Lanxess Bayer/Lanxess

| 2005/11/9 Lanxess サルティゴ(Saltigo) - ハイテック化学の新しい名前 ランクセスの精密化学品のスピンオフが始まる ビジネスユニット精密化学品は、新名称、新方向、そして新ビジネスモデルで、別法人として 来年 ランクセスから独立する。 「2006 年の第2四半期以降、世界中に私たちの精密化学品の専門知識を、ランクセスの全額出資子会社であるサルティゴ(Saltigo)から販売します。」と、ビジネスユニット精密化学品の責任者であり、サルティゴ(Saltigo)の代表取締役に任命された、アクセル ヴェスタハウス博士が マドリッドで開催された精密化学品において権威のある国際医薬品原料・中間体見本市で、述べた。 社員によって提案されたサルティゴ(Saltigo)の名前は、イタリア語で“飛ぶ“という意味の”saltare”を基に、活力に満ちた成功した未来への躍進ということを意味する。 サルティゴ(Saltigo)は、医薬品、農薬、特殊化学製品分野の顧客の為の受託ソリューションを開発、製造、販売する。 LANXESS plans package of measures to speed development at Saltigo |

Bayer sets allotment ratio for Lanxess shares at 10 to 1

LANXESS sees itself as an independent company that is well-positioned for the future

Lanxess closes rubber, fiber plants at Marl, Goch, Germany

Chinese JV for antioxidants for the rubber industry

Restructuring in fine chemicals and styrenic resins business units of Lanxess

Lanxess to cut jobs and restructure styrenics

Important element of second package of restructuring measures negotiated (NBR in France)

LANXESS subsidiary Rhein Chemie to consolidate U.S. production in Chardon, Ohio

LANXESS invests more than EUR 20 million in new capacities in Germany

LANXESS opens engineering plastics compounding plant in China

LANXESS expands compounding capacities for high-tech plastics in China

LANXESS'Styrenic Resins has a new name: Lustran Polymers

Lanxess opens the new European headquarters of Lustran Polymers in Spain

LANXESS invests in chloroprene rubber

LANXESS realigns its EPDM rubber business

LANXESS invests in new site in China

"LANXESS has not made an offer for Degussa"

LANXESS increases capacities for EPDM rubber

LANXESS opens new plant in China

Lanxess is prepared to pay 4-6 bln eur for Degussa

LANXESS and Hankook Tire sign long-term supply contract of SBR and polybutadiene rubber

LANXESS projects significant new investment in butyl rubber in Asia

INEOS agrees joint venture with LANXESS to operate the ABS plastics business

LANXESS builds new ion exchange facility in India

Lanxess invests Eur10 million in Dormagen EVA copolymer

Lanxess walked away from talks to buy Petroflex of Brasil

LANXESS' new segment structure

LANXESS to produce up to 100,000 tpa of butyl rubber in Singapore

LANXESS makes first acquisition of pigment plants in China

LANXESS opens Rubber Research Center in Qingdao

Lanxess: Reported bid for DSM's EPDM division

LANXESS responds to global economic crisis and shifts investments

LANXESS Acquires Polyol Specialist in China

LANXESS divests Chinese joint venture stake

Lanxess in talks to buy rubber group Eliokem

LANXESS: new Jhagadia site up and running

LANXESS starts up new plant for ion exchange resins in India

LANXESS and TSRC to create rubber joint venture in China

LANXESS expands capacity of butyl rubber plant in Belgium

LANXESS: Largest Leather Chemicals investment in China ever

LANXESS to acquire DSM Elastomers

LANXESS produces five millionth metric ton of caprolactam

LANXESS steps up commitment to biobased raw materials

LANXESS Acquires Syngenta’s Material Protection Business

LANXESS selects Singapore as site for world’s largest Nd-PBR plant

LANXESS to break ground in Singapore for world’s largest Nd-PBR plant in September, 2012

Lanxess in talks about acquiring Taminco

LANXESS to produce first bio-based EPDM rubber in the world

LANXESS to expand its EPDM operations in the Netherlands

LANXESS strengthens commitment to Brazilian automotive sector

LANXESS strengthens global phthalate-free plasticizer portfolio

LANXESS strengthens commitment to renewable raw materials with investment in BioAmber

LANXESS strengthens its butyl rubber site in Belgium

LANXESS starts up new nitrile butadiene rubber plant in China

LANXESS builds new plant for polyamide in Belgium

LANXESS to build world’s largest EPDM plant in China

| British Plastics &

Rubber September 17, 2006 Lanxess says it's time to stop consolidating and to start expanding Lanxess

has formally launched itself on the acquisition trail.

After 18 months of

consolidation since it was created from a

group of businesses not fitting with the new Bayer life

sciences image, Lanxess has declared

itself not only seeking acquisitions, but able to spend a

lot of money. |

New joint venture

strengthens business in China

LANXESS in China ー managing chemistry

Weifang: New site sets LANXESS on course for growth

http://www.press.bayer.com/News/News.nsf/id/665C2EC35E473A22C1256F1C0036B14E

Bayer AG has

reorganized practically all of its chemicals operations and large

parts of its polymer activities into a new company called LANXESS, which is subject to the

approval of Bayer AG's stockholders'

meeting, will

be spun off and its shares will be distributed to the existing

shareholders of Bayer AG.

Aiming for success with clear objectives - in China and

worldwide

The LANXESS

Shanghai Pigments Company manufactures color pigments in Shanghai

for use in the Chinese construction and paint industries.

Bayferrox® and chrome oxide pigments

for coloring a diverse range of products, such as concrete parts,

roofing tiles, paints and coatings, plastics, paper and special

pigments for toners and other applications, have been proving

their mettle for many years now. The products offer high

standards of quality as well as being simple and environmentally

friendly to process.

In 1999, the Rhein

Chemie (Qingdao) Ltd. began producing additives for the rubber

and mineral oil industries. Lubricant additives, for example, are

used everywhere where there is a need to prevent friction,

frictional heat and wear and to protect material against

corrosion. Rhein Chemie has established itself in the lubricant

industry as one of the leading additive manufacturers for

industrial lubricants.

Today the leather business unit has the highest sales volume

amongst all the business units of LANXESS in China. The company

offers its customers cutting-edge products and technologies

coupled with application-specific expertise. The LANXESS Wuxi Leather

Chemicals Company, founded in conjunction with the Wuxi

Dyestuff Factory, has been producing leather chemicals since 1998

in Wuxi, north-west of Shanghai.

LANXESS - Top company in a growth market

A joint-venture

company is therefore to be set up in collaboration with the Weifang

Yaxing Chemicals Company in Beijing on September 28, 2004. This is

a further instance of LANXESS' concept of flexible, goal-focussed

management of the chemicals business. The purpose of the joint

venture is to manufacture hydrazine hydrate, whose market is

currently enjoying annual growth rates running into double

figures. ヒドラジン水和物

With its

involvement in Weifang LANXESS (* LANXESS Yaxing

Chemical (Weifang) Company Ltd. )expects to become one of the leaders on

the Chinese hydrazine hydrate market for three reasons: "We

will have a production unit with very high capacity, we will

offer the best quality and we also will be way out in front in

terms of process engineering," said Wang Yongli, President

of the LANXESS Chemical Company in China.

Weifang - a viable location with a strong partner

Weifang Yaxing Chemicals Company is an ideal joint-venture

partner for manufacturing top-quality hydrazine hydrate. And

Weifang is also the perfect location for such a facility. For

this reason, LANXESS

will transfer its hydrazine hydrate plant from its site in

Baytown, Texas, USA, to Weifang, which is intended to begin supplying the

Chinese and international market from the end of 2005.

September 28,

2004 Bayer WEIFANG :山東省維坊

Weifang Yaxing Chemical :維坊亜星化学

LANXESS

intensifies operations in China

New chemicals joint venture

http://www.press.bayer.com/News/News.nsf/id/1EF7B0C599FD6CBEC1256F1C0036567A

Leverkusen-based

chemicals company LANXESS and the Weifang Yaxing Chemical Company

Ltd. of Weifang are founding a joint-venture company to

manufacture hydrazine hydrate, an intermediate for the chemical

industry. Hydrazine hydrate is used by the agro and the

pharmaceutical industry as well as for the production of plastic

additives and for water conditioning. LANXESS will own 55

percent,

meaning the Weifang

Yaxing Chemical Company's stake will be 45 percent.

"We're looking to achieve concerted growth in China,"

says Dr. Axel C. Heitmann, Chairman of the LANXESS Board of

Management. "And we're collaborating with expert partners in

order to reach this goal. It means we can cost-effectively tap

into new markets and develop existing market positions without

having to make large investments."

LANXESS: Top company in a growth market

Partnering for better performance

The joint-venture company will be called LANXESS Yaxing Chemical

(Weifang) Company Ltd. and headquartered in Weifang in Shandong

province, China. Dr. Ming Guang Chen of LANXESS is the designated

general manager of the new company.

LANXESS has over 550 employees in Mainland China and Hong Kong

and currently three production facilities in Shanghai, Qingdao,

Wuxi and a soon to count Weifang among these sites.

Backgrounder

hydrazine hydrate

http://www.press.bayer.com/News/News.nsf/id/582F040BBF07537AC1256F1C0033676F

Hydrazine hydrate

is a colorless liquid with a smell similar to ammonia. The

substance was synthesized for the first time by German chemist

Julius Wilhelm Theodor Curtius in 1887. He had his discovery

patented in Germany and the USA.

Hydrazine hydrate is sold in different concentrations. The

LANXESS Yaxing (Weifang) Chemicals Company Ltd. production

facility will be capable of manufacturing 64 %, and therefore the

best quality hydrazine hydrate. With the launch of production in

Weifang, it will be the only plant in China to produce hydrazine

hydrate of this quality.

The possibilities for use and potential application areas of this

inorganic substance as an intermediate for the chemicals industry

are extremely varied. Hydrazine hydrate is used by the agro- and

pharmaceutical industry as well as for the production of plastic

additives.

It is used as an intermediate for chemical synthesis and, for

example, for the production of azodicarbonamide, a blowing agent

for the foaming of plastics. Foam plastics are processed in many

consumer goods as for shoes, furniture and cars.

The pharmaceuticals industry requires hydrazine hydrate to

manufacture medicines, including those for the treatment of TB,

forms of depression and hypertension. And for crop protection

products, hydrazine is a vital intermediate for growth

regulators, for instance.

A further important application for hydrazine hydrate is

corrosion protection in closed water circuits. As an antioxidant,

it protects pipes from rust and premature aging, particularly in

the steam circuits of the power industry, thus significantly

increasing plant reliability.

Bayer 2004/10/6

Bayer sets allotment ratio for Lanxess shares at 10 to 1

http://www.press.bayer.com/news/news.nsf/id/2004-0591

- Stockholders to

vote on the spin-off on November 17

- Lanxess issues EUR 200 million mandatory convertible bond to

Bayer

In connection with the planned spin-off of new chemical company

Lanxess, stockholders of Bayer AG will be granted one Lanxess

share for every ten Bayer shares that they hold. This is provided

for in the Spin-Off and Acquisition Agreement to be voted on at

an Extraordinary Stockholders' Meeting in Essen on November 17.

Lanxess

net debt EUR 1.5 billion

Lanxess will have net debt of approximately EUR 1.5 billion,

including pension commitments, when the spin-off takes effect.

The financial liabilities to the Bayer Group are to be redeemed

by drawing on a syndicated credit line. This EUR 1.0 to 1.5

billion credit line will consist of a short-term and a long-term

tranche.

Trading

relationship will continue

Bayer and Lanxess will continue to trade with each other despite

their separation, with supply and service agreements running for

between one and seven years. Some of these agreements include

exclusive supply relationships, especially for strategically

important products.

日本経済新聞 2004/11/26夕刊

独バイエル 化学子会社を完全分離 来年1月上場 事業絞り込み

独バイエルは25日、化学事業子会社ランクセスの株式を来年1月に上場させると発表した。バイエルは化学に加え、医薬などヘルスケア、農業化学、素材科学の4事業による分社経営だが、ランクセスヘの出資をゼロにして完全分離。医薬など高付加価値事業に絞ってグループ経営を進める。

化学は自動車と並ぶドイツの基幹産業で、第二次大戦後は化学・医薬兼業のBASFとヘキスト、バイエルの三大総合化学メーカー体制が続いてきた。だが、ヘキストは仏社と合併して仏バイオ大手のアベンティスに変身。BASFは医薬部門を売却して化学専業となった。今回バイエルが医薬などに特化することで、ドイツの総合化学時代は名実ともに終わる。

LANXESS sees

itself as an independent company that is well-positioned for the

future

http://mediarelations.lanxess.de/lanxess/lnxnews.nsf/752d3bba3f96c9a8c1256e63003f4426/6f3c9a5109a2ac46c1256f57002be8bc/$FILE/2004-0708E.rtf

・ Major European chemicals producer makes

competitiveness and earnings power elements of its core strategy

・ Sales in first nine months grow 4.5

percent to EUR 5.0 billion

・ EBITDA margin increases to more than 7

percent

・ First investments announced

A new global company presents itself to the public today: formed

from the chemicals arm and some of the polymers activities of

Bayer AG, LANXESS will begin operating as an independent company

at the start of 2005. A completely new company with some 20,000

employees, its own corporate structure and 2003 sales of EUR 6.3

billion (based on the combined financial statements) has been

created in record time since the decision was taken to spin off

these operations in November 2003.

LANXESS has four segments, each of which already reports annual

sales of well over EUR 1 billion. The Performance Rubber segment specializes in solid

rubber for the rubber and tire industries. LANXESS is thus a

leading partner to the global tire industry.

Engineering

Plastics

focuses on the production of high-quality plastics for electrical

and electronics appliances, furniture, sports and leisure

applications and automotive engineering.

The Chemical

Intermediates segment comprises basic chemicals, intermediates

for the pharmaceuticals and crop protection sectors and inorganic

pigments for coloring concrete and coatings.

Performance

Chemicals is

a classic area of the specialty chemicals business. Its portfolio

comprises material protection products, processing chemicals for

leather, textiles and paper, ion exchange resins, polymer

additives such as flame retardants.

Platts 2004/12/25

Lanxess closes rubber, fiber plants at Marl, Goch, Germany

Lanxess announced Thursday it has closed down two plants in

Germany as part of a major restructuring program to save Eur25-mil

($33-mil). "Reducing debt will be a main priority for

Lanxess," according to a company spokesman. The plants that

have been closed were the polybutadiene rubber facility at Marl and elastic rotro garn fiber

plant at Goch,

the company said. The fiber plant producers Lanxess's trademark

Dorlastan fiber.

February 28, 2005 Lanxess

Joint venture established with two partners in China

LANXESS accelerates growth in China

http://mediarelations.lanxess.com/lanxess/lnxnews.nsf/id/2005-0012-EN

Access to the

world's most dynamic tire market Doubling of capacities for

leather chemicals

LANXESS AG is stepping up its growth in the rapidly developing

Chinese chemicals market. With a new joint venture, LANXESS

intends to be the first western player to set up a production

facility in China for antioxidants for the rubber industry. The joint venture, in

which LANXESS is a minority shareholder, will begin manufacturing

the well-proven high-tech product in the second half of 2006. The

plant is located in an industrial park in Tongling in the Chinese

Province of Anhui.安徽省銅陵市

The new

company is called Anhui Tong Feng Shengda Chemical Co. Ltd. The two major partners are

Xinda, which is involved on the production side and is an

established chemicals manufacturer, and TongFeng, a financial

investment company listed on the Shanghai stock market.

A second project that will drive LANXESS's

Chinese and Asian business involves the doubling of production

capacity for leather

chemicals.

For this, two new production plants have been built in the Wuxi無錫Industrial Park in a record time of 15

months, and these are now to be formally dedicated. "We are

taking advantage of the opportunity to expand our leading

position on the Chinese leather chemicals market," said

Wienkenhover.

The third project involves a hydrazine hydrate facility, for which the

groundbreaking ceremony will be held on March 1 in Weifang山東省維坊.

2005/4/11 LANXESS

Restructuring in Fine Chemicals and Styrenic Resins business

units

http://mediarelations.lanxess.com/lanxess/lnxnews.nsf/752d3bba3f96c9a8c1256e63003f4426/2e65e272f8696e69c1256fe0005b2e84/$FILE/2005-0049e.pdf

- Talks with employee

representatives have started

- Analysis of styrenics facilities at Dormagen and Tarragona

The Board of Management of LANXESS AG has decided to structurally

realign its Fine Chemicals business unit and consolidate

production capacities in its Styrenic Resins unit. The economic

situation of both these business units is unsatisfactory. Talks

with the employees' representatives started today. The intention

is to improve the chemical company's international

competitiveness.

The plans call for the closure of unprofitable fine

chemicals production units in Leverkusen and a European Styrenic

Resins facility.

Analyses of the facilities in Tarragona, Spain, and Dormagen,

Germany, are currently ongoing in this connection. The annual

savings are estimated at about EUR 100 million.

Second phase of

restructuring

http://64.233.167.104/search?q=cache:oREWK-CNAhQJ:mediarelations.lanxess.com/lanxess/lnxnews.nsf/id/2005-0117-EN+lanxess+global+restructuring+package+&hl=ja&client=firefox-a

The newly announced

restructuring measures relate mainly to the following business

units and locations:

| ・ | Technical

Rubber Products (TRP): The goal in this business unit is to streamline the manufacture and marketing operations of the nitrile butadiene rubber (NBR) business. Some EUR 150 million has been invested in this business over the past decade, yet losses of roughly EUR 200 million were incurred in the same period. The reorganization will focus on the production site at La Wantzenau, France. |

| ・ | Leather

(LEA): Plans call for an increase in the efficiency of global administration and production activities. |

| ・ | Inorganic

Pigments (IPG): The production site for yellow pigments at New Martinsville, West Virginia, United States will be closed. |

| ・ | RheinChemie (RCH): The U.S. site at Trenton, New Jersey, which has been operating below capacity for years, will be closed. |

| ・ | Textile

Processing Chemicals (TPC): The loss-making site at Wellford, South Carolina, United States will be closed. |

Said LANXESS Management

Board Chairman Axel C. Heitmann: “The extensive restructuring in the

United States will boost our competitiveness in a market that is

very important for LANXESS.” U.S. sales account for about 20

percent of the Group total. LANXESS currently has 15 sites there,

10 of which house production facilities. About 2,100 people work

for LANXESS in the U.S.

First

phase of restructuring on schedule

Implementation of the savings program presented at the beginning

of June for the company's two biggest loss-makers, the Styrenic

Resins and Fine Chemicals business units, is proceeding to schedule. In Styrenic Resins, new appointments have been made to

key global management positions. The carve-out of the Fine Chemicals business unit into an

independent, medium-sized company under the umbrella of the

LANXESS Group is due to be completed by the end of the first

quarter of 2006. The company will be headquartered in Leverkusen

and will employ about 1,350 people worldwide. Two production

units have been closed as part of the reorganization already

initiated. The fine chemicals production operation at Murcia,

Spain, is to be relocated to Leverkusen.

October 14, 2005

Important element of second package of restructuring measures

negotiated

LANXESS saves EUR 11 million in France

http://mediarelations.lanxess.com/lanxess/lnxnews.nsf/id/2005-0140-EN?Open&ccm=000000&l=EN

LANXESS has commenced the

restructuring measures for the French site La Wantzenau that were

announced in August. From 2006 LANXESS aims to save EUR 11

million annually there. “I am delighted that the management

has put a package of measures on the table that is acceptable to

all sides,” says LANXESS CEO Dr. Axel C.

Heitmann. “Therefore, we can sustainably

lower our annual cost base and at the same time safeguard as many

jobs as possible at the La Wantzenau site.”

The savings will be

achieved through process optimization and a solidarity pact that

has been negotiated with all unions concerned. Through this

solidarity pact and the corresponding accompanying measures 83

jobs will now be reduced in a socially responsible manner instead

of the 100 jobs initially envisaged.

The measures in France are part of the second phase of

restructuring announced in August through which LANXESS will

achieve savings of EUR 60 million.

In La Wantzenau the Technical Rubber Products Business Unit

produces nitrile-butadiene rubber, currently employing around 400

staff there. Before implementation the La Wantzenau cost saving

package is subject to a number of formalities according to French

law.

On a global level, the Technical Rubber Products Business Unit

will achieve further savings through job reductions and process

optimization.

In September, following negotiations with union representatives

LANXESS announced a EUR 10 million savings package in the

Styrenic Resins Business Unit in Spain.

British Rubber & Plastics 2005/6/27

Lanxess to cut jobs and restructure styrenics

Losses in Lanxess' styrenics business are to be curtailed with a major restructure and substantial job losses. The styrenics business is focused on two sites, Dormagen in Germany and Tarragona in Spain. Lanxess plans to concentrate its speciality grades at Tarragona, reducing capacity at Dormagen which will make high quality products for use in Bayer Material Science's Bayblend PC/ABS. Around 300 jobs will be lost at Dormagen.

Alongside the styrenics restructure Lanxess is also making economies in its fine chemicals business at the two sites, with a view to making it an independent business. Some 500 jobs will be lost in Germany, and a further 160 jobs are likely to be lost across the two businesses bringing total German job cuts to 960 by the end of 2007 with annual savings of Eur 100 m.

LANXESS

subsidiary Rhein Chemie to consolidate U.S. production in

Chardon, Ohio

http://mediarelations.lanxess.com/lanxess/lnxnews.nsf/id/2005-0147-EN?Open&ccm=000000&l=EN

Changes are part of the second global restructuring package announced in August

Chemicals group

LANXESS is consolidating the U.S. manufacturing operations of its

Mannheim, Germany-based subsidiary Rhein

Chemie Rheinau

GmbH at the latter's Chardon, Ohio, site as part of the group's

second restructuring package. This package, announced in August

2005, is designed to save LANXESS some EUR 60 million annually,

on a global basis. Rhein Chemie's other U.S. site at Trenton, New

Jersey, is to be closed by the end of 2006 and production

transferred to Chardon. The state of Ohio is supporting the

relocation with tax breaks and other financial incentives.

Rhein Chemie manufactures a variety of products for the rubber,

lubricants, plastics and polyurethane industries.

2006/4/7 Lanxess

LANXESS invests more than EUR 20 million in new capacities in

Germany

Expansion of performance polymers

production / Start-up of second facility to manufacture cold

sterilants for beverages

http://mediarelations.lanxess.de/lanxess/lnxnews.nsf/ID/FC88C8C59236A5F4C1257149002EB791?OpenDocument

Chemicals group LANXESS

is investing more than EUR 20 million to expand production

capacities in Germany.

At its Krefeld-Uerdingen site, the LANXESS Semi-Crystalline

Products (SCP) business unit is spending around EUR 12 million

expand the production of polyamide-6 for its Durethan(R) engineering plastic. The enhanced

unit is scheduled to come on stream in early 2007 and would give

LANXESS one of the world's largest production facilities for

polyamide-6. In the coming five years, the company is aiming for

a 50-percent increase in sales of its high-tech plastics Durethan(R) and Pocan(R).

At its Dormagen site, LANXESS has invested more than EUR 10

million in an entirely new facility to manufacture Velcorin(R), a

cold sterilant 滅菌剤 for beverages, for the Material

Protection Products (MPP) business unit.

April 27, 2006 Lanxess

LANXESS opens compounding plant in China

The LANXESS

chemical group's Semi-Crystalline Products (SCP) Business Unit

has opened its first production site in Asia, located some 120

kilometers northwest of Shanghai. A state-of-the-art compounding

plant for the engineering plastics Durethan(R)

(polyamide) and Pocan(R) (polyester) started production on April 27,

2006 on the site of LANXESS Wuxi Chemicals Ltd. Annual production of some 20,000 tons of

plastic is

envisaged in the first phase. The total investment is in the

region of EUR 20 million..

LANXESS Wuxi Chemicals Co. Ltd.

Activities

Leather business unit:

・ Production of leather chemicals

・ Distribution of leather chemicals for the entire Asia Pacific region

・ Research and development in the field of leather chemicals

Semi-Crystalline Products business unit:

・ From today: Production of high-performance plastics

Milestones 1998: Launch of leather chemicals production (Bayer) in Wuxi 2005: Commissioning of two new production plants for leather chemicals after only 15 months of construction, thereby doubling production of leather chemicals,and

opening of largest and most modern R&D center for leather chemicals in the region2006: Commissioning of a new production plant for the high-tech plastics Durethan(R) and Pocan(R), further expansion planned

LANXESS、中国での活動強化 ヒドラジン水和物JV設立

New joint

venture strengthens business in China

LANXESS in China ー

managing

chemistry

Weifang: New site sets LANXESS on course for growth

http://www.press.bayer.com/News/News.nsf/id/665C2EC35E473A22C1256F1C0036B14E

LANXESS -

strong roots for a strong future

Aiming for success with clear objectives - in China and worldwide

The

LANXESS Shanghai Pigments Company manufactures color

pigments in Shanghai for use in the Chinese construction and

paint industries. Bayferrox® and chrome oxide

pigments for coloring a diverse range of products, such as

concrete parts, roofing tiles, paints and coatings, plastics,

paper and special pigments for toners and other applications,

have been proving their mettle for many years now. The products

offer high standards of quality as well as being simple and

environmentally friendly to process.

In 1999, the Rhein Chemie (Qingdao) Ltd. began producing

additives for the rubber and mineral oil industries. Lubricant

additives, for example, are used everywhere where there is a need

to prevent friction, frictional heat and wear and to protect

material against corrosion. Rhein Chemie has established itself

in the lubricant industry as one of the leading additive

manufacturers for industrial lubricants.

Today the leather business unit has the highest sales volume

amongst all the business units of LANXESS in China. The company

offers its customers cutting-edge products and technologies

coupled with application-specific expertise. The LANXESS Wuxi

Leather Chemicals Company, founded in conjunction with the

Wuxi Dyestuff Factory, has been producing leather chemicals since

1998 in Wuxi, north-west of Shanghai.

LANXESS - Top company in a growth market

Following its objective to remain efficient and growth-oriented,

LANXESS is currently tapping into the particularly fast-growing

Chinese market for hydrazine hydrate, an intermediate for the

chemical industry. Hydrazine hydrate is used by the agro and

pharmaceutical industry as well as for the production of plastic

additives and for water conditioning.

A joint-venture company is therefore to be set up in

collaboration with the Weifang Yaxing

Chemicals Company 維坊亜星化学

in Beijing

on September 28, 2004. This is a further instance of LANXESS'

concept of flexible, goal-focussed management of the chemicals

business. The purpose of the joint venture is to manufacture hydrazine

hydrate, whose market is currently

enjoying annual growth rates running into double figures. ヒドラジン水和物

With

its involvement in Weifang LANXESS (* LANXESS Yaxing

Chemical (Weifang) Company Ltd. )expects to become

one of the leaders on the Chinese hydrazine hydrate market for

three reasons: "We will have a production unit with very

high capacity, we will offer the best quality and we also will be

way out in front in terms of process engineering," said Wang

Yongli, President of the LANXESS Chemical Company in China.

Weifang - a viable location with a strong partner

Weifang Yaxing Chemicals Company is an ideal joint-venture

partner for manufacturing top-quality hydrazine hydrate. And

Weifang is also the perfect location for such a facility. For

this reason, LANXESS will transfer its

hydrazine hydrate plant from its site in Baytown, Texas, USA, to

Weifang, which is intended to begin

supplying the Chinese and international market from the end of

2005.

July 12, 2006 Lanxess

LANXESS inaugurates hydrazine hydrate plant in Weifang

Successful relocation of plant from Texas, USA, to China

http://mediarelations.lanxess.de/LANXESS/lnxnews.nsf/ID/2006-0142-ENThe LANXESS chemicals group today inaugurated a plant for producing hydrazine hydrate in Weifang in the Chinese province of Shandong 山東省維坊. The plant had previously been dismantled in the USA and transported to China. “This marks a further key milestone for us in boosting our profitable growth in Asia,” said Axel C. Heitmann, Chairman of the LANXESS Management Board, at a press conference in Weifang. “Relocating the plant enables us to become one of the leading hydrazine hydrate producers in China,” adds Heitmann. China is the fastest growing hydrazine hydrate market in the world.

LANXESS - a leading hydrazine hydrate producer in China

With an initial capacity of 12,000 metric tons a year, the new plant is one of the largest of its kind in the world and complies with the latest US standards in environmental protection and occupational safety. Hydrazine hydrate is used in the agro, pharmaceuticals, automotive and leisure industries, for example. Most of the raw materials required are being supplied by the joint venture partner Weifang Yaxing Chemical Company Ltd. LANXESS has a 55 percent share in the joint venture LANXESS Yaxing Chemical (Weifang) Company Ltd., founded in September 2004. LANXESS is the first international investor in the new Weifang Industry Park.

2006/8/30 Lanxess

New name for LANXESS business unit

Lustran

Polymers - a new strong ABS brand

Focus

on colored ABS and ABS specialties

The LANXESS business unit

Styrenic Resins has a new name: Lustran Polymers. With this name

change, the chemical group's business unit is focusing on the top

brand Lustran(R). The name change is a consequence of the

repositioning of the business, which has already taken place, to focus on ABS

specialties and pre-colored grades. The name Lustran Polymers

visualizes the color-intensive new beginning of the LANXESS

business unit Styrenic Resins. A new graphic with a

color-balanced logo gives vivid expression to the claim: “The colorful difference”. With its wealth of technical

expertise and cutting-edge technology, Lustran Polymers will make

its debut as a distinctive and independent brand on October 1,

2006.

On gaining its independence, LANXESS started an exemplary

restructuring of the previously unsatisfactory business. The key

feature of this process is regionalization with independent

management teams who

manage the business under their own regional and operational

responsibility from product development and production through to

marketing. This allows them to deal with customer requirements

more quickly, on a more individual basis and with more focus,

because they are familiar with the peculiarities of the regions

and product portfolios concerned.

Lanxess portfolio Bayer/Lanxess Bayer

Engineering Plastics

Lustran Polymers a major global supplier of ABS, SAN and PA-ABS plastics.

ABS grades: Novodur®, Lustran® and AbsolacTM

SAN grades: Lustran® and AbsolanTM

ABS/PA grades: Triax®,

ASA and AES

Polymers: Centrex®Semi-Crystalline Products Durethan®, engineering plastics based on polyamide 6 and 66,

Pocan®, engineering plastics based on polybutylene terephthalate,

range of glass fibers as reinforcements for plastics, caprolactam, adipic acid,

Perlon®, Atlas® and Bayco®, Polyamide monofilamentsDorlastan Fibers(スパンデックス) LANXESS has sold its Dorlastan fibers business (the former Business Unit Fibers)

to the Japanese company Asahi Kasei Fibers Corporation

Performance Rubber

Butyl Rubber

Polybutadiene Rubber

Technical Rubber Products

Chemical Intermediates

Basic Chemicals Producer of high-quality industrial chemicals and aromatic compounds Inorganic Pigments for the coloration of construction materials and special applications for toner pigments and catalysts. Saltigo fine chemicals and intermediates for the agrochemical and pharmaceutical industries.

Performance Chemicals

Material Protection Products Full range of biocides and specialty products for wood preservation, disinfection and industrial

and beverage preservation._Functional Chemicals Plastics additives, phosphorus and specialty chemicals, and organic and inorganic colorants. Leather One of the the major suppliers of leather chemicals and systems solutions for all stages

in the manufacture of leather goods.Textile Processing Chemicals Development of chemicals for a wide range of textile processing applications Rhein Chemie additives for the rubber, lubricants, polyurethanes and plastics industries Rubber Chemicals High-quality rubber chemicals for the tire industry and the production of technical rubber products. Ion Exchange Resins Lewatit® ion exchange resins are used in water treatment and in the production of food and pharmaceuticals. LANXESS has sold its former Business Unit Paper to the Finnish chemicals group Kemira Oyj

Official opening of the new European headquarters of

Lustran Polymers in Tarragona

Investments of more than EUR 20 million / LANXESS business

unit is largest ABS manufacturer in Spain

The LANXESS chemical company today officially opened the new European headquarters of the recently renamed Lustran Polymers business unit in the Spanish city of Tarragona. Part of the production facilities for manufacturing ABS plastics had earlier been transported from Dormagen in Germany to Tarragona. Regional management for business in Europe and Latin America was also transferred from Germany's Lower Rhine region to Catalonia in July. This increased the Lustran Polymers workforce in Spain to 300.

September 20, 2006

Lanxess

LANXESS invests in

chloroprene rubber

Chemicals group

LANXESS has invested more than EUR 15 million in the production

of chloroprene rubber (CR) in Dormagen. The project is aimed at

optimizing processes and safety and expanding capacity, and is

due for completion by the end of the year. This move by the

company has been in response to the changing global market

environment.

“The investments

will enable us to continue reliably serving our customers from

the CR processing industry in the future,”

says Ingo Fischer,

head of Global Product Management for CR at LANXESS's Technical

Rubber Products business unit. ”In addition we are in close

contact with the authorities to prepare for additional expansion.”

The aim is to

increase further the capacity. If the project runs smoothly, the

chances of obtaining a permit from the authorities quickly are

rated high.

Chloroprene is used

in a large number of applications in the field of technical

rubber goods, e.g. hoses, cables, transport belts, and in the

automotive segment in axle boots, windscreen wiper blades and

belts. Apart from technical rubber goods CR is also used in

adhesive raw materials and latex applications.

The Technical

Rubber Products business unit belongs to the Performance Rubber

segment, which achieved total sales in fiscal 2005 of EUR 1.678

billion.

ランクセス、繊維加工用化学品事業を売却へ

~ オランダの投資会社エゲリアと、繊維加工用化学品ビジネスユニットの経営陣が同事業を獲得 ~

ドイツの化学会社ランクセスグループは、繊維加工用化学品事業の売却を発表しました。北米地域以外の全ての拠点における繊維加工用化学品ビジネスユニットの業務は、オランダの投資会社エゲリア(Egeria)と、繊維加工用化学品ビジネスユニットの経営陣に売却されます。売却される事業の2005年の売上は、約1億3,000万ユーロで、約330人が同事業に従事しています。繊維加工用化学品の北米地域の業務については、現在、売却とは別の選択肢が検討されています。エゲリア社との売買契約書は、11月10日午前(現地時間)に締結されました。売却価格は5,400万ユーロで、売却は今年末までに完了する予定です。

売却完了後、この事業は、タナテックス ケミカルズ(Tanatex

Chemicals BV)に社名変更されます。

2006/12/14 Lanxess

LANXESS acquires

activities from The Dow Chemical Company in South Africa

and divests

textile processing chemicals business in North America

・First corporate

acquisition implemented

・Leather business

unit strengthens core business

・Complete control

of value chain from chromium ore to leather tanning materials

・World's most

modern processing facility for the precursor of tanning materials

Chemicals group

LANXESS is purchasing the chrome chemicals activities of The Dow

Chemical Company in South Africa. LANXESS is to acquire the 50%

interest in Chrome International South Africa

(CISA),

Newcastle, South Africa, which The Dow Chemical Company currently

owns through its subsidiary Sentrachem. The remaining 50% of CISA

is already owned by LANXESS. It has been agreed not to disclose

the purchase price. Closing of the transaction, which is subject

to the approval of the antitrust authorities and the Board of The

Dow Chemical Company, is expected for the first quarter of 2007.

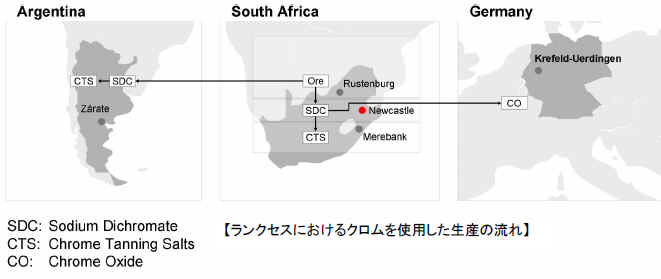

CISA社は、1990年代半ばに設立され、1999年より操業を開始した、年間70,000トンのニクロム酸ナトリウム(Sodium Dichromate)を製造する化学会社です。ニクロム酸ナトリウムは、主に皮革用なめし剤(Chorome Tanning Salt)の製造に使用されており、CISA社はニクロム酸ナトリウムの原料を、南アフリカのルステンブルグにあるクロム鉱山で採掘しています。CISA社の主な取引先は、ランクセスの無機顔料

ビジネスユニット(Chrome

Oxide 製造)

と同社の南アフリカのメルバンクにあるクロムなめし剤の製造プラントです。従業員数は約120人を擁し、2005年の売上高は、約4,000万ユーロです。

皮革用化学品

ビジネスユニットは、世界の皮革業界におけるリーディング・サプライヤーで、南アフリカで従事する330人を含めて、現在約1,000人の従業員を擁しています。CISA社のランクセスグループへの統合後、皮革用化学品

ビジネスユニットの従業員の約30%は、南アフリカにて業務に従事することになります。

Textile processing

chemicals business in North America to be divested 北米以外

At the same

time, LANXESS is now divesting all the activities of its Textile

Processing Chemicals (TPC) business unit in North America. Star Chem, a specialist in textile and

speciality chemicals, will acquire the operations based in the

United States and Canada and will employ major parts of the

workforces. StarChem is a subsidiary of Star Holdings, Inc.,

Dalton, Georgia, USA, and will be headquartered in Wellford,

South Carolina, USA.

StarChem Ltd is a supplier of automotive paint refinishing products.

http://www.starchem.co.uk/

LANXESS plans package of

measures to speed development at Saltigo

EUR

30 million investment to modernize the production base /

EUR

10 million to build a high-tech multi-purpose plant /

New,

specially tailored worktime models

LANXESS, the Leverkusen-based chemicals group, plans to develop the business of its fine chemicals subsidiary Saltigo. EUR 30 million has been earmarked for plant modernization, and new worktime models are to be introduced. A state-of-the-art multi-purpose facility costing a further EUR 10 million is already under construction.

February 15, 2007

Lanxess

LANXESS steps up expansion in India

Significant investment possible in 2007 / Objective is to grow

sales appreciably

Only recently, LANXESS launched two projects to accelerate

profitable growth in India. In January, a new plant for the

production of the polymer-bound

rubber chemical Rhenogran went on stream in Madurai. This

was the response from the LANXESS Rhein Chemie Business Unit to the rapidly growing demand

from Indian tire manufacturers and other rubber processors for

polymer-bound chemicals to improve product quality, processing,

economic efficiency, health and environmental protection. ゴム薬品のマスターバッチであるレノグラン

At the same time,

LANXESS is in the process of building a new facility in Moxi for coloring ABS

plastics.

With double-digit growth rates, India is the strongest-growing

market for ABS plastics in Asia, and Lustran Polymers boasts the

highest sales of any LANXESS business unit in India. In 2006 LANXESS

ABS Ltd.,

which is listed on the Mumbai stock exchange and belongs to the

Business Unit Lustran Polymers, increased its operating profit by

around 40 percent compared with the previous year.

The new facility is a further step towards the expansion of ABS capacity from

60,000 to 80,000 t/y.

Capacity can be further raised to 100,000 t if needed. The

project will enable LANXESS to consolidate its leading position

with this business in India and to continue participating in the

strong market growth.

ラインケミー、インドで「レノグラン」の製造を開始

~インドのゴム加工会社で定評のあるレノグランの提供を強化~

ドイツの化学会社、ラインケミーは、インドのマドゥライにある親会社ランクセスの製造拠点に併設された新プラントでゴム薬品のマスターバッチである「Rhenogran(R)」の製造を2007年1月22日付けで開始したことを発表しました。これは、市場におけるゴム薬品のマスターバッチへの需要の高まりに対応するためです。

ラインケミーは、新たにインドでもレノグランの製造を開始することで、インドのゴム業界の需要に対応した製品ポートフォリオを揃えるだけでなく、ゴム薬品のマスターバッチ業界における国際的なサプライヤーとしての地位を確固たるものにしつつあります。ラインケミーは、2006年3月に中国の青島にある製造拠点のレノグランの製造能力を2倍に引き上げました。ランクセス インド社は、以前からラインケミーの一部製品を製造しています。日本でもまた、レノグランはラインケミージャパンの豊橋工場で製造されています。ラインケミーは、すべての主要な市場でレノグランを提供することをめざしており、世界中の顧客の需要に対しても個別に対応したソリューションを展開します。

LANXESS ABS Limited (← Bayer ABS ← ABS Plastics Limited )

http://www.lanxessabsindia.com/companypro.htmlThe erstwhile ABS Plastics Limited now LANXESS ABS Limited played a pioneering role in developing the market for the versatile engineering thermoplastic material - Acrylonitrile Butadiene Styrene (ABS) in India, when it started its operation in 1978 by manufacturing and marketing ABS polymer under the brand name of ABSOLAC. Since then the company has been continuously growing through a planned process of aggressive market development and consolidation, technology updation and capacity build up. The company also set up India's first modern and dedicated Styrene Acrylonytrile (SAN) plant in 1993, with technical know-how from JSR, Japan for manufacture of various grades of ABSOLAN- SAN.

In early 1997, Bayer Industries Private Limited, a 100% holding company of the German major, Bayer AG acquired a majority share of 51% in ABS Industries Limited. The company then became a part of the Bayer group and was rechristened as Bayer ABS Limited.

LANXESS India Private Ltd. (which is 100% subsidiary of LANXESS AG Germany) acquired 89,63,564 equity shares of Rs.10/- each in Bayer ABS Ltd (BABS) constituting 50.97% of paid-up capital of the paid up share capital of Bayer ABS Limited from Bayer Industries Private Ltd and became a holding Company of the Company.

To meet the increasing demand, LANXESS ABS Limited intends to enhance the capacity of ABS to 80,000 tpa from the current 60,000 tpa within a short period and the Company is further increasing this capacity to 100,000 tpa in the course of next two years, which is quite possible at a nominally higher cost through an additional investment in machinery and de-bottlenecking in the existing plants.

Lanxess in India

Thane

At Thane, 245 LANXESS employees manufacture 6,000 tons of caoutchouc 天然ゴム chemicals per year. The technical development center for the Asian pacific region for caoutchouc chemicals is also located here.

Madurai

The Madurai site manufactures leather chemicals, but LANXESS also uses the production plant to produce caoutchouc additives for the product line Rhenodiv. This project is to satisfy the rapidly growing demand from Indian tire manufacturers. In January 2007 a new plant in Madurai started to produce the rubber chemical Rhenogran.

Nandesari, Moxi and Katol

The production sites for Lustran Polymers ABS・SAN products are located near Vadodara at Nandesari, Moxi and Katol, where about 413 employees manufacture 60,000 tons of ABS and 60,000 tons of SAN per year. The largest turnover in India is achieved by the Lustran Polymers business unit which has a share of more than 50% of total sales there. LANXESS also operates a research and development center at Moxi as part of its global ABS development network.

LANXESS realigns its EPDM rubber business

To strengthen

its competitiveness, chemicals group LANXESS is to realign its

ethylene-propylene-diene rubber (EPDM) business. Marketing,

research, production and controlling will in future be

assigned to LANXESS Buna GmbH in Marl, Germany.

Similarly, LANXESS will pool its EPDM operations in the USA in a

separate legal entity to be known as LANXESS

Buna LLC.

Robert Gnann, Managing Director of LANXESS Buna GmbH, will assume

global responsibility for the EPDM business.

The EPDM line is part of the portfolio of the Technical Rubber

Products (TRP) business unit. To take advantage of synergies, sales and

technical service for EPDM will continue to be managed together

with the other products of the TRP business unit.

"EPDM is an important element of our core business. This new

focus will help us meet customer demand more quickly, respond

more speedily and expand our position as a major global supplier

of technical rubber," explains Dr. Günther Weymans, the head of

LANXESS's Technical Rubber business unit. "These measures

also increase cost transparency, thus making cost monitoring more

efficient."

Buna® EP has been the only rubber

material to qualify for the discipline of sealing the roof of the

soccer stadium in Tianjin for the Olympic Games in Beijing in

2008. It impresses with its outstanding resistance to weathering,

ozone and aging and its good dimensional stability even in the

face of strong fluctuations in temperature. Other fields of use

are hoses, extruded profiles, including dense automotive class A

profiles, and injection molded goods.

---

In Germany the core EPDM activities of marketing management, controlling, manufacturing, and research and development will be organized as part of LANXESS Buna GmbH in Marl, Germany. The global EPDM business will be headquartered in Germany. In the United States, the marketing management, manufacturing and controlling activities of EPDM will be carved out into a new company, LANXESS Buna LLC, early next year. This includes the production unit in Orange, Texas.

2001年2月6日 バイエル株式会社

バイエル、米国とドイツにおける合成ゴム生産能力増強へ

バイエルは、伸び続ける合成ゴム需要に対応するため、1億ユーロ以上の投資をして、マール(ドイツ)とオレンジ(米国テキサス州)にあるエチレン - プロピレン - ジエンゴム (EP(D)M) 生産施設拡大のプロジェクトを実施する。

マールでは、第三生産ラインを増設することによって、同施設の生産能力は、6万トン増え、11万 5,000トンになる。また、オレンジにある生産工場に最新設備を導入することによって、米国での生産能力が 7万トンに拡大される。このゴムの総生産能力は、2003年以降年産18万5,000トンになる見込みである。

これら 2つの生産施設の拡大により、市場への EP(D)M の継続供給が確保され、高品質製品に対する顧客の要求も満たされることになる。バイエルは世界有数の EP(D)M 生産者としての地位を確立することを長期的目標としている。

バイエルのEP(D)M は、ブナEPという商標のもと販売されており、主として、自動車業界で窓やドアのシールに、また建設・電線用でも使用されている。

1933年 スチレン・ブタジエンゴム ブナS の工業化に成功。

1938年にドイツ政府の戦争準備のための4ヵ年計画に基づいて、スチレン・ブタジエンゴム Bunaの製造のため、I.G. Farben 74%、Hibernia (当時は国営であったエネルギー会社Vebaの子会社の鉱山会社)26%出資でHulsが設立された。 http://www.knak.jp/blog/2006-8-2.htm#sabic

Lanxess March 5,

2007

LANXESS invests in new site in China

As part of its Asia strategy, the LANXESS chemicals group is

building a new plant for the manufacture of lubricant

additives in Qingdao, China. The production facility, which

belongs to LANXESS's subsidiary Rhein Chemie, will go on stream at the latest

in the fourth quarter of 2008 and will initially employ 50

people. It is estimated that the amount in euros to be invested

will be a single-digit million value. “The new facility is a further step

in our drive to increase profitable growth in Asia,”

said LANXESS

Management Board Chairman Dr. Axel C. Heitmann. “We are rigorously expanding our

presence here.”

In Qingdao Rhein

Chemie has been producing rubber chemicals since 1999 within a

joint venture. Capacity of polymer-bound chemicals (Rhenogran)

was doubled last year with the commissioning of a second

production unit. LANXESS currently employs more than 800 staff in

China, of which 160 work for Rhein Chemie in Qingdao.

LANXESS has not made an offer for Degussa

Chemicals Group LANXESS denies the claim of a newspaper article that the company has issued a take-over bid for Degussa.

Today's edition (Wednesday, March 21, 2007) of the “Rheinische Post” newspaper claims that LANXESS has “surprisingly issued a new bid to acquire the RAG subsidiary Degussa”. LANXESS denied this to various news agencies today.

LANXESS has not issued a bid to take over Degussa, either now or in the past, according to Christoph Sieder, head of Corporate Communications at LANXESS AG. "Degussa is wholly owned by the RAG Group, there is therefore no acquisition project on our part," he added.

Last September LANXESS announced that it would be moving into the acquisition phase. When examining strategic options in the sector as a whole, Degussa has also played a role. LANXESS had, however, always maintained that the chemical company Degussa was not for sale.

LANXESS increases

capacities for EPDM rubber

Optimization measures take effect

To meet rising consumer demand for ethylene-propylene(-diene) rubber (EPDM), the LANXESS chemicals group wants to increase its annual production capacities to more than 140,000 metric tons. To this end, the company is investing in debottlenecking and modernization measures such as enhanced process control.

Last year LANXESS realigned its EPDM business. Marketing, research, production and controlling were assigned to LANXESS Buna GmbH in Marl, Germany. In the USA, LANXESS is to pool its EPDM operations in LANXESS Buna LLC, which became a separate legal entity on March 1, 2007.

LANXESS opens new plant

in China

Facility ensures economic supply of raw materials for pigment

production - low capital expenditure - fast commissioning

Chemicals group LANXESS today opened a new plant in Shanghai as part of its Asia strategy launched in 2006. This is the Group's second production facility for inorganic pigments in China.

The plant with an annual capacity of approximately 20,000 tons will be operated by the Inorganic Pigments business unit to supply raw materials for the production of inorganic pigments in Shanghai, which started in 1996. LANXESS had previously sourced these raw pigments from suppliers.

“The new facility is an important step in our drive to increase our profitability in Asia,” said LANXESS Management Board member Dr. Ulrich Koemm at the inauguration. “With this backward integration, we can significantly improve our profitability in this segment.”

2007/5/6 forbes.com

Lanxess CEO

Heitmann says co is prepared to pay 4-6 bln eur for RAG's Degussa

Lanxess AG chief

executive Axel Heitmann told Handelsblatt his company is prepared

to pay 4-6 bln eur for RAG AG's Degussa chemical business, should

the conglomerate's plans to launch an initial public offering

fail.

Heitmann told the

newspaper in an interview scheduled to appear in tomorrow's

edition that if RAG is 'looking for alternatives to a listing',

Lanxess will make an offer for the business.

RAG has yet to set

a date for its IPO, which could take place as early as next year.

May 8, 2007 Lanxess

LANXESS and Hankook Tire sign long-term supply contract

LANXESS's Polybutadiene Rubber business unit and the South Korean

tire manufacturer Hankook Tire have put their cooperation on a

firm footing with the conclusion of a long-term supply

contract. In

the next five years LANXESS will supply solution SBR and

polybutadiene rubber. It is planned to more than double

the volume supplied within the next five years. The contract was

signed in Dormagen on May 7, 2007 by Jeong Ho Park, General

Manager of Global Raw Material Purchasing of Hankook Tire, and

Dr. Joachim Grub, head of the Polybutadiene Rubber business unit.

Hankook Tire operates tire manufacturing facilities in South

Korea and China and from the middle of 2007 in Hungary. The

Polybutadiene Rubber business unit, which is the world's biggest

supplier of polybutadiene rubber, belongs to the Performance

Rubber segment. This segment recorded sales of EUR 1.776 billion

in fiscal 2006.

LANXESS projects significant new investment in rubber business

With costs of a magnitude of roughly EUR 400 million, the new production facility would be the largest investment in the company's history

Chemical group LANXESS seeks to expand its global position in the butyl rubber market and is pursuing plans to build a new facility in Asia.

Negotiations at three possible sites, Singapore, Kuantan in Malaysia and Map Ta Phut in Thailand, will begin immediately.

LANXESS presses ahead with worldwide butyl rubber expansion

North America: Plant

expansion by more than 40 percent implemented, further expansion

by 10 percent started - Europe:

Capacity increase by 10 percent completed - Asia: New world-scale

plant projected

The chemicals group LANXESS is pressing ahead with the worldwide expansion of its butyl rubber business. At its Canadian Sarnia site the company has completed the first phase of a plant expansion that will increase its butyl rubber capacity there by 42 percent. LANXESS has already started a second phase of expansion at the Sarnia plant, increasing annual capacity by another 10 percent in 2009.

In order to satisfy the growing global demand for butyl rubber the company is also accelerating its expansion in Europe and Asia. At the Zwijndrecht, Belgium facility LANXESS already increased capacity by 10 percent in 2006. In addition, LANXESS announced plans last week to build a new butyl rubber facility in Asia.

LANXESS

builds new ion exchange facility in India

Around 200 new jobs / Investment

volume approx. EUR 30 million

The

LANXESS chemicals group is to build its new ion exchange

resin plant

in the Indian state of Gujarat. Construction work on the EUR 30

million site at the new Jhagadia Chemical Park near Baroda is set

to begin in the second quarter of 2008. Production is scheduled

to start at the beginning of 2010, with 200 new employees being

taken on.

In March of this year, LANXESS launched an international

competition that sites in China, India and Singapore entered. The Jhagadia Chemical Park in

India was selected because it already has an excellent industrial

infrastructure in place.

Germany's Lanxess invests Eur10 million in Dormagen EVM facility

German specialty chemicals group Lanxess announced Friday that it is to invest Eur10 million ($13.875 million) to expand its ethylene-vinyl acetate copolymer (EVM) plant at Dormagen. A current permit allows for a maximum volume of 15,000 mt/year at the site, an amount that could be realistic by 2009, the company said.

Lanxess walked away from talks to buy Petroflex of Brasil - report

Lanxess AG was in advanced talks to buy Brasilian rival Petroflex but walked away from negotiations, Financial Times Deutschland reported, citing unidentified sources at Petroflux and other unnamed people familiar with the matter.

The deal would have been worth between 250 and 300 mln eur, according to the newspaper.

A Lanxess spokesman declined to comment on what he called 'market rumors,' Financial Times Deutschland said.

LANXESS to

invest about EUR 1 billion by 2009

New segment structure for the 13 business units / Earnings

targets will now be reached in 2008

LANXESS AG, Leverkusen, will now position itself as a specialty chemicals group following the divestment of its Lustran Polymers business unit. “Our place is as a specialty chemicals group at the core of the chemical industry,” declared Management Board Chairman Axel C. Heitmann at this year's Investor and Media Day in London. As part of a systematic market orientation, LANXESS will organize its 13 business units into three segments starting in October 2007 following the divestment of the commodity plastics activities. The new segments are named Performance Polymers, Advanced Intermediates and Performance Chemicals.

Ineosは2007年6月29日、Lanxess との間でABS事業の合弁会社設立で合意したと発表した。

合弁会社の社名は INEOS ABS で、Lanxess のABS事業のLustran Polymers を引き継ぐ。

Ineos が合弁会社に51%を出資

2007/7/4 Ineos、Lanxess のABS事業を買収へ

Only

acquisitions that create value

A central criterion for an acquisition, said Heitmann, is that it

must be accretive to earnings per share within three years at the

latest. LANXESS is well prepared for acquisitions, he went on,

but “we will never pursue an

acquisition simply for the sake of size. We will act only when

the time is right.”

New three-segment

structure.

| 従来の組織 | 新組織 |

| Performance

Rubber (Butyl Rubber, Polybutadiene Rubber, Technical Rubber Products) |

Performance Polymers |

| Engineering Plastics - Semi-crystalline | |

| Engineering Plastics - Lustran Polymers | (INEOS ABS) |

| Chemical Intermediates - Basic Chemicals | Advanced Intermediates. |

| Chemical Intermediates - Fine Chemicals | |

| Chemical Intermediates - Inorganic Pigment | Performance Chemicals |

| Performance

Chemicals (Material Protection、Functional Chemicals、Leather、Rhein Chemie、 Rubber Chemicals、Ion Exchange Resins) |

Lanxess

walked away from talks to buy Petroflex of Brasil

2007/12/13 Lanxess Lanxess walked away from talks to buy Petroflex of Brasil

LANXESS to acquire Petroflex chemicals group of Brazil

Leverkusen-based

specialty chemicals group LANXESS is to acquire an interest of

approximately 70 percent in Petroflex S.A, Brazil, at a provisional price

equivalent to EUR 198 million. Petroflex, a listed company based

in Rio de Janeiro, is among the world's large-scale producers of

synthetic rubber. The stake to be purchased by LANXESS includes

the holdings of the current major shareholders Braskem and

Unipar. The

transaction requires the approval of the relevant antitrust

authorities.

LANXESS will submit

a

public takeover offer for the remaining ordinary shares at the proper time under Brazilian

law.

In 2006 Petroflex had some 1,300 employees and sales equivalent

to about EUR 500 million. The group's 2007 output at its three sites in

Brazil -

Cabo in Pernambuco State, Duque de

Caxias in Rio de Janeiro State and Triunfo in the State of Rio

Grande do Sul - will exceed 400,000 tons. Its elastomer products range

from solution rubber to emulsion rubber and comprise 70 brands.

The products are used especially in the manufacture of tires as

well as for tubing and plastics. One third of its output is

exported to more than 70 countries.

December 13, 2007 PRNewswire-FirstCall

BRASKEM S.A. , the leading company in the thermoplastic resins industry in Latin America and third- largest Brazilian industrial company owned by the private sector, announces that, jointly with Unipar -- Uniao de Industrias Petroquimicas S.A. ("Unipar") and other parties, entered into a Share Purchase Agreement on this date with the German company Lanxess Deutschland GmbH ("Lanxess") for the sale of Petroflex Industria e Comercio S.A ("Petroflex") shares. The amount of shares to be sold add up to 17,102,002 common shares and 7,416,602 preferred shares representative of 72.38% of total common shares and 69.68% of capital stock of Petroflex, at a total price of R$ 526,680,000, which corresponds up to R$ 22.86 per common share and R$ 18.29 per preferred class "A" share. Braskem is selling its total share interest, which represents 33.57% of Petroflex common shares and 33.46% of its preferred shares.

2007/12/13 BRASKEM

Braskem Announces Sale of

Share Interest in Petroflex

BRASKEM S.A., the leading company in the thermoplastic resins

industry in Latin America and third- largest Brazilian industrial

company owned by the private sector, announces that, jointly with

Unipar -- Uniao de Industrias Petroquimicas S.A.

("Unipar") and other parties, entered into a Share

Purchase Agreement on this date with the German company Lanxess

Deutschland GmbH ("Lanxess") for the sale of Petroflex

Industria e Comercio S.A ("Petroflex") shares. The

amount of shares to be sold add up to 17,102,002 common shares

and 7,416,602 preferred shares representative of 72.38% of total

common shares and 69.68% of capital stock of Petroflex, at a

total price of R$ 526,680,000, which corresponds up to R$ 22.86

per common share and R$ 18.29 per preferred class "A"

share. Braskem is selling its total share interest, which

represents 33.57% of Petroflex common shares and 33.46% of its

preferred shares.

LANXESS:

Petroflex to become a wholly owned subsidiary

Successful

tender offer for remaining shares in Brazil

Petroflex

to be delisted

Way

cleared for squeeze-out of minority stockholders

The

tender offer by specialty chemicals group LANXESS AG for the

remaining shares of Petroflex S.A. in Brazil has been met with

great interest. Under the public tender offer to the minority

stockholders LANXESS has acquired a further 27 percent of

Petroflex shares, giving it a total interest of around 97 percent

in the company. The offer period ended on October 16, 2008. This

high acceptance rate enables LANXESS to acquire all the remaining

shares by way of a squeeze-out and thus to become the sole owner

of Petroflex. The success of the offer also means that Petroflex

can be delisted from the stock exchange. The purchase price for

the 27 percent of the share capital now acquired is equivalent to

about EUR 60 million. In the tender offer, LANXESS had offered

the minimum price which is required by law to be paid to holders

of common shares. As previously announced the total price for 100

percent of the shares including net debt therefore amounts to

about EUR 370 million.

Said LANXESS CEO Axel C. Heitmann: “I'm pleased with the positive

response to our offer. Now that we are about to successfully

complete the acquisition procedure, we can focus our energies on

further integrating Petroflex into the Group.”

The German based

group purchased a majority shareholding in Petroflex earlier this

year. This acquisition has allowed LANXESS, one of the leading

global suppliers of synthetic rubbers, to significantly improve

its presence in the South American region.

LANXESS Corp. announces restructuring of LANXESS Inc. Sarnia Site to maintain competitive leadership in global rubber industry

Sarnia butyl operation

restructures

At the site of the company's recently completed $100 million butyl plant expansion, LANXESS Inc. is

implementing a 24 month restructuring aimed at improving the

global competitiveness of its butyl products. The move is aimed

at removing increased operating expenses due to higher energy and

raw material costs in addition to the impact of the Canadian

dollar on labor.

The expansion of the Sarnia butyl plant made it the largest, most modern facility of its kind in the world. By December of 2008, total production capacity will be 150 thousand metric tonnes. Together with today's announced site restructuring, the plant modernization will improve the plant's productivity. Over the next 24 months the site will reduce its manpower operating requirements by approximately 270 positions.

Global NBR production consolidated

LANXESS AG will consolidate global NBR production in La

Wantzenau, France over the next few months. The process will

involve closing a 64 year old nitrile

butadiene rubber production facility located in Sarnia, Canada by the end of May, 2008.

LANXESS to

make record investment in Singapore

Expenditures

of up to EUR 400 million for a new chemical site /

Production

of halobutyl for tire industry from 2011 /

Around

200 new highly-skilled jobs

Specialty

chemicals group LANXESS AG is set to make the biggest single

investment in its history in Singapore. A new chemical production

site for synthetic rubber is to be built at the chemical park on

Jurong Island. LANXESS has earmarked a record amount of EUR 400

million for this investment. From 2011, the site in Singapore

will produce up to 100,000 tons of butyl rubber annually, making the LANXESS plant

the largest facility of its type in Asia. Construction is due to

begin in the first quarter of 2009 and will be completed by the

end of 2010. Some 200 new jobs will initially be created.

LANXESS began evaluating potential locations in Malaysia, Thailand

and Singapore in

June 2007.

Already today, LANXESS is a global market leader in the synthetic

rubber business. In the past two years, LANXESS significantly

expanded its production rubber facilities in Zwijndrecht,

Belgium, and Sarnia, Canada. The Singapore site will complete the

global production network. In combination with the completion of

the latest expansion phase in

Sarnia,

the company will have an annual capacity totaling 280,000 metric

tons of butyl rubber in

2010.

シェルケミカルズは、2010年からジュロン島に隣接するブコム島にあるシェル・イースタン・ペトロケミカルズ・コンプレックス(SEPC)のブタジエン抽出設備から、パイプラインを通してブタジエン抽出後のラフィネートをランクセスに供給することにしている。

LANXESS

makes first acquisition in China

Take-over of one of China's largest iron oxide pigment facilities

With its

first acquisition in China, specialty chemicals company LANXESS

AG is expanding the Asian business of its Inorganic Pigments

business unit. In Jinshan near Shanghai LANXESS is to acquire two

production units from its previous cooperation

partner Jinzhuo Chemicals Company Ltd, one of which it had already

leased since 2007. With this acquisition LANXESS will expand its

global production capacity for inorganic pigments by five percent. The parties have

agreed not to disclose the purchase price.

Jinshan: The most modern iron oxide pigment facility in China

The site started producing iron oxide yellow pigments last year

and has a total capacity of 30,000 metric tons per year. Half of this capacity

was already utilized by LANXESS. The facility is one of China's

largest and uses state-of-the-art and environmentally compatible

production methods.

Next step

within “LANXESS goes Asia”

initiative

LANXESS opens Rubber Research Center in Qingdao

Win-win situation for LANXESS and

Chinese rubber industry

German specialty chemicals company LANXESS AG today opened a new Rubber Research Center (RRCQ) in Qingdao, Shandong Province. Established in close cooperation with Qingdao's University of Science and Technology (QUST), the world-class research center is located within the university's vicinity. It is jointly operated by the LANXESS business units Technical Rubber Products, Butyl Rubber and Performance Butadiene Rubbers, and marks an investment of some USD 16 million.

2008/10/7 Plastics Information Europe

Lanxess: Reported bid for DSM's elastomers division

The “Financial Times Deutschland” newspaper has reported that chemical company Lanxess has made a bid for the EPDM business of DSM. Neither company has commented on the possible transaction.

DSM has assigned its elastomers business to its base chemicals unit whose operations are earmarked for divestment. The elastomers segment generates sales of around EUR 500m annually with sealing systems for automotive, construction and electrical applications.

LANXESS responds to

global economic crisis and shifts investments

Specialty chemicals group LANXESS AG responds to the global

economic crisis by taking further measures.

Affected by the decision is the construction of the Butyl

Rubber plant in Singapore. According to the revised plans,

the new Butyl Rubber facility is expected to commence operations

in 2012, with groundbreaking - previously scheduled for January

2009 - postponed until the fall. Additionally, plans for capacity

expansions in Leverkusen and Antwerp and the planned move of the

group headquarters from Leverkusen to Cologne will also be

postponed.

LANXESS Acquires Polyol Specialist in China

LANXESS AG is

strengthening its market presence in the important Asia region by

acquiring the business and production assets of Jiangsu Polyols

Chemical Co., Ltd.

in Liyang, Jiangsu province, eastern China.

The deal is expected to close in the third quarter of 2009,

pending for regulating authority's approval.

Jiangsu Polyols mainly produces trimethylolpropane. LANXESS' business unit Basic

Chemicals is already a major supplier of TMP in China and will

integrate Jiangsu into its global operations.

| 主な用途 | アルキッド樹脂塗料、ポリウレタン樹脂塗料、印刷インキ | |

|---|---|---|

LANXESS: Production in Singapore to start in 2014

Postponement made necessary by drop in demand / New technology for the large-scale project / Bulk order from tire manufacturer Hankook

Due to

the continuing global economic crisis, specialty chemicals group

LANXESS AG is postponing the construction of its

new butyl rubber facility in Singapore. Production is now scheduled to start in 2014. LANXESS will use the time to

finish developing an innovative technology for butyl rubber

production that will then be used at the new facility. The 100,000 tpa plant originally planned for

Singapore, which would have cost up to EUR 400 million to build,

had been due on stream in 2012.

Independent of the

project postponement, LANXESS will continue to expand its

presence in Singapore. The company is currently negotiating with

the Singapore Economic Development Board (EDB) with a view to managing the

global business of the Butyl Rubber business unit from there in

the future.

Said Heitmann: “This dynamic city is the hub of

our activities in Southeast Asia and continues to play a key role

in our highly successful strategy for the Asian region.”

The Group currently

runs the Southeast Asian business of all its 13 business units

from Singapore.

LANXESS is a technology leader in the global market for synthetic

rubber and supplies all the leading tire manufacturers and other

customers worldwide. The focus is on the premium segment,

including numerous new grades of rubber for energy-saving tires

with improved running properties such as braking characteristics. A five-year

agreement recently signed with South Korean tire manufacturer

Hankook

underlines the growing importance of the Asian market. This new

supply agreement for butyl rubber covers the period from 2010

through 2014. LANXESS already concluded a long-term supply

agreement with Hankook, the world's seventh-largest tire

manufacturer, for styrene-butadiene rubber and

polybutadiene rubber in 2007. Hankook has a workforce of 14,000

and had sales equivalent to about EUR 2.5 billion in 2008.

LANXESS completes acquisitions in India and China

German

specialty chemicals group LANXESS has successfully completed the

acquisitions of the chemical businesses and production assets

belonging to Indian company Gwalior Chemical

Industries Ltd as

well as China's Jiangsu Polyols Chemical Co. Ltd. The transactions have received

the necessary approvals from the anti-trust authorities and

Gwalior shareholders. Both transactions have taken economic and

legal effect on September 1, 2009.

LANXESS is paying EUR 82.4 million - including debt - for the assets of Gwalior, while

the acquisition price for Jiangsu Polyols will remain

undisclosed. Both transactions complement the portfolio of

LANXESS' business unit Basic Chemicals,

which is one of the leading manufacturers of raw materials for

agrochemicals, polymers, surface coatings, and pigments.

“These

acquisitions in India and China are further milestones in our

company's long-term growth strategy in the BRIC countries”, said Axel C. Heitmann, Chairman of

LANXESS' Board of Management. “We will start to integrate these

two businesses into our group and warmly welcome the new

employees into the LANXESS family.”

Gwalior

is one of the largest Indian producers of benzyl products and one

of the leading global producers of sulphur chlorides for the agrochemicals and

pharmaceuticals as well as for the flavor and fragrance

industries. In its business year 2008/2009 (ended March 31) the

Indian company achieved sales of approximately EUR 57.8 million

and currently employs about 400 permanent staff mainly based at

its production site in Nagda, Madhya Pradesh state.

Jiangsu

Polyols achieved

sales of about EUR 10 million in 2008 and currently employs some

170 staff at its facility in Liyang, west of Shanghai. It mainly

produces trimethylol propane (TMP) that is used in lubricants,

paints, and coatings. LANXESS's business unit Basic Chemicals is

already a major supplier of TMP in China.

LANXESS is a leading specialty chemicals company with sales of EUR 6.58 billion in 2008 and currently 14,335 employees in 23 countries. The company is represented at 46 production sites worldwide. The core business of LANXESS is the development, manufacturing and marketing of plastics, rubber, intermediates and specialty chemicals.

LANXESS streamlines

global production network

Divestment

of Chinese joint venture stake and U.S. site

LANXESS AG has taken further steps to streamline its global

production network and thus reduce operating costs in the face of

the economic crisis and competitive business environment.

The specialty chemicals group has sold its 55 percent stake in

the hydrazine hydrate joint venture LANXESS Yaxing

(Weifang) Chemicals Company Ltd. to its Chinese partner Weifang

Yaxing Group 亞星集団. The joint venture was founded in

September 2004 and is based in the Weifang Industry Park in

Shandong province, China. Both parties have agreed not to

disclose financial details.

2005 3 山東省イ坊市 ヒドラジン水和物工場起工(Baytown, USAから設備移設)〈2006/7稼動〉

July 12, 2006 Lanxess

LANXESS inaugurates hydrazine hydrate plant in Weifang

Successful relocation of plant from Texas, USA, to China