トップページ

計画名 : The

Nanhai project Back

Shell

inks deal for $4-bil petchem complex in China

日揮など3社、総額1000億円受注

Bechtel consortium set to

manage Nanhai project

2005年6-7月にも誘導品の試運転

First

over-the-fence sales agreement signed with Huizhou MMA

Co. Ltd. (恵州恵菱化成有限公司)

CNOOC associates with

WorleyParsons to build 12 million tonne refinery in Daya

Bay

CNOOC’s

Huizhou Refining Project Starts Construction 恵州

CNOOC and Shell Nanhai

petrochemicals complex moves into start-up phase

Successful start up of

CSPCL complex, Daya Bay

CNOOC and Shell to expand

capacities in Daya Bay

中海シェル石油化学、エチレン増設が完成

JV名 : CNOOC

and Shell Petrochemicals Company Limited

(中海シェル石油化学)

当事者: Shell Nanhai BV 50%

CNOOC

Petrochemicals Investment Limited (CPIL) 50%

↓

CNOOC (China

National Offshore Oil Corporation) 90%

Guangdong

Investment and Development Company 10%

原料: ナフサ、コンデンセート(カタール)

生産開始予定: 2006年初め

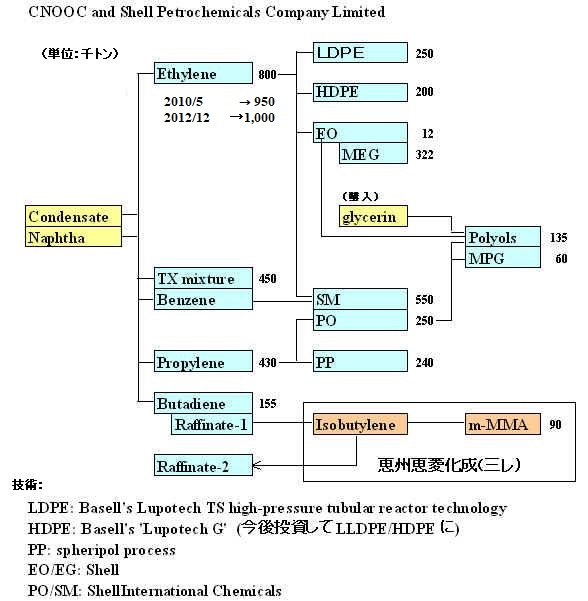

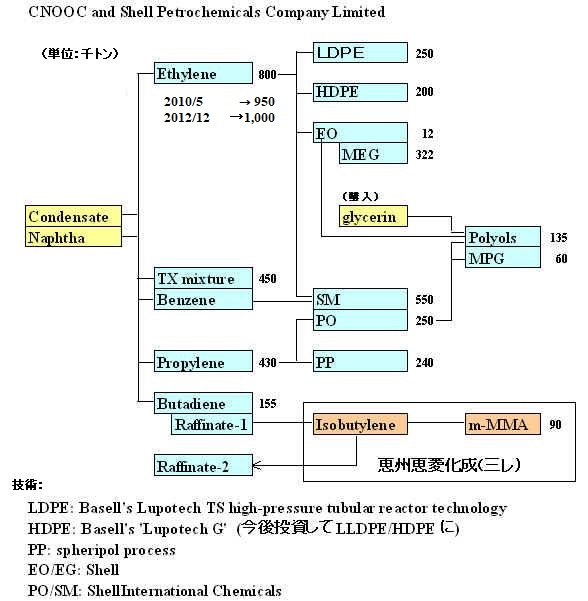

計画能力 (単位:トン):

Product

|

|

増強計画

|

|

|

→ 950

|

|

|

:

|

|

|

:

|

|

|

:

|

|

|

:

|

|

|

:

|

|

|

:

|

Styrene monomer

|

560

|

:

|

Polyols

|

185

|

:

|

Monopropylene

glycol

|

60

|

:

|

Monoethylene

glycol

|

320

|

:

|

立地: 広東省(恵州市)大亜湾 Daya Bay Economic and Technical Development Zone

(Shell Homepage)

http://www.shellchemicals.com/corporate/1,1098,967,00.html

The joint venture partners - Shell Nanhai BV and CNOOC

Petrochemicals Investment Limited - will build, own and

operate a USD4billion petrochemicals complex in Daya Bay,

south east China. They will also market the resulting

products, primarily into the domestic market.

Project partners

The project will be a 50:50 joint venture between:

Shell Nanhai BV, a

member of the Royal Dutch/Shell Group of Companies

CNOOC Petrochemicals

Investment Limited (CPIL)

90% of CPIL is owned by the

major state-owned oil and gas enterprise CNOOC (China

National Offshore Oil Corporation) and 10% by Guangdong

Investment and Development Company, an investment company

authorised by the People's Government of Guangdong Province

Location

The Nanhai complex will be built in the Daya Bay Economic and

Technical Development Zone, in the Guangdong Province in

southern China. This is an area of growing economic and

industrial activity, some 80 kms north east of Hong Kong

Island.

Project scope

Platts 2002/10/31

Shell inks deal for $4-bil petchem

complex in China

China National Offshore Oil

Corp and Shell Friday inked a deal to set up a $4.3-bil

petrochemical complex in the Daya Bay Economic and Technical

Development zone in Guangdong province, a company release

said.

2003/6/5 Asia Chemical

Weekly

BSF set to manage Nanhai project

Shell Chemicals and China National Offshore Oil Corporation

(CNOOC) has appointed the BSF consortium, comprising Bechtel,

Sinopec Engineering and Foster Wheeler, to carry out the

project management on the $4.3bn Nanhai petrochemical complex

in China.

| 2004年11月19日 Chemnet

Tokyo |

| 中国の中海シェル石油化学(CSPC)、来年6-7月にも誘導品の試運転 |

| |

(上海発=特約)

シェルと中国海洋石油(CNOOC)の50/50 合弁会社の中海シェル石油化学(CSPC)は来年11月に80万トン/年のエチレン設備をスタートさせる予定だが、これに先立ち誘導品の試運転を来年6ー7月に行うことが明らかになった。

CSPCのコンプレックスは広東省恵州市の大亜湾で建設されているが、誘導品としてはSM 55万トン/PO 25万トン、LL/HDPE 20万トン、LDPE25万トン、PP 24万トン、MEG 32万トンなどがある。エチレン完成までの間は原料のオレフィンは外部から購入する。

80万トン/年のエチレン設備は当初は輸入コンデンセート(天然ガスの採取・精製の過程で得られる常温・常圧で液体の炭化水素)を原料として使用する。中国海洋石油の12百万トン/年のリファイナリー完成後はナフサに切り替える。

関係者によると、シェル技術ではクラッカーは重質油からナフサまで幅広い原料を使用できる。公称能力は80万トンだが、改造なしで100万トン以上のエチレンを生産できるという。

|

2005/9/3 Asia Chemical

Weekly

CNOOC associates with

WorleyParsons to build 12 million tonne refinery in Daya Bay

China National

Offshore Oil Corporation (CNOOC) has sign a deal with Australian

engineering firm -WorleyParsons- to build the USD 2.1 billion (17

billion yuan) refinery in Daya Bay, Huizhou, Guangdong Province.

CNOOC has awarded a USD35 million contract to WorleyParsons, and

the latter will provide integrated project management team (IPMT)

services for CNOOC's big refinery, which is adjacent to the

Complex of CNOOC/Shell Petrochemicals Company

(CSPC)

in Daya Bay.

The refinery will have oil processing capacity of 12 million

tonne/year (250,000 barrels/day), and the feedstock of crude oil

would be sourced from CNOOC's Penglai offshore

field in Bohai Bay.

CNOOC get the final approval from government for this refinery

project in the mid of last year, and it is the company's first

refinery in China. The refinery was planned to provide the

naphtha feedstock for CSPC's 800, 000 tonne/year ethylene

cracker.

The CSPC's cracker is expected to start up by the end of this

year, and it will use condensate as feedstock until the CNOOC's

refinery starts up and provides naphtha.

Currently, the design work is underway, and the refinery is

expected to start construction in the end of 2005 and to come

onstream in H1 of 2008.

China Chemical

Reporter 2005/12/15

CNOOC’s Huizhou Refining Project

Starts Construction 恵州

On December

15th, 2005 the 12 million t/a refining project of Nanhai

Petrochemical solely funded by China National Offshore Oil

Corporation (CNOOC) held a ceremony for its groundbreaking

and started construction in Petrochemical Zone of Daya Bay

Economic and Technology District, Huizhou恵州, Guangdong province with the

investment of RMB19.3 billion. Approved on August 3rd, 2004,

the project will be completed and conducted wet commissioning

in June 2008.

With the capacity of 12 million t/a processing

offshore high acid-content heavy crude oil, the large refining project

will manufacture mainly petrochemical products such as

qualified gasoline, kerosene, diesel oil, and raw material

for ethylene cracking (1.5 million t/a), p-xylene (800 000

t/a) etc.

2005/12/30 Shell

CNOOC and Shell Nanhai

petrochemicals complex moves into start-up phase

2005/12/30

CNOOC and Shell Petrochemicals Company Limited

Largest Capital

Investment for a Sino-foreign joint venture Project in China

---CNOOC and Shell Nanhai petrochemicals complex moves into

start-up phase

2006/2/10 CNOOC and

Shell Petrochemicals Company

Successful start up

of CSPCL complex, Daya Bay

CNOOC and Shell Petrochemicals Company Limited (CSPCL) today

announced it successfully produced on-specification ethylene

and propylene on 29th January, 2006 at its petrochemicals

complex in Daya Bay in Huizhou, Guangdong Province in China,

following the completion of start-up and commissioning

activities.

This marks another major milestone in the start-up phase of

the world-scale cracker project, jointly owned by CNOOC

Petrochemicals Investment Company Limited and Royal Dutch

Shell (Shell) since the project final investment decision was

taken in November 2002.

"We are all very excited and pleased with the quick

progress to on-specification ethylene and propylene

production since our previous announcement of construction

completion on December 30," Mr Simon Lam, Chief

Executive Officer of CSPCL said.

"This is testimony to the capability of the people of

CSPCL and our contractors who have worked in excellent

partnership to achieve this." he added.

With the successful production of C2/C3, the start up of

downstream units will follow.

2008/4/15 Asia Chemical

Weekly

CNOOC and Shell to expand

capacities in Daya Bay

China National Offshore Oil Corporation (CNOOC) and Shell will

expand the petrochemical capacities in Daya Bay, Huizhou,

Guangdong Province.

According to the industrial sources, CSPC - the jv between CNOOC

and Shell, will expand the ethylene capacity to 1.1 million

ton/year

from the currently 800,000 ton/year at the end of 2009, by adding

investment of USD100 million.

その後、95万トンに修正

At the same time, CNOOC

plans to build another 12 million refinery in Daya Bay, make the total

refining capacity up to 24 million ton/year, so as to provide

sufficient crack feedstock for the ethylene project and more

refined oil products to the fuel-lacked Guangdong Province. In

Nov. 2007, the Huizhou local government officers held a meeting

with Shell in London, at that time, Shell had expressed interests

to join the second refinery in Daya Bay.

The first refinery in Daya Bay, invested solo by CNOOC, has 12

million ton/per year capacity, which is under construction and it

is expected to start up by October 2008.

Before CSPC, Shanghai based SECCO and Nanjing based YPC-BASF have

announced the cracker expansion plans. SECCO has planed to expand

ethylene capacity to 1.1 million ton/year from the currently

900,000 ton/year and is expected start up in Sep. 2009. YPC-BASF has planned to expand

ethylene capacity to 750,000 ton/year from 600,000 ton/year by H2 2009 or H1 2010.

The SECCO's expansion

project is under the environmental assessment, which is an

important stage in the project preparing. Besides ethylene

from 900,000 ton/year to 1.1 million ton/year, the BTX

capacity will be expanded to 600,000 ton/year from 500,000

ton/year. SM capacity will be expanded to 650,000 ton/year

from 500,000 ton/year.

2010/5/25 上海

中海シェル石油化学、エチレン増設が完成

シェルと中国海洋石油(CNOOC )のJVの中海シェル石油化学は5月21日、広東省恵州市大亜湾のエチレンクラッカーの増設が完成したと発表した。

同社はエチレン能力を現行の80万トンから95万トンに増やした。(既報の110万トン計画から修正)

また、EO/EGとSM/POも増強したが、詳細は発表されていない。

(業界筋の未確認情報では、MEGは32万トンから40万トンに、SMは55万トンから75万トンに、POは25万トンから34万トンに、それぞれ増強)

増設工事は2009年5月にスタートし、本年4月に完成した。

中海シェル石油化学のほか、上海のSECCO(BP、シノペック、上海石化)は2009年にエチレンを90万トンから119万トンに増強しており、南京のBASF-YPC

(BASF、シノペック)も2010年に60万トンから74万トンに増強する。

December 17, 2015 Fibre2Fashion News

Shell & CNOOC JV to build another ethylene cracker 中海シェル石油化学(CNOOC

and Shell Petrochemicals)

Shell Nanhai B.V. and China National Offshore Oil Corporation (CNOOC) who

operate a 50:50 JV will develop additional chemicals facilities next to the JV's

existing petrochemical complex, including an ethylene cracker.

“The agreement includes the ongoing construction of an

ethylene cracker and ethylene derivatives units, including a

styrene monomer and propylene oxide (SMPO/PDO)

plant,” a Shell press release stated.

“The new cracker will increase Nanhai's ethylene production capacity

by over 1 million tons per year, about

double its current capacity,” it said.

“The expansion of the Nanhai petrochemical complex supports the Chinese

long-term petrochemicals strategy,” said Yang Hua, chairman of CNOOC.

“We are delighted that Shell will contribute to the project and our joint

venture with industry-leading technology to produce petrochemicals for China's

growing domestic markets,” Hua added.

Shell will apply its proprietary Omega and Smpo/Pod

technologies to produce ethylene oxide and ethylene glycol, increasing

volumes and range of Nanhai's high quality products.

Ben van Beurden, CEO of Royal Dutch Shell said, “This agreement demonstrates our

confidence in the Shell-CNOOC partnership and our ongoing commitment to China,

after over 100 years of Shell operations in country.”

“It also underlines our confidence in the strong growth potential for chemicals

in China and we look forward to further collaborations with CNOOC and growing

together with all our business partners,” he too added.

CNOOC has already begun construction of the new petrochemical complex and

commercial production from the new facilities is expected in around two years'

time.

The expansion would increase the total ethylene production at the Nanhai

petrochemical complex to around 2 million tons per year.

The site, with a strong track record of reliable and safe operations, converts a

variety of liquid feedstocks into ethylene and derivative products. (AR)

Several linked derivative units have also started up and the

remaining units will start up progressively over the next

few weeks. These new units were constructed by CNOOC and are

owned and operated by the existing

CNOOC and Shell Petrochemical Company (CSPC) joint venture.

| 第一期

2006/1 Phase I

project started up

2010/5 ethylene cracker debottlenecked

800,000 tpa → 950,000 tpa

2012/12 ethylene output exceeded

1,000,000 tpa

|

第二期

2018/5 start-up

Ethylene

1,200,000 tpa

SMPO

SM 630,000 tpa

PO 300,000 tpa

Ethylene oxide

150,000 tpa

Ethylene glycol

480,000 tpa

High quality

polyols 600,000 tpa |

The new ethylene cracker

increases ethylene capacity at the complex

by around 1.2 million tonnes

per year, more than doubling the capacity of the complex,

and benefits from a deep integration with adjacent CNOOC

refineries. The new facility will also include a

styrene monomer and propylene oxide (SMPO)

plant, which will be the largest in China when it

begins operations.

“The start-up of the new

ethylene cracker and derivatives units is a significant

milestone for Shell,” Graham van’t Hoff, Executive Vice

President for Royal Dutch Shell plc’s global Chemicals

business, said. “I would like to thank our partner CNOOC for

its excellent project delivery. As the largest single-site

ethylene complex in China, CSPC is key to Shell Chemicals’

growth ambitions.”

He Zhongwen, Chairman and

President of CNOOC Oil & Petrochemicals Co. Ltd, said: “The

expansion project demonstrates great synergies between

CNOOC’s engineering, construction and management

capabilities, and Shell’s advanced technologies in

chemicals. It has been recognised by the government as a

role model for major industrial projects in China. This

shows what we can achieve through effective international

partnerships. We can now produce more and better chemical

products for the growing domestic market.”

The new complex utilises

Shell’s proprietary OMEGA, SMPO and polyols technologies to

produce ethylene oxide, ethylene glycol, propylene oxide and

high-quality polyols, as well as advanced technologies for

polyolefins, phenol and oxo-alcohols production. It is the

first time that Shell’s industry-leading OMEGA and advanced

polyols technologies have been applied in China.

With a strong track

record of reliable and safe operations, the petrochemicals

complex produces olefins and derivative products that are

used in a wide range of industrial and consumer products,

including household appliances, cars, furniture and

computers.

The new cracker is

world-scale, and adds more than 1 million tonnes per annum

ethylene capacity to produce high-value petrochemical

products.

The complex benefits from

deep integration with the adjacent CNOOC refineries.

The expansion enables further monetization of

advantaged feedstock from nearby CNOOC refineries,

responding to the anticipated strong Chinese domestic demand

in the long term.

Mar 22, 2016

CNOOC and Shell take

final investment decision to expand petrochemical

complex in China

China National Offshore Oil Corporation (CNOOC) and

Shell Nanhai B.V. today announce the final

investment decision to expand CNOOC and Shell

Petrochemical Company’s (CSPC) existing 50:50 joint

venture (JV) in Huizhou, Guangdong Province, China. This

decision follows the announcement of a Heads of

Agreement in December 2015 between the two partners.

Subject to regulatory approvals, CNOOC and Shell have

agreed that CSPC should take over CNOOC’s ongoing

project to build additional chemical facilities next to

CSPC’s petrochemical complex.

The project includes the ongoing construction of a new

ethylene cracker and ethylene derivatives units, which

will increase ethylene capacity by more than 1 million

tonnes per year, about double the current capacity. It

will also include a styrene monomer and propylene oxide

(SMPO) plant, which will be the largest such plant ever

built in China.

Shell will apply its proprietary

OMEGA, SMPO and polyols technologies to produce

150,000 tonnes per annum (tpa) of

ethylene oxide, 480,000 tpa

of ethylene glycol and

600,000 tpa of high quality polyols. This

increases the volumes and diversity of CSPC’s high

quality product range to around 2 million tonnes per

year, as well as enhances overall energy efficiency. It

will be the first time that Shell’s industry-leading

OMEGA and advanced polyols technologies will be applied

in China.

Nov 2, 2016

Shell will apply

its proprietary OMEGA, styrene monomer and propylene

oxide (SMPO) and polyols technologies to produce

150,000 tonnes per annum (tpa) of ethylene oxide,

480,000 tpa of ethylene glycol,

630,000 tpa of styrene

monomer, 300,000 tpa of propylene oxide, and

600,000 tpa of high quality polyols. This more than

doubles the volumes and range of CSPC’s high quality

products to around 6 million tonnes per year. It

will be the first time that Shell’s industry-leading

OMEGA and advanced polyols technologies are applied

in China.

The CSPC site, which

has a strong track record of reliable and safe

operations, currently converts a variety of liquid

feedstocks into olefins and derivative products. These

are used in a wide range of consumer goods, including

computers, plastic bottles and washing liquids.