan of the 322-acre

industrial site with completion in the spring of 2011. By that time, according to Dow,

all employees will have left the site, equipment and buildings

will have been removed, and the site will be in an

environmentally secure state. At present, three of the site’s four manufacturing units have

been shut down and are in various stages of decommissioning as

they are readied for demolition, which will begin next year. The

remaining facility on the site, Dow’s Propylene Oxide Derivatives

unit, will close in April 2009.

2007/10/23 AFP Carbide legacy fouls Dow's buiness deal with Indian Oil Corporation

India, Dow Chemical may settle Bhopal gas disaster claims: report

India could reach an out-of-court settlement with US giant Dow Chemical to clean up the Bhopal gas disaster site and end liability claims after more than two decades, a report said Monday.

India's law ministry said the move would clear "legal hurdles" to future Dow Chemical investments in India by setting up a fund to clean up thousands of tonnes of contaminated soil along with other measures to resolve long-running lawsuits linked to the disaster, the Hindustan Times newspaper reported.

Thousands of people were killed on December 3, 1984 when a then Union Carbide plant at Bhopal in central India disgorged 40 tonnes of lethal methyl isocyanate gas in one of the world's worst environmental disasters.

Dow Chemical, which took over Union Carbide in 2001, has long insisted that all liabilities regarding the disaster were settled when Union Carbide concluded a 470-million-dollar compensation settlement with New Delhi in 1989.

But local and federal court cases in India have challenged that view with lawsuits calling for more compensation for survivors and liability claims for ongoing health problems linked to the disaster.

Dow Announces Plans to Suspend Production at Union Carbide Polypropylene Manufacturing Facility in Louisiana

The Dow Chemical Company

(TDCC) today announced that Union Carbide Corporation (UCC), a

wholly-owned subsidiary of TDCC, will suspend production at its

polypropylene manufacturing facility at St. Charles

Operations in Hahnville, Louisiana, in anticipation of an expected

decision to shut down the facility by year end.

“The

closing of the St. Charles Operations polypropylene plant is a

difficult decision, but due to a number of factors, including the

inability to secure a source of economically

sustainable propylene, the use of older

technologies at

the plant and needed capital improvements to maintain operations to Dow

standards, it will be unavoidable,” said Julie McAlindon, Dow

Polypropylene Global Business Director.

The polypropylene plant has a capacity of 500/MM lbs.

Dow to Exit Hydroxyalkyl Acrylates Market

The Dow Chemical Company announced today its intent to stop producing and marketing hydroxyalkyl acrylates (HAA) by the end of 2007.

The HAA product line includes hydroxyethyl acrylate (HEA) and hydroxypropyl acrylate (HPA). These products are sold largely to major coatings formulators for use in automotive topcoat applications.

“Dow’s competitiveness in the HAA market has deteriorated significantly as a result of high raw material costs, industry overcapacity and declining demand with a shift to low acid HAA products,” explained Chris Kok, global HAA product manager.

This decision has no

impact on Dow’s standing as a leading acrylic

acid and acrylic ester producer. Dow manages those products

independently from the HAA line.

Dow Polyurethanes

Continues Growth in Asia Pacific

Dow

to Acquire Remaining Joint Venture Shares of Pacific Plastics

(Thailand) Ltd.

Dow Polyurethanes, a business group of The Dow Chemical Company (Dow), announced today that Dow will acquire the remaining shares of Pacific Plastics (Thailand) Limited (PPTL). A joint venture between Dow, Siam Cement Group (SCG) and two other minority partners, PPTL represents ownership of the polyols and polyurethane systems facility located in Map Ta Phut, Thailand. Dow is acquiring the remaining 51 percent ownership in the joint venture directly for an undisclosed sum. Once the transaction is completed, the polyols and polyurethane systems facility will be wholly owned by Dow.

November 27 2007 Gazprom 詳細

Gazprom Group and The Dow Chemical Company sign memorandum of intentions in gas processing sector

Today at the Gazprom

Headquarters Alexey Miller, Chairman of the Gazprom Management

Committee, Dmitry Konov, President of Sibur Holding, Andrew

Liveris, President, Chief Executive Officer and Chairman of the

Dow Chemical Company have signed a Memorandum of Intentions in

the area of high-value added hydrocarbon processing.

The document stipulates examination of prospects to set up a

joint venture based on new petrochemical production

facilities

of the Dow Chemical Company in Germany, joint natural gas

processing in the Valanginian deposits of the Yamal-Nenets Autonomous

Okrug as well as examination of cooperation

opportunities in other sectors.

The parties will create a working group to preliminary evaluate

economic feasibility to set up a joint venture and to prepare a

draft agreement for further joint technical and economic

research.

Reference:

SIBUR Group is the largest vertically integrated petrochemical

holding company in Russia that includes OAO SIBUR Holding, OAO AK

SIBUR and OOO SIBUR.

The Group includes 34 enterprises, which process the major volume

of Russian hydrocarbons via the integrated technological chain

ranging from initial processing to manufacturing final products

for consumers. The executive functions are exercised by the

management company OOO SIBUR.

OAO SIBUR Holding is part of the Gazprom Group. SIBUR Holding

turnover in 2006 was RUR 121.9 bln, with net income of RUR 21.4

bln.

The Dow Chemical Company is the largest chemical company in the

USA operating in more than 175 countries. The Company produces

chemical products, packaging and agricultural products. In 2006

Dow annual sales and net profit exceeded USD 49.1 bln and USD 3.7

bln, respectively.

In pursuance of the Memorandum within the examination of the

issue related to participation in extraction of light hydrocarbon

mixtures in the Valanginian deposits of the Yamal-Nenets

Autonomous Okrug and its processing at the petrochemical large

capacity complexes in the territory of the Russian Federation.

The Dow Chemical Company, Gazprom and SIBUR Holding will examine

an opportunity to set up a joint venture.

Dow Announces Further Moves to Bolster Competitiveness

In its ongoing drive to improve the efficiency and cost effectiveness of its global operations, The Dow Chemical Company has announced plans to shut down a number of assets and make organizational changes within targeted support functions. As a consequence of these activities, approximately 1,000 jobs will be eliminated from across several functions, geographies and businesses.

The most significant financial impacts of today’s announcement are described below.

Dow will record an impairment 減損 charge related to its manufacturing site in Lauterbourg, France, as a result of overcapacity within the industry, a disadvantaged cost position, and increasing pressure from generic suppliers. As required, the Company has launched an information/consultation process with the local employee representatives on the closure project.(Dow AgroSciences LLC :the largest granulation facility for Dithane* fungicide)

Dow will exit the automotive sealers 下塗り材business in North America, Asia Pacific and Latin America within the next nine to 18 months, and will explore strategic options in Europe. The decision, which reflects concerns about the unit’s ability to meet the financial expectations of this business, will allow the Company to focus its resources on delivering differentiated and higher value technologies to the automotive industry.

The Company will write down its investment in a joint venture - Pétromont and Company, Limited Partnership - due to an unfavorable financial outlook, reflecting significant long-term economic challenges.

Established in 1980, Pétromont is a Canadian limited partnership equally owned by Dow Chemical Canada Inc., a wholly-owned subsidiary of The Dow Chemical Company, and by Éthylec Inc., a wholly-owned subsidiary of the Société générale de financement du Québec.

It manufactures high-density polyethylene and basic petrochemicals (olefins) which are sold throughout the world, primarily to North American markets.

The Company’s styrene plant in Camaçari, Brazil, will be idled on January 1, 2008, in the wake of escalating competition and weak industry fundamentals.

The Company will close its manufacturing facility for hydroxyethyl cellulose located in Aratu, Brazil, in the face of capacity limitations, high structural and raw material costs, and aging technology. After studying several options to improve the profitability of the facility, the Company opted to close the plant during the first quarter of 2008.

Union Carbide Corporation, a wholly owned subsidiary of the Company, will shut down its polypropylene facility at St. Charles Operations in Louisiana before the end of the year. The decision was driven by a number of factors, including the substantial capital costs required to maintain long-term operations at the facility.

And the Company will significantly reduce support functions, including R&D, at the Union Carbide site in South Charleston, West Virginia, as those functions continue to align their activities more closely with Dow’s strategic growth objectives. Approximately 200 jobs will be affected.

The Dow Chemical Company to Exit ABS and SAN Sales in the Americas for All Non-Automotive Markets

Dow’s Engineering Plastics business announced it is exiting ABS (Acrylonitrile Butadiene Styrene) and SAN (and Styrene Acrylonitrile) sales in the Americas for all non-automotive markets by February 1, 2008. Dow ABS/SAN assets in Europe are not impacted by this announcement.

“This decision has been made after a thoughtful and prudent assessment that clearly indicated the fundamentals of the market do not support our continued involvement,” said Mark Remmert, Engineering Plastics Business Director, Dow. “It is the ultimate intention of the ABS business to convert the Allyn’s Point (Gales Ferry, Conn.) and Hanging Rock (Ironton, Ohio) trains to polystyrene production and include them in the proposed styrenics Joint Venture between Dow and Chevron Phillips Chemical.

Mass ABS production in Midland, Mich., will continue in support of the automotive industry and be marketed exclusively through Dow Automotive. All products will be supplied from the Midland, Mich. plant.

ABS and SAN are plastics used in a wide variety of applications within the construction, automotive and durables markets.

December 04, 2007

The Dow Chemical Company to Close Latex Plant at Freeport, Texas

The Dow Chemical Company announced today the decision to close its Latex production facility at Freeport, Texas in 2008. The Latex plant at Freeport is only one of 7 latex plants that serve the North American paper, paperboard and carpet industries. The Freeport facility employs approximately 18 people, who will be redeployed to other roles within Texas Operations, currently Dow’s largest integrated site, serving all eight of Dow’s Global Business Groups.

“The closing of our Latex facility in Freeport was a difficult decision, but due to the reduction in industry demand and productivity improvements across the plants, the decision was necessary,” said Philippe Raynaud de Fitte, general manager, Dow Paper and Carpet Latex.

“We believe we can better service the North American customer base by leveraging alternative manufacturing facilities and reduce overall structural costs by shutting down this location” said Donna Babcock, North American Product Director, Dow Paper and Carpet latex.

The Latex plant will operate into the first half of 2008. Beyond that timeframe, Dow will supply Latex from other manufacturing locations across its grid in North America to service customer demand. Since Dow customers are served from a multiple manufacturing grid system rather than from individual sites, Dow anticipates no disruption in supply.

Dow,

Chevron Phillips Chemical Name Leadership Team for Styrenics

Joint Venture

The Dow Chemical Company and Chevron Phillips Chemical Company LP

(Chevron Phillips Chemical) today announced the leadership team

for their proposed styrenics joint venture. The new company,

which will be known as Americas Styrenics, will be

headquartered in Houston, Texas. Americas Styrenics will be a

leading integrated producer of polystyrene, building on the

wealth of manufacturing, commercial and technological expertise

of its parent companies to create the market leader in the

Americas.

Tim Roberts has been named President and Chief Executive Officer

of Americas Styrenics. Roberts is currently the Styrenics General

Manager for Chevron Phillips Chemical.

The new company is expected to have approximately 600 employees

across the Americas. To form the joint venture, Dow intends to

contribute six polystyrene plants (Torrance,

California; Gales Ferry, Connecticut; Ironton, Ohio; Joliet,

Illinois; Guaruja, Brazil and Cartagena, Colombia). Dow’s styrene plant in Camacari,

Brazil is no longer in the scope of the joint venture. Chevron

Phillips Chemical intends to contribute a styrene monomer

plant in St. James, Louisiana and a polystyrene plant in

Marietta, Ohio.

Dow and Chevron Phillips Chemical continue to work toward

finalizing transaction documents with a goal of commencing joint

venture operations during the first quarter of 2008. The

companies signed a non-binding Memorandum of Understanding to

form the joint venture in April.

ダウとクウェートのPIC、グローバル石化JVを設立 発表 詳細

ダウは12月13日、クウェート国営石化会社 Petrochemical Industries Company (PIC) との間でグローバルな石化JV(50/50)を設立すると発表した。

JVは米国に本拠を置き、PE、PP、PC、エチレンアミン、エタノールアミンを製造販売する。売上高は110億ドル以上で、従業員は世界で5,000人。

ダウは2006年3月に、基礎部門の強化をJV化を通して行う方針を明らかにした。他社と新しいJVをつくるだけでなく、場合によっては既存の設備を出してJVにすることも行うとした。ダウはこの戦略を “asset light” strategy ( asset light

とは「資産を持たない、減らす」という意味 )と呼んでいる。

世界各地でJVを新設するとともに、エチレングリコール事業をPICとの50/50JVのMEGlobal にしている。また、本年にPS事業を出し、Chevron Phillips Chemical との間で北南米のSM/PSの50/50JV

Americas Styrenics を設立することとした。

今回の計画はその一環で、ダウはこれら製品の事業設備の権利の50%をPICに売却した上で、両社でJVを設立する。資産価値は190億ドルで、ダウはPICから税引前で95億ドルを受け取る。

JVはPICの原料ソースとダウの技術・マーケティング能力をベースとし、ダウでは「営業開始の初日からグローバルリーダーとなる石化会社をつくる」としている。ダウとしては基礎事業をJVで運営することで、資金を他の機能性事業、マーケット志向事業に投資するとしている。

今後、詳細を詰め、所要の認可を受けて、2008年後半に設立する予定。

Shanghai Daily December 20, 2007

Dow has US$5b fund for

China investment

Dow Chemical Co of the United States has US$5 billion of funds to

invest in China over the next decade, and hopes its new venture

with a Kuwaiti partner could help, its chairman said yesterday.

The huge investment budget excludes a potential

multi-billion-dollar coal-to-chemicals project in Shaanxi

Province for which Dow and Chinese partner Shenhua Group Corp are

conducting a feasibility study, Chairman and Chief Executive

Officer Andrew N. Liveris said in Shanghai.

To date, the largest US chemical maker has invested US$500

million and has earmarked another US$400 million in China, its

third-largest market behind the US and Germany.

"China is playing a leading role in Dow's global commitments

and its business success - and this will only increase in the

future," Liveris said, adding Dow seeks a bigger presence in

China's booming petrochemical sector.

China has just approved Sinopec Corp's US$5-billion joint venture

oil refinery and petrochemical project with Kuwait Petroleum Corp

in Guangdong Province, in which Dow and other foreign firms had

been in talks to hold a stake.

Liveris said Dow is interested to participate in large integrated

refining and petrochemical projects in China, while declining to

be more specific on the Sinopec-KPC project yesterday.

Dow recently announced plans to form a landmark US$11-billion

equally-owned venture with Petrochemical Industries Co, a unit of

KPC.

"Our joint venture with Kuwait means that we have an

opportunity to participate if the Kuwaiti petroleum company finds

a right project in China," Liveris said.

Wang Jin, an analyst at Orient Securities, said it is a good

strategy on Dow's part to use the KPC venture to expand in China.

"China may prefer such partners from Kuwait and Saudi Arabia

which can bring crude oil resources for its large petrochemical

projects, while western firms typically provide technology and

management skills," Wang said.

2008/1/21

canplastics.com

Aux Sable Canada and Dow Chemical announce ethane deal, strategic

alliance

Joint venture company Aux Sable Canada Ltd. has struck a

deal to sell ethane and ethylene from its

Heartland off-gas plant to Dow Chemical Canada Inc.

The agreement makes Aux Sable Canada the first company in Canada

to extract ethane and ethylene from the byproduct gas of a bitumen upgrader (オイルサンドに含まれるビチューメンを合成原油に変換する設備). The Heartland

off-gas plant is under construction just north of Dow Chemical's

complex in Fort Saskatchewan, Alberta. Its feedstock will come

from BA

Energy's Heartland upgrader.

According to Aux Sable Canada, the arrangement involves up to 8,000 barrels per

day of ethane and ethylene.

THE CANADIAN PRESS January 17, 2008

Aux Sable, a joint venture of Enbridge Inc., Fort Chicago Energy Partners and Williams Cos., will be the first in Canada to extract ethane and ethylene from the byproduct gas of a bitumen upgrader.

The Heartland off-gas plant is under construction just north of Dow Chemical's complex in Fort Saskatchewan, northeast of Edmonton.

BA Energy Inc. was established in 2002 to engage in the business of upgrading bitumen and heavy oil feedstock into high-quality crude oils by applying proprietary technology developed by Value Creation Inc., the founding shareholder of BA Energy. BA Energy is constructing the Heartland Upgrader, a bitumen and heavy oil upgrader in Strathcona County, northeast of Edmonton, Alberta.

BA Energy Inc. is at the forefront of emerging technologies to accelerate development of Canada's oil sands and heavy oil resources. The company was established in Alberta in 2002 to construct and operate the Heartland Upgrader, which represents the next generation of bitumen upgrading technology. The Heartland Upgrader will be an independent, merchant upgrader with the flexibility to purchase feedstock from a variety of producers and to produce synthetic crude oil products tailored for a majority of the North American refinery market. It will be the first stand-alone bitumen upgrader in western Canada.

オイルサンドは、カナダ西部のアルバータ州の北方に位置する3地域に多く賦存する粘度質の黒いアスファルト状の炭化水素であるビチュメンと砂・粘土の混合物です。石油を含んだ油層が地殻変動で地表近くに移動し、地下水との接触や生化学反応によって揮発成分が失われたことによりできた石油資源とされており、その埋蔵量はサウジアラビアの石油に相当するものと推定されています。

BA Energy社(Value Creation企業グループ)は、Strathcona郡でHeartland Upgraderプロジェクトの建設を進めています。Upgraderは3期に分けて建設され、各期とも50,000/日のビチューメンを生産する予定です。当初の計画では第1期の稼動開始は2007年を予定していましたが、2008年まで遅れる見込みです。

Location: Strathcona County, northeast of Edmonton, Alberta, Canada Construction: Three phases (2006 - 2013) Site work began: September 2005 Ultimate capacity: Up to 260,000 barrels per day of oil sands bitumen blend Phase I capacity: Up to 77,500 barrels per day Projected start-up of Phase I: 2008 Phase 1 capital cost: $900 million Cdn (Q1/2006 dollars) Engineering partners: Jacobs Engineering Group Inc. and Larsen & Toubro Limited カナダ・アルバータ州オイルサンド産業の最新動向 http://www.altanet.or.jp/Oilsand_Update_2007.pdf

オイルサンドの採掘方法は、基本的に露天掘りと油層内回収法の2つに分かれます。

露天掘りはFort McMurray の北のAthabasca 油田で採用されています。鉱区を覆っている表土を取り除いてオイルサンドを露出させたうえで、トラックとシャベルを使う採掘方法によって砂を取り除きます。抽出段階では、湯を注ぎ、スラリー(鉱泥)を攪拌してビチューメンと砂を分離させます。

これに対して油層内回収法では、オイルサンドがまだ地下にある間に、ビチューメンを砂から取り出します。最も簡単な方法はプライマリーまたは「コールド」法と呼ばれるもので、熱を加えなくてもオイルサンドが坑井の表面まで上がってくるような油田で採用されています。多くの油層内回収プロジェクトでは、熱を加えてビチューメンを液状化し、坑井の表面までポンプで吸上げています。油層内回収プロジェクトの中にはcyclic steam stimulation(CSS)法式を採用しているものもあります。垂直の坑井を通してオイルサンドに蒸気を注入し、次に液状化したビチューメンを同じ坑井を通してポンプで地上に吸上げる法式です。その他の油層内回収法プロジェクトではsteam assisted gravity drainage(SAGD)法式を採用しています。この法式では、水平の坑井を通してオイルサンドに蒸気を注入すると同時に、蒸気注入坑井の直下に設置したもう1本の水平坑井を通して液状化したビチューメンを引き上げます。また、最近登場した油層内回収法で、水蒸気の補完または代替として溶剤を使用するvapour recovery extraction(VAPEX)法式や、Petrobank Energy and Resources社がパイロット事業として行なっている地下で燃焼させるTHAIプロセスがあります。

Dow Plans Major Capital

Investment to Support Continued Growth in Performance Businesses

Signs Long-Term VCM Agreement with Shintech

The Dow Chemical Company announced today that it will break ground this year on a state-of-the-art membrane chlor-alkali production facility in Freeport, Texas. The new, more energy efficient facility is designed to provide a long-term reliable supply of chlorine to derivative products. Startup is planned for 2011.

Dow is also announcing today the renewal of an important long-term commercial arrangement to supply vinyl chloride monomer (VCM) to Shintech, a Dow customer for more than 30 years, in Freeport, Texas. "This supply agreement with Shintech, which will partly fund our new investment, is further evidence of our commitment to our asset-light strategy," Liveris continued. "While we are not forming a joint venture, Shintech remains a strategic partner in our chlor-alkali output in the U.S. Gulf Coast."

In 2007, Dow announced plans for future chlor-alkali investments in the Middle East and China. With Saudi Aramco, Dow signed an MOU to develop one of the largest grassroots chemicals production complexes in the world at Ras Tanura in Saudi Arabia, which is expected to include a world-scale chlor-alkali production unit. With the Shenhua Group, Dow signed an MOU to develop a coal-to-chemicals project to be located in the Shaanxi Province, People’s Republic of China, which is also expected to include a chlor-alkali and vinyl unit.

Petromont halts petrochemical production in Quebec

Petrochemical manufacturer Petromont & Co, a joint venture of Dow Chemical Co and an arm of the Quebec provincial government, said on Tuesday it will suspend operations on April 30 because of the strong Canadian dollar and expensive feedstock.

The company, which has

annual sales of $750 million, said it will shut its plants in Varennes and

Montreal, Quebec.

It said on its Web site that it employs 325 at the two sites.

Established in 1980, Pétromont is a Canadian limited partnership equally owned by Dow Chemical Canada Inc., a wholly-owned subsidiary of The Dow Chemical Company, and by Éthylec Inc., a wholly-owned subsidiary of the Société générale de financement du Québec.

olefins:

Ethylene & Propylene, Mixed C4’s, Hydrogen, Combustible Gases, HPG-B & Pentenes, Heavy Fuel Oil, Acetylene,

Methyl Acetylene Propadiene, Digester Liquor (Spent Caustic), BTX

Platts Feb 12, 2008

Petromont to suspend ethylene, HDPE production on April 30, 2008

The steam cracker has the capacity to produce 297,000 mt/year of

ethylene and 278,000 mt/year of high density polyethylene. The steam cracker is flexible in

what feedstocks it can take and depending on the feed mix, can

also produce mixed crude C4's, propylene, industrial gases, and

other products.

In March 2007 a Canadian dollar was equivalent to about $0.85, It appreciated to a peak of

nearly $1.08 in early November 2007 and has since devalued to

just under $1.00.

Petromont's plants would be mothballed in case a buyer emerges

for the assets or market conditions change to allow for a

profitable restart of the units, the company said.

Feb. 12 2008 Pétromont

Pétromont announces it's suspending its operation for an undetermined period

Pétromont and

Company, Limited Partnership announced today the interruption of

its operations for an undetermined period. Pétromont shall

proceed to suspend its operations on April 30, 2008.

This difficult context is the result of several factors,

including the strong Canadian dollar and persistent difficulty in

obtaining petroleum-based feedstock at competitive prices. These

factors have had a major impact on the Company's profitability,

and in light of the equally unfavourable conditions affecting the

petrochemical sector across North America, Pétromont has

no choice but to suspend its operations.

The petrochemical facilities will be kept intact in the event

that the market conditions change or an expression of outside

interest is received.

The Company's senior management is sensitive to, and will assist

in dealing with the adverse impacts of this decision as well as

the uncertainty and anxiety for employees and their families.

Pétromont is a major Québec petrochemical company

with average annual sales of $750 million. It operates two plants

in the Montréal region. The first, in Varennes,

manufactures basic petrochemicals, while the plant in Montréal East produces

polyethylene resins sold mainly on the North American markets.

Pétromont is a limited partnership owned equally by Dow

Chemical Canada Inc. and the Société générale

de financement du Québec.

PetroChina Fushun Selects Dow and Aker Kvaerner for PP Project in China

PetroChina Fushun Petrochemical Company has selected Dow’s UNIPOL™ Polypropylene Process Technology for its new 300 KTA polypropylene facility, and Aker Kvaerner will provide the extended process design package and technical advisory services. The plant will be built in Fushun, Liaoning Province, The People’s Republic of China, and is scheduled for completion in 2010. The world-scale facility is the fourth polypropylene plant in China over the past 24 months to use UNIPOL™ Polypropylene Technology from Dow Technology Licensing (DTL), a business group of The Dow Chemical Company.

Including the PetroChina Fushun project, UNIPOL™ Polypropylene Technology will be used globally to produce more than 10 million metric tons of polypropylene per year, which will be more than 16 percent of total global capacity.

AKER KVÆRNER ASA, through its subsidiaries and affiliates ("Aker Kvaerner"), is a leading global provider of engineering and construction services, technology products and integrated solutions. The business within Aker Kvaerner comprises several industries, including Oil & Gas, Refining & Chemicals, Mining & Metals and Power Generation. The Aker Kvaerner group is organized in a number of separate legal entities. Aker Kvaerner is used as the common brand/trademark for most of these entities.

Dow Sharpens Focus on

Portfolio Optimization

The Dow Chemical Company announced today that it is realigning a

number of businesses to a newly created business group, Dow Portfolio

Optimization.

Each of the businesses within the new group has been earmarked

for strategic evaluation, with the goal of defining how best to

maximize its long-term value to the Company - whether that be

through realignment to other Dow businesses, joint ventures or

divestitures.

George Biltz, who currently heads the Company’s Specialty Plastics and

Elastomers portfolio, has been appointed business group president

of the new portfolio, which will include SARAN(TM) Products

and Specialty Films, Polycarbonate, Compounds and Blends,

Synthetic Rubber, and Specialty Copolymers. Going forward, the Company expects

to align other Dow businesses to the portfolio as they are

assessed for strategic alignment with Dow’s transformational strategy.

SARAN PVDC Products

旭化成

「サランラップ」はいきなり誕生した商品ではありません。

20世紀初頭世界初の合成樹脂ベークライトが誕生しますが、以来アメリカでは合成樹脂の研究を熱心に進めていました。

その研究の成果が(ポリ塩化ビニリデン)という形で実を結び、この合成樹脂をアメリカは戦争に活用しました。

この合成樹脂は、太平洋戦線で兵士を悩ませた蚊から身を守るための蚊帳、ジャングルを行進する兵士を水虫から守る靴の中敷き、銃や弾丸を湿気から守るための包装フィルムなどが、主な用途だったそうです。

戦争が終わり、フィルムに様々な改良がなされましたが、ナチュラルチーズを包装する以外に用途が見つかりませんでした。

1940年代後半のある日、フィルム製造メーカーの職長を務めていたラドウィック、アイアンズの二人は、妻を伴って近所の人々とピクニックに出かけました。

ラドウィックの奥さんは、たまたま夫が会社で作っていたフィルムにレタスを包んで持っていきました。

すると「このラップとてもきれい。どこで手に入れたの?」「私も欲しい。どこで売っているの?」と大変な評判になってしまいました。

そこでラドウィック、アイアンズの二人は、驚き、早速翌日上司に報告し、クリング・ラップ・カンパニーを設立して開発に着手し、ダウケミカル社から取り寄せた樹脂のロールを紙管に巻き付けて箱詰めし、サランラップ第1号が完成したという訳です。

完成すると近郊の都市でも試験的に販売され、結果は上々でした。名前もラドウィック、アイアンズの二人の妻サラ(Sarah )とアン(Ann)にちなんで「サランラップ」と決定されました。

発売から2年後の1952年にはダウケミカル社が生産を担当し、サランラップは全米に進出することになります

日本では、1952年に旭化成とダウケミカル社との提携により、折半出資企業「旭ダウ(株)」が設立され、1960年(昭和35年)にサランラップを発売開始いたしました。

Dow Chem board rejects call for study on pesticide health effects

The board of Dow Chemical

has rejected a proposal by shareholders for an independent study

on the impact of Dow's pesticide products on human health, saying

it would be an unnecessary expense and "without benefit to

our shareholders."

A group of shareholders have petitioned the board to commission

an independent report to be published by May 2009, analysing the

extent to which Dow's products may cause or exacerbate asthma ぜんそく, and detailing Dow policies and

activities to phase out or restrict ingredients linked with

asthma and other respiratory 呼吸器官

problems. The

proponents are seeking to present the proposal at the

shareholders' annual meeting on May 15 in Michigan.

May 28, 2008 http://www.chicagotribune.com/news/local/chi-dioxin-29-both-may29,0,7252768.story

Dow Chemical ordered to

clean up area in Michigan near its headquarters

High levels of dioxin found

Federal

officials Wednesday ordered Dow Chemical to clean up high levels

of dioxin recently discovered in homes and yards in a Saginaw,

Mich., neighborhood downstream from the company's world

headquarters.

Company officials still contend dioxin-contaminated soil and

sediment doesn't threaten people or wildlife. At the same time,

they say the company is prepared to restore

polluted areas, but they disagree with state and federal

officials about how the project should be carried out.

Federal and state officials met with Dow executives Wednesday to

discuss how the cleanup will proceed.

May 30, 2008 SAGINAW NEWS

Dow ordered to clean home sites

Federal and state environmental officials have ordered Dow Chemical Co. to scrub down 10 homes and properties along the Tittabawassee River that are victims of ''widespread dioxin contamination.''

The homes on Riverside are 10 to 20 yards from the river and flood more often than other homes in the floodplain, officials said.

Recent tests show dioxin levels at a home as high as 23,000 parts per trillion, more than 20 times higher than the state standard for mandated cleanups.

Boeing, Dow Chemical fined 926 million over nuclear pollution

A Denver, Colorado court has fined Dow Chemical Co. and Boeing Co. a combined 926 million dollars for property damages caused by plutonium contamination from a nuclear weapons plant.

The court set the fines in a judgement handed down late Monday after a jury found Dow and Rockwell International Corp, which Boeing bought parts of in 1996, responsible for damages claimed by thousands of property owners near the Rocky Flats (Colorado) Nuclear Weapons Plant in a trial that concluded in February 2006.

In the class action suit launched 18 years ago, some 12,000 plaintiffs accused Dow and Rockwell of allowing plutonium from the Rocky Flats plant to contaminate their property, especially residential areas downwind from it, endangering the residents' health and slashing their property values.

Kane's judgment arrived more than two years after a jury returned a verdict in the trial, which ended in Feburary 2006.

At the time, the federal jury decided the two contractors damaged land around the plant through negligence that exposed thousands of property owners to plutonium and increased their risk of health problems.

The court Tuesday fined Dow 653.3 million dollars and Boeing 508.1 million in compensatory damages, but then set a cap of 725.9 million dollars for both for compensating the plaintiffs, according to the ruling.

It also fined Dow 110.8 million dollars and Boeing 89.4 million in exemplary damages. 懲罰的賠償

Located about 25 kilometers (15 miles) northwest of Denver, the Rocky Flats plant was operated by Dow from 1953 to 1975, and then by defense contractor Rockwell until its closing in 1994; it supplied the plutonium triggers 起爆装置 for the US nuclear bomb arsenal.

Fires, equipment leaks and loose storage controls during that period were the sources of significant releases of plutonium and other radioactive substances.

In 1989 the Federal Bureau of Investigation and the US Environmental Protection Agency raided the plant over alleged environmental crimes, ultimately leading to its shutdown.

Dow Acquires Rohm and

Haas, Creating World’s Leading Specialty Chemicals and

Advanced Materials Company

$18.8 Billion Transaction Marks

Pivotal Point in Dow’s Transformation

Dow and Rohm and Haas today announced a definitive agreement, under which Dow will acquire all outstanding shares of Rohm and Haas common stock for $78 per share in cash. The acquisition of Rohm and Haas will make Dow the world’s leading specialty chemicals and advanced materials company, combining the two organizations’ best-in-class technologies, broad geographic reach and strong industry channels to create an outstanding business portfolio with significant growth opportunities.

* Rohm and Haas' equity at $15.3bn、taking on $3.5bn of Rohm and Haas debt.

The transaction marks a decisive move in Dow’s transformation into an earnings growth company with reduced cyclicality. Last December, Dow announced a joint venture with Petrochemical Industries Company of the State of Kuwait (PIC). With the collective impact of these two deals, performance products and advanced materials will represent 69 percent of Dow’s total sales, on a 2007 pro forma basis, compared with 51 percent prior to these transactions.

Financing for the acquisition includes an equity investment by Berkshire Hathaway and the Kuwait Investment Authority in the form of convertible preferred securities for $3 billion and $1 billion respectively. Debt financing has been committed by Citi, Merrill Lynch and Morgan Stanley who acted as financial advisors on the transaction.

* Billionaire Warren Buffett's Berkshire Hathaway group

Andrew N. Liveris, Dow

chairman and CEO, commented:

“The acquisition

of Rohm and Haas is a defining step in our transformational

strategy to shape the “Dow of Tomorrow”

- a high value,

diversified chemicals and materials company, creating the largest

specialty chemicals company in the United States with a leading

global position in performance products and advanced materials.

August 29, 2008 Dow Reichhold Specialty Latex

Dow Reichhold sells synthetic latex technology

Dow Reichhold Specialty Latex today announced the sale of nitrile butadiene synthetic latex product recipes, equipment and technology used in manufacturing dipped gloves to Bangkok Synthetics Co., Ltd. The sale is expected to close within 30 days. Dow Reichhold previously announced the cessation of all business activities and closure of its facilities before the end of 2008.

The assets purchased include process equipment located in Dow Reichhold plants in Chickamauga, Georgia, and Cheswold, Delaware. Bangkok Synthetics Co., Ltd. will relocate the equipment to Thailand.

August 19, 2008 Dow Reichhold Specialty Latex

Dow Reichhold announces site closures, plans to cease all business activities

Dow Reichhold Specialty Latex, a 50/50 joint venture between The Dow Chemical Company and Reichhold, Inc., has announced the planned sale of certain business assets, the permanent closure of all facilities, and the intention to cease all business activities before the end of 2008.

The Dow Chemical Company intends to buy back those business assets originally contributed by Dow at the time of constitution of the joint venture, and will service the respective customers directly in the future. The sale is expected to close within 30 days.

Dow Reichhold is also pursuing the sale of certain other business assets originally contributed by Reichhold to the joint venture.

Dow Exploring Divestiture Options for Clear Lake Operations Acrylic Acid and Esters and North American UCAR Emulsion Systems Specialty Latex Business

The Dow Chemical Company announced today that it is exploring divestiture options for its Clear Lake Operations acrylic acid and esters, and UCAR Emulsion Systems specialty latex business in North America. Dow has engaged J.P. Morgan to act as financial adviser in support of this effort.

The exploration of strategic options for the business is driven by Dow’s interest in proactively mitigating potential anti-trust issues associated with its previously announced acquisition of Rohm and Haas.

The business includes an acrylic acid and esters production plant located in Texas (Clear Lake), and UCAR Emulsion System specialty latex product plants located in Louisiana (St. Charles), Illinois (Alsip), California (Torrance) and a commercial and technical center in North Carolina (Cary). As divestiture options are considered, the business will continue to be sharply focused on effectively managing operations, competing in the market, delivering exceptional value to customers, and the safety of Dow employees.

UCAR Emulsion Systems (Dow Performance Chemicals部門)

UCAR Emulsion Systems develops, manufactures and sells UCAR acrylic, vinyl acrylic and styrene acrylic latexes, branched vinyl ester NEOCARTM latexes, and ethylene-modified EVOCARTM latexes. These products are used in the architectural coatings, adhesives, construction products, industrial coatings, textile, traffic paints, and paper markets. UES also produces and markets complementary UCARTM POLYPHOBETM Rheology Modifiers as well as sells CELLOSIZETM Hydroxyethyl Cellulose (HEC).

Dow Epoxy and Shanghai Tian Yuan Huasheng Sign Long Term Raw Materials Supply Agreements for Two Proposed Plants in Shanghai

Dow Epoxy, a business unit of The Dow Chemical Company (“Dow”), has signed long term raw materials supply agreements with Shanghai Tian Yuan Huasheng Chemical Co., Ltd. (TYHSC:上海天原華勝化工公司) for its planned 100,000 MTPA liquid epoxy resin (LER) plant in 2010 and 150,000 MTPA glycerine-to-epichlorohydrin (GTE) plant in 2011 at Shanghai Chemical Industry Park (SCIP).

TYHSC will provide caustic soda and anhydrous HCL for the LER and GTE plants at SCIP and receive recycled brine from Dow for chlor-alkali production. The total contract value over 10 years is in excess of US$400 million. TYHSC, a wholly-owned subsidiary of Shanghai Chlor-Alkali Chemical Co., Ltd. (SCAC), is the newly-built production base of SCAC at SCIP.

2008/11/13 Dow

Dow Announces Post Close Organization for Rohm and Haas

Advanced Materials Division

Marking Major Step in Dow’s Transformation to an Earnings

Growth Company

The Dow Chemical Company announced today the anticipated post

close organization for the previously announced Rohm and Haas

Advanced Materials Division, which will take effect following

the regulatory approval and close of Dow’s pending acquisition of Rohm and

Haas. Closing is targeted for early 2009. Pierre Brondeau,

currently president and chief operating officer of Rohm and Haas,

will lead the Rohm and Haas Advanced Materials Division of Dow.

* Coatings,

* Building and Construction,

* Paper and Textiles,

* Specialty Packaging and Films,

* Designed Polymers and Separation Technologies,

* Electronic Materials

December 01, 2008

Dow

Dow and PIC of Kuwait Sign Binding Joint Venture Agreement to

Launch K-Dow Petrochemicals

The Dow Chemical Company (Dow) and Petrochemical Industries

Company (PIC), a wholly owned subsidiary of Kuwait Petroleum

Corporation (KPC), today announced that they have signed the

Joint Venture Formation Agreement and other key definitive

agreements regarding the formation of K-Dow Petrochemicals, a 50:50

joint venture that will be the leading global

supplier of petrochemicals and plastics.

It is expected that the new company will begin operations

no later than January 1, 2009, with closing on that date as

articulated in the December 13, 2007 MOU announcement.

K-Dow will be a leading global supplier of essential

petrochemicals and plastics and will manufacture and

market polyethylene, ethyleneamines, ethanolamines, polypropylene

and polycarbonate, and will also license polypropylene technology

and market related catalysts.

Upon closing of the transaction, each shareholder plans to

receive a $1.5 billion special cash

distribution, paid by K-Dow.

The gross payment by PIC is expected to be approximately

$7.5 billion, with the net payment of $6 billion, including the special cash

distribution from K-Dow.

Dow expects to receive $9 billion in total pre-tax

proceeds related to the transaction. These proceeds include the

special cash distribution from K-Dow of $1.5 billion.

Dow and PIC also announced today that two of their existing 50:50 joint

ventures will be moved into K-Dow: MEGlobal, a world leader in

ethylene glycol, and Equipolymers, a supplier of PET resins.

K-Dow will have estimated sales of $11 billion and with the addition of MEGlobal

and Equipolymers the total annual revenue of K-Dow will be $15 billion.

Dec 04, 2008

Houston Chronicle

Dow will cut

production, contract jobs at Freeport complex

Dow Chemical Co. plans to slash production and cut contract

workers at its massive Freeport complex amid a recession-fueled

drop in demand for autos and other consumer goods that contain

the company's products, the company said Wednesday.

The largest U.S. chemical maker will cut output at the complex to

less than 40 percent of capacity from Dec. 15 to Jan. 5 and send

home a "significant portion" of its 4,000 contract

workers, said Tracie Copeland, a Dow spokeswoman in Freeport.

---

Platts 2008/12/4

Cutbacks at Texas City

were also expected although details were not available.

At Texas City, Dow has the capacity to producer 720 million

lbs/year of VAM and 150 million mt/year of chemical grade

propylene.

In Freeport, the company can manufacture up to 3.4 billion

lbs/year of ethylene; 560 million lbs/year of solution PE

(LLD/HDPE); 660 million lbs/year LDPE; 915 million lbs/year of

MEG; 1.267 billion mt/year of polymer grade propylene and 1.4

billion lbs/year of styrene monomer.

December 08, 2008 Dow Texas

Dow Accelerates

Implementation of its Transformational Strategy

New Streamlined Operating Model to

Reflect New Portfolio and Current Economic Realities

The Dow Chemical Company today announced a series of aggressive

actions to accelerate its transformational strategy in light of

current economic realities.

Dow’s transformation to a lean

Corporate Center, a shared Business Services group and three

business operating models, effective January of 2009, will

accelerate the Company’s ability to shed high-cost assets

and centralized functional structures. As part of the actions

announced today, Dow will eliminate approximately 5,000

full-time jobs,

close

20 facilities in high-cost locations and divest several

non-strategic businesses. The job reductions represent a

reduction of roughly 11 percent of Dow’s global workforce. Once fully

implemented, these actions are expected to result in $700 million

in annual operating cost savings by 2010 and are additional to

the previously announced cost synergies of $800 million in the

same timeframe for the anticipated Rohm and Haas acquisition.

In addition, reflecting poor current market conditions, Dow will temporarily idle

approximately 180 plants and significantly reduce its contractor

workforce worldwide by approximately 6,000 as predicated by reduced

operations.

“Transformation,

by definition, requires a commitment to working differently. We

are moving from a highly centralized and standardized approach,

to operating three very different business models with a lean and

efficient Corporate Center. Today’s restructuring is designed to

support the Dow of Tomorrow,” said Dow Chairman and CEO Andrew

N. Liveris. “However, we are accelerating the

implementation of these measures as the current world economy has

deteriorated sharply, and we must adjust ourselves to the

severity of this downturn.”

The new Dow will

comprise three different business operating models: Joint

Ventures/Asset Light;

Performance

Products;

and Health

& Agriculture, Advanced Materials and other Market Facing

Businesses.

Specific details on these business structures will be outlined

early next year.

December 24, 2008 Kuwait Times Statement of The Dow Chemical

Cabinet reviews Dow deal

The Cabinet discussed in

an extraordinary meeting yesterday the controversial

multibillion-dollar deal with US giant Dow Chemical and delayed a

final decision on the fate of the deal until today, informed

sources said. The council reviewed objections to the deal raised

by a large number of MPs and discussion focused on whether to

scrap the deal or go ahead with it.

MP Musallam Al-Barrak, spokesman of the Popular Action Bloc,

which threatened to grill the prime minister if the deal was not

scrapped before the start of next year, meanwhile accused unnamed

sides of trying to promote the deal. Barrak said in a statement

the attempts of those sides to secure a final approval to the

deal, which is against the interests of the Kuwaiti people,

"are known to all". He also demanded that members of

the Supreme Petroleum Council (SPC) who are "putting

pressure to secure the passage of the deal" should first

disclose their contractual relations with Kuwait Petroleum Corp

or its companies.

Controversy over the deal, which cost Kuwait $7.5 billion, has

widened as many MPs have backed a threat by the Popular Bloc to

quiz the prime minister if he does not scrap the deal before

January 1, when it officially becomes effective. Liberal MP Saleh

Al-Mulla criticized the statements of Oil Minister Mohammad

Al-Olaim about the deal, saying the minister has resigned and

should not issue statements on controversial issues. He said it

was illogical for a resigned government to speak about a huge

deal and the only party which has the right to do so is the next

Cabinet.

MP Abdulaziz Al-Shayeji called for handling huge projects like

the Dow Chemical deal, the fourth refinery and others with more

professionalism and transparency. He said the government should

carefully study the economic and investment feasibility of huge

projects and publish all information about them. If found

feasible and profitable, the government should go ahead with

them. Shayeji is a member of the Islamic Constitutional Movement,

to which the oil minister belongs.

Another ICM MP Jamaan Al-Harbash said that if the Dow deal is

found to be profitable and good for Kuwait, the government should

go ahead with it and if the contrary was true, it should be

scrapped immediately. But Harbash insisted that the deal should

not be scrapped only under political pressure, adding that there

will be political consequences for any decision the government

takes.

The oil minister said on Monday that the government will go ahead

with the deal despite opposition by MPs, adding that the deal

passed through proper channels and it was of strategic importance

for Kuwait. If the deal is not cancelled before the start of next

year, any party that withdraws from the deal is liable to pay a

penalty of up to $2.5 billion.

2009/1/5 The

Lubrizol Corporation

Lubrizol Acquires

Dow Thermoplastic Polyurethane Business

Expands

EstaneR Engineered Polymers Product Portfolio with Industry

Leading Brands

The Lubrizol

Corporation announced today that it has acquired the

thermoplastic polyurethane (TPU) business from The Dow Chemical Company, a $54 billion diversified

chemical company. This acquisition, structured as a sale and

purchase of assets, will expand Lubrizol’s Estane(R) Engineered Polymers

business. The Dow TPU business had 2007 revenues of approximately

$85 million. The deal closed on December 31, 2008.

Located in La

Porte, TX, Dow’s TPU product line spans the

continuum between elastomeric and rigid TPU properties. The two

key brands representing the business are:

Although Dow has

demonstrated proven product development capabilities, strong

customer relationships and a solid industry reputation over the

years, it has decided to exit its TPU business due to a re-focus

on investment priorities and the lack of a strategic fit.

About The Lubrizol

Corporation

The Lubrizol

Corporation is an innovative specialty chemical company that

produces and supplies technologies that improve the quality and

performance of our customers' products in the global

transportation, industrial and consumer markets. These

technologies include lubricant additives for engine oils, other

transportation-related fluids and industrial lubricants, as well

as fuel additives for gasoline and diesel fuel. In addition,

Lubrizol makes ingredients and additives for personal care

products and pharmaceuticals; specialty materials, including

plastics technology and performance coatings in the form of

specialty resins and additives. Lubrizol’s industry-leading technologies in

additives, ingredients and compounds enhance the quality,

performance and value of customers’ products, while reducing their

environmental impact.

With headquarters

in Wickliffe, Ohio, The Lubrizol Corporation owns and operates

manufacturing facilities in 19 countries, as well as sales and

technical offices around the world. Founded in 1928, Lubrizol has

approximately 6,950 employees worldwide.

January 08, 2009 Rohm and Haas

Rohm and Haas Updates Status of Regulatory Process for Pending Acquisition by the Dow Chemical Company

Rohm and Haas Company reported today that the European Commission has determined that the pending acquisition of Rohm and Haas by The Dow Chemical Company does not contravene EC competition law. With this decision, the transaction has obtained all necessary approvals in Europe.

The sole remaining regulatory clearance necessary for the transaction to close is that of the U.S. Federal Trade Commission.

Rohm and Haas Company continues to work diligently towards completing the proposed transaction with Dow in early 2009.

Jan. 16, 2009 Houston Chronicle

Dow Chemical begins layoffs, says it’s closing a Texas City unit

Dow Chemical Co. has

begun laying off workers in Texas and in other regions and will

close a third manufacturing plant in the state as part of a

corporate restructuring announced last month.

Layoffs started this week at all of the Midland, Mich.-based

chemical giant’s operations in Texas, where the

company employs 6,000 people at manufacturing sites in La Porte, Freeport, Texas City, Clear

Lake, Seadrift

and an administrative office in Houston, Dow spokeswoman Tracie Copeland

said.

Dow, the nation’s largest chemical maker, also

will shut down a production unit at its manufacturing complex in Texas City. The unit, which makes solution vinyl

resins, also called SVR, will close later this year, and

the company hopes to reassign its 58 workers, Copeland said. The

Texas City unit joins two plants at the Freeport complex - a styrene unit at Plant B and a chlor-alkali unit at Oyster Creek - also being

shuttered as part of the restructuring.

閉鎖するプラントはFreeport complex にあるSMプラント、クロルアルカリプラントと、Texas City 工場にある塩ビ・酢ビ共重合樹脂(SVR:Solution Vinyl Resin)プラント。

SVRプラントは年末までに閉鎖され、生産販売をやめる。この2、3年売上数量が激減しており、その結果コスト高となって損益が悪化している。

SVRはUCARのブランドで売られており、VYHH(塩ビ・酢ビ共重合樹脂)、VMCH(塩ビ・酢ビ・マレイン酸共重合樹脂)、VAGH(塩ビ・酢ビ・ビニルアルコール共重合樹脂)などがある。塗料・インキ・接着剤等に幅広く使用される。

ダウはこの事業の売却を検討していたが、3年前に売り上げが増加し、採算が向上したため、売却を取り止めた。

FTC Intervenes in Dow Chemical's $18.8 Billion Acquisition of Rohm & Haas

Commission Order Requires Divestiture of Acrylics and Other Industrial Chemical Assets to Preserve Competition

Dow Chemical Company has settled Federal Trade Commission charges that its proposed $18.8 billion acquisition of rival chemical manufacturer Rohm & Haas Company would be anticompetitive and would violate federal law. Under the proposed consent order allowing the transaction to proceed, Dow will sell a range of assets to an FTC-approved acquirer, including its acrylic monomer, hollow sphere particle, and acrylic latex polymer businesses. Dow also must put procedures in place to ensure it does not have access to competitively sensitive non-public information regarding any businesses it acquires from Rohm & Haas.

“Dow and Rohm & Haas are direct and significant competitors in certain markets for acrylics and other industrial chemicals used to make coated paper products, paints, and adhesives,” said David P. Wales, Acting Director of the FTC’s Bureau of Competition. “The FTC consent order announced today will ensure that consumers continue to benefit from competition in the markets for these important products and will not face the prospect of higher prices as a result of the acquisition.”

According to the Commission’s complaint, Dow’s proposed acquisition of Rohm & Haas would reduce competition in the North American markets for the research, development, manufacture, and sale of certain acrylic monomers - including glacial acrylic acid, butyl acrylate, and ethyl acrylate - as well as hollow sphere particles and acrylic latex polymers for traffic paint used to mark lines on streets and highways.

Each of the relevant acrylic monomer products is made from crude acrylic acid. Glacial acrylic acid is used in the production of super-absorbent polymers which are used in personal care and hygiene products. Butyl acrylate and ethyl acrylate are acrylate esters used to make the latex polymers that are used in paints, architectural coatings, and pressure-sensitive adhesives. Hollow sphere particles are a type of specialty polymer used in the manufacture of coated paper to provide gloss, brightness, and opacity. Acrylic latex polymer for traffic paint is a quick-drying polymer used to mark highway traffic lines.

The FTC contends that each of the relevant product markets is highly concentrated and that the proposed acquisition would lead to fewer competitors in each market. For the acrylic monomer markets, the deal would reduce the number of significant competitors from four to three, with the combined Dow/Rohm & Haas having a significant share of each market. The combined firm would have a more than 40 percent share in the market for glacial acrylic acid; a nearly 75 percent share in the market for butyl acrylate; and a nearly 90 percent share in the market for ethyl acrylate. The markets for hollow sphere particles and acrylic latex polymer for traffic paint are even more concentrated, the complaint states, as Dow and Rohm & Haas currently are the only two suppliers. In those markets, the proposed acquisition would be a merger to monopoly.

Finally, the complaint alleges that the proposed acquisition would eliminate direct and substantial competition between Dow and Rohm & Haas in the relevant markets, reducing competition and increasing Dow’s ability to exercise market power unilaterally. The complaint also alleges that the proposed transaction would increase the likelihood of coordinated interaction for glacial acrylic acid, butyl acrylate, and ethyl acrylate. New entry or fringe expansion in these markets is unlikely to counteract the alleged anticompetitive impact of the acquisition.