トップページ

2004/9/27 China

Chemical Reporter

Red Lion and KCI Establish Joint Venture

According to the agreement reached between Red Lion Coatings International Co Ltd and KCI of

Korea,

the two sides have decided to jointly fund a joint venture

coating company in Beijing. The business scope of the company is

to conduct systematic production and sales of paint products and

provide related after-sale services. The equity ratio between the

two sides is 50:50 and the specific amount of investments will be

defined in the joint venture contract.

KCI KUNSUL CHEMICAL

INDUSTRIAL DO.,LTD 建設化学

http://www.jebi.co.kr/english/e_contents_01_01.html

“Swallow Brand Paint, Kunsul Chemical” has been keeping its top record in

paint industry in Korea for 60 years from the time it was

established in December 1945. From the time when Korea was

declared independent from Japanese colony, when there were

barely a few industries, we started to develop Coating

Technology and helped rebuilding of the nation. As one of the

results, we developed Alkyd Resins and developed the area of

Synthetic Resins for Coating. At the same time, we have been

pouring our efforts to invent and improve through our own

studies and adoption of advanced technologies from overseas.

Currently, we are manufacturing about 20,000 different kinds

of coatings such as decorative coating, general industrial

coating, coil coating, can coating, marine and heavy-duty

protective coating as well as high technology industrial

coating. With the inauguration of the new manufacturing

facility, we have added ability to meet the needs of

consumers and it also has increased ability to serve

consumers with better technical support and above all, with

better quality products.

Most of all, our technology has been accredited for ISO9001

which also means our technology is being recognized in many

different countries all over the world. Moreover, we are

preparing to acquire ISO14001 for environment-friendly

industry.

Kunsul Chemical will do our best to develop and invent new

technology and better service to consumers aiming to be the

leader of 21th century’s paint industry.

2004年10月4日

中国・ASEANニュース速報

アモイに中国最大の台湾企業投資区

中国・アモイ市政府が、同市の同安区および翔安区に総面積250平方キロメートルの台湾企業投資区を設置する開発案が実現しそうだ。台湾企業のための投資区としては中国最大の規模で、台湾プラスチックグループのナフサプラントなど大型投資の誘致につなげたい考えだ。

すでに福建省政府の許可を得て、国務院の正式な批准を待っている段階という。台湾企業投資区はアモイ市海滄区、杏林区、集美区、および福州の4カ所にあるが、これらはすでに飽和状態で、新たな投資誘致には新規の土地開発が必須という。

3日付工商時報が伝えた。

「人民網日本語版」2004年10月10日 シノケム

中国中化集団、仏石油企業と合弁会社設立へ

中国中化集団は9日、フランスの石油企業、トータル社との石油合弁会社設立に関する合意書に調印した。双方の共同投資額は約9億元で、7年以内に中国環渤海地域に当たる北京、天津、河北省、遼寧省の4省(直轄市)で、ガソリンスタンド200店による石油小売ネットワークを構築する。新会社の株式は中化集団が51%、トータル社が49%をそれぞれ所有する。この提携事業で、2012年までにガソリン100万立方メートル(約80万トン)を販売する計画。

中国・ASEANニュース速報 2004年10月12日

南京に太陽電池工場、年産量30メガワット

http://www.e-plastics.gr.jp/japanese/nna_news/news/news0410_2/04101202.htm

江蘇省の国有企業集団、中電電気集団の子会社、中電光伏太陽能有限公司が南京市の江寧経済開発区で、太陽電池工場の建設を開始した。1期工事の投資額は3,000万米ドル、年産量は30メガワットに達する予定。完成後は中国国内最大規模の太陽電池生産基地となる。11日付東方早報が伝えた。

中電電気集団は変圧器や絶縁材料、ケーブルなどを、研究開発、生産、販売する企業集団。固定資産総額は8億元で、年間売上高は10億元に上る。

2004/10/16 Asia Chemical

Weekly シノペック子会社鎮海煉油化工 浙江省鎮海

Zhenhai Refining and Chemical (ZRCC), a subsidiary of Sinopec (China

Petroleum and Chemical Corp.), has get the nod from Chinese NDRC

to build an 800,000 ton ethylene cracker in Zhenhai, Zhejiang, province.

| 修正 2004/11/16 The

capacity of this project is 1000 000 tonne/year. 最終承認

ZRCC was considering

building a SM/PO unit and MEG facility as parts of the

ethylene project. If this route is chosen, then the

facilities would produce 500 000-600 000 tonne/year of

MEG, around 800 000 tonne/year of styrene and 360 000

tonne/year of PO.

China Chemical Reporter

2005/2/28

Zhenhai Modified Ethylene Project

According to the approval order of the State Development

and Reform Committee and the judgment advice of the China

International Engineering Consult Corp., Zhenhai

Refining and Chemical Company modified its ethylene project plan

into eleven production line and related matching

facilities including 1 million t/a ethylene cracker, 800

000 t/a cracking gasoline hydrogenation, 600 000 t/a

aromatics extraction and 650 000 propylene

oxide/monoethylene glycol, with a total investment of

RMB21.5 billion. The former plan had a design of 800 000

t/a ethylene cracker, 300 000 t/a aromatics extraction

and 500 000 propylene oxide/monoethylene glycol etc. with

a total investment of RMB17.8 billion. (CCR2004 No. 31)

The project will rely on the large scale refining base in

Zhenhai Refining and Chemical Company, which is located

in Ningbo, Zhejiang Province. After its completion, the

chemical companies in the Ningbo Chemical Industry Zone

will get convenient materials supply.

2005/3/23 Chemnet

Tokyo PO/SM承認

| 鎮海煉油化工のエチレン100万トン計画、詳細が明らかに |

| |

(上海発=特約)

シノペック子会社の鎮海煉油化工は昨年10月、国家発展改革委員会(NDRC)から、浙江省鎮海での80万トン・エチレン計画の承認を受けた。

その後、同計画は本年2月、エチレン能力を100万トンに拡大すると、変更発表されたが、このほど、誘導品などその詳細が明らかになった。鎮海煉油化工によると、全体計画は以下の通り。

エチレン 1,000千トン

BTX 500千トン

ブタジェン 150千トン

SM 600千トン

PO 280千トン

MEG 650千トン Dow技術導入

PE 300-400千トン →450 Unipol

PP 300千トン

China

Chemical Reporter 2006/3/29

Zhenhai 1 Million T/A Ethylene Project Approved

On March 17th, 2006, the National Development and

Reform Commission announced that it has approved

the 1 million t/a ethylene project in Zhenhai

Refining & Chemical Co., Ltd., located in

Zhenhai, Zhejiang province. According to the

whole plan of China Petrochemical Corporation

(Sinopec Group), the project is scheduled to be

started construction in 2006 and completed in

2009.

Zhenhai

got approval of 800,000t/y ethylene project

from NDRC in 2004 and after that they changed

their plan to 1,000,000t/y.

The procedures of ZRCC new ethylene project

as follows:

1. send to NDRC for approval,

2. get nod from NDRC, and then sent to State

Council for approval,

3. State Council give nod and feedback to

NDRC,

4. NDRC give feedback to ZRCC

|

|

The big

ethylene project was expected to cost 17.78 billion Yuan (about

$2.14 Billion); the project will also integrate 450kt/year

gasoline hydrogenation, 100kt/year butadiene extract, 300kt/year

aromatics extract, 300kt/year PE, and 840kt/year ethylbenzene

projects.

The start-up date

has not been revealed, but construction of a plant as such size

usually takes at least three years.

Feedstock for the

project would come from the company’s refinery. ZRCC is the biggest

refinery in China. It has the capacity of 16m tonne/year

currently, and would expand its 16m tonne/year refinery to 20m

tonne/year in mid-2006. The expansion would provide sufficient

naphtha to feed the proposed cracker. Zhenhai currently imports

most of its crude oil from the Middle East.

In the past, media

reported that Zhenhai has held talks with Arco Chemical and

Lyondell Chemical Company about a cracker project, but those

discussions were terminated in 1999.

According to the

report from Chinese media, the 800kt ethylene project will be

build by ZRCC only instead of by a joint venture.

ZRCC has completed

the para-xylene (450,000 tons) and polypropylene (200,000 tons)

plants, and has begun operating them at last year.

2004/5/19 Reuters

Zhenhai Refining

plans China's top ethylene plant

http://uk.biz.yahoo.com/040519/80/etxts.html

Platts 2004/10/22

その後の状況

SABIC, Dalian Shide mull

refinery-petrochemical project in China

Saudi Arabian petrochemical giant

SABIC is in talks with China's

Dalian Shide to build an

integrated refinery and naphtha cracker complex in Dalian, China,

a source close to SABIC said Friday.

The two sides were conducting a feasibility study on the project

and had yet to reach a decision on the scale of the facilities.

Initially, SABIC was seeking an equal contribution of $2-bil from

each side for the project. The feasibility study is expected to

be completed by the end of 2004. If the project proceeds as

planned, the refinery-petrochemical complex would likely be

completed by 2008.

China Chemical Reporter

2004-10-20 3M release

Cooperation between Meilan Group

and 3M Dyneon

Jiangsu

Meilan Group and 3M Dyneon of

the United States have recently started cooperation in the

establishment of a PTFE (四フッ化エチレン) production base in Meilan Group. The

project will facilitate the overall improvement of product

quality in the fluorine plastic processing sector in China.

3M Dyneon will use factory buildings, equipment and workers in

Meilan Group to produce PTFE. The production will start in around

15 months and products will be sold to different regions in the

world. 3M Dyneon will make long-term commitments to Meilan Group

in developing advanced fluorine chemical technologies and

strengthening the leading position of fluorine-containing

polymers in China.

Jiangsu Meilan Chemical Plant

(Group)

http://www.chinameilan.com/en/aboutus.htm

Jiangsu Meilan Chemical Plant

(Group), a state-owned large-scale chemical enterprise. With

the continuous reform and innovation for several years, the

company has formed a product chain based on the chlorine

alkali chemical products and headed by the fluoro chemical

products. She has become

a very important base for Chinese organic fluorine products

researching, developing and production. In 2000, she was

recognized as a national major high-tech enterprise by the

Chinese Scientific Institute and the Ministry of National

Science and Technology.

The main products of the company are : 1)

OrganicFluoro-material products: polytetrafluoroethylene

resins with the trademark of “Meilan”, hexaflooropropylene, vinylidene

fluoride, polyvinylidene fluoride (PVdF), fluoro elastomer

F26; 2) Fluoro-refrigherant Products: industrial

monchlorodifluoro-methane and substitutes for Freon; 3)

Chlorides: methyl chloride (industrial dichloromethane,

industrial trichloromethane). 4) Chlorine-alkali products:

industrial sodium hydroxied, industrial synthetic

hydrochloric acid, industrial liquid chlorine, industrial

hydrogen, p-toluidine etc..

日本経済新聞 2004/10/26

中国、石油メジャー育成

大手3社の事業制限撤廃 国際競争力高める

中国は大手石油3社の事業制限を廃止する。海洋資源開発専業会社、中国海洋石油へ陸上開発や石油精製事業を認可するとともに陸上開発の中国石油(ペトロチャイナ)、中国石油化工(シノペック)へ海洋での石油開発を認可する。世界的にエネルギー確保へ向けた競争が激しくなる中、欧米メジャー(国際石油資本)に対抗できる「中国版メジャー」を育成し、エネルギー事業の国際競争力を高める狙いがある。

中国大手石油3社

売上高、純利益は2004年1-6月実績、単位は億元、カッコ内は前年同期比増加率、%

| |

売上高 |

純利益 |

主な事業範囲 |

| ペトロチヤイナ |

1,795(21.4) |

452(17.3) |

陸上開発、精製、給油所 |

| シノペツク |

2,754(34.1) |

161(50.6) |

陸上開発、精製、給油所 |

| 中国海洋石油 |

160(13.0) |

70(11.2) |

海洋開発 |

October 19, 2004

Halliburton

Tianji Group selects KBR's technology for 450ton/day aniline

plant in China

KBR has been awarded a contract by Fangyuan Chemical Industry Development

Co., Ltd. of the Tianji Group to provide a process technology license

and basic engineering package for a 450 metric ton/day aniline plant located in Lucheng,

Shanxi, China. 山西省

The facility

will utilize DuPont aniline technology, which is available to KBR

through a

licensing alliance with DuPont, to produce high quality aniline product.

KBR will also supply critical imported equipment for the project,

as well as training and field services. KBR is the engineering

and construction subsidiary of Halliburton (NYSE:HAL).

Aniline is a chemical intermediate used to make MDI (methyl diphenyl

diisocyanate),

which is primarily used to create polyurethane foams.

2004年11月08日 Chemnet Tokyo

浙江省寧波市、2010年までに中国の「主要石化基地」に

大規模コンビナート、石油精製と一体で建設

浙江省政府は2010年までに寧波市が中国の石化基地の中で最も重要なものの1つになるとみている。

寧波市には鎮海地区、北崙地区、大謝島の3つの石化基地がある。鎮海地区にはシノペック子会社の鎮海煉油化工(ZRCC)の石油精製基地がある。

省政府では2010年までに寧波の原油精製能力を30百万トン/年にするとともに、エチレン合計2百万トン/年の新設の計画をたてている。

現在、鎮海煉油化工の原油精製能力は16百万トン/年で、2006年央には20百万トンに拡大する。同社は最近、国家発展改革委員会から鎮海での80万トン・エチレン計画の承認を受けた。BTX 30万トン、PE30万トン、エチルベンゼン84万トンなどを建設する。原料ナフサは原油精製能力増で賄う。同社はエチレン計画に先行して、パラキシレン45万トン、PP

20万トンを既に生産している。

また台湾プラスチックが先日、中国国務院に対してエチレンプラント建設の投資申請を行った。建設地は寧波市の北崙経済技術特区とみられ、同特区内にエチレン年産120万トン規模のナフサプラントを設ける。台プラグループでは北崙地区で台プラがPVC年産30万トンの工場がまもなく完工するほか、台湾化学繊維のABS工場(125千トン)が量産を開始している。将来的にはアクリル酸エステル、PP、PTAの各工場も生産を開始する予定。

この他寧波市では煙台万華ポリウレタンのMDI計画や、三菱化学のPTA計画が進行している。煙台万華ポリウレタンは煙台万華合成革集団有限公司の子会社で、大謝島にMDI16万t

設備を完成させた。2006年には3倍増の24万tに増やす計画で将来は原料から一貫生産を行う予定。

三菱化学は中国における高純度テレフタル酸(PTA)事業計画を決定し、本年6月に、日本の投資会社・寧波PTA投資(三菱化学/伊藤忠/三菱商事)と中国中信集団(CITIC)

の90%/10%の合弁会社 寧波三菱化学有限公司を設立した。314百万米ドルを投じて大謝島に60万トン/年の工場を建設する。2006年9月に生産開始の予定だ。

2004/11/10 CCR

DMC Line Went into Operation in Jinzhou 遼寧省大連市金州 Dimethylcarbonate (炭酸ジメチル)

Jinxi Natural Gas Chemical Co Ltd

recently announced the production-starting of its 15 000 t/a DMC line in Liaoning Province.

Simultaneously, the methanol expansion project from 300

000 t/a to 600 000 t/a was

also completed.

Liaoning Huajin group (遼寧花錦

group )

http://www.huajinchem.com/ehuajin/about/a0101.asp

Liaoning Huajin Chemical

Group, composed of Liaohe Group and Jinhua Group, is a special large-scaled

chemical-industrial enterprise group.

In Jan. 1997, Liaohe Group

issued successfully Type A stock 130 million stock-shares,

and then invested all the mobilized capital on Jinxi Natural Gas

Chemical Center Plant,

thus realizing the trans-regional combination of the two

large enterprises in Liaoning Province.

Liaoning Huajin group

In Jan. 1950, Jinxi

Chemical Plant was set up on the base of Jinxi Refinery

Plant left over from former Japanese and Koumintang

military, and subsequently recovered and expanded for

several times.

After several decades'

development, especially the recent twenty years of the

implementation of reform and open policy in China, it has

grown up to a chemical complex enterprise group which

mainly runs chemical fertilizers, polyolefin

resins, chlorine&sodium hydroxide, plastics

processing, fine chemicals, and commercial trade, what it

produces includes 6 types in more than 100 grades of

products, its annual urea production capacity has reached

1.1 million MTA, being the largest chemical fertilizer

producer, and its chlorine & hydroxide production

capacity 280 thousand MTA, ranking the leading position

in China, some products such as fertilizer, catalyst and

caustic soda etc. are often exported abroad.

2004/03/31

伊藤忠ケミカルインフォメーション

明倫集団が四川省達州市でメタノール

https://www.cheminfo.jp/itc-chem/group_A/chemsearch/chemsearch.asp?Menu=Mes&MesID=114814:21:00

情報筋によれば、深セン明倫集団有限公司は、四川省達州市で天然ガスを原料にしたメタノール年産400千トンプラントを建設することを計画している。

同社は既に、達州市とプラントサイトの所在地である宜漢県との間で同プロジェクトに関する意向書を締結している。プラントサイトには、宜漢県胡家鎮にある達州市万通機械廠の用地を予定している。

同プロジェクトは、投資総額は100百万ドルで、メタノールの原料には達州市の豊富な天然ガス資源を利用する計画である。同社は現在、同プロジェクトの提案書を作成しており、完成次第、認可を取得するため市当局へ提出される予定である。

同プロジェクトの下流で、メタノールの誘導品を生産するかどうかについては、未だ決定していない模様である。

同社は、エネルギー、金融、食品加工、貿易、電子等関連事業で30社を超える子会社を持っており、香港証券取引所に明倫集団(香港)有限公司を上場している。

2004/03/30 伊藤忠ケミカルニュース

開祥電力が河南省義馬市でメタノール

情報筋によれば、河南省の鄭州市に本拠を置く河南開祥電力実業投資有限公司は、河南省義馬市でメタノールプラントを2系列、生産能力合計年産400千トンのプ

ラントを建設することを計画している。

同プロジェクトは、既に河南省政府の認可を取得しており、前後二期に分けて建設される。総投資額は1,600百万元で、プラントサイトは馬義市の馬嶺工業区を予定している。

第1期工事は、930百万元を投資して、石炭ガス化プラントとメタノール年産200千トンプラントを建設する計画にて、建設期間は18ヶ月を予定している。石炭ガ

ス化プラントはシェブロンテキサコ社(ChevronTexaco

Corp)の技術を採用する予定である。第2期工事は、第1期と同規模のメタノールプラントを更にもう1系列建

設する予定である。

同社は、シェル社の石炭ガス化技術も併せ検討しており、若し、採用する技術を変更する場合は、当局から再度認可を取得することが必要となる。その結果、建設開始が遅れる可能性もあり、同プロジェクトの操業開始予定は未だ決定していない。

同プロジェクトは、同社と義馬市政府との合弁事業となる予定であるが、更に同プロジェクトへの投資に興味を持つ山東省の企業とも会談が持たれている模様である。

「人民網日本語版」2004年11月11日

中国、DDTなど残留性有機汚染物質の削減へ

世界151カ国が締結し、83カ国が批准している「残留性有機汚染物質(POPs)に関するストックホルム条約」が11日、正式に中国で発効した。中国は今後、同条約に掲げられたDDT、ダイオキシンなど健康と環境に最も有害な化学物質12種類の削減・廃絶に段階的に取り組んでいく。

国家環境保護総局の汪紀戎副局長は「中国は同条約に規定された各項の義務を全面的に履行するとともに、同条約の資金システムと二カ国間・多国間協力を活用し、国内のPOPs問題を解決していく」と述べている。

これらの化学物質12種類のうち、9種類はかつて中国で大量に生産され、一部は現在も使用されている。すでにDDT、クロルデン、ヘキサクロロベンゼン、マイレックスの殺虫剤4種について5年間の猶予を申請しており、その間に代替品への移行を進めていく方針だ。

▽残留性有機汚染物質(POPs)

人類の健康と環境に有害な化学物質で、環境内に長期間残留、食物連鎖の中で蓄積されていく。

(注)ストックホルム条約では以下の12品目(PCBsは重複)を規制している。

1)製造・使用の禁止/廃絶 付属書A記載物質(9物質)

アルドリン、クロルデン、ディルドリン、エンドリン、ヘプタクロール、

ヘキサクロロベンゼン、 マイレックス、トキサフェン、PCBs

2)製造・使用の制限 付属書B記載物質

DDT(マラリア対策のみ許可)

3)非意図的生成物の削減・廃絶 付属書C記載物質(4物質)

PCDD/PCDF(ダイオキシン類/フラン類)、HCB、PCBs

2004/11/13 China

Chemical Information Net

5 POPs still produced and used in country

http://www.sinocheminfo.com/asp/news/content.asp?id=15741

China has five years

to stop production of four pollutantstargeted as part of

international efforts to clean up the environment. The

Stockholm Convention lists 12 persistent organic pollutants

(POPs) that should be eliminated to preserve the environment.

Five of them are still produced in China. The Stockholm

Convention, signed by 151 countries and ratified by 83, aims

to eliminate POPs, which are highly insidious pollutants.

In China, the convention took effect yesterday, but the

country has applied for immunity which would allow it to

continue producing DDT, hexachlorobenzene (HCB), chlordane

and mirex for another five years, said Yue Runsheng, vice

head of international co-operation under the State

Environmental Protection Administration. That would give

China five years to stop production and use of them. China

can apply for another five-year term, but no further

exemptions are allowed. The country has been making efforts

to control the five pollutants, said an administration

source.

DDT is mainly used in pesticides

while small amounts are used in mosquito repellent, incense

and some medical storage. There are two DDT manufacturers in

China, with a total annual output of about 4,000 tons, said

Zang Wenchao, of the administration's pollution control

department.

Only one company still produces about 2,000 tons of HCB every year, Zang said. HCB

is used to produce sodium pentachlorophenate, a medicine.

Chlordane

and mirex are

both used to kill destructive white ants and are more widely

produced. There are nine chlordane manufacturers with an

output of 500 to 800 tons per year, while up to 30 tons of

mirex are put out by five producers.

Still other POPs listed in the convention for which China is

not seeking immunity, may be harder to eliminate. PCBs are

one, particularly considering the amount in circulation is

difficult to pinpoint because electrical components with PCBs

are still circulating but no longer in production. Zang said

China stopped production years ago and most electrical

equipment containing PCBs has been discarded.

China Chemical Information

Net 2004/11/13

More Daqing millions for JV

http://www.sinocheminfo.com/asp/news/content.asp?id=15734

Daqing Petroleum and Chemical Group (大慶石油化工集團) is investing 38 million

yuan(HK$35.7 million) more to produce vinyl acetate in a joint

venture project in Mudanjiang city in Heilongjiang province(黒龍江省牡丹江). The Mudanjiang Dongbei Chemical Engineering Company(牡丹江東北化工有限公司), a joint venture between

Daqing Petroleum and Daqing Gaoxinqu (高新技) Qinglian Petroleum and Chemical, is

planning the second phase of the Mudanjiang Plant upgrade.

Daqing Petroleum

holds a 55 per cent stake in the joint venture and has already

injected 50 million yuan in the first phase of the project. Phase

II will begin in 2005 and, upon completion, the plant is expected

to produce 45,000

tons per annum of vinyl acetate, an organic chemical used in paper

making, construction and textile industries.

the mass

production of Mudanjiang vinyl acetate plant will be

commenced in the fourth quarter of 2004 and the annual

production capacity is expected to reach 15,000 tonnes.

Upon the completion of the (phase 2) project, the production

capacity of the vinyl acetate plant is expected to be further

enhanced upto 45,000 tonnes per annum.

the company

adopted a production

method using calcium carbide, which helped lessen reliance on high

crude oil prices, and also made it more competitive against

companies that used the acetylene methodology.

酢酸とアセチレン との反応

「人民網日本語版」2004年11月16日

シェルなど3社、石炭液化油を共同開発

シェル(中国)有限公司、神華集団有限責任公司、寧夏煤業集団有限責任公司は15日、北京で合意書に調印し、クリーンな石炭液化油を中国で共同開発することに合意した。

石炭液化油は将来において大規模に活用され、中国が石油に過度に依存している体質を転換するのに有望であるとともに、石炭利用の効率化を高める意味もある。

今回の合意書によると、6―9カ月間の事業化調査期間中、3社はシェルの石炭液化油(間接液化―CTL)技術を中国における活用の可能性について研究していく。研究内容には市場分析、経済指標評価、技術解決策、関連規定の審査、プロジェクト地点の確定が含まれる。シェル(中国)有限公司公共事務部では「合意書は事業化調査の業務のみを決め、協力の踏み込んだ内容はまだ話し合っていない」としている。

神華集団有限責任公司は陝西省に、寧夏煤業集団有限責任公司は寧夏回族自治区に、それぞれ石炭間接液化工場を建設する。計画によると、2工場の最初の建設規模は年産300万トンで、総投資額はそれぞれ300億元ほどと予測される。

中国・ASEANニュース速報

2004年11月17日

【台湾】台プラ、江蘇呉淞江に紡織原料生産拠点

台湾プラスチックグループは、中国・江蘇省の南部、呉淞江にある面積150ヘクタールの工業区に、紡織原料の重要生産拠点を設置する。長江デルタ地帯に浙江省寧波の中間原料工場、江蘇省昆山のエレクトロニクス材料工場と合わせた3大石化加工拠点を設け、雲林県麦寮の第6ナフサプラントを最上流とする垂直統合生産システムの完成を目指す。16日付工商時報が伝えた。

グループ傘下の南亜塑膠工業(南亜プラスチック)の呉嘉昭副総経理によると、同投資計画は台プラグループの王永在副董事長が10月中旬に訪中した際に確定した。初期段階では9,500万米ドルを投じ、ポリエステル繊維工場、ポリエステル長繊維工場、加工糸工場、織布染色加工工場などを設置し、生産規模は約20万トンとなる見込み。これは、台湾での生産量の約半分、グループ全体の約2割で数字的には大きくないものの、中国の内需市場への供給が主な目的で、台湾市場およびベトナムなどの海外市場向けは引き続き麦寮工場からの出荷が中心となる。

■港湾と高速道が決め手

呉淞江は、付近に1,000トン級の大型コンテナ船が停泊できる港湾設備を擁し、高速道路で上海と直結している。こうした物流面での優位性を、投資先として評価した。完成後は、同グループの船隊を利用して麦寮から、原料となるエチレングリコール(EG)や芳香族化合物の高純度テレフタル酸(PТA)を搬入し、呉淞江でナイロン繊維、チップ、加工糸に加工してから高速道路で長江デルタ地帯の各都市に出荷する。輸送に恵まれた地理条件を生かして内需市場の速やかな攻略を狙う。

■紡織関連の拠点を統合

総投資額1億8,800万米ドルに上る昆山工業区は、112ヘクタールの敷地内に月産1,200トンの銅箔工場1基と、プリント基板(PCB)工場、ガラス繊維工場、ガラスクロス工場を持つ。呉副総経理によると、南亜塑膠は6月の董事会で同地に月産1,450トン規模の銅箔工場と、年産4万トンのガラス繊維製造窯およびガラスクロス工場を増設する投資計画を承認しており、現在経済部投資審議委員会(投審会)に申請中だ。しかし、事業分担と原料輸送の利便性から、同工業区は今後、プリント基板を主としたエレクトロニクス材料事業の発展に特化させる方針。紡織関連の投資は全て呉淞江の工業区に集中させる考えだ。

一方、土地面積500ヘクタール、投資額7億米ドルでグループ最大の投資規模となる寧波では、台湾化学繊維(台化=フォルモサ・ケミカルズ&ファイバー)のアクリロニトリル・ブタジェン・スチレン(ABS)工場が量産を開始したほか、台湾塑膠工業(フォルモサ・プラスチック)によるポリ塩化ビニル樹脂(PVC)工場の完成が間近。将来的には、アクリル酸エステル(AE)、ポリプロピレン(PP)、ポリスチレン(PS)、PTAなど各工場も生産を開始し、石化中間原料の一大生産拠点となる見通し。同工業区と麦寮のナフサプラントとで石化原料の分業体制を築くが、原料となる塩化ビニルモノマー(VCM)およびスチレンモノマー(SM)は麦寮からの供給に頼る。また、寧波は中国の内需市場向けに注力し、麦寮は台湾の内需市場と中国からの間接輸出市場向けの出荷を手がけるなど、市場の棲み分けを図る。両者の生産比重は、4対6となる見通しだ。

2004/11/19 Sinopec Sinopec QRCC starts up refinery

and PP project

Sinopec Qingdao Refining

and Chemical Co., Ltd. Is Established 山東省青島

http://english.sinopec.com/en-newsevent/en-news/2229.shtml

On 18 Nov, the launch

ceremony of Sinopec Qingdao Refining and Chemical

Co.,Ltd. was held in

Qingdao. The former Vice Chairman of CPPCC, Mr. Chen Jinhua,

Deputy Secretary of Shandong provincial CPC Committee and Party

Secretary of Qingdao, Mr. Du Shicheng, Vice Major of Shandong

province, Mr. Zhang Zhaofu, Chairman of Sinopec Mr. Chen Tonghai,

Vice Chairman and President of Sinopec, Mr. Wang Jiming attended

the launch ceremony.

Qingdao Refining

Project is the key petroleum and chemical project in China,and the

first ten million tonnes level refinery newly established by

Sinopec in 21st century, playing an important role in adjusting

the domestic refining industry structure, improving international

competence of the refining enterprises and well boosting the

local economic development. Qingdao Refining Project was designed

in accordance with the concepts and visions of 21st century

refinery with the salient characteristics of the scale economy,

advanced technology, leading friendly environment and etc. From

the process of raw material, processing, to product refining, the

whole production line adopted the hydrogen refining process

technology. The process installation and system engineering

adopted the integrated energy-saved expertise. In the aspects of

the product structure, quality and public engineering

consumption, friendly environment index and etc. rank at the

leading position domestically, meet the international advanced

standard.

The establishment of

Qingdao Refining and Chemical Co., Ltd. marks the Qingdao

Refining Project has been embarking on an accelerating

construction path. From sources, the project is expected to be

completed and put into operation in the first half of 2007. After

going on stream, the annual refining capacity of the imported

sour crude is estimated to be 10 million tonnes, the production of the refining

oil over 7.6 million tonnes, it is estimated that over RMB 20

billion sales revenue will be realized, meanwhile, the product

quality and every economic technology index will be improved to

meet Euro Ⅲ and international advanced standard

respectively.

Qingdao Refining

Project received great support from the related departments of

the State Council, Shandong provincial government and CPC

committee and Qingdao city. In Feb 2001, Sinopec group, Shandong

provincial government and Qingdao municipal government signed the

“Letter of Intent for cooperation on

Qingdao Refining Project”. Afterwards, the State Council

approved the project proposal and in June 2004 formally approved

the project feasibility report.

In addition, in

order to better provide storage and transportation auxiliary

service for Qingdao Refining Project, Sinopec and Huarun

Petroleum and Chemical (Group) Ltd. signed the “Agreement

on Shares transfer of Qingdao Qirun Petroleum and Chemical Ltd.”. The

Company acquired the all shareholdings of Qingdao Qirun

Petroleum and Chemical Co., Ltd. held by Huarun Petroleum and

Chemical (Group) Ltd.

Qingdao

Refining Project was

invested by Sinopec, Shandong International Trust

Investment Company and Qingdao International Trust Investment

Company, which held 85 per cent, 10 per cent and 5 per cent equity respectively. Total

investment of the project is estimated to RMB 9.713 billion

(including US $0.177 billion). Construction of the

project is expected to be completed in 2007.

Qingdao

Qirun Petroleum and Chemical Co. Ltd., established in 1993, was invested by

Sinopec and Huarun Petroleum and Chemical (Group) Ltd., which

held 59.5 per cent and 40.5 per cent equity respectively. The

company was put into production in August 1996, and its principle

operations are storage, transportation and transfer of crude,

refining oil products and petrochemical products.

Nov. 22, 2004 Eastman

Eastman Joint Venture Plant in China Starts Operations

http://www.eastman.com/News_Center/News_Archive/Corporate_News/2004/041122.htm

Eastman Chemical

Company (NYSE:EMN) announced today that Qilu 斎魯Eastman Specialty Chemical Ltd. (QESCL) has begun

operations in Zibo, Shandong Province, People's Republic of

China. QESCL is a joint venture between Sinopec Qilu

Petrochemical Company and Eastman Chemical Ltd., a wholly owned

subsidiary of Eastman Chemical Company.

The new plant produces Texanol ester alcohol and TXIB

plasticizer.

The plant is able to meet the total demand of Eastman's current

customers for these products in China. Construction of the plant

began in September 2003.

This investment is Eastman's second major project in China in the

specialty chemicals markets. It follows the establishment of Nanjing Yangtzi Eastman

Chemical Ltd., a 50-50 joint venture with Yangtzi Petrochemical

Industrial Corporation established in 1998 to manufacture Eastotac hydrocarbon

tackifying resin for adhesives.

2004/11/30 Asia

Chemical Weekly

Qilu

Petrochemical 斎魯 starts up world scale oxo

alcohol plant

Qilu Petrochemical, a subsidiary of Sinopec, has brought

on-stream a world scale oxo alcohol plant in Zibo, Shandong

province. 山東省ジボ市

The new plant

uses LP Oxo low pressure process technology. And the plant produces 171 200 tonne/year of

2-ethylhexanol (2-EH) and 19 600 tonne/year of iso-butyraldehyde. The technology was

developed by British company Davy Process Technology with

cooperation from Union Carbide (Dow Chemical) and Johnson

Matthey.

The propylene feedstock is sourced from the company's ethylene

complex. Sinopec Qilu Petrochemical took over the plant from the

contractors on 30 October 2004 and the plant was already

operating at full capacity.

The products of this plant will be mainly used to produce DOP

plasticizer, which will be used either captively or sold in the

regional market.

A little earlier, the jv of Eastman and Qilu Petrochemical - Qilu

Eastman Specialty Chemical Ltd. (QESCL) - has also begun

operations at its $30m oxo derivatives plant in Zibo. The oxo

derivatives plant produces Texanol ester alcohol and TXIB

plasticizer; the plant would meet the demand of Eastman's current

customers for these products in China.

オキソ法(oxo process)

オレフィンに一酸化炭素と水素を反応させて、飽和アルデヒドを合成する方法。通常、得られたアルデヒドは水素添加または二量化後、水素添加してアルコールに変えられるので、この工程を含めてオキソ法と称する場合が多い。例えばプロピレンを原料として、オクタノール、ブタノールを得る方法等。

LP Oxo Low

Pressure Oxo Process Technology

http://www.dow.com/licensing/what/lowoxo_l.htm

The LP Oxo

(TM) Low Pressure Oxo Process is the world's leading process

for the production of oxo alcohols from olefins. It is the

result of a collaboration between Davy Process

Technology (DPT) and Union Carbide Corporation that

began in 1971. To date, this process technology has been

adopted in 27 projects in 14 countries, representing most of

the world's oxo alcohols capacity licensed during the last 20

years. The LP Oxo technology has been awarded the Kirkpatrick

Chemical Engineering Award as well as an R&D 100 Award

for a new generation of catalysts.

Today, the process is licensed by Davy Process Technology in

conjunction with The Dow Chemical Company, following its

acquisition of Union Carbide in February 2001. Dow has

extensive commercial experience with this technology and

operates it in four manufacturing facilities worldwide. While

DPT provides plant design services and Dow provides

proprietary catalysts, the two companies jointly provide

operator training, start-up assistance and ongoing technical

support to licensees.

The Process

The LP Oxo Process involves the reaction of propylene with

synthesis gas (a mixture of hydrogen and carbon

monoxide) to produce butyraldehydes. Usually the normal

butyraldehyde is converted to 2-ethylhexanol (2EH). It is also possible

to convert normal or iso-butyraldehydes to normal and

iso-butanols and other derivatives. 2EH is used

mainly in the production of plasticizers to add flexibility

to PVC, while butanols and their derivatives are used

extensively for their solvent properties.

Davy Process

Technologies

http://www.davyprotech.com/

Davy Process

Technologies Limited (DPT) has as its core business the

supply of licences to operate advanced process technologies

related to the manufacture of Oil and Gas, Petrochemicals,

Commodity Chemicals, Fine Chemicals and Pharmaceuticals. To

sustain this business the company undertakes a programme of

continuous development to improve its technology portfolio.

Davy Process Technologies (Switzerland) AG (DPT-CH) also

offers proprietary process technologies together with

specialist equipment, development capabilities, front end

engineering and turnkey project management to the Fine

Chemicals and Pharmaceutical Intermediates markets.

2004/11/23 Platts

China's Yisheng

to launch second PTA plant in Ningbo by late 2006

China's Zhejiang

Yisheng Petrochemical Co Ltd has scheduled to launch a second purified

terephthalic acid plant in Ningbo at the end of 2006, a company

source said Tuesday.

The capacity of its new PTA unit will be similar to its first plant, of 530,000 mt/yr. The company was in the

midst of procuring equipment for the plant, with the process

expected to take up to 18 months, the source added. Similarly,

the company would buy paraxylene feedstock for plant, with the

output expected to be diverted to its affiliate companies.

Zhejiang Yisheng is a 50/50 joint venture between two polyester

producers, Hengyi and Rongshen, which are based in

Xiaoshan蕭山, in Hangzhou杭州. The two companies operate a total of

1.1-mil mt/yr of polyester capacity in China.

Asia Chemical

Weekly 2005/3/22

Yisheng starts up

PTA plant at Ningbo, plans the second project

Zhejiang Yisheng (浙江逸盛) Chemical started up its

530 kt/a PTA plant at Ningbo on 18 March, a few weeks later than

the planning.

Industry sources suppose the delay of this plant was due to

engineering problems. According to the company's original plan,

the starts-up date should be in early March.

The plant is now operating at 70% of capacity, and the company

will raise the operating rate gradually to 100% of capacity by

early April.

The PTA plant is based on Invista's technology, it will have a

maximum PTA capacity of 600 kt/a. All of the PTA output would be

supplied to its two shareholders which operate polyester

facilities in Hangzhou.

Yisheng is a joint venture between two private companies,

Zhejiang Hengyi Group (浙江恒逸集團) and Zhejiang Rongshen Chemical Fibre Group (浙江榮盛化纖集團). All of the PTA output

will be for its two shareholders which operate polyester

facilities in Hangzhou.

Furthermore, Yisheng has planned another same scale (530 kt/a)

PTA project in Ningbo. The company is still awaiting the approval

from the Chinese government for the second PTA project, and the

second project is expected to start up at end-2006 or in early

2007.

Zhejiang Hengyi

Group Co., Ltd.

http://www.hengyi.com/HENGYI/english/about.asp?#intro

Established in October 1994, Zhejiang Hengyi Group Co., Ltd. is a

large-scale industrial enterprise concentrating on polyester,

filature and weaving manufacture, as well as R & D and trade.

With total assets of RMB Yuan 1.5 billion, it covers an area of

530,000m2 and employs more than 3,000 staff. Besides processing

180,000T polyester yarns yearly, the Company annually

manufactures 50,000T polyester chips, 300,000T melt direct

textile polyester filaments and 70 million square meters garment

fabrics of various kinds. Over 200 different brand-new fabrics

are developed every year. Its annual import and export volume

reaches USD 70 million. In 1998, the Company became the first

company to pass ISO9002 quality certification in Xiaoshan's

textile industry. In 2000, the Company was listed as the

excellent unit in quality management. By sticking to the

management idea of "depending on talents and survive through

quality" and in the spirit of "making unswerving

efforts to obtain further success", the Company encourages

all the staff to strive for the long-range target of

"letting China's long textile history re-glitter in our

generation."

Rongsheng

Chemical Fiber Group Co., Ltd

http://www.xiaoshan.gov.cn/invest/meeting/qiyie/rongshen.htm

Rongsheng

Chemical Fiber Group Co., Ltd is a large-scale company, mainly

engaging in the development, research and production of chemical

fiber products, as well as real estate and trade etc. Since the

establishment of company, it has been insisting on the way of

specialized development. The parent company---Rongsheng Chemical

Fiber Group Co., Ltd has the following subsidiaries, namely

Zhejiang Rongxiang Chemical Fiber Co. Ltd., Zhejiang Rongsheng

Chemical Technology Research and Development Co. Ltd., Zhejiang

Rongsheng Trading Co., Ltd., Hangzhou Rongsheng Real Estate Co.,

Ltd. and Hangzhou Rongsheng Textile and Chemical Fiber Co., Ltd.

etc. The Group occupies more than 1500 square meters, employs

over 2000 people and has with total assets of 1.5 billion RMB

Yuan and realized output value 2.0 billion Yuan in 2002.

The group shares great human resources advantage. Employees with

university educational background account for 10% in addition to

those with master degrees. It also introduces engineers (or with

equivalent professional title) and managerial talents form Taiwan

to form a strong team for R&D and management.

The group insists on sustainable development and the combination

of manufacturing with R&D through the cooperation with

Zhejiang Institute of Science and Technology (ZIST). It has

established Zhejiang Rongsheng chemical fiber technology R&D

Co. Ltd. that provides the company with strong ability of

product, design and R&D.

The group owns international advanced polymerization, spinning

and texturing equipment, the total production capacity reaches

200,000 tons. The main products branded "RongXiang" are

sold very well in domestic and oversea markets, and are awarded

honors as "Zhejiang customer's satisfactory product"

and "famous brand in Zhejiang".

2004/11/25 Platts

China's Yizheng new PET bottle plant on track for Dec launch

China's Yizheng Chemical Fibre Co plans to start up a

PET-bottle grade chip plant in Yizheng by December and a

polyester staple fiber and polyester film plant next year, a

company source said Thursday. Yizheng plans to commission its 200,000 mt/yr solid-state

polymerization plant which will produce bottle grade chips, by December, the source

said. It also plans to start up a 100,000 mt/yr PSF plant and a 160,000 mt/yr polyester

film grade facility in the second and third quarters of 2005

respectively. Yizheng is increasing its PET bottle-grade chip

production to meet rising local demand, the source added. It is

one of China's largest PET bottle-grade producers and the

country's largest polyester fiber maker.

Yizheng Chemical

Fibre Co., Ltd.

http://www.english-ycfc.com/

Yizheng Chemical

Fibre Co., Ltd. (hereinafter referred to as Yizheng Chemical) is

a holding company of Sinopec Corp. and also the largest production base of

chemical fibre and chemical material in China. According to its

production capacity in 2001, Yizheng Chemical is the 4th largest

polyester manufacturer in the world.

Main equipment and technologies for PET and spinning was imported from Zimmer, AG in Germany and from Toyobo Co., Ltd. in Japan

respectively. Phase 1 construction of the project was started in

1982, the first production unit was put into operation in

Jan.1984, Phase 2 started in Jan.1985 and was completed in

Oct.1990, resulting in PET production capacity of 500 thousand

t/y. The total investment for Phase 3 is RMB3.67 billion, main

equipment and technologies were imported respectively from

countries as France, Germany, America, Japan and Italy. Phase 3

was started in Nov.1993 and completed in Sep.1995.

Yizheng Chemical Fibre Co., Ltd. was registered on December 31,

1993 and listed 1 billion H-Stock shares, 2 billion A-Stock

shares and 4 billion new H-Stock shares respectively in HK United

Exchange Co., Ltd. and Shanghai Stock Exchange in March of 1994,

January and April of 1995.

Yizheng Chemical is mainly engaged in the produce and sales of

polyester chips and polyester fibers and covers businesses in the

produce and sales of chemical fibers and chemical products, the

produce of auxiliary materials and textile machinery, the

development of textile technology and technology service. Yizheng

Chemical has introduced many advanced equipments and implemented

many technological reform and innovation, thus our products had

reached the internationally advanced textile technology at the

end of 1990s and achieved ISO9001(2000)quality certificate.

By that time, being a national important production base of

chemical fibre and its raw materials and with a capacity of

1,000,000 t/y in PET products, including 540,000 t/y in PET fibres, and 350,000 t/y in PTA.

同社の能力

企業情報ユナイテッド・ワールド証券

主要株主 Sinopec(42.00%)

HKSCC Nominees Limited

(33.62%)

China International

Trust and Investment Corporation (18.00%)

住 所 Yizheng City, Jiangsu

Province, PRC 江蘇省儀征市

事業概要 ポリエステル樹脂チップとポリエステル繊維の製造と販売。ほかに織機と織機技術の研究開発も。

企業沿革

同社は、中国のアパレル産業用の天然繊維不足を解消するため、中国政府が打ち出した緑化プロジェクト推進組織として、1978年に設立された。同社の主な活動は、中国におけるポリエステル・チップとポリエステル主体繊維の製造と販売である。同社は、中国最大、世界第5位のポリエステル製造会社である。現在、2種類の原材料を外部からの供給に依存している。同社の製品は、中国全土で販売されており、広範な顧客基盤を持つ。また、海外にも製品を輸出している。同社の本社と製造工場はイージェン市内にある。

2004年12月1日 化学工業日報

伊藤忠、フッ酸の中国合弁2期増設が完成

伊藤忠商事が中国浙江省・永康市で建設していた無水フッ化水素酸(フッ酸)の第2期増設工事が完了、12月半ばにも商業生産入りする。年産1万5000トン能力で、中国最大のフッ酸メーカー・鷹鵬化工との合弁で昨春から稼働した1万トンに続くプラントとなる。

伊藤忠と鷹鵬化工は昨年11月、フッ酸設備増設で合意。両社はすでに昨春から浙江伊鵬化工有限公司(伊藤忠60%、鷹鵬化工40%出資)の1万トン設備を稼働しているが、今回、両社均等出資の新合弁会社「浙江藤鵬化工有限公司」(薫事長・石塚新弥伊藤忠無機化学品部長)を設立、永康で工場・プラント建設を進めていた。プラントは11月半ばに完成、試運転段階に入っており、今月半ばにも商業生産に移行できる見通し。

立地点となる永康は蛍石の主産地・浙江省に位置し、増設プラントは既設1万トンプラントに隣接して建設。

中国鷹鵬化工 http://www.yingpengchemical.com/introduction-e.htm

Yingpeng

Chemical Co., Ltd. China, a UK-owned venture located on the Land of Fluorspar - Yongkang, Zhejiang,

China, is the only large enterprise in China that is

specialized in the whole process of fluorite industry from fluorite mining

to the manufacture, research, development, and marketing of

fluoride chemicals.

Our main

products include fluorspar, fluorspar powder for

hydrofluoric acid, anhydrous hydrogen fluoride, hydrofluoric

acid, fluoride cryogen, industrial fluorides, fluoride

pharmaceutical and pesticide intermediates, etc.

As an ISO9002

registered company, all our products are produced in

accordance with standard specifications. Our products have

been marketed across China and exported to Europe, America,

and Southeast Asia.

2004/12/4

China Chemical Weekly

Hong Kong's KingBoard plans large Methanol Project in Chongqing 建滔化工

Hong

Kong based chemical company -- KingBoard Chemical has signed a

agreement with Changshou Chemical Park of Chongqing(重慶) city. According

to the agreement, KingBoard will invest about 205 million Dollars

(1.7 billion Yuan) to construct a methanol facility.

The proposed project will hold the capacity of 750 000

tonne/year. The project is planned to start

construction in the beginning of 2005, and is scheduled to come

on-stream in 2006.

Beside the proposed project in Chongqing, KingBoard has also

planned a 600 000

tonne/year Methanol project with CNOOC in Dongfang, Hainan

province. The project is owned by CNOOC-KB Chemical (the joint

venture is 60% owned by CNOOC Chemical and 40% by Kingboard). The

Hainan project will start up in October 2006. (Originally

expected to start up in H1 2006, but it was delayed)

With the advantage of rich Natural Gas, Chongqing has attracted

some investors. Mitsubishi Gas Chemical (MGC) associated with

Chongqing Chemical & Pharmaceutical Holding Group, planned an 850 000 tonne/year methanol

project.

In Chongqing city, currently

there is only one Methanol producer Sichuan Vinylon Plant (is owned by Sinopec), which has the

capacity of about 240 000 tonne/year.

参考 Hongkong's Kingboard to

bring China phenol-acetone onstream in '05-'06

Asia

Chemical Weekly 2005/7/12

KingBoard's

kick-off construction for Methanol Project in Chongqing

KingBoard has started

the kick off construction for the 450,000

tonne/year methanol project in Changshou

Chemical Industry Park (CCIP) of Chongqing city in Mid-June

of 2005. According to the source of this company, it is the

first-Phase of investment of KingBoard. The investment for

the 450, 000 tonne/year methanol project is about USD 84.5

million (RMB 700 million). The project is expected to come

on-stream in late 2006.

Industry

medias earlier reported that Kingboard planed an methanol

project with the capacity of 750,000 tonne/year in Chongqing;

the project was planned to start construction in the

beginning of 2005, and to come on-stream in 2006.

While,

Kingboard changed its earlier plan. According to the source,

after the completion of 450,000 tonne/year methanol project,

Kingboard maybe expand the capacity of methanol to 1350,000

tonne/year depend on the market

situation.

Beside

the investment in Chongqing, KingBoard has also planned a 600 000 tonne/year Methanol

project with CNOOC in Dongfang, Hainan

province. The project is owned by CNOOC-KB Chemical (the

joint venture is 60% owned by CNOOC Chemical and 40% by

Kingboard). The Hainan project will start up in October 2006.

Also

in CCIP, Mitsubishi Gas Chemical (MGC) associated with

Chongqing Chemical & Pharmaceutical Holding Group,

planned an 850 000 tonne/year

methanol project. The project is expected to

be commissioned in late 2007 or in 2008.

2004年12月13日 Chemnet Tokyo

中国政府、上海石油化工のMEG増設計画承認

(上海発=特約)

シノペック子会社、上海石油化工は高純度テレフタル酸(PTA)の能力を現有年産28万トンから40万トンに引き上げる計画を進めているが、このほど、中国政府から上海金山区でのモノエチレングリコール(MEG)の増設計画の承認を受けた。

38万トンの第二プラントを建設するもので、第一プラント22万トンと合わせ、年産60万トンとなる。既に技術導入交渉をはじめており、2年後のスタートを目指す。

原料エチレンは金山区の自社エチレンクラッカーから供給する。同社は現在、70万トンと15万トンの2プラントで合計85万トンのエチレン能力をもつが、来年をめどにこれを100万トンとし、数年後には140万トンに引き上げる考えである。このため原油精製能力も約6割増やす意向。

MEGの中国での需要は2002年が302万トン、2003年で346万トン、これに対して国内生産はそれぞれ91万トン、97万トンであった。中国ではPTAの増設計画が相次ぎ、2ー3年で自給体制が出来上がるが、原料MEGについては数年間は不足状況が続くとみられている。

2004年12月17日 中国・ASEANニュース速報 参考

茂名石化、エチレンプラントを拡張

中国石油化工集団傘下の茂名石油化工で15日、エチレンプラントの拡張工事が始まった。

今回の拡張事業は60億元以上を投じて進められる。2006年9月の完工を予定しており、茂名石化のエチレン年産能力は現在の36万トンから100万トンにまで拡大することになる。同時に合成樹脂、高密度ポリプロピレン、高圧ポリプロピレンの生産も拡大する。

2006/4/25

China Chemical Reporter

Maoming Petrochemical Ethylene

Expansion Project Carries forward

With the total investment of

RMB7.5 billion, the 1 million t/a ethylene expansion project

in Sinopec Maoming Petrochemical Company (MPC) carries

forward rapidly in Maoming of Guangdong province, South

China.

By April 10th, 2006, 18 items of the 36 branch projects

completed wet commissioning, which totally spent over RMB3

billion. Among which, the boiler coal-to-oil technologic

renovation project started production on February 28th, 2006

and the 460 000 t/a aromatics unit expanded from 160 000 t/a

effectively started production on March 31st, 2006 ahead of

schedule. It is estimated that the 1

million t/a ethylene unit will start production in July and

outlet qualified products in September 2006.

It is released that the

ethylene expansion project in MPC is the national key

renovation project. The feasibility report was formally

approved by the National Development and Reform Commission on

October 13th, 2003.

The expansion project started construction on December 15th,

2004.

Platts

2006/5/22

China's Sinopec completes 150 kt/year butadiene plant in

Maoming

China's Sinopec Maoming has completed the construction of a

150,000 mt/year butadiene

plant in Maoming, Guangdong, the firm said in its web site.

Along with the cracker expansion, Maoming also built a new 220,000

mt/year swing HDPE/LLDPE plant and

a 460,000 mt/year aromatics

complex.

In addition, the firm is slated to complete by June or July

the construction of a 350,000 mt/year HDPE

plant, a 300,000 mt/year PP plant and expansion of its

ethylene capacity by 640,000 mt/year to 1 million mt/year.

Sinopec Maoming is a subsidiary of China's state-owned oil

and petrochemical company Sinopec.

2004/12/17 Chemnet Tokyo 天津誘致

天津市がサウジとエチレン年産100万トン設備

中国天津市はかねて石油化学センターの大型化を検討、外資企業の参加を求めていたが、06年の完成を目ざしてエチレン年産100万トン規模の設備建設に着手することになった。

現地情報によると、中国石化(SINOPEC)がサウジアラビアのアラムコ(国営石油会社)と合弁で、同市の渤海湾に面した化学工業区(塘沽)に同センターを建設する。

この化学工業区には現在、年産11万トンクラスのエチレン設備があるが、これを一挙に10倍の111万トンに拡充するわけで、ポリエステル、ポリエチレン、スチレンなど誘導品設備の建設とともに、国内外の注目を集めている。

中国の石油センターはこのところ大型化への動きが活発化。ロイヤルダッチシェルが広東省の恵州でエチレン年産90万トン設備(06年完成)の建設をきめたほか、上海市(奉賢区)では英BP(ブリティッシュペトロリアム)との合弁で同90万トン設備2基の建設にとりかかっている。

これより先、南京の独BASFによる年産40万トンの増設(計年産100万トン)が、ことしの秋に完成している。また江蘇省張家港市や上海市(高橋区)でも増設が行われ、ここ2,3年の間にエチレン年産600~700万トン規模で拡大が進む。

同国の石油化学センターは中央政府が基本計画をきめている。天津市では今回の計画を5年がかりで検討してきたが、さる11月に中央政府の認可を得た。サウジアラビアとの提携は原料となる石油の確保が第一のねらい。

また、サウジアラビアの海外での石油化学分野の本格的な進出はこれが初めて。原料確保を求めた中国と、石油の付加価値を高めようとするサウジアラビアのねらいが、一致した計画である。サウジアラビアは同国内でも日本の石化連合や住友化学との合弁で、エチレン生産の拡大にのりだしている。

日本の石油化学勢の中国でのエチレン部門への参加は、これまでに具体化していないが、誘導製品事業は高付加価値のポリエチレンテレフタレート、アクリルなどですでに実現している。しかし、ポリエチレン、ポリプロピレンなどの汎用品については具体化しておらず、中国からの誘いもみられない。

なお、天津市の石油化学大型化計画では米ダウケミカルと話し合いが進められていたが、ダウの意向が定まらず、見送りとなった。

2004/12/22

Asia Chemical Weekly

Gaoqiao Petrochemical gets

go-ahead for the projects in SCIP

Gaoqiao

Petrochemical Co. - a subsidiary of Sinopec - broke ground on its

acrylonitrile styrene butadiene (ABS) and styrene butadiene

rubber (SBR) projects on 18 December in Shanghai Chemical

Industry Park (Caojing, Shanghai), a company source said.

Total

investment of two projects would cost 255 million USD (2.11

billion yuan). The SBR project, which with the capacity

of 100 000 tonne/year, would cost 77 million USD; the ABS project,

which with the capacity of 200 000 tonne/year, would cost 178

million USD.

Both

projects will be solely owned by Gaoqiao, and the ABS project will

use the technology of Dow Chemical; while the SBR project will

use the technology of Asahi Kasei.

The

ABS project is slated for mechanical completion in March 2006 and

commercial production in June 2006. The SBR project is targeted

to achieve mechanical completion at the end of 2005 and

production in early 2006.

Part

of the feedstocks will be souced from Shanghai Secco

Petrochemical Co which is building a 900 000 tonne/year cracker

complex in Caojing. Secco¨s complex is

scheduled to start commissioning in March 2005.

Also,

Gaoqiao Petrochemical has started

commissioning its new 200 000 tonne/year phenol-acetone plant in

SCIP.

The

company started feeding cumene feedstock to the plant on 18

December, and commercial production is expected to start at the

end of December. Gaoqiao is importing cumene feedstock until

propylene supplies are ready from Secco.

At

the present, Gaoqiao is producing a total of 160 000 tonne/year

of phenol and acetone from two plants in Pudong, Shanghai.

According

to the source from the company, Gaoqiao is in talks with Mitsui

Chemicals for a bisphenol A (BPA) facility, which would source

its feedstock from the former¨s phenol-acetone project.

シノペック子会社の上海高橋石油化学は、18日上海市漕涇地区の上海ケミカルパークでABSとSBRプラントの地鎮祭を行った。

ABSは能力20万トン/年で建設費178百万ドル、SBRは10万トン/年で77百万ドル。いずれも高橋石油化学の単独事業で、ABSはダウ技術、SBRは旭化成の技術を使用する。いずれも2006年前半の稼動を目指す。原料の一部は漕涇地区で90万トンエチレンを建設中の上海賽科石油化工(BP/シノペック/上海石化)から供給を受ける。

高橋石油化学は上海の浦東地区で2系列計16万トンのフェノール/アセトンプラントをもっているが、漕涇地区で新しく20万トン/年のフェノール/アセトンプラントの運転を開始した。18日に原料キュメンの投入を開始し、月末には商業生産開始を予定している。

同社は三井化学との間で、これを原料にしたビスフェノールA製造について交渉中と言われている。

China Chemical Reporter

2004/12/27

Sinopec to Construct Chemical Facilities in Shanghai

China Petroleum &

Chemical Corporation (Sinopec Corp.) plans to build the

biggest domestic styrene-butadiene rubber (SBR) facility and the global biggest

production capacity of ABS resin in single line with total investment

of RMB 2.1 billion. The two projects will be managed by

Gaoqiao Petrochemical Company.

The SBR and ABS facilities are both downstream relating

projects of 900 000 t/a ethylene in Shanghai SECCO

Petrochemical Co Ltd.

Platts

2006/9/21

Shanghai Gaoqiao

completes 200 kt/year ABS plant construction

China's Shanghai Gaoqiao completed construction of its 200,000

mt/year acronitrile-butadiene-styrene plant on Wednesday, a source

close to the company said Thursday.

Meanwhile, the company began operations at a separate 100,000

mt/year styrene butadiene rubber unit ( in Gaoqiao 誤り) in early September, and has

already begun producing on-spec material for sale in the spot

market, the source said.

*The SBR and ABS

facilities are both downstream relating projects of 900 000

t/a ethylene in Shanghai SECCO Petrochemical Co Ltd.

2006/7/11 Asia Chemical Weekly

Sinopec Gaoqiao starts up SBR project in SCIP

Shanghai Gaoqiao Petrochemical Co. (Gaoqiao

Petrochem),

a subsidiary of Sinopec, has started up its 100 000 tonne/year

SBR project at Shanghai Chemical Industry Park (SCIP), in

Caojing, Shanghai.

Gaoqiao Petrochem has started feeding feedstock into the unit,

and could produce on-spec products by the end of July or early

August, if it goes smoothly. The project was broken ground at the

end of 2004; it took Gaoqiao Petrochem one year and a half to

complete the construction.

The project is based on Asahi Kasei technology, and the feedstock

of SM/Butadiene are sourced from SECCO, which is running a 900

000 year ethylene complex in SCIP. SECCO's complex has 90 000

tonne/year Butadiene and SM 500 000 tonne/year SM capacity.

Besides the new SBR project, Gaoqiao Petrochem also operates a

100 000 tonnes/year polybutadiene rubber (PBR) unit at Pudong,

Shanghai.

China imported about 284 kt SBR in 2004 and 234 kt SBR in 2005.

The 200 000 tonne/year ABS project of Gaoqiao Petrochemical is

under construction, and it is expected to start up by the end of

2006.

China

Chemical Reporter 2004/12/21

Three

Fine Chemical Projects Start Construction in Shanghai Huayi 上海華誼集団公司

On

December 18, Shanghai Huayi (Group) Company (Huayi:上海華誼集団公司) laid the

foundation for its fine chemical base in Shanghai Chemical

Industry Park with the construction starting of three fine

chemical projects.

The

1 000 t/a polyvinylidene fluoride (PVDF:フッ化ビニリデン) and 100 t/a HFA(ヘキサフルオロアセトン)project of Shanghai

3F New Materials Co Ltd, (上海三愛富新材料)a subsidiary

company of Huayi Group, drove the fist pile into the ground.

The

first phase of Tianyuan Group

Huasheng Company(上海天原華勝化工: Tianyuan Group

subordinated to Huayi)’s caustic soda

and PVC project entered the all-round construction phase in the

same day.

On

December 19, Shanghai Huayi Microelectronic

Material Co Ltd, as another important fine chemical

project, laid the foundation.

China

Chemical Reporter 2006/12/14

Shanghai 3F PVDF Resin Project Starts up

The first phase of the PVDF (polyvinylidene fluoride) resin

project recently put on stream in Shanghai 3F New Materials Co.,

Ltd, a subsidiary company of Huayi Group上海華誼集団公司.

Located in Shanghai 3F Caojing Plant in Shanghai Chemical

Industry Park, construction of the PVDF resin project was

started on December 18th, 2004. With a design capacity of 1

000 t/a, the first-phase project include 200 t/a injection

degrade products, 500 t/a coatings degrade products, 200 t/a

adhesive degrade products and 100 t/a other products.

Shanghai

Huayi (Group) Company

http://www.shhuayi.com/htm/introduction_english.htm

Shanghai

Huayi (Group) Company is a large-scale enterprise group

established by re-organization of assets with the authority

of the State Assets Administrative Committee of Shanghai

Municipal People's Government. The Company commands more than

20 wholly-owned and share-holding branches including Shanghai

Tianyuan (Group) Co., Ltd, Shanghai Tyre & Rubber

(Group) Co., Ltd, Shanghai Coking & Chemical Corporation,

Shanghai Wujing Chemical Co., Ltd.

Huayi (Group) Company has 11 design or research institutes, 2

national enterprise technological centers, 8 municipal

enterprise technological centers and even post doctor

scientific research stations. The number of products

manufactured in the company amounts to about ten thousands

under more than ten categories, covering fundamental

chemicals, rubber and plastic products, chemical reagent,

biochemicals, chemical equipment and others.

Shanghai

Huayi (Group) Company is the main stockholder of Shanghai

Chemical Industry District Development Co., Ltd and Shanghai

Pharmaceutical (Group) General Company. Three of its branch

companies issue stocks on the market, among which two

companies issue both A-and B-shares.

Shanghai

Huayi (Group) Company lays stress on introduction of foreign

investment and strengthening of foreign cooperation. At

present, it has already established over ten joint ventures

and cooperative enterprises with many world-famous chemical

companies including Du Pont, BASF, Bayer, ATOFINA and BOC.

Moreover, the Company also owns several enterprises and joint

ventures in Hong Kong, North America, Africa, South-East Asia

and other foreign regions.

Shanghai

3F New Materials(上海三愛富新材料)

http://plastics.2456.com/eng/vex/vb01.asp?T1=3&T2=15027

Shanghai

3F New Materials Co., Ltd., a high-tech company listed in

Shanghai Stock Exchange Center, is specialized in research

and development, manufacture and marketing of fluoropolymers,

fluorine-containing refrigerants and fine chemicals. 3F is a

China-based company with its marketing and R&D centers in

Shanghai and production bases in Shanghai and Changshu. As a

leading manufacturer in China, 3F has been dedicating itself

to the breakthrough of the manufacturing and application

commercialization, creating classic and permanence.

Scope

of Products

Thermoplastics, Rubbers, Fillers,

Starting materials, intermediate, polymerisation auxiliaries

Shanghai

Huayi Microelectronic Material Co., Ltd.

2004年10月19日 Electronic

Journal

http://www.electronicjournal.co.jp/news/2004/10/19.html

英BOC Edwardsは10月15日、台湾Asia

Union Electronic Chemical(AUECC)と中国の電機メーカー向けにウェットプロセスケミカル製品を供給するため、Shanghai

Huayiグループと合弁で「Shanghai Huayi

Microelectronic Material Co., Ltd.」を設立すると発表した。AUECCはShanghai

Huayi Microelectronic Materialを拠点に、半導体・FPD向けの超高純度ケミカルを販売していく。新工場へは2000万ドルを投資し、2005年半ばの量産開始を予定している。

China Chemical Reporter

2004/12/24

1.0 Million t/a Methanol to Build in Erdos 内蒙古・鄂尓多斯

Dongsheng District Government in

Erdos City, Inner Mongolia signed an agreement on construction of

1.0 million t/a methanol project with Huajian Energy Chemical Co

Ltd located in Erdos on December 18, 2004.

The project will be constructed in two phase with total

investment of RMB 3.0 billion in Dongsheng District. Its

production capacity in the first phase will be 400 000 t/a, and

begin construction in August 2005. 600 000 t/a methanol will be

set up in the second phase and start building in 2007.

2005/1/3 Asia Chemical Weekly

Dushanzi Petrochemical gets

approval for cracker project CNPC・新疆独山子石化

Dushanzi Petrochemical, a subsidiary

of PetroChina, has got the final approval from the Chinese

government for its 1m tonne/year cracker project in Dushanzi,

Xinjiang. At the same time, the company has also got the approval

for the plan to expand its 6m tonne/year refinery to 10m

tonne/year.

Dushanzi Petrochemical had targeted to start up the proposed

cracker in 2007-08. But the date of start-up may be delayed as a

cracker project would take at least three years to complete.

The Dushanzi's project is in line with the target of PetroChina

to increase ethylene production to at least 1m tonne/year in

three sites -- Daqing City in Heilongjiang province大慶(黒龍江省), Jilin City in Jinlin province吉林省, and Dushanzi in Xinjiang.

PetroChina is building a crude-oil pipeline from Atas in

Kazakhstan to Xinjiang in China, and the pipeline will be

completed at the end of 2005. So, the cracker project was

believed to own high priority to PetroChina, because it was

linked to the crude-oil pipeline project.

Integrated with the proposed project, some downstream facilities

have also been planned. That include aromatics (with the

capacities of 240 000 tonne/year of benzene, 130 000 tonne/year

of toluene, and 70 000 tonne/year of mixed xylenes); HDPE (300

000 tonne/year); LDPE (600 000 tonne/year); PP (550 000

tonne/year); SM (320 000 tonne/year); PS (130 000 tonne/year),

and SBS (88 000 tonne/year).

At the present, Dushanzi Petrochemical is operating a 220 000

tonne/year cracker at the same site.

2005/9/1 Asia Chemical

Weekly

Dushanzi Petrochemical

started construction for expansion projects in Xinjiang

On August 22, 2005, Dushanzi Petrochemical Company-a subsidiary

of PetroChina- started construction for its refinery

and ethylene expansion projects in Dushanzi, Xinjiang Autonomous

Region.

The expansion projects include refinery and ethylene facilities.

After the expansion, Dushanzi will have a crude oil processing

capacity of 10 million tonne/year, up from the current six

million tons; and will have ethylene capacity of 1.2 million

tonne/year, up from current 220,000 tonne/year.

Total costs for the construction of expansion projects will be

USD 3.23 billion (RMB 26.2 billion). The refinery expansion

project is expected to complete by 2007, while the ethylene

expansion project is expected to complete by 2008.

Most of crude oil for the Dushanzi refinery will be sourced from

Kazakhstan through a 1,200- kilometre cross-border pipeline. Construction of the Sino-Kazak

oil pipeline started last September. When the first phase is

completed by the end of this year, the pipeline will be able to

supply 10 million tonne/year of crude oil to Dushanzi;

Furthermore, after the completion of the second phase is

completed, the capacity of this pipeline will be double to 20

million tonne/year.

パイプラインはカザフスタン・Atasuから新疆の阿拉山口(Alashankou)を経由し独山子までを結ぶ。

なおペトロチャイナはカザフスタンの石油会社Aktobemunaigaz

の株式85.12%を保有しており、Kenkiyak

周辺の油田権益(Kenkiyak、Zhanazhol

油田など)を保有する。更に同社は先日、カザフスタンに油田の権益を持つカナダのペトロカザフスタンを買収すると発表している。

2005/9/14 Asia

Chemical Weekly

German's Linde wins $140m contract from Dushanzi

cracker

German's Linde has been selected as one of

contractors by PetroChina International for Dushanzi

ethylene cracker. The contract

which with an order value of USD 140 million was signed in

Beijing on Sep. 11. According to the agreement, Linde

will supply process technology and key components for its new

cracker. On August, Dushanzi Petrochemical Company

started the construction for both its refinery and the 1

million tonne/a ethylene projects. The ethylene project is

expected to start production in the H2 of 2008.

Besides, the derivatives projects for the ethylene complex

also be confirmed, and all the proposed derivatives plants

are expected to come onstream in 2008. The derivatives

projects show below:

600,000 tonne/a HDPE/LLDPE swing unit

300,000 tonne/a HDPE

550,000 tonne/a PP

600,000 tonne/a BTX

320,000 tonne/a SM

130,000 tonne/a PS

130,000 tonne/a butadiene

100,000 tonne/a SBR

80,000 tonne/a SBS

120,000 tonne/a MTBE/butene-1

20,000 tonne/a 1-hexene

China Chemical Reporter

2005/1/13

Caustic Soda Project Starts Construction in Ningbo

A 100 000 t/a ionic membrane caustic soda project and 35 000 t/a

chlorinated paraffin project, as the first phase of Ningbo

Zhenyang Chemical Development Co Ltd's plan, recently started

construction in Ningbo Chemical Industry Park.

2005.01.13

Dow Corning

Dow

Corning And Wacker Reach Agreement On Integrated Manufacturing

Site In China

PLANT TO BE BUILT IN SHANGHAI AREA

Wacker-Chemie GmbH and Dow Corning Corp., have finalized the

master agreement for their planned Asian joint ventures to

produce silicone intermediates and fumed silica in the Shanghai

area. According to the agreement that has been approved by both

Boards of Directors, the partners intend to build a world-scale

production complex for siloxane and

fumed-silica. The joint ventures will involve

capital expenditures totaling several hundred million dollars.

Construction work is scheduled to start immediately upon issuing

of the necessary licenses by the Chinese authorities.

Chemnet

Tokyo 2005/2/3

中国、石炭からのアセチレン製造で実験装置

プラズマにより石炭破砕法、合肥市に完成

中国は石油・天然ガスの供給不足を解消するため燃料に石炭を利用する新技術の開発に取り組んでいるが、このほど安徽省合肥に2メガワットの水素プラズマを使った石炭破砕アセチレン製造実験装置を完成させ、関係者の注目を集めている。

石炭破砕のアセチレンは化学原料にも使われる可能性を持ち、米ダウケミカルが中国挟西省での大規模なアセチレン、エチレン生産を検討中と伝えられているが、石油価格が1バレル50ドルを超す現状で、このアセチレン新製法が工業化の現実味を帯びている。

中国科学院プラズマ研究所では、すでにプラズマトーチで生ずる平均温度5,000℃の水素プラズマを使って粉炭と水素ガスを化学反応させ、アセチレンを含む混合ガスをつくり、分離、濃縮することによって高品質のアセチレンを得る技術を持つ。実験装置の完成でクリーンな石炭の大規模利用の見通しがえられれば、半世紀前のコークスと石炭からのアセチレン製法が新技術でプロセスを変えて復活することになる。

アセチレンは有機化学品の基本原料だが、石油化学法によるエチレンにとってかわられた。エネルギー消費量が多く、大量の資源を使い、環境汚染がひどいことが、カーバイド法を排除したわけだが、クリーンに高い効率でアセチレンを直接生産することができれば、中国ばかりでなく世界的な拡がりで工業化が進められそうである。

Platts

2005/2/18

ExxonMobil,

Sinopec in preliminary talks on ethylene project

The Guangzhou branch of Sinopec operates a refining and

petrochemical complex in the Huangpu district of Guangzhou, the

provincial capital of Guangdong. The complex centers around a

refinery with 7.7-mil mt/yr (154,000 b/d) of crude processing

capacity and a naphtha cracker with 200,000mt/yr of ethylene

output capacity.

The

blueprint of SGC and its parent Sinopec is to ultimately lift

SGC's refining capacity to 18-mil mt/yr

and ethylene output capacity to 800,000mt/yr.

2005/2/23 Asia

Chemical Weekly

Zhejiang Yisheng

Chemical preparing for the start-up of PTA plant

Zhejiang Yisheng Chemical(浙江逸盛化学) is on schedule to start

feeding its new 530 000 tonne/year PTA plant in Ningbo, Zhejiang,

with feedstock at the end of this week. The production was

expected to begin this weekend or in early March. This is in line

with the company's original plan.

Zhejiang Yisheng Chemical Company is a joint venture between two

privately owned local companies, Zhejiang Hengyi Group (浙江恒逸集團) and Zhejiang Rongsheng Chemical

Fibre Group (浙江榮盛化纖集團). The cpmpany was taken

22 months to complete building the PTA plant.

The new plant, based on Invista's technology, will have a maximum

PTA capacity of up to 600 000 tonne/year. All of the PTA output

would be supplied to its two shareholders which operate polyester

facilities in Hangzhou.

China imported 3.1 Mt PTA in 2001, 4.3 Mt PTA in 2002 and 4.55 Mt

in 2003. China’s imports of PTA in 2004

reached 5.7 Mt, up approximately 24% over 2003.

Industrial analysts think that PTA imports would ease in 2005 in

some degree, because of the start-ups of two PTA plants in China.

The one is the Yisheng Chemical’s 530 000 tonne/year

project in Ningbo, Zhejiang; the another is the project of

Zhejiang Hualian Sunshine Petrochemical (浙江華聯サンシャイン石化), it has targeted to

start up its 600 000 tonne/year project in Shaoxing, Zhejiang, in

March or April 2005.

Platts

2006/9/16

China's Yisheng to

start up new PTA plant as PX shortages ease

China's Zhejiang

Yisheng Petrochemical will start up its second purified

terephthalic acid (PTA) plant in the second-half of November

2006, a company source said Monday.

The plant, located in Ningbo, China will have a production

capacity of 650,000 mt/year of PTA. It is located near

Zhejiang Yisheng's existing PTA

plant,

which following a debottlenecking earlier this year, has a

production capacity of 660,000 mt/year of PTA.

PX SHORTAGES HAVE DELAYED SEVERAL PTA EXPANSIONS

China Chemical

Weekly 2005/2/25

SPC commissions

new refinery, total capacities reaches 14m tonne/year

Shanghai Petrochemical Co (SPC), a subsidiary of Sinopec,

commissioned its newly completed 8m tonne/year refinery in

Jinshan, Shanghai, on Feb. 22. The total capacities of SPC

reached 14m tonne/year; and it becomes the second largest refiner

in China, just under the ZRCC (16m tonne/year).

The new refinery, which was taken SPC more than 1 year to

complete and with total costs of 46.8 million USD (388 million

CNY), is to replace the SPC¨s existing No 1 refinery

(2.8m tonne/year). SPC also operates a No 2 cracker (6m

tonne/year) with an ethylene capacity of 700 000 tonne/year. The

company¨s No 2 refinery is

located at the same site as the new refinery.

SPC plans to use the added naphtha output from the new refinery

to feed its proposed cracker. It plans to build a 500 000-600 000

tonne/year cracker to replace its existing 150 000 tonne/year No

1 cracker, while the proposed cracker project has yet to be

approved by the Chinese government yet.

At the present, SPC is not likely to run both of its No2 and No3

refineries at their designated combined capacity of 14m

tonne/year, because the downstream projects are under planning

and preparing.

SPC now produces a total of 850 000 tonne/year of ethylene from

two crackers in Jinshan. One is a 700 000 tonne/year unit;

another is 150 000 tonne/year unit.

SPC imports more than 90% of its crude oil, with 50% of it

sourced from the Middle East.

2005/3/3 人民日報日本語版

重慶市が世界レベルの天然ガス化学工業基地を建設

重慶市経済委員会がこのほど発表した『重慶天然ガス化学工業投資促進レポート』の中で、第11次5カ年計画期に重慶市は天然ガス化学工業に総額430億元を投じて、10~20年間を費やして、世界レベルの天然ガス化学工業基地を作り上げる計画を立てていることを明らかにした。

同『レポート』は、重慶市の将来の発展目標は全国の重要天然ガス化学工業基地とファイン・ケミカル基地を作り上げることを中心とし、「長寿天然ガス化学工業」、「?

陵化学肥料」と「万州塩化学工業」の三大化学工業パークを築き上ることにある、としている。そして10~20年間を費やして、この三大化学工業パークを世界レベルの天然ガス化学工業基地に仕立て上げることになっている。

全般的な計画・目標を2段階に分けて実施することとなっており、第1段階は、2010年までに中期目標を達成し、第2段階は、2011年~2020年まで長期目標を達成することになっている。三大パークの売上高は2010年に200億元になり、2020年に600億~800億元になる。第11次5カ年計画期に、重慶市は当面100以上の重要工業プロジェクトの実施を計画しており、投資総額は2300億元にのぼり、そのうち資源加工業の投資総額は1230億元で、天然ガス化学工業が約35%を占め、430億元に達する。

重慶市が計画している長寿天然ガス化学工業パークは、長寿地区の既存の四川ビニロン工場、長寿化学工業本工場、四川燃料化学工業本工場、長風化学工場、川慶化学工場など大規模な化学工業企業をベースに、長寿天然ガス化学工業グループ会社を創設し、天然ガス化学工業とメチルアルコール、酢酸、補助剤のシリーズ製品などを重点的に発展する。2005年末までに同工業パークの年間生産総額は60億元に達すると予測されている。

同『レポート』は重慶市の天然ガス生産量に対して、非常に楽観視しており、2010年までに天然ガス生産量は100億立方メートルに達すると予測している。ただ、現在重慶市の天然ガス供給には、毎日25万立方メートル、年間で1億立方メートル近くの不足が見られ、計画中のプロジェクトが期限どおりに完成すれば、重慶市の天然ガスの需要にはかつてない伸びが見られる、とされている。

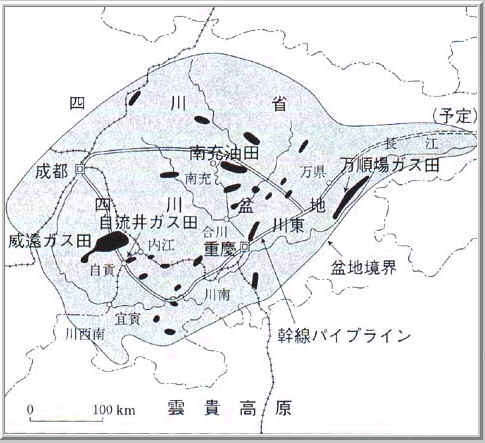

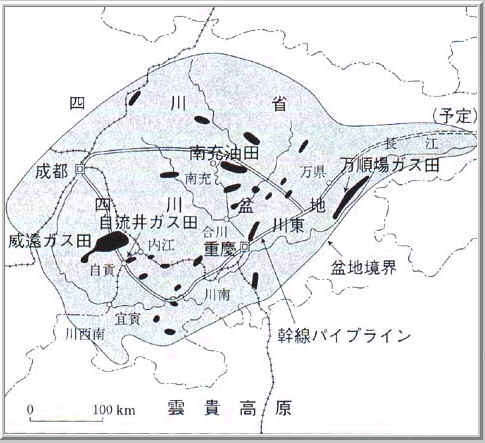

四川盆地の天然ガスパイプライン網

http://www.iijnet.or.jp/IHCC/seiiki-jukei-city-map01-gas01.html

四川盆地内を円を描くように敷設されているガスパイプライン幹線網は、域内の主要都市(成都~重慶、成都~南充)間を結び、「川東」ガス田で、合流している。このパイプラインは、武漢市まで延伸される。

四川盆地内の天然ガスは主な用途としては、化学肥料工場の原料用(全体の60%)、化学工業や他の工業の原・燃料、あるいは輸送用(CNG、圧縮天然ガス・バス)や民生用として280万戸の家庭でガスが使用されている。これらの供給パイプライン網の総延長はおよそ1万kmにも及んどいる。

China Chemical Reporter 2005/3/3

PE Pipe Brought on-stream in March

Guangzhou Fengye PE Pipe

Industrial Co., Ltd. will formally produce PE pipes in March this

year. The company will produce mainly the following: PE water

supply pipe, PE fuel gas pipe, PE steel skeleton reinforced

spiral double wall corrugated pipe, PE double corrugated pipe.

The capacity of the first stage project will reach 30 000t/a.

2005/3/13 Asia Chemical Weekly

China's government reassessing the ACN Ban in Yangtze River

China's government has enlisted a consulting organization to

conduct additional tests to determine whether acrylonitrile (ACN)

should be categorized as a "hyper toxic" chemical; and

whether the transportation ban of ACN in Yangtze River should be

extended, according to the industry sources.

Two of these tests for ACN have been already completed; while the

third and last test has yet to be completed. Once the third test

has been finished, the China! ̄s government will conduct an environmental

impact report on the chemical product.

If the report is positive for the ACN suppliers; that mean

China's government maybe ease the ACN Transportation Ban in

Yangtze River.

For the environmental concerns, The Chinese government has banned

shipments of acrylonitrile (ACN) via the Yangtze River with

effect since 1 June, 2004, and imposed a $10/tonne surcharge for

ground transportation of ACN.

Taiwanese ABS producers operating in China, such as Chi Mei and

Grand Pacific Petrochemical Corp (GPPC), have been the most

affected by the transport ban and have incurred higher costs.

The two Taiwanese ABS producers and some suppliers of ACN to

China have been lobbying with the Chinese government for a

lifting of the ban since last year. They contend that the

transportation of hazardous chemical by ground route is more

dangerous than by waterways.

China Chemical Reporter 2005/3/10

Chitianhua and Hongfu Jointly

Develop Coal Chemical Industry

Guizhou Chitianhua Group Co.,

Ltd. (貴州赤天化股フェン有限公司) and Guizhou Hongfu Industry Development

Co., Ltd. signed agreement in Guiyang (貴陽), a few days ago, for jointly

constructing the project of 300 000 t/a synthetic ammonia and of 300

000 t/a urea. The anticipated

construction cycle of the project is two years, with a total

investment of RMB2.5 billion and the Chitianhua Group Co., Ltd.

as the holding company.

China Chemical Reporter 2005/3/14

Blue Star and SKC to Establish a Strategic League on PU

On February 22 China National Blue Star

Corp. and SKC Company of Korea held a signing ceremony for the letter of

cooperative intent on the establishment of strategic league for

PU (polyurethane). The two parties would make cooperation on PU

development in a form of strategic league for mutual benefit and

promote cooperation on the potential PU business in Asian area,

reinforce the respective leading position in the chemical

industry in Asian area.

Presently the world's PU

industry has been gaining speedy development it has kept at a 6%

growth rate for the past five years, becoming the fastest growth

one among the chemical industry. Blue Star has currently had capacities of

30 000 t/a of TDI, 80 000 t/a of propylene oxide, 140 000 t/a of

polyether-polyols and 10 000 t/a of PU. Cooperation with SKC means Blue Star will

entirely get involved in PU business and form its own PU

industrial chains.

2005/3/15 BP 交渉

BP and Sinopec to Sign a Joint

Venture Contract for their Nanjing Acetic Acid Plant

http://www.bp.com/genericarticle.do?categoryId=2012968&contentId=7004865&PC=102aabfeb8d00

BP and Sinopec announced today in

Beijing that they had signed a joint venture contract to build a 500,000 tonne per year

acetic acid plant in Nanjing, Jiangsu province.

Located in Nanjing, at the heart of the Yangtzi Delta - one of

the most dynamic regions in economic development in China, this

world-scale joint venture is expected to be on stream in the

second half of 2007. The plant will incorporate BP’s world leading CATIVAR technology and the

equity split between BP and Sinopec is 50:50. The Sinopec investment will take place

through the Yangtzi Petrochemical Company, a majority owned

Sinopec Corporation subsidiary.

Notes to editors:

BP and Sinopec announced on 10th May 2004 that they had signed a

heads of agreement in London for the joint venture in Nanjing,

during the Chinese Premier Wen Jiao Bao's visit to the UK.

The Nanjing plant will become part of BP’s high growth acetyls and aromatics