台湾プラスチック(FPC) Group Major Products

事業

概要 No.6 Naphtha Project

麦寮コンビナート 2002/11 エチレン増強完了

麦寮で第3期エチレン計画

Third Cracker

at Mailiao Formosa

sees new cracker completion by early next year

Formosa Plastics gets govt backing for

Phase IV expansion

Formosa Plastics expands capacity at

Mailiao complex.

中国計画 → 2002/5 台湾政府、PVC計画承認 中国税関にVCM輸入・製品輸出申請

Taiwan's FPC to

delay startup of Ningbo PVC project

Citibank to loan

to Formosa Chemical for ABS & PVC in mainland China

Formosa Plastics plans acrylates complex

in China.

Formosa Plastics gains OK for

Acrylic Ester and PS China plants

Formosa Plastics plans 300,000t PP

plant in Ningbo → 450,000t

China's Formosa PP

(Ningbo) delays new PP unit start to Q2 2007

Taiwan Formosa Plastics

likely to start Ningbo PP runs early-Apr

Formosa targets Ningbo PTA

plant start-up during April

450,000

mt/year polypropylene plant

300,000

mt/year polyvinyl chloride plant and

300,000 mt/year acrylic ester plant. |

【台湾】台プラ、寧波にナフサプラント投資申請へ

【台湾】台化、寧波のPTA工場に追加投資

台プラ、30億元で寧波にバース5基増設

台プラとシノペック、業務提携で交渉 台プラ、報道を否定

台プラの対中投資案、1.4億ドルが認可

台プラのナフサ工場、中国国務院に申請

FPG May Forgo

Ningbo Mega Ethylene Project

台プラ、江蘇省呉淞江に繊維生産拠点

Formosa to complete

construction of Ningbo ethylene tank by 2007

Formosa Plastics Group

Plans to Invest in China Mainland

王永慶董事長インタビュー

米でBordenからPVCプラント購入

FPC、PP子会社の持ち株比率98%に

Formosa to Form Holding Company ; Plans

acrylic Esters Plant in China

旭化成 イオン交換膜法食塩電解設備受注

Formosa to build new 400 kt/yr

EDC plant by 2004-2005

Formosa advances naphtha cracker

completion by a year to 2006

Formosa plans 50kt PP debottlenecking for

mid-November

【台湾】台プラのベトナム拠点、4月に生産開始

台塑石化、プロピレン増産で中国へ供給

台湾プラスチック、12月にMMA生産能力を1.4万t増の8.4万tに

(Jchem News 2004/8/27)

【台湾】長春、台プラ第6ナフサに大型投資

台プラの石油精製工場、雲林に建設計画

テキサスのフォモサプラスチックで爆発事故

Formosa Plastics Point Comfort

Plant Resuming Operations

Taiwan's Nan Ya Plastics Corp aims

to start new BPA line by Oct

Taiwan's FCFC to bring new PS

plant in Ningbo online in October

Taiwan's FCFC mulls start-up of

new PTA plant before June 2008

Formosa Petrochemical: To Build

Butadiene Rubber Plant In China

事業

台湾(別紙「台湾の石化」の青字がFPCの事業)+USA (+中国計画)

台湾プラスチック概要 (1999年時点)

1.台湾プラスチック

1954年10月、王永慶現会長が設立した台プラグループの中核企業で、塩ビ関連事業が半分を占める。

2.南亜プラスチック

58年8月に設立された台湾最大のポリエステル繊維メーカーであり、民間企業では台湾最大の売上高規模を誇る。

3.台塑石化

92年5月、台湾プラスチック40%/南亜プラスチック30%/台湾化学繊維30%出資合弁会社として資本金150億元で設立された。雲林県麦寮区に大規模な石油化学コンプレックスを建設

(化学工業日報 2000/10/26)

麦寮コンビナート

偉容現す台湾「麦寮コンビナート」

エチレン135万トン体制 47プラント順次稼働へ

世界が注目し、アジアの石油・石油化学の構図を大きく塗り替えるとみられる台湾プラスチック(FPC)グループが推進する一大プロジェクト「麦寮コンービナート」。47のプラント群が林立し、36万トンのタンカーが岸壁に横付けしている姿は壮観である。

化学工業日報 2002/6/26

台湾FPC、麦寮で第3期エチレン計画

台湾プラスチック(FPC)グループは、台湾・雲林県麦寮の石化コンビナートで、年産150万トンのエチレン設備を中心とした第3期石化計画の検討を開始した。

Formosa

Petrochemical Okays Third Cracker at Mailiao

http://www.chemchannels.com/chemchannel/homepage/General/Newprojects/newproject.asp

Company

:

Type :

Date :

Detail : |

Formosa

Petrochemical Corp. (FPC; Taipei)

Individual

Running and will be completed in second-halr year 2006.

Formosa Petrochemical Corp. (FPC; Taipei) says its board

has approved construction of a previously announced

naphtha cracker at Mailiao, Taiwan. The unit will cost

NT$25 billion ($724.6 billion) and will have capacity for

1.2 million m.t./year of ethylene, 600,000 m.t./year of

propylene, and 170,000 m.t./year of butadiene *, says Wilfred

Wang, executive v.p. Completion is scheduled for

second-half of 2006. FPC says it has applied to the

Environmental Protection Agency (EPA; Taipei) for

approval of the third cracker. ABB Lummus Global has

begun basic engineering.

FPC has two ethylene plants at Mailiao, with a combined

capacity of 1.7 million m.t./year. Downstream producers

at the complex have requested that FPC build a third

cracker to meet additional raw material requirements from

planned downstream expansions, FPC says. Three members of

the Formosa group jointly own 90% of FPC. They are

Formosa Chemicals & Fibres Corp. (FCFC), Formosa

Plastics, and Nan Ya Plastics. FPC employees hold the

rest. Nan Ya is completing its

third ethylene glycol (EG) plant and planning a fourth

unit there; FCFC is planning a third

styrene plant; and Formosa Plastics is planning to expand

vinyl chloride monomer capacity, FPC says.

FPC will fund the project mainly from cash flow, and the

rest from bank loans, the company says. FPC forecasts a

more than doubling of net profits in 2003, to NT$17.8

billion, on sales up 30%, to NT$220 billion. Separately,

the parents of FPC plan a separate listing for the

company on the Taipei Stock Exchange next November, Wang

says. * and a 3rd aromatic unit

which is able to produce 1.1

million tons of aromatics annually. (APIC 2006 台湾資料)

|

Platts

2006/10/16

Taiwan's Formosa sees new cracker

completion

by early next year

Taiwan's Formosa

Petrochemical expects to complete its third

cracker in Mai Liao by early next year, a company

source said Monday. The cracker will have a nameplate ethylene

capacity of 1.2 million mt/year and a propylene capacity of

600,000 mt/year.

In related plant news, completion of Taiwan's Nan Ya Plastics's

new 600,000 mt/year monoethylene glycol line in Mai Liao has been

delayed to March next year at the earliest due to difficulties in

securing and fitting of plant equipment and electronics.

Formosa Plastics

Corporation, U.S.A.

http://www.fpcusa.com/

1981 StaufferからDelaware工場買収

1983 Texas(Point Comfort)工場建設 2002年増設

1990 Louisiana(Baton Rouge)工場建設

2002 to Purchase Illiopolis,

Illinois, Facility from Borden Chemicals and Plastics

Capacities(単位:million pounds) 2002年

| |

Delaware |

Illinois |

Louisiana |

Texas |

Caustic

|

+

|

+

|

450

|

* 1,785

|

EDC

|

+

|

+

|

547

|

* 2,135

|

PVC Suspension

Resin

|

+

|

+

|

918

|

1,266

|

PVC Dispersion

Resin

|

144

|

+

|

+

|

+

|

Specialty

PVC Resins

Commodity

PVC Resins |

+

|

200

200 |

+

|

+

|

VCM

|

+

|

+

|

1,410

|

840

|

Ethylene Gas

|

+

|

+

|

+

|

3,411

|

HDPE

|

+

|

+

|

+

|

1,484

|

LLDPE

|

+

|

+

|

+

|

582

|

PP

|

+

|

+

|

++

|

1,495

+140

|

* The Ion Exchange Membrane

(IEM) Plant, which produces caustic and chlorine, and the

EDC Plant are owned

by Formosa Plastics Corporation, America and managed by FPC

TX.

(Chemical Week Mar 06, 2002 )

Formosa

Starts Up PE and PP Units at Point Comfort

Formosa

Plastics says it has brought a 550-million lbs/year

high-density polyethylene (PE) unit and a 350-million

lbs/year polypropylene (PP) unit at Point Comfort, TX

onstream. The PP unit is the second train of a

700-million lbs/year plant; the first train came

onstream last April.

Formosa

Plastics Corporation, U.S.A. together with its

subsidiaries (Formosa), is a full-service manufacturer

and supplier of plastic resins and petrochemicals. Our

operations include chemical and petrochemical

manufacturing, natural gas drilling, and polyvinyl

chloride (PVC) downstream processing.

Formosa's plastic resins and petrochemicals are

manufactured at four chemical manufacturing subsidiaries:

Formosa Plastics

Corporation, Delaware (dispersion PVC); Formosa

Plastics Corporation, Illinois (specialty and

commodity PVC); Formosa Plastics

Corporation, Louisiana (caustic soda, EDC,

suspension PVC, and VCM); and Formosa

Plastics Corporation, Texas (caustic soda,

EDC, suspension PVC, VCM, ethylene, HDPE, LLDPE, and PP).

Energy and raw materials for our chemical manufacturing

operations are supplied by three additional subsidiaries

acquired in 1988: Lavaca Pipe Line

Company (natural gas

transmission), Neumin Production

Company (exploration and

production of natural gas and oil), and

Formosa Hydrocarbons Company, Inc. (gas

processing). Formosa processes these raw materials into

energy (electricity and steam) and intermediates

(ethylene and propylene gas) used in the manufacture of

our products, helping to ensure consistent quality and

uninterrupted supply.

Acquired in 1982, J-M Manufacturing

Company, Inc. (J-M) produces PVC pipe

for sewer, water main, and general construction

applications. J-M has grown to be the world's largest

manufacturer of PVC pipe with 1999 sales exceeding $500

million. J-M operates 14 plants throughout the U.S. with

some of the most modern production facilities in North

America.

In 1994, Formosa formed the

Formosa Transrail Corporation to operate and

maintain its newly acquired rail fleet. Consisting

primarily of new, large volume railcars, the fleet

transports products to customers across North America and

Mexico, allowing the company to expedite all rail

shipments and helping to ensure on-time deliveries.---------------------

In 1978, we began to invest in the United States, in

order to secure a supply of petrochemical materials. We

selected the United States as the location for our

overseas investments because, in addition to rich natural

resources and well-established legal, political, and

economic systems, the country possessed an excellent

infrastructure and a well-educated workforce.

After years of effort, Formosa Plastics Corporation,

U.S.A., Nan Ya Plastics Corporation USA, Formosa Plastics

Corporation, America, and Nan Ya Plastics Corporation,

America were established. In addition, J-M Manufacturing

Company, Inc. and Neumin Production Company were

acquired. Presently, we own several large petrochemical

plants, secondary and tertiary processing plants, and

natural gas wells.

Polyvinyl chloride (PVC) and its related products were

the original product groups in our U.S. operations.

Currently, our annual production capacity for PVC resin

has reached 971,000 MT. FPC is the largest U. S. producer

of PVC pipe (840,000 MT/year), PVC rigid film (105,000

MT/year), and PVC flexible film (96,000 MT/year).

Widening our scope of operations, we now have a polyester

plant in South Carolina (860,000 MT/year) and an ethylene

glycol plant in Texas (327,000 MT/year). Due to the

quality and fair pricing of our products, the demand has

been exceptionally high.

To further vertically integrate our production, in 1990

we invested U.S.$1.9 billion to build the first olefins

plant and 8 related petrochemical intermediate plants. In

1994, we successfully launched our expansion project.

Followed by the completion of a second olefins plant in

2002, we now can produce 1,500,000 MT/year of ethylene,

860,000 MT/year of polyethylene, 630,000 MT/year of

polypropylene, 1,008,000 MT/year of NaOH, and 1,200,000

MT/year of ethylene dichloride. Formosa Plastics

Corporation, U.S.A. is a single-source supplier of PVC,

PP, and PE with the capability of modifying production to

meet varying market demands.

In 1990, we set up the Inteplast Corporation, a state of

the art facility in Texas, for production of BOPP,

stretch film, XF film, PP corrugated sheet, Rigid PVC

Sheet, foam board, and PE shopping bags.

|

| PVC Resin |

97,100 |

Formosa Plastics

Corporation, U.S.A |

| VCM |

1,021,000 |

Formosa Plastics

Corporation, U.S.A |

| Caustic Soda |

1,008,000 |

Formosa Plastics

Corporation, U.S.A, Formosa Plastics

Corporation, America |

| Chlorine |

896,000 |

Formosa Plastics

Corporation, U.S.A, Formosa Plastics

Corporation, America |

| EDC |

1,209,000 |

Formosa Plastics

Corporation, U.S.A, Formosa Plastics

Corporation, America |

| Ethylene |

1,500,000 |

Formosa Plastics

Corporation, U.S.A |

| Propylene |

644,000 |

Formosa Plastics

Corporation, U.S.A |

| HDPE |

600,000 |

Formosa Plastics

Corporation, U.S.A |

| PP |

630,000 |

Formosa Plastics

Corporation, U.S.A |

| LLDPE |

264,000 |

Formosa Plastics

Corporation, U.S.A |

| EG |

327,000 |

Nan Ya Plastics

Corporation, America |

| PVE Rigid Pipe |

840,000 |

J-M |

| Polyester Staple Fiber |

860,000 |

Nan Ya Plastics

Corporation, America |

| Flexible PVC Film |

960,000 |

Nan Ya Plastics

Corporation, America |

| Rigid PVC Film |

105,600 |

Nan Ya Plastics

Corporation USA |

| BOPP |

120,000 |

Inteplast |

| Stretch Film |

32,000 |

Inteplast |

| PE Bags |

198,000 |

Inteplast |

| XF Film |

76,000 |

Inteplast |

| PP Corrugated Sheet |

65,000 |

Inteplast |

| PVC Sheet |

40,000 |

Inteplast |

| Concentrates |

30,000 |

Inteplast |

| Natural Gas |

8,472,00000MMBTU |

Neumin |

| Condensate |

284,000 BBLS |

Neumin |

| Liquefied Natural Gas |

582,000 BBLS |

Neumin |

----------

In 1932 Yung-ching Wang

borrowed $200 from his father, a Taiwanese tea merchant,

to buy a rice mill near the town of Jiayi. The mill was

destroyed by Allied bombs in 1944, but Wang went on to

make a fortune in timber and founded Formosa Plastics, a

small polyvinyl chloride (PVC) plant, in 1954. He bought

the technology from the Japanese, later joking that he

didn't even know then what the "P" in PVC stood

for.

At first Wang had trouble finding buyers for his PVC

resins. In 1958 he set up his own resin processor, Nan Ya

Plastics, and later formed Formosa Chemicals & Fibre

to make rayon backing for PVC leather (1965). For the

next 15 years, the company grew into the Formosa Plastics

Group (FPG), an exclusively Taiwanese enterprise.Between 1980 and

1988 Wang bought 14 US PVC manufacturers, including

Imperial Chemical's vinyl chloride monomer plant (1981),

Stauffer Chemical's PVC plant (1981), and Manville

Corporation's PVC businesses (1983). He started building

a Texas PVC plant in 1981 and cut construction costs up

to 40% by importing equipment from Taiwan. When the PVC

market became saturated in the mid-1980s, Wang

diversified, building plants to make semiconductor

chemicals.

Wang

bought several Texas-based oil and gas properties in

1988, including 218 producing wells, a gas-processing

plant, and a pipeline firm. Faced with stricter pollution

controls in Taiwan, Wang began building an ethylene plant

in Point Comfort, Texas, in 1988.

In 1992 Wang wanted to build an ethylene complex in

mainland China, where there were no pollution controls.

Taiwan balked at the proposal, suggesting that FPG build

at home. Attempting to circumvent a Taiwanese law against

direct investment in the mainland, Wang sought Chinese

approval through subsidiary Formosa Plastics Corporation,

U.S.A. In 1993 Chinese authorities rejected a plan that

would require them to finance up to two-thirds of a $7

billion petrochemical complex.

Formosa Plastics bought bankrupt US computer maker Everex

Systems in 1993. Meanwhile, the group's focus again

turned to mainland China when Nan

Ya Plastics made plans in 1994 to build three plants

along China's Long River.

The 1995

death of Wang's mother (at age 108) set off a power

struggle between family factions. The company won

licenses in 1996 to build power plants, which would make

FPG Taiwan's first private-sector power supplier and end

a 50-year government utility monopoly. That year, in

defiance of Taiwan's policy of limiting investment in

China, FPG announced it would build a power plant there.

Pressure from the Taiwanese government put the project on

hold in 1997.

FPG upped its investment in a new Taiwanese petrochemical

complex in 1998. It formed ventures with Asahi Chemical

to make spandex fiber and with France's Renault to make

hybrid (gasoline/electric) cars. Also that year the group

admitted to combining mercury-laden waste with cement and

sneaking the toxic mixture to Cambodia disguised as 3,000

tons of cement block. FPG apologized after villagers

living near the dump became ill.

Undaunted

by a history of animosity between the two countries,

Formosa Plastics and FPG's other flagship companies in

1999 invested a 60% stake in the production of power

plants in the Chinese province of Fujian. The following

year, the company announced plans to build a PVC plant in

China as well.

|

| |

|

中国計画

(化学工業日報 2001/5/28)

台湾FPC

中国にエチレン拠点 独自出資

04年、100万トン超計画 誘導品で日本と合弁も

台湾プラスチック(FPC)グループが、中国にエチレン年産100万−120万トンを頂点とした世界規模の石油化学コンプレックスを建設する方向で検討に入った。総投資額は約60億ドルで、うち約20億ドルは自己資金でまかなう見通し。立地は逝江省・寧波と江蘇省・太昌(上海近郊)が有力候補で、早ければ2004年にも完成させる。

Financial

Times Information 2002/5/21

FPG to start developing petrochemical zone in mainland China

Chairman Wang

Yung-ching of the Formosa Plastics Group (FPG) estimated

the group will have to inject a combined NT$150 billion

to have complete manufacturing operations at a special

petrochemical zone in Ningbo, in mainland China's Zejiang

Province(逝江省・寧波). Wang made the estimation after the

Ministry of Economic Affairs (MOEA) gave the long-waited

approval to Formosa Plastics Corp.'s (FPC) US$49 million

investment plan in the mainland to build a polyvinyl chloride (PVC)

factory.

The Taiwan

Economic News May 21, 2002

Government OKs

Formosa Plastics, Hon Hai projects in China

The US$49 million project of the

Formosa Plastics Group (FPG), one of Taiwan's top plastics

suppliers, has been withheld by government for around one

year.

FPG's plan is to build a polyvinyl chloride (PVC) factory

in Ningbo, Zhejiang Province, China. The investment

capital will be remitted to mainland China within three

months. It will take two or three years to complete the

construction of the factory, which is expected have a

production capacity of 300,000 tons of PVC a year.

Chemical Week

2002/6/26

Registers China PVC Plant with Customs Authorities

Formosa Plastics

says it has registered with China's customs authorities

its previously announced 300,000-m.t./year polyvinyl

chloride (PVC) plant at Ningbo for imports of raw

materials and exports of finished product.

Asia Chemical

Weekly 2003-12-18

Taiwan's FPC to delay startup of Ningbo PVC project

Formosa Plastics Corp (FPC) has delayed the startup of its

polyvinyl chloride (PVC) project in Ningbo, Zhejiang, China,

to October 2004, according to a company source.

Originally

due onstream in the middle of 2004, the 300 000 tonne/year

plant was rescheduled for mechanical completion in August

2004.

2004-10-19

China Chemical Information Net

FPC

delays PVC start-up again.

The start up of Formosa Plastic Corp's 300,000 tonnes/y PVC

facilityat Ningbo, China, has been put back, for the second

time, to the end of 2004. Start up was initially planned for

mid-2004.

(化学経済 2001/2)

王永慶董事長インタビュー

この人に聞く

台湾プラスチックグループ 王永慶董事長

人の10倍考え、10倍の努力で克服

台湾最大の民間企業グループである台湾プラスチックグループは2000年には雲林県麦寮にアジア最大の石油化学コンビナートを完成,稼働を開始した。

塩化ビニル樹脂(PVC)日産4トンからスタートした同社は奇跡的な成長を遂げた同国の象徴ともいえる存在である。

PVC生産能力1000倍に

麦寮石化コンビナート軌道に

怖くないシンガポール石化製品

(Formosa 2002/3/8 発表)

Formosa Announces

Intent to Purchase Illiopolis, Illinois, Facility from Borden

Chemicals and Plastics Operating Limited Partnership

http://www.fpcusa.com/comm/news/pr030802.html

Formosa Plastics

Corporation, U.S.A. (Formosa) today announced that it has

entered into an asset purchase agreement to acquire the

Illiopolis, Illinois-based polyvinyl chloride (PVC)

operations of Borden Chemicals and Plastics Operating Limited

Partnership (BCP). The transaction is subject to

approval in bankruptcy court.

New York

(Platts)--28Mar2002

The US Bankruptcy Court for the District of Delaware

Thursday approved the bid by Formosa Plastics

Corporation, Delaware, to acquire the assets and

operations of Borden Chemicals and Plastics' polyvinyl

chloride plant in Illiopolis, Illinois, for approximately

$35-mil, subject to adjustments for working capital and

other items.

Discussions

continue concerning disposition of BCP's plant in

Geismar, Louisiana,

said Mark Schneider, president and chief executive

officer, BCP Management, the general partner of BCP.

(CHEMICAL WEEK NEWSWIRE Mar

11, 2002)

Formosa Agrees to

Acquire BCP's Illinois Vinyls Unit

(略)

BCP, which filed for

Chapter 11 bankruptcy protection last spring, is required to

place its Illiopolis plant on the auction block before it can

be sold to Formosa. Other interested parties can submit bids

through March 21. If other bids are received, the auction

will be held on March 25. BCP idled the Illiopolis unit early

last year, citing weak market demand. BCP recently

completed the sale of its 600-million lbs/year PVC plant at

Addis, LA to Shintech. The sale leaves BCP with its

275-million lbs/year plant at Geismar.

化学工業日報 2002/6/17

FPC、PP子会社の持ち株比率98%に

台湾の大手石化メーカーの台湾プラスチックス(FPC)は、ポリプロピレン(PP)子会社の永嘉化学工業の持ち株比率を49%から98%に引き上げた。

化学工業日報 2002/11/21

台湾FPC、麦寮でエチレン増強完了へ

台湾プラスチック(FPC)グループの台塑石油化学(FPCC)が進めていたエチレン設備の増強がこのほど完了、同社のエチレン年産能力は160万トンとなったことが明らかになった。

2002/12/2 Chemical Week

Formosa to Form

Holding Company; Plans Esters Plant in China

The firms to be

merged are Formosa Plastics; Formosa Chemicals & Fibre;

Nan Ya Plastics; Formosa Petrochemical; and Formosa Taffeta.

Formosa says it

plans to apply to the Taiwanese government for approval to

build a 230,000-m.t./year acrylic esters plant

at Ningbo, China.

The plant will cost $163 million, Formosa says.

December 11, 2002

Financial Times

Citibank, Bank of China to jointly

lead US$217 M. loan to Formosa Chemical

Citibank and Bank of China

will jointly lead a US$217 million seven-year syndicated loan

to finance construction of a petrochemical plant to be built

by Formosa Chemical & Fibre Corp. in Ningpo, Jiangsu

Province of mainland China

April 4, 2003 Financial Times

FPC to expand VCM.

Vinyl chloride monomer (VCM)

capacity at Formosa Plastic Corp's 720,000 tonne/y facilities in

Mailiao, Taiwan, is to be increased by 80,000 tonne/y. Project

completion is expected by the end of 2004. During 2003, the

company also intends to raise ethylene dichloride capacity at

Mailiao by 200,000 tonne/y to 800,000 tonne/y.

May 28, 2003

Financial Times

Formosa Plastics

gets govt backing for Phase IV expansion

Premier Yu Shyi-kun

yesterday promised full support to the latest investment plan

of Taiwan's petrochemical giant, the Formosa Plastics Group,

for the fourth-phase expansion of its petrochemical complex

in Mailiao, Yunlin County in southwest Taiwan

June 13, 2003

Financial Times

Formosa Plastics expands capacity at Mailiao complex.

Formosa Plastics is

to invest NT$5 bn in capital expenditure projects in Mailiao,

Taiwan, during 2003. Capacity for caustic soda is to be increased by

350,000 tonnes/y to 1.05 M tonnes by Jun 2004. Capacity for vinyl

chloride monomer

is to be improved by 200,000 tonnes/y to 1.52 M tonnes by Apr

2004. High-density polyethylene (HDPE) capacity is to be increased

by 50,000 tonnes/y to 500,000 tonnes/y. Low-density

polyethylene (LDPE) and ethylene-vinyl acetate copolymer capacity is to be increased

by 40,000 tonnes/y to 240,000 tonnes/y. Capacity for linear

low-density PE (LLDPE) will rise by 24,000 tonnes/y to

264,000 tonnes/y before the end of 2004. In Sep 2002 Formosa

Plastics completed the expansion of acrylic

esters at

Mailiao by 18,000 tonnes/y to 198,000 tonnes/y. Formosa

Petrochemical is to expand ethylene capacity at the same site

from 1.45 M tonnes/y to 1.7 m tonnes.

July 28, 2003 Financial

Times

Formosa Plastics gains OK for Acrylic Ester and PS China plants

The Ministry

of Economic Affair's Investment Commission recently approved

two of Formosa Plastics Group's mainland China investment

proposals.

Formosa Plastics plans to invest US$49.57 million in an

AE(Acrylic Ester) plant and Formosa Chemicals will invest

US$17 million in a PS plant, both in Ningpo.

August 15, 2003 Financial

Times → 450,000t

Formosa Plastics plans PP plant in Ningbo in eastern China

The Formosa

Plastics Group (FPG) has decided to increase its

petrochemical investment in mainland China by setting up a

polypropylene (PP) in Ningbo on the eastern cost of the

mainland

The plant will have an annual output of 300,000 metric tons of the petrochemical

material

Platts 2003/9/3

Formosa advances naphtha cracker

completion by a year to 2006

Taiwan's Formosa Petrochemical has

moved forward by a year the planned completion of its No 3

naphtha cracker at Mai Liao to early 2006, a company source said

Wednesday. Formosa would begin construction by the end of 2003.

Platts 2003/10/13

Taiwan's Formosa plans 50kt PP debottlenecking for mid-November

Taiwan's Formosa Plastics Corp has planned a mid-November

debottlenecking at its 180,000 mt/yr PP plant in Lin Yuan that

would expand the capacity of the plant by 50,000 mt/yr to 230,000

mt/yr, a company source said

Monday. The plant would be shut down for about 10 days to

accomplish the expansion.

Platts 2003/10/13

Formosa to expand

Texas PP capacity with Chisso technology

Formosa

Plastics Corp, USA reported Monday that in late September

2003 it signed the first licensing agreement for Newcon, Chisso Corp's

reactor thermoplastic polyolefin (RTPO) alloy.

http://www.chisso.co.jp/pro.html

リアクターTPO ニューコン

柔軟、耐熱、寸法安定性/自動車部品、弱電部品、日用品、包装用フィルム、シート

2004/2/25 Platts

Formosa to start second phase ACN

debottlenecking project in May

Taiwan's Formosa Plastics

Corp plans to start the second phase of a debottle-necking

project at its 200,000 mt/yr acrylonitrile plant in Mai Liao

in May, boosting total capacity at the plant to 240,000 mt/yr, a company source said Wednesday.

Formosa uses most of its

existing ACN output captively, and would export the

additional ACN output to its new 120,000 mt/yr ABS plant in

Ningbo, China, slated for

start-up in early April, the source said.

2004年3月4日中国・ASEANニュース速報

【台湾】台塑、中油にナフサ建設で提携提案へ

http://www.e-plastics.gr.jp/japanese/nna_news/news/news0403_1/04030407.htm

台湾プラスチック傘下の台湾塑膠工業(フォルモサ・プラスチック)と台湾聚合化学品(USIファーイースト)は、3月20日の総統選挙後にも中国石油の郭進財董事長に対し、エチレン年産100万トンのナフサプラントの建設に関して提携を提案する考えだ。3日付経済日報が伝えた。

中油は、現在の第3および第4ナフサプラントに代わる、年産120万トンおよび年産100万トンのエチレン工場2基の新規建設を計画中。また、雲林台西石化科技工業団地にも年産100万トンのエチレン工場を建設する予定だ。これらの新エチレン工場の完成後、同社のエチレン生産は高雄の精油所での生産分50万トンを含め、年間で370万トンに達する。

Platts 2004/3/24

Taiwan Formosa to

complete 600,000 mt/yr styrene unit in H2 2006

Taiwan's Formosa Chemical

and Fibre plans to

complete its styrene monomer unit in Mai Liao, currently under

construction, in the second half of 2006, sources close to the

company said Wednesday.

FCFC's new No 3 unit

would have a nameplate capacity of 600,000 mt/yr, and would boost

the producer's total styrene capacity at its Mai Liao complex to

1.05-mil mt/yr.

中国・ASEANニュース速報 2004/6/10

【台湾】台プラ、寧波にナフサプラント投資申請へ

台湾プラスチックグループは近く、中国・浙江省寧波市北崙経済技術特区にエチレン年産80万トン規模のナフサプラント建設の投資申請を行う。投資総額は約300億台湾元。

寧波北崙では、台湾塑膠工業(フォルモサ・プラスチック)がプラスチック原料のポリ塩化ビニル(PVC)、ポリプロピレン(PP)、アクリル酸エステル(AE)などを生産、台湾化学繊維(フォルモサ・ケミカルズ&ファイバー)が芳香族化合物の高純度テレフタル酸(PTA)、ポリスチレン(PS)、アクリロニトリル・ブタジェン・スチレン(ABS)などを生産している。今回のナフサプラントなどの石化川上事業は、台塑石化(フォルモサ・ペトロケミカル)が統括に当たる。

2004/7/2

中国・ASEANニュース速報

【台湾】台化、寧波のPTA工場に追加投資

台湾化学繊維(台化=フォルモサ・ケミカルズ&ファイバー)は6月30日、中国・浙江省寧波の100%出資子会社、台化興業(寧波)に4,830万米ドルを追加投資して、高純度テレフタル酸(PTA)の生産能力を拡大することを決定した。

同社のPTAの年産能力は現在、雲林県・麥寮工場と宜蘭県・龍徳工場の2工場あわせて150万トン、中国では60万トンに達しており、PTAの売上高は同社の全体売上高の3割を占めている主要事業だ。

Platts 2004/7/5

Formosa

Plastics plans new PP plant in Ningbo for late 2006

Taiwan's

Formosa Plastics Corp has planned a new 450,000 mt/yr

polypropylene plant in Ningbo, China, slated for completion by

late 2006 or early 2007, a company source said Monday.

The

new PP plant would source propylene from the new cracker (No 3

naphtha cracker at Mai Liao)

Platts

2006/7/19

China's Formosa PP (Ningbo) delays new PP unit start to Q2

2007

China's Formosa Polypropylene (Ningbo) had delayed the start

up of its new 450,000 mt/year polypropylene

plant by

four to six months, to the second quarter of 2007, a company

source said Wednesday. The PP plant will be constructed at

the company's new petrochemical complex in Ningbo, Zhejiang,

eastern China.

In addition to the PP plant, Formosa Plastics Corp operates a

300,000 mt/year polyvinyl

chloride plant and a 300,000 mt/year acrylic ester plant.

2004年7月8日 中国・ASEANニュース速報

【台湾】台塑石化、プロピレン増産で中国へ供給

http://www.e-plastics.gr.jp/japanese/nna_news/news/news0407_1/04070802.htm

台塑石化(フォルモサ・ペトロケミカル)は、約100億台湾元を投じて、オレフィン分解およびプロピレン生産工場を雲林県麦寮の第6ナフサプラント内に設ける。中国・浙江省寧波の北崙技術経済特区に建設するポリプロピレン(PP)生産工場への供給を視野に入れた大型投資計画だ。7日付経済日報が伝えた。

第6ナフサプラントの第3オレフィン工場における年産量は、エチレン120万トン、プロピレン60万トン、ブタジエン18万トンとなっている。このうち、オレフィン分解設備の新設で、プロピレンの年産量が85万トンまで増加することになる。

■寧波工場は50%規模拡大

■事業拡大で中国で石化王国を

2004年7月20日

中国・ASEANニュース速報

【台湾】台プラ、30億元で寧波にバース5基増設

http://www.e-plastics.gr.jp/japanese/nna_news/news/news0407_3/04072002.htm

台湾プラスチックグループは、中国・浙江省寧波の北崙港にバース5基を増設する。原料の輸入を強化するほか、生産製品の輸送も視野に入れる。19日付工商時報が伝えた。

中国・ASEANニュース速報 2004年8月13日 台プラ、報道を否定

台プラとシノペック、業務提携で交渉

http://www.e-plastics.gr.jp/japanese/nna_news/news/news0408_2/04081304.htm

王永在・台湾プラスチックグループ副董事長は11日、同グループの幹部らとともに中国石油化工集団(シノペック)の上層部と、両者間での原油の委託精製、原料供給、貿易などの業務に関する戦略的提携の協議を行った。

台プラグループは浙江省寧波市の北崙経済技術特区にエチレン年産120万トン規模のナフサプラントの建設を計画しているが、台湾政府はまだナフラプラントの対中投資を許可していない。このため、シノペックとの提携によって北崙への石化原料の供給を期待している。

2004年9月7日

中国・ASEANニュース速報

【台湾】長春、台プラ第6ナフサに大型投資

http://www.e-plastics.gr.jp/japanese/nna_news/news/news0409_2/04090704.htm

総投資額1,246億台湾元に上る台湾プラスチックグループの第6ナフサプラント第4期工程に、長春グループが参入する。投資額は200億台湾元近くに上る大規模なもの。特殊プラスチックなどの生産も行う予定で、アジア太平洋地区の石油化学業界で競争力向上を図る。

6日付工商時報によると、台湾塑膠工業(フォルモサ・プラスチック)の李志村総経理が長春グループの投資計画を明らかにし、「原料は現在建設中の第3号ナフサ分解プラント(OL―3)から調達する」と語った。長春グループの林書鴻董事長は、「投資案はすでに行政院環境保護署(環境庁)に提出した。環境アセスメントの分析を経て、実行に移す」と慎重姿勢を崩さなかったものの、台プラと長春という石化業界の2強が、雲林県麦寮の第6ナフサプラントで強力タッグを結成するのは既定路線となった。

■競合先から提携先へ

中国・ASEANニュース速報 2004年10月15日

【台湾】台プラの対中投資案、1.4億ドルが認可

http://www.e-plastics.gr.jp/japanese/nna_news/news/news0410_2/04101504.htm

台湾プラスチックグループ傘下の台湾塑膠工業(フォルモサ・プラスチック)、台朔重工、南亜プラスチック各社の中国投資案3件が13日、経済部(経済省)投資審議委員会(投審会)の認可を得た。

投資の内訳は、台湾塑膠が6,900万米ドルを中国浙江省の投資子会社、台湾塑膠工業ポリプロピレン(寧波)へ増資するほか、台朔重工が4,900万米ドル同じく寧波に華亜鋼鉄を設立、南亜プラスチックが2,600万米ドルを江蘇省昆山の投資子会社、南亜ガラス繊維(昆山)への増資に充てる。

中国・ASEANニュース速報 2004年11月2日

【台湾】台プラのナフサ工場、中国国務院に申請

1日付経済日報によると、台湾プラスチックグループの王永在副董事長が先日、中国国務院に対してナフサプラント建設の投資申請を行った。

建設地は浙江省寧波市の北崙経済技術特区とみられ、同特区内にエチレン年産120万トン規模のナフサプラントを設ける。台プラグループにとっては、第6ナフサプラントに続く石油化学関連の大型投資となる。しかし、政府はナフサプラントの対中投資を開放していないことから、王副董事長は台湾と中国の両政府の認可を得てから計画を進展させることを強調した。

寧波北崙では、台湾塑膠工業(フォルモサ・プラスチック)によるプラスチック原料のポリ塩化ビニル(PVC)の年産30万トンの工場がまもなく完工するほか、台湾化学繊維(台化=フォルモサ・ケミカルズ&ファイバー)のアクリロニトリル・ブタジェン・スチレン(ABS)工場が量産を開始している。将来的にはアクリル酸エステル(AE)、ポリプロピレン(PP)、芳香族化合物の高純度テレフタル酸(PTA)の各工場も生産を開始する予定だ。

中国・ASEANニュース速報 2004年12月14日

【台湾】台プラの石油精製工場、雲林に建設計画

http://www.e-plastics.gr.jp/japanese/nna_news/news/news0412_2/04121401.htm

台湾プラスチックグループは、雲林県の離島工業区に1,200億台湾元を投じ、日産60万バレル規模の石油精製工場を建設する計画だ。ナフサの自製率を高め、グループの台塑石化(フォルモサ・ペトロケミカル)などのコスト削減が狙い。第6ナフサプラントとも結合し、同地の石油化学基地がさらに拡大する。13日付経済日報が伝えた。

台プラが開発を予定するのは、離島工業区の中の4カ所ある工業区のうち、新興区と台西区にまたがる2,000ヘクタール以上の土地。投資額1,200億元は、第6ナフサプラントにも匹敵する。位置的にも麦寮区の第6ナフサプラントの南に隣接し、同工業区に台プラの石油化学事業が集中することになる。

■石油精製量、日産100万バレルに

■中国石油との競争激化

2005/5/3 Platts

Formosa to complete construction of Ningbo ethylene tank by 2007

The storage tank would be able to hold roughly 44,000mt of

ethylene, which

would primarily support Formosa's recently completed 300,000 mt/yr PVC

plant in Ningbo. The

tank would also be able to provide ethylene for Formosa's planned

450,000

mt/yr polypropylene plant in Ningbo, scheduled to complete construction in

late 2006 or early 2007.

2005/10/7

Formosa Plastics Point Comfort

Plant Resuming Operations

テキサスのフォモサプラスチックで爆発事故 CSB調査 CSB報告

現地時間の6日午後3時05分、テキサス州ポイント・コンフォートにあるフォモサ・プラスチックの工場で爆発事故があり、11人が負傷した。うち1人は火傷で重症。爆発は第二オレフィン系列のプラントで発生した。同社では爆発場所は「プラスチック原料をつくるプラント」としているだけで、どのプラントかは不明。3時間後に鎮火した。同社によるとフォークリフトがプロピレンパイプを破損し、漏れたガスが地を這って流れ、引火して爆発した。同社では爆発したエリア(範囲は明らかにされていない)は無期限に停止するとしている。2つのハリケーンの影響で既にエチレンは不足状況となっており、フォモサの停止が石化製品の需給に影響を与えると見られている。.

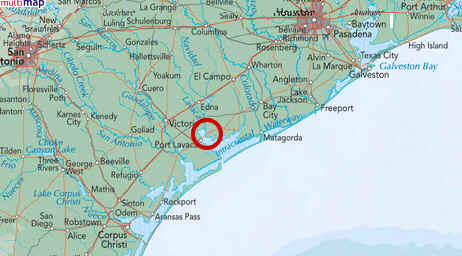

フォモサ・プラスチックは台湾の台湾プラスチックの子会社。ポイント・コンフォート工場(テキサス州のガルベストンとコーパスクリスティの中間に位置)は1983年建設の主力工場で、エチレン、クロルアルカリ、EDC、VCM、PVC、HDPE、LLDPE、PPを生産している。当初はVCMとPVCだけであったが、1994年に15億ドルをかけた大増設を行ってオレフィン、LLDPE、

HDPE、クロルアルカリ、EDC、PP、co-generation

工場を建設、1997年の10億ドルの増設で第二オレフィン(818千トン)、HDPE(250+150千トン)、PP(332千トン)工場

を建設した。この第二オレフィンの系列で今回の事故が発生した。工場全体で1600人のフルタイムの従業員と400人の契約社員を抱えている。

同社のホームページによると2002年時点の能力は以下の通り。

クロルアルカリ 811千トン

EDC 970

VCM 382

PVC 575

エチレン 1,550

HDPE 675

LLDPE 265

PP 680

フォモサ・プラスチックは他にデラウエア工場(PVC:1981年スタウファーから購入)、ルイジアナ工場(クロルアルカリ、EDC、VCM、PVC:1990年建設)、イリノイ工場(PVC:2002年ボーデンから購入)を有している。

フォモサ・プラスチックでは事故が続出している。このため各官庁では係員を同地に派遣し、調査を開始した。

1998年12月にはポイント・コンフォートのEDCプラントで爆発があり、26人が負傷した。2004年4月にはイリノイ工場でVCMの漏洩による爆発があり、4人が死亡、6人が負傷した。また本年4月にはVCM等の漏洩による環境基準違反で15万ドルの罰金を払っている。

( Diana

Wilson: Formosa Plastics 反対運動 )

なお、本年3月にはテキサスシティのBPの製油所が爆発し、15人が死亡、170人が負傷している。

TAIPEI (AFX) -

Formosa Plastics Corp said a group plant in Texas was hit by

an explosion and fire but the incident should only have a

limited impact on the company.

'Formosa

Plastics Corp only owns 6 pct of the Texas plant, the impact on our operations

and shareholders' interest should be very limited,' a company

official said.

Two other group

members, Nan Ya Plastics Corp and

Formosa Chemicals & Fibre Corp, own a combined 4

pct stake

in Formosa Plastics Corp USA, the official said.

The

above-mentioned firms are all members of Formosa Plastics

group.

Houston

Chronicle 2005/10/7

8 hurt in

plastics plant explosion

Cause of accident at Formosa facility in S. Texas is unknown

http://www.chron.com/cs/CDA/ssistory.mpl/topstory/3386038

In an

increasingly familiar scene along the Texas coast, black smoke

and flames streamed from a Point Comfort industrial plant

Thursday, following an explosion that injured at least eight

workers.

The blast at Formosa Plastics Corp. was the third to strike a

Texas industrial facility this year and the second to hit one of

the Taiwan-based company's U.S. facilities in 17 months.

In addition to the Point Comfort explosion, the CSB also is

investigating an April 2004 blast that killed four

workers and injured six at a Formosa plant in Illiopolis, Ill. The company's other two

U.S. facilities are located in Delaware City, Del., and Baton

Rouge, La.

In December 1998, a blast rocked

the Point Comfort plant's ethylene dichloride unit, rattling windows as far

as 35 miles away and injuring 26 workers.

Last April, the Texas Commission on Environmental Quality fined

the facility $150,000 for violations of air pollution laws that

included releases of toxic chemicals such as vinyl chloride.

Over the past decade, the U.S. Occupational Safety and Health

Administration has inspected the Point Comfort plant a dozen

times, five of them resulting in violations, OSHA online records

show.

In 1994, the company completed a $1.5 billion expansion, building

its first olefins unit. In 1997, the plant

underwent a second $1 billion expansion, in which it constructed

a second olefins unit ・the part of the plant

that erupted Thursday.

The Victoria

Advocate October 8, 2005

Pipeline break cause of explosions

Thursday's explosions at Formosa Plastic Point Comfort plant

happend when a contract employee using a forklift and pulling an

air cart backed into a 6-inch line carrying liquid propylene,

causing a break in a fitting or valve, plant officials said

Friday in a memo.

The pipeline was carrying the propylene at 165 pounds of

pressure. The gas that was released from the pipeline vaporized

into a cloud when it reached the atmosphere. The gas, which is

heavier than air, traveled along the ground until it reached an

ignition source and exploded, according to the memo.

Although all employees are back on the job, "The plant is

shut down," said Jack Wu, vice president of business

development. "The damage is all in the Olefins 2

unit. The

fire automatically shuts everything down."

Wu said all employees are back at work getting ready to start up

the plant, which he said, "technically, would take maybe two

days."

Multinational

Monitor MAY 1991

- VOLUME 12 - NUMBER 5

Taiwan Brings

Toxics to Texas

http://multinationalmonitor.org/hyper/issues/1991/05/front.html

In a victory for

a tiny, embattled environmental movement in Calhoun County,

Texas, the Environmental Protection Agency (EPA) delayed granting

the Taiwan-based Formosa Plastics Corporation the wastewater

discharge permits it needs to begin operations at the company's

newly expanded facilities. The EPA announced in February 1991

that it is requiring the preparation of an environmental impact

statement before it will grant the permits. Formosa Plastics,

Taiwan's largest chemical producer, has a history of

environmental degradation and violations both in Taiwan and in

its plants in the United States.

Oct. 13,

2005 Houston

Chronicle

Formosa Plastics

Point Comfort Plant Resuming Operations

Fire Extinguished, Damage

Appears Limited and Production Resumes

No Off-Site Environmental

Impact or Damage Found

Formosa Plastics Corporation, U.S.A. announced today that the

last remaining minor fire resulting from an explosion on October

6 at its Point Comfort, Texas plant was extinguished early

yesterday morning and that operations at the facility had

resumed.

The company also said that damage from the explosion and

resulting fire appears to have been limited to what is known as

the "Purification Area" of

the Olefins 2 production unit.

October 14, 2005

The U.S. Chemical Safety and Hazard Investigation Board

CSB Probe of Point Comfort Formosa Plastics Incident Continues as

Team Weighs Safety Issues; No Root-Cause Investigation Planned

http://www.csb.gov/index.cfm?folder=news_releases&page=news&NEWS_ID=247

The U.S.

Chemical Safety and Hazard Investigation Board (CSB) is

continuing its probe of the propylene fire and explosions that

heavily damaged an olefins unit at the Formosa Plastics facility

in Point Comfort, Texas, on October 6, injuring approximately 13

workers. Most injuries were minor, but two workers were admitted

to the burn unit at a Galveston hospital, and one remains

hospitalized there.

After six days at the incident site, investigators yesterday

returned to Washington, DC, where they planned to brief agency

Board members and staff. Investigators have conducted

approximately 24 witness interviews; examined the damaged area of

the facility's Olefins 2 unit; and reviewed process diagrams,

procedures, and other documentary evidence. Based on current

evidence, investigators will not recommend a full root-cause

investigation of the incident by the CSB. However, work to

understand the circumstances of the incident will continue.

CSB lead investigator Jim Lay, P.E., said, "Witness accounts

indicate that a forklift truck towing an air supply trailer may

have collided with a drain line near a ground-level control valve

station carrying highly flammable liquid propylene. We intend to

gather additional evidence before confirming this theory. Shortly

after the trailer entered the vicinity of the valve station,

witnesses saw a downward jet of escaping hydrocarbon, which

formed a rapidly expanding vapor cloud. Within a few minutes, the

vapor cloud found an ignition source, causing an explosion and

fire." Major fires continued for a number of hours as

additional piping was damaged and more flammable hydrocarbons

were released.

Mr. Lay said that access to the exact point of origin of the

release was still restricted this week due to structural hazards,

residual flammable materials, and ongoing emergency response and

firefighting activities. "Portions of the olefins unit where

the incident was centered show extensive damage from heat. The

site shows relatively little blast damage, consistent with a

series of unconfined, open-air explosions or deflagrations,"

Mr. Lay said.

Immediate issues before the investigative team include

characterizing the extent of secondary damage from the explosion

and examining the effectiveness of the facility's vehicular

control policies and the protection of vulnerable piping from

vehicular collision. Mr. Lay said team members would be returning

to the plant as early as next week to continue the probe.

In addition to work at the Formosa site, investigators went into

the Point Comfort and Port Lavaca communities to assess the

impact of the incident. One school near the plant was temporarily

evacuated on the day of the incident and two highways were closed

for several hours. Investigators determined that approximately 15

members of the public sought medical evaluations at area

hospitals; none was admitted to the hospital for treatment.

The CSB is an independent federal agency charged with

investigating industrial chemical incidents. The agency's board

members are appointed by the president and confirmed by the

Senate. CSB investigations look into all aspects of chemical

incidents, including physical causes such as equipment failure,

as well as inadequacies in safety management systems.

The Board does not issue citations or fines but does make safety

recommendations to plants, industry organizations, labor groups,

and regulatory agencies such as OSHA and EPA. Please visit our

website, www.csb.gov. For more information, contact Daniel

Horowitz at (202) 261-7613 and (202) 441-6074.

2006/7/20 CSB(US Chemical

Safety and Hazard Investigation Board)

CSB Issues Case Study of Formosa Plastics Point Comfort, Texas,

Fire and Explosions: Unprotected Piping, Non-Fireproofed

Structures, Lack of Automatic Shutoff Valves Noted as Causes;

Flame-Resistant Clothing Recommended

http://www.csb.gov/index.cfm?folder=news_releases&page=news&NEWS_ID=304

The U. S. Chemical Safety

Board (CSB) issued its final report and recommendations today in

the October 6, 2005, fire and

explosions

at the Formosa Plastics Corporation, USA, plant in Point Comfort,

Texas. In addition, the CSB released a Safety Video which

includes a computer animation depicting events leading to the

accident.

The Point Comfort complex, on the Texas Gulf Coast, is the

largest Formosa facility in the U.S., employing 1,400 full-time

workers and 400 contactors. The accident occurred in the plant's Olefins II Unit,

which converts either natural gas liquids or naphtha into

products such as propylene and ethylene. The accident began when a

vehicle - a forklift towing a trailer loaded with cylinders of

breathing air used in maintenance - snagged a valve, pulling it

out of the system. This caused the release of a

large volume of propylene which then ignited, creating a

large fire. The initial explosion knocked several operators to

the ground and burned two men, one seriously. Fourteen workers

sustained minor injuries evacuating the complex.

The CSB Case Study concludes that had the Olefins II

unit been equipped with automated shutdown valves it may have been possible to stop

the propylene flow, limiting the size of the fire. Operators were

unable to reach manual valves to stop the release due to the

presence of the growing vapor cloud.

The investigation noted that the valve hit by the trailer was unguarded, and vulnerable to being hit by

vehicles. The Case Study also noted that some steel

supports were not fireproofed, and collapsed. This caused the failure of pipes designed to carry

flammable hydrocarbons to the unit's flare system, where they could be safely burned

in the atmosphere. Without this safety system in place,

pressurized flammable gases continued to feed the fire, which

burned for five days. In addition, the CSB found that flame resistant

clothing was

not required for all employee activities within the Olefins II

unit where there were large quantities of flammable liquids and

gases.

CSB Board Member John Bresland said, "This began with a

seemingly minor event, in which a trailer bumped into a drain

valve. But the incident had disastrous consequences because the

facility was not better prepared for a large chemical release.

The fires and explosions at Formosa's Point Comfort plant provide

compelling reasons to analyze vulnerabilities that could lead to

a major chemical accident."

CSB lead investigator Robert Hall said, "Our investigation

focused on how this facility was designed to protect against

major fire hazards. We found that the unit's design engineering

firm used plans that had not been updated to incorporate the

latest standards for fireproofing steel structures. Furthermore, workers were not

wearing flame resistant clothing, which would have helped to

protect them against the flash fire that occurred. We found that

improved design practices and protective clothing could have

reduced the impact of this accident."

The Board issued several formal safety recommendations. Formosa

Plastics Corp. USA, the Point Comfort plant, was urged to revise

its policies and procedures for analyzing hazards, to include

vehicle impact dangers, fireproofing of structural steel and

mechanisms for controlling chemical releases such as remotely

controlled isolation valves. The Board also recommended that

Formosa provide fire resistant clothing to workers exposed to the

dangers of flash fires.

The Board recommended that Kellogg, Brown, and Root, the company that designed

Formosa's facility, use the most current safety standards -

including standards for fireproofing -- when designing new

facilities. And the Center for Chemical Process Safety, a leading

safety organization, was urged to strengthen its hazard

evaluation guidelines to include vehicle impact hazards and

isolation of equipment during emergencies.

The CSB Safety Video, "Fire and Explosions at Formosa

Plastics Corp.," may be viewed and downloaded on www.CSB.gov

from the Video Room. Copies of this and all CSB videos are

available on a DVD and may be obtained free of charge by

submitting an online request form found on the website.

The CSB is an independent federal agency charged with

investigating industrial chemical accidents. The agency's board

members are appointed by the president and confirmed by the

Senate. CSB investigations look into all aspects of chemical

accidents, including physical causes such as equipment failure as

well as inadequacies in safety management systems, regulations,

and industry standards.

The Board does not issue citations or fines but does make safety

recommendations to plants, industry organizations, labor groups,

and regulatory agencies such as OSHA and EPA. Visit our website,

www.CSB.gov.

Platts

2006/1/19

Taiwan's Nan Ya

Plastics Corp aims to start new BPA line by Oct

Taiwan's Nan Ya Plastics Corp is aiming to start production of a

new bisphenol-A (BPA) plant by October, a company source said

Thursday. The company is currently in the midst of building the

new 130,000 mt/yr plant at Mailiao,

Yunlin.

Nan Ya Plastics currently operates 3 bisphenol-A plants at the

same site. These have a total production capacity of 290,000

mt/yr.

FCFC has a total phenol capacity of 440,000

mt/yr in

Mailiao, Yunlin.

Group Major Products

Product

Name

|

Capacity

(MT/Y)

|

Company

|

Division

|

PVC

Resin

|

1,329,000

|

FPC

|

Plastics

Div.

|

VCM

|

1,520,000

|

FPC

|

Plastics

Div.

|

Caustic

Soda (liquid)

|

1,050,000

|

FPC

|

Plastics

Div.

|

Caustic

Soda (flake)

|

46,700

|

FPC

|

Plastics

Div.

|

Chlorine

|

366,700

|

FPC

|

Plastics

Div.

|

Hydrochloric

Acid

|

133,000

|

FPC

|

Plastics

Div.

|

MBS

|

156,000

|

FPC

|

Plastics

Div.

|

POM

|

25,000

|

FPC

|

Plastics

Div.

|

Chlorosolvents

|

48,900

|

FPC

|

Plastics

Div.

|

Fluorochlorohydrocarbon

and substitetes

|

21,600

|

FPC

|

Plastics

Div.

|

Processing

Aids

|

7,200

|

FPC

|

Plastics

Div.

|

AHF

|

11,000

|

FPC

|

Plastics

Div.

|

HDPE

|

450,000

|

FPC

|

Polyolefin

Div.

|

LDPE

|

90,000

|

FPC

|

Polyolefin

Div.

|

EVA

|

110,000

|

FPC

|

Polyolefin

Div.

|

LLDPE

|

240,000

|

FPC

|

Polyolefin

Div.

|

Acrylic

Acids

|

141,000

|

FPC

|

Tairylan

Div.

|

Super

Absorbent Polymer

|

24,000

|

FPC

|

Tairylan

Div.

|

AN

|

200,000

|

FPC

|

Chemical

Div.

|

CAN

|

3,000

|

FPC

|

Chemical

Div.

|

MMA

|

70,000

|

FPC

|

Chemical

Div.

|

ECH

|

80,000

|

FPC

|

Chemical

Div.

|

MTBE

|

15,100

|

FPC

|

Chemical

Div.

|

B-1

|

17,000

|

FPC

|

Chemical

Div.

|

Calcium

Carbide

|

54,000

|

FPC

|

Calcium

Carbide Div.

|

Lime

|

234,000

|

FPC

|

Calcium

Carbide Div.

|

Calcium

Carbonates

|

258,000

|

FPC

|

Calcium

Carbide Div.

|

Taical

|

12,000

|

FPC

|

Calcium

Carbide Div.

|

U-cal

|

14,400

|

FPC

|

Calcium

Carbide Div.

|

Light

Master Batch

|

36,000

|

FPC

|

Calcium

Carbide Div.

|

PTMG

|

14,000

|

FASC

|

Business

Div.

|

BPA

|

114,000

|

Nan

Ya

|

4th

Plastics Div.

|

PBT

|

13,200

|

Nan

Ya

|

4th

Plastics Div.

|

Unsaturated

Polyester Resin

|

30,000

|

Nan

Ya

|

4th

Plastics Div.

|

Plastic

Stablizer

|

8,400

|

Nan

Ya

|

4th

Plastics Div.

|

PU

Resin

|

28,800

|

Nan

Ya

|

4th

Plastics Div.

|

DOP

|

335,000

|

Nan

Ya

|

DOP

Div.

|

Anhydrous

Sodium-Sulfate

|

100,439

|

FCFC

|

1st

Chemical Div.

|

Carbon

Disulfide

|

18,500

|

FCFC

|

1st

Chemical Div.

|

Sulphuric

Acid

|

134,000

|

FCFC

|

1st

Chemical Div.

|

Dodecyl

Benzene Sulphonic Acid

|

24,500

|

FCFC

|

Detergent

Div.

|

Powder

Detergent

|

66,000

|

FCFC

|

Detergent

Div.

|

Liquid

Detergent

|

8,520

|

FCFC

|

Detergent

Div.

|

Benzene

|

70,000

|

FCFC

|

2nd

Chemical Div.

|

PX

|

810,000

|

FCFC

|

2nd

Chemical Div.

|

OX

|

200,000

|

FCFC

|

2nd

Chemical Div.

|

SM

|

600,000

|

FCFC

|

2nd

Chemical Div.

|

Phenol

|

200,000

|

FCFC

|

2nd

Chemical Div.

|

Acetone

|

123,000

|

FCFC

|

2nd

Chemical Div.

|

PTA

|

1,450,000

|

FCFC

|

3rd

Chemical Div.

|

DMF

|

40,000

|

FCFC

|

3rd

Chemical Div.

|

PS

|

260,000

|

FCFC

|

Plastic

Div.

|

ABS

|

39,000

|

FCFC

|

Plastic

Div.

|

PP

|

360,000

|

FCFC

|

Plastic

Div.

|

PC

|

100,000

|

FCFC

|

Plastic

Div.

|

Nylon-6

Resin

|

219,000

|

FCFC

|

Nylon

Div.

|

Ethylene

|

1,700,000

|

FCFC

|

Alkene

Div.

|

Propylene

|

850,000

|

FCFC

|

Alkene

Div.

|

Butadiene

|

272,000

|

FCFC

|

Alkene

Div.

|

PP

|

300,000

|

YCCIC

|

Business

Div.

|

Electron-grade

hydrofluoric acid

|

3,700

|

FDACC

|

Business

Div.

|

NH4F

|

2,200

|

FDACC

|

Business

Div.

|

Buffer

hydrofluoric acid

|

1,800

|

FDACC

|

Business

Div.

|

Naphtha

|

3,800,000MT

|

FPCC

|

Refinery

Div.

|

Gasoline

|

5,800,000KL

|

FPCC

|

Oil

Product Div.

|

Disesel

|

7,600,000KL

|

FPCC

|

Oil

Product Div.

|

Aviation

fuel/kerosene

|

2,250,000KL

|

FPCC

|

Oil

Product Div.

|

Fuel

Oil

|

1,800,000KL

|

FPCC

|

Oil

Product Div.

|

LPG

|

380,000MT

|

FPCC

|

Oil

Product Div.

|

Jan 19,

2007 (SinoCast via COMTEX)

Formosa Plastics Group Plans to Invest in China Mainland

Formosa Plastics Group, one of the largest family firms of

Taiwan, plans to build the factory of oil refining and ethene in

Ningbo, located in Zhejiang province of China, according to

sources.

This plan includes establishing 10

million tons oil refinery, 1.2 million tons splitting ethene

factory, 600,000 tons propylene factory and other chemical

products.

* ethene(IUPAC name)=ethylene

Platts

2007/8/14

Taiwan's FCFC to bring new PS plant in Ningbo online in October

Taiwan's Formosa Chemical and Fibre Corp expects to bring its new

polystyrene plant in China, Ningbo, on-stream in October, a

company source said Tuesday.

The 200,000 mt/year plant was previously slated to

start up in August but due to incomplete construction works at

the plant's facilities, that was postponed to Q4 of this year.

Styrene monomer feedstock would be provided by FCFC's new No 3 SM

plant in Mailiao. The new 600,000 mt/year unit has been running at 100%

nameplate capacity since June 8.

2008/1/21

Platts

Taiwan's FCFC mulls start-up of new PTA plant before June 2008

Taiwan's Formosa Chemical and Fibre Corp. is looking at the

possibility of bringing its new 400,000

mt/year purified terephthalic acid plant in Loong-der on stream

before June this year, a company source said Monday afternoon.

FCFC currently operates two PTA plants in Mailiao, both with a

production capacity of 500,000 mt/year. The company also has an

existing 700,000 mt/year PTA plant in Loong-der.

FCFC's new PTA capacity comes on the heels of recent start-ups

and expansions, most notably China's BP Zhuhai 900,000 mt/year

PTA plant in Zhuhai and South Korean Taekwang Industrial's newly

expanded 950,000 mt/year PTA plant in Ulsan.

2008/3/20

Platts

Taiwan Formosa Plastics

likely to start Ningbo PP runs early-Apr

Taiwan's Formosa Plastics

is likely to start commercial operations at its long-delayed 450,000 mt/year

Ningbo polypropylene plant early-April, sources said

Thursday.

Formosa finished construction work on the plant in June last

year, but was unable to start commercial operations, pending

approval from the Chinese government to use a discharging 揚荷

port for refrigerated

propylene.

Plaltts 2008/4/7

Formosa targets Ningbo

PTA plant start-up during April

Taiwan's Formosa Chemical

and Fibre Corp

is aiming to start up its 600,000 mt/year purified

terephthalic acid

plant in Ningbo, eastern China, by the end of April--having

recently received approval from the central Chinese government to

begin operations--a company source said Monday.

Meanwhile, Formosa Plastics also recently received approval from the

Chinese government to discharge refrigerated propylene to Ningbo. This would also allow the company

to start commercial production at its 450,000 mt/year polypropylene plant there.

2008/04/08 CENS

FPG May Forgo Ningbo Mega

Ethylene Project

In response to the pledge

of president-elect Ma Ying-jeou (国民党候補の馬英九氏) allowing Maoliao麦寮 harbor of the Formosa Plastic

Group (FPG) to undertake direct cross-Taiwan Strait shipment,

Y.C. Wang王永慶, founder of FPG, said yesterday

(April 7) that the group will forgo its mega ethylene project in

Ningbo of mainland China.

Wang made the remarks during a meeting between him, Ma, Morris

Chang, chairman of Taiwan Semiconductor Manufacturing Co. (TSMC),

and Terry Guo, chairman of Hon Hai 鴻海 group, dubbed as an occasion for

Ma to seek advices from the three business tycoons on the

development of Taiwan`s economy.

Wang Jui-hua, vice president of FPG`s Group Administration Office

and daughter of Y.C. Wang, noted that with opening up of direct

cross-Strait shipment, FPG will be able to transport its

petrochemical products from Mailiao to the mainland and therefore

may not have to execute its mega ethylene project in Ningbo of

China`s Zhejiang province.

Wang fell short of confirming FPG`s decision to forego the

project outright, saying that despite the narrowing of the gap

between investment conditions of Mailiao and Ningbo following

inauguration of direct cross-Strait shipment, the two projects

aim at different markets, and as such FPG would still execute the

Ningo project should the government flash a green light.

Remarks of Wangs appear to underscore the difficulties

confronting the FPG for the Ningbo project, mainly due to

opposition of leading indigenous Chinese petrochemical makers, as

a result of which China Petrochemical Corporation may take over

the project.

FPG`s mega ethylene project in the Beilun Petrochemical Zone

of Ningbo City envisions annual crude-oil refining capacity of 10

million metric tons and ethylene capacity of 1.2 million metric

tons, similar to its existing petrochemical complex in Mailiao

offshore industrial zone.

sankei 2008/10/16

台プラ創始者、王永慶氏が死去

【台湾のテレビ各局によると、台湾の「経営の神様」といわれた台塑集団(台湾プラスチックグループ)の創始者、王永慶Wang Yung-Ching,氏が15日朝(米東部時間)、米ニュージャージー州の病院で、心筋梗塞のため死去した。91歳だった。

遺体は16日に台湾に運ばれる予定という。

「台湾の松下幸之助」とも評される王氏は、16歳で起業して1954年に台プラを創設。早くから巨大市場を抱える中国への進出を決め、中国要人とも交流関係を持つ台湾経済界の重鎮的な存在だった。

Wang died on early

Wednesday morning in New York during a business tour to the

United States from Oct. 11, the group said in a statement.

Wang set up the

Formosa Plastics Corporation in 1954, which is now a major

conglomerate in Taiwan. Its business covers biotechnology,

petrochemical processing and electronic components production.

---

He was Taiwan's

second-richest person with a net worth of US$6.8 billion

(HK$53.04 billion).

フォーブスの2007年度世界長者番付によると、世界で82位に富豪とされている。

Taipei-born Wang opened a

rice store as his first business in 1932 before founding Formosa

Plastics Corp, Taiwan's biggest diversified industrial group, and

then Nan Ya Plastics Corp. in 1958.

Jun 16, 2011 Dow

Jones

Formosa

Petrochemical: To Build Butadiene Rubber Plant In China

Formosa Petrochemical Corp., Taiwan's only private refiner, plans

to build a 50,000-metric-ton-a-year

butadiene rubber plant in the eastern Chinese city

of Ningbo, Chairman Wilfred Wang

said Thursday.

The company expects to complete construction of the Ningbo plant

in 2013, Wang said at a shareholders' meeting, but didn't

elaborate.

He also said there is rising uncertainty over second-half global

demand for petrochemical products, largely due to a potential

slowdown in the Chinese economy amid a slew of tightening

measures.

Formosa plans to focus more on exports to Southeast Asian nations

to avoid the impact of a possible slowdown in Chinese demand, he

said.