http://www.syntech.com.cn/en/company.asp

DSM SABIC ACQUIRES DSM's POLYOLEFINS

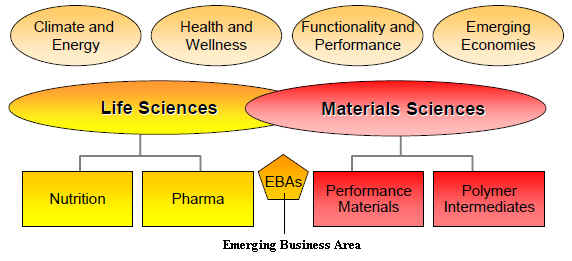

DSM is active worldwide in life

science products, performance materials, polymers and industrial

chemicals. The group has annual sales of EUR 8 billion and

employs about 22,000 people (year-end 2001) at more than 200

sites worldwide.

DSM ranks among the global leaders in many of its fields. The

company's strategy is aimed at generating sales of approx. EUR 10

billion in 2005. At least 80% of these sales should be generated

by specialties, i.e. advanced chemical and biotechnological

products for the life science industry and performance materials.

As such, this strategy represents a continuation of the company's

ongoing transformation and concentration on global leadership

positions in high-added-value activities characterized by high

growth and more stable profit levels.

DSM is a highly integrated group of companies that is active

worldwide in the field of chemicals, life science products and

plastics with:

$5.9 billion in sales

22,000 people

More than 200 sites around the globe

DSM's headquarters are in Heerlen, The Netherlands. DSM's activities are organized in business groups corresponding to three coherent product/market combinations:

Life Science Products

Performance Materials

Polymers & Industrial Chemicals

The company's principal products are:

intermediates and ingredients for the pharmaceutical and food industries

performance materials (like engineering plastics, resins and synthetic rubbers) for the automotive and electrical/electronics industries

polymers as well as industrial chemicals for a wide range of manufacturing industries

DSM is the global market leader for several products including:

enzyme technologies and products

anti-infectives

caprocalctam

melamine

EPDM rubber

DSM Hydrocarbons

... operates two steam crackers which mainly produce polymer raw materials. The most important of these are ethylene and propylene, which are supplied to other DSM business groups as feedstocks for the production of polyethylene, polypropylene, EPDM rubber and acrylonitrile.

The product range further includes butadiene, benzene, MTBE, gasoline components, raw materials for hydrocarbon resins, aromatics, carbon black oil and styrene.At the core of the DSM Hydrocarbons division, is its pair of naptha steam crackers with a combined annual capacity of over one million tons of ethylene and approximately 470 thousand tons of propylene. Additionally, DSM Hydrocarbons operates several modern downstream plants for benzene, butadiene, gasolines and an integrated unit for MTBE, carbon-black feedstocks, solvents and C9 resinfeed.

DSM Polyethylenes

ranks among the leading producers of polyethylenes in Europe in terms of both market position and cost price.

DSM Polyethylenes produces a variety of polyethylenes using several technologies. These materials are mainly used in the packaging industry.DSM Polypropylenes

...manufactures polypropylene as well as a wide range of compounds based on this polymer.

The business group has a total production capacity of 750,000 tpa (including DSM Polyolefine). The products are used in packaging (flexible and rigid), fibres, automotive parts (e.g. bumper systems), pipes and electrical and electronic (E&E) components and equipment.

The business group aims to expand its position as a leading polypropylene supplier. In Western Europe, DSM holds a market share of 11% in polypropylene.In 1997, DSM established DSM Polyolefine in Gelsenkirchen and took over the polyethylene and polypropylene activities of Veba Oel. This represented the ideal platform for implementing the group’s polymer strategy.

DSM currently has a polypropylene capacity of 750,000 tpa divided over three plants (total capacity of 550,000 tpa) at the large, integrated DSM site at Geleen (The Netherlands) and one plant in Gelsenkirchen in Germany (DSM Polyolefine GmbH, the former Vestolen GmbH). By the year 2001, when a new plant in Gelsenkirchen comes on stream, capacity will amount to more than 1 million tpa.

Existing facilities with an annual capacity of approximately 300,000 metric tons of polyolefines are being modernized and expanded, and two modern new plants will boost production to almost a million metric tons per year by the year 2001 to triple present production with a workforce of 500.

DSM Hydrocarbons Americas, Inc.

is a sales office whose primary business focus is on the sales and procurement of products for DSM Hydrocarbons in The Netherlands.DSM Hydrocarbons Americas’ geographical focus is the USA, Canada, Mexico, Venezuela and Colombia. For the Latin American market DSM Hydrocarbons Americas also sells caprolactam, cyclohexanone and specialty chemicals.

Contract to sell Roche’s vitamins, carotenoids and fine chemicals

business to DSM signed

http://www5.dsm.com/en_US/html/media/press_releases/03-03-roche.htm

DSM and Roche announced today that the contract to acquire Roche’s vitamins, carotenoids and fine chemicals business has been signed. This transaction is subject to approval by the anti-trust authorities.

For Roche, this agreement allows to further focus our group on our two high-tech pillars, pharmaceuticals and diagnostics to further establish our position as a leading, innovation driven healthcare company.”

2003/2/21 Financial Times

DSM pays EUR 300 M less for Roche vitamins division.DSM is to pay EUR 300 M less for Roche's vitamins division because the slowdown in economic growth has had an adverse effect on the vitamins market.

May 1, 2003 Dow Jones

EU Delays Decision On DSM's Purchase Of Roche Operations

2004/1/14 DSM

DSM、日本におけるロシュのビタミンおよびファインケミカルズ事業の統合を完了

ロシュ・ビタミン・ジャパン株式会社は、新社名「DSM ニュートリションジャパン 株式会社」で、日本市場におけるさらなるビジネス展開を推進オランダのスペシャリティ・ケミカル・カンパニーであるDSM N.V. (本社:オランダ ヘーレン市、会長:ピーター・エルバディング、以下 DSM)は、DSMによるロシュ社(スイス)のビタミンおよびファインケミカル事業の買収にともなう、日本における事業統合を正式に完了したことを、本日発表しました。

これにより、ロシュ・ビタミン・ジャパン株式会社(本社:東京都大田区、代表取締役社長:レオ・ダーム)は、2004年1月1日付けで「DSM ニュートリションジャパン株式会社」(DSM Nutrition Japan K.K. 以下 DSMニュートリション ジャパン)に社名変更し、DSMの日本市場におけるライフサイエンス事業の中核を担う組織として、引き続き高品質な製品の開発と製造に努めてまいります。

2004/11/24 DSM

Royal DSM N.V.

intends to participate in North China Pharmaceutical Group

Corporation

http://www.dsm.com/en_US/html/media/press_releases/35_04_NCPC.htm

Today, Royal DSM N.V.,

headquartered in Heerlen, The Netherlands, confirmed that it is

engaged in discussions with North China Pharmaceutical Group

Corporation (“NCPC”) of Shijiazhuang石家庄,

Hebei Province河北省, People’s Republic of China, regarding a

strategic partnership via a.o. participation in the equity ownership

of North China Pharmaceutical Company, Ltd. (“NCPC Ltd.”), a company which is listed on

the Shanghai stock exchange. DSM’s equity participation in NCPC

Ltd. is related to the establishment of joint ventures in the

area of vitamins and anti-biotic products.

NCPC

NCPC, together with

its affiliates, is one of the largest vitamins and

antibiotics manufacturers in the People’s Republic of China, originally

established in 1953 in Hebei Province. NCPC comprises 28

controlled subsidiaries, 12 associated companies, and an

additional 20 indirectly controlled subsidiaries. Total 2003

group revenues of NCPC are approximately RMB 7 billion (EUR 700

million).

Platts 2005/8/19

DSM Nanjing to start expanded CPL plant, full rates end '05

DSM Nanjing Chemical Co is looking to start up its newly-expanded

caprolactam plant in Nanjing, China in the first half of

September, a company source said Friday.

The plant with its capacity now doubled to

140,000 mt/yr is currently in a

pre-commissioning state, and on water runs to get the functions

going, the source added. Operations will be stabilized initially

at 70% of capacity, with the full start-up by the end of 2005.

China Chemical Reporter 2005/9/7

DSM Deretil Formed JV

with Shangyu Yuntao Chemicals

http://www.ccr.com.cn/news_view.asp?ID=737

DSM

Deretil,

global leader in the field of development, production and sales

of side chains for betalactamic antibiotics and the Chinese

company Shangyu Yuntao Chemicals Company, announced that they have formed

a Joint Venture for the production of DL Phenyl Glycine and D(-) Phenyl

Glycine. DSM

Deretil acquired 51% of the shares and obtained an option to

acquire the remaining 49% to gain full ownership of the

company within the next three years.

“With

this joint venture we realize the opportunity to combine Deretil’s superior technology with the low

cost infrastructure of a Chinese manufacturer. This enables us to

further build on the value proposals we can make to our customers

and supply them with the quality they need in the highly

competitive anti-infective market”, concludes Lluis Franquesa,

General Manager of DSM Deretil at the closing of the agreement.

DSM Deretil is part of DSM N.V. through its DSM Anti-Infectives

Business Group. And Shangyu Yuntao Chemicals Company is a

privately owned company located in Shangyu 上虞

of Zhejiang

province浙江省 in eastern China, and was

established in 2001. Shangyu Yuntao Chemicals produces DL Phenyl

Glycine and D(-) Phenyl Glycine, has annual sales of around

US$7.3 million.

DSM Deretil

http://www.dsm.com/en_US/html/deretil/Deretil_Home.htmDSM Deretil is a business unit of DSM Anti-Infectives, one of the business groups of DSM. DSM is active worldwide in life science and nutritional products, performance materials and industrial chemicals.

We are a leading company in the field of the development, production and sales of side chains for betalactamic antibiotics. DSM Deretil has a worldwide presence, long experience in the market and a strong customer focus orientation.

Globalization is a must for the pharmaceutical industry and DSM Deretil is in the lead. For crucial subjects like research & development, information & communication technology , personnel training, production sites, production processes, international customers and logistics this is firmly addressed in DSM Deretil's management strategy.DSM Anti-Infectives comprises DSM’s activities in the field of development, production and sale of raw materials, intermediates, and bulk actives for anti-infectives such as antibiotics (for combatting bacterial infections) and anti fungals (for combatting fungal infections).

DSM opens

R&D Center in China

http://www.dsm.com/en_US/html/media/press_releases/24_05_DSM_RD_China.htm

DSM, the

world-leading supplier of life science and nutritional products,

performance materials and industrial chemicals, today opened its

first Research & Development (R&D) Center in China. The

center is located in Shanghai.

The DSM R&D Center China will be the company's

main R&D base in the country and will form a vital part of

DSM's global R&D network. In addition to carrying out product

and applications development work, the center will support DSM's

businesses in several other ways: by tracking market trends, by

proactively responding to the needs of customers, and through

interaction with the external know-how infrastructure, such as

partners in universities, scientific research institutes and

industry. DSM Nutritional Products, DSM Food

Specialties and DSM NeoResins will be the first three DSM

businesses to operate facilities at this R&D Center.

DSM Nutritional Products, formerly Roche Vitamins and Fine Chemicals, is the world's leading supplier of vitamins and carotenoids to the feed, food, pharmaceutical and cosmetic industries.

DSM Food Specialties is a leading producer of specialty food and feed ingredients. The product portfolio includes enzymes, yeast extracts, natamycin, starter cultures and media, cheese and meat coatings, antibiotic residue tests and natural beta-carotene.

DSM NeoResins We offer waterborne technologies such as acrylic emulsions and polyurethane dispersions for application in water-based coatings and water-based printing inks.

2005/9/30

DSM

DSM sells styrene-butadiene rubber business to Lion Chemical

Capital LLC

http://www.dsm.com/en_US/html/media/press_releases/26_05_SBR.htm

DSM and Lion

Chemical Capital LLC today announce the agreement on

the sale of the DSM business unit SBR

(styrene-butadiene rubber) to Lion Chemical Capital LLC. The

transaction will take the form of an asset deal.

The sale is a result of DSM’s corporate strategy,

Vision 2005: Focus & Value, which has transformed the company

into a specialty company focusing

on life science products and performance materials over the last few years.

As a consequence, the SBR business no longer fits into DSM's

portfolio.

Lion Chemical Capital

In 2004, Lion acquired the largest

independent rubber compounding business in North America from

PolyOne Corporation. The business, Excel

Polymers,

has over USD 400 million in revenues and includes eight plants

located in the US, Mexico, U.K. and China. Excel Polymers

provides effective solutions to both high volume and the most

challenging technical rubber applications. The businesses will be

operated as independent operations.

Lion closes on DSM rubber business

Lion Chemical Capital, LLC, a private New York-based investment firm, has announced the closing sale on DSM Copolymer Styrene-Butadiene Rubber (SBR). The new company will be called Lion Copolymer, LLC and will continue to be headquartered in Baton Rouge, La. Terms of the transaction were not disclosed.

SBR is used primarily by tire manufacturers and makers of conveyor belts, hoses and gaskets.

With this sale, Lion Copolymers will be one of the largest SBR producers in the United States, with revenues exceeding $200 million.

DSM acquires

Chinese resins producer Syntech

http://www.dsm.com/en_US/html/media/press_releases/29_05_syntech.htm

Dutch specialty chemicals company Royal DSM N.V. today acquired Syntech, a producer and marketer of coating resins. Syntech has annual sales of around USD 30 million, generated with a broad portfolio of coating resins. The acquisition of Syntech further strengthens DSM's liquid coating resins portfolio and will enable DSM to further accelerate the expansion of its activities in the Chinese market.

Syntech's activities are concentrated at one location in Shunde (Guangdong province 広東省順徳). The site includes production facilities, self-owned R&D laboratories and a pilot plant for product development.

![]()

http://www.syntech.com.cn/en/company.asp

2006/4/18

DSM

DSM to double capacity for engineering plastics in China 江陰市

http://www.dsm.com/en_US/html/media/press_releases/dep_china.htm

Royal DSM N.V.

today announces the opening of its new

compounding site for engineering plastics at Jiangyin

in the Jiangsu province of China on April 26, 2006. This

project will double the total capacity for the product lines

Stanyl(R) PA46, Akulon(R) PA6 and Arnite(R) PBT. These materials

are used in manufacturing key molded components for the

automotive, electrical and electronics, consumer and industrial

segments.

DSM to build two

new engineering plastic plants at Chemelot site, Geleen (NL)

Royal DSM N.V. today announces that it has decided to construct

two new manufacturing facilities at its Chemelot site in Geleen,

the Netherlands. DSM is making these investments in response to

excellent market growth for two of the company’s top specialty products, Stanyl(R)

polyamide 46 and Stamylan(R) UH ultra-high

molecular weight polyethylene, which is used among other things

as a raw material for Dyneema(R) high strength fibers.

The new Stanyl(R) plant and the new Stamylan(R) facility, which

will each double existing production

capacity,

are scheduled to come on line in 2008. The total investment will

be around EUR 100 million.

Stanyl

Stanyl, the highest performance polyamide in the world, is a

unique, high-crystallinity material that exhibits exceptional

heat resistance, stiffness and strength, chemical resistance and

processability. In addition, it has a low coefficient of friction

and resists creep and deformation. Automotive applications of

Stanyl include chain tensioners, engine covers, gears, sensors

and clutch rings. Electrical applications include connectors,

circuit breaker housings, microswitches, electric motor parts,

and a variety of components for consumer electronics. Consumer

applications include muffler covers for gas operated tools, water

kettle components including safety switches, and a variety of

other hand and power tool components.

Stamylan UH

Stamylan UH is a very high molecular weight polyethylene that

exhibits excellent toughness and resistance to abrasion,

outstanding chemical resistance and good low friction, non-stick

characteristics. It is widely used for wear-resistant components

in industrial, bulk materials handling and sports equipment as

well as in ultra-strong fibers.

Dyneema

Dyneema is a super strong polyethylene fiber that offers maximum

strength combined with minimum weight. It is up to 15 times

stronger than quality steel and up to 40% stronger than aramid

fibers, both on a weight-for-weight basis. Dyneema is an

important component in marine and offshore ropes, in cables and

nets, in safety gloves for the metalworking industry and in fine

yarns for applications in sporting goods and the medical sector.

In addition, Dyneema is used in bullet resistant armor and

clothing for police and military personnel.

DSM Engineering Plastics

DSM Engineering Plastics is a business group forming part of DSM’s Performance Materials cluster.

DSM Engineering Plastics is a global supplier of Stanyl PA 46 and

Akulon 6 and 66 polyamides, Arnitel TPE-E, Arnite PBT and PET

polyesters, Xantar polycarbonate, Yparex extrudable adhesive

resins, and Stamylan UH Ultra High Molecular Weight PE. These

materials are used in technical components for electrical

appliances, electronic equipment and cars, in barrier packaging

films as well as in many mechanical and extrusion applications.

The business group had annual sales of EUR 705 million in 2005.

It employs 1400 people worldwide and has eight production

locations in Europe, the USA and Asia. With StanylR, it is the

global market leader in high heat polyamides.

DSM starts initiative to extend its material portfolio for the orthopedic industry

Royal DSM N.V. today announces the start of an initiative to enter the market of ultra high molecular weight polyethylene (UHMWPE) for use in total joint arthroplasty 関節形成 and other medical devices. In the coming years DSM Biomedical will make significant investments in a research and development program focused on UHMWPE grades with optimized material properties, specifically aimed at currently unmet clinical needs in this orthopedic 整形外科 segment. This strategic material development links on to DSM’s activities in the Biomedical Emerging Business Area, which is an important element of DSM’s strategy Vision 2010 - Building on Strengths.

超高分子量ポリエチレン(UHMWPE)は、その優れた耐磨耗性及び耐衝撃性や低摩擦係数の故に、膝関節や股関節の整形外科の移殖に適した材料とされてきた。

DSM is already active in the orthopedic market with Dyneema Purity®, a fiber technology which was developed specially to obtain the required highest levels of quality and purity in medical applications, such as orthopedic implants.

Although DSM currently already is one of the major suppliers of Ultra High Molecular Weight Polyethylene, supplied under the trade name Stamylan® UH, DSM’s UHMWPE is not applied in arthroplasty applications yet.

UHMWPE:超高強力ポリエチレン繊維「Dyneema」原料

Dyneema fibers are made using a DSM patented (1979) method called gel spinning.

A precisely heated gel of UHMWPE is processed by an extruder through a spinneret

Dyneema Purity® is a highly purified grade of Dyneema® developed specifically for use in medical applications where maximum strength and minimum weight are required. It is ideal for orthopedic implants, for example, as it allows smaller implants to be used, and is flexible and resistant to abrasion. Similarly, its strength can be used for surgical instruments for minimally invasive procedures.

Typical applications for Stamylan UH (supplied in the form of a powder)

- Automotive industry: battery separators

- Electrical: cable clamps, contact breakers and insulation components

- Food and beverage industry: star wheels, sliding rails, scrolls and feed worms, guide and deflector rollers, chute tables

- Pulp and paper industry: suction box covers, scraper blades, foil covers

- Textile industry: pickers and buffers

- Chemical industry: pumps, valves and seals

- Leisure industry: sliding surfaces for skis and snowboards

- General machinery: bearings, gears, rollers, chain guides and tensioners

- Bulk materials handling mining and agriculture: linings for silos, hoppers, trucks and ships, industrial drains

- Porous parts: dust collection filters, water purification, perfume absorption, sound reduction and fluidisation

- Ultra strong PE fibers: cables, ropes, fishing lines, ballistic vests, lightweight composite armour for vehicles and helmets

- Microporous film: Lithium-ion battery separators, micro-filtration, specialty fabrics and tape

DSM to invest in caprolactam plant at Chemelot, Geleen, the Netherlands

Royal DSM N.V. has decided to invest in capacity expansion and modernization of the caprolactam plant at the Chemelot Industrial Park in Geleen (NL). The total investment costs amount to EUR 25 million. This investment will allow DSM to gradually expand the capacity of the plant according to market demands.

Caprolactam is the key raw material for Nylon-6, a highly versatile material that is used to make not only textile, carpet and technical fibres, but also engineering plastics and packaging films. Nylon-6 is found in numerous applications ranging from conveyor belts, parachutes and lingerie to automotive air-inlets and packaging for fresh food products.

DSM says its Fibre Intermediates subsidiary is the leading global supplier of caprolactam, the key raw material for nylon 6.

It has three operating companies with a combined annual capacity of more than 0·5 million tons in Europe, the Americas and Asia Pacific.DSM Fiber Intermediates increased its production capacity by expanding the annual caprolactum capacity at the DSM Nanjing Chemical Corporation from 70,000 tons per year to 140,000 tons by the end of 2005.

2007/10/8 DSM 高強度ポリエチレン

DSM expands Dyneema® production in Greenville, USA 高強度ポリエチレン

Royal DSM N.V. today announces that it will invest to expand Dyneema® UD (UniDirectional bullet resistant sheet) production by 25% in its Greenville, North Carolina (USA) manufacturing facility.

The investment is driven by the increasing demand for Dyneema® UD in the US market for personal and especially vehicle security and protection against terrorism. Production in Greenville has a strong focus on supplying the US army and law enforcement agencies. By adding extra capacity to its highly integrated Greenville site, DSM remains capable of meeting increasing demand for its products and highly committed to the long term development of the US market. The new line is expected to come on stream in mid 2008. This news also comes on the heels of the recent decision to invest in a new Technical Service center at DSM’s Stanley, NC (USA) facility.

“Investing in further growth of Dyneema® in the US is in line with the focus on our local, and faithful customers and fits perfectly with the recently announced acceleration of DSM’s strategy, Vision 2010 - Building on Strengths, in which market-driven growth and innovation is one of the key pillars,” comments Nico Gerardu, member of DSM’s Managing Board and responsible for the Performance Materials cluster. “DSM will continue to further expand its global capacity for Dyneema® fiber and UD materials to maintain its global market leadership position. To our customers this should provide another example of our commitment to be the world’s most reliable and capable quality supplier of HPPE products.”

About DSM Dyneema

DSM Dyneema is the inventor and manufacturer of Dyneema®, the world’s strongest fiber™. Dyneema®

is an ultra strong

polyethylene fiber that offers maximum strength combined with

minimum weight. It is up to 15 times stronger than quality steel

and up to 40% stronger than aramid fibers, both on weight for

weight basis. Dyneema® floats on water and is extremely

durable and resistant to moisture, UV light and chemicals. The

applications are therefore more or less unlimited. Dyneema®

is an important

component in ropes, cables and nets in the fishing, shipping and

offshore industries. Dyneema® is also used in safety gloves for

the metalworking industry and in fine yarns for applications in

sporting goods and the medical sector. In addition, Dyneema®

is also used in

bullet resistant armor and clothing for police and military

personnel.

Dyneema® is produced in Heerlen (The Netherlands) and in Greenville, North Carolina (U.S.A.). DSM Dyneema is also a partner in a high modulus polyethylene (HMPE) manufacturing joint venture in Japan. Further information on DSM Dyneema is available at www.dyneema.com.

DSM to increase engineering plastics compounding capacity in China by 50%

Royal DSM N.V. today announces that it will expand its engineering plastics compounding capacity at the site in Jiangyin 江陰(China). The investment will increase the capacity of the compounding plant by 50% and the added capacity will be operational towards the end of 2008. This comes as an enhancement to DSM’s existing capacity, which was doubled in 2006 with the opening of this new greenfield site.

DSM opened its greenfield compounding plant for engineering plastics in Jiangyin in 2006 and is currently building a world-scale polyamide 6 polymerization plant at the same site, which will start production in 2008. At the Jiangyin site DSM manufactures Stanyl®, a high performance polyamide (PA46), Akulon® PA6, Arnite® PBT and PET, and Arnitel® TPE, which it supplies to customers throughout Asia in the automotive, electrical/electronics and manufacturing industries. The Jiangyin site also houses a Research and Development Center for engineering plastics, from which DSM supports customer developments throughout the region.

DSM invests in ‘green’ polymers from CO2

DSM Venturing, the corporate venturing unit of Royal DSM N.V., today announced that it has made an investment in Novomer Inc. The companies also plan to sign a cooperation agreement. Financial details of the investment will not be disclosed.

Novomer is developing a technology platform to use carbon dioxide and other renewable materials to produce performance polymers, plastics and other chemicals. The company’s products combine environmental benefits with improved materials performance and can be used in a range of applications, from injection molded parts for electronics to paper coatings and medical implants.

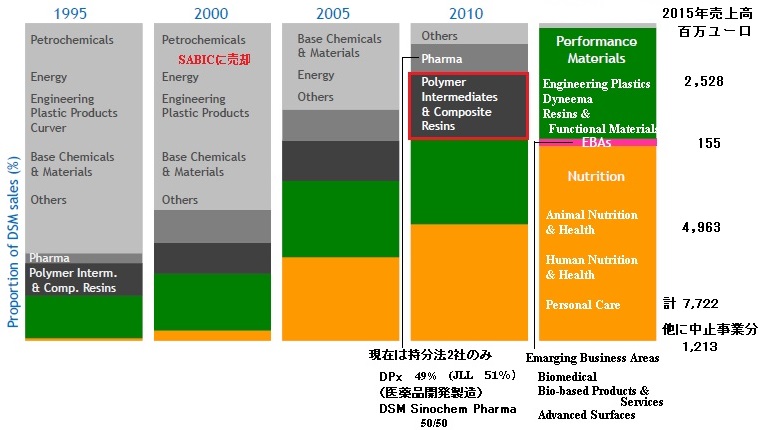

DSM to sell Special Products to Arsenal Capital as first divestment following accelerated Vision 2010

Royal DSM N.V., the global Life Sciences and Materials Sciences company headquartered in the Netherlands, has reached an agreement in principle with Arsenal Capital Partners (United States) on the sale of DSM Special Products BV. It is the first divestment following the accelerated Vision 2010 strategy. The transaction is expected to close in early Q2 2008, subject to regulatory and legal approvals.

The sale is a result of the acceleration of DSM’s transformation into a Life Sciences and Materials Sciences company. As outlined in the strategic program Vision 2010 - Building on Strengths a number of businesses which do not fit in the strategy, including DSM Special Products, will be divested.

DSM Special Products is

the producer of Purox, an ingredient used in food as well as in a

range of industrial applications. It also produces an ingredient

for VevoVitall®, a product for the animal health

market that will remain with DSM Nutritional Products. The supply

of this ingredient for VevoVitall® to DSM Nutritional Products will

not be affected due to an existing long-term supply agreement.

DSM Special Products employs 126 people in Rotterdam and Sittard

(Netherlands). They will all transfer to the new owner.

Benzoic Acid 安息香酸(Purox B), Sodium Benzoate (Purox

S)

DSM invests in development of bio-based materials in China

DSM Venturing, the corporate venturing unit of Royal DSM N.V., today announced that it has participated in a USD 20 million financing round in Tianjin Green Bio-Science Co., Ltd (China). The proceeds will be used to build China’s largest manufacturing plant for Polyhydroxyalkanoates (PHA) in the Tianjin Economic Development Area (TEDA).

微生物産生ポリエステル(ポリヒドロキシアルカン酸 PHA) は、バイオマス由来の有機物をある種の微生物に与えることにより得られる脂肪族ポリエステル

The plant’s construction will commence in Q2 2008, and is expected to start production in early 2009. It will have an annual production capacity of 10,000 tons of PHA.

About Tianjin Green

Bio-Science Co., Ltd.

Tianjin Green Biosciences Co., Ltd (TGBS), located in the

High-Tech Park of Tianjin University in TEDA, Tianjin, is

dedicated to developing and producing biodegradable polymers and

products. Research demonstrates that the PHAs TGBS developed have

excellent biodegradable, processing performance and

biocompatibility. Due to its special properties, the PHA could be

developed for use of high value added products including high

strength fiber, pressure sensitive adhesive, aqueous adhesive,

human tissue engineering product, etc., as well as applications

in food and commodity packaging, with the potential to substitute

50% petroleum-based plastic in application.

DSM inaugurates Akulon® PA6 polymer plant in China

Royal DSM N.V., the global Life Sciences and Materials Sciences company headquartered in the Netherlands, today announces the inauguration of its new polymer plant in Jiangyin (Jiangsu province, China) 江蘇省江陰市. The plant produces high viscosity grades of Akulon® polyamide 6 (PA6) aimed at the fast growing high end food packaging market in Asia. Construction of the plant, which was announced in September 2006, involved several tens of millions of USD.

DSM Engineering Plastics

DSM Engineering Plastics is a Business Group in the Performance

Materials cluster of DSM, with sales in 2007 of EUR 839 million

and approximately 1,550 employees worldwide. It is one of the

world's leading suppliers of engineering thermoplastics offering

a broad portfolio of high performance products including Stanyl®

high performance

polyamide and Akulon® 6 and 66 polyamides, Arnitel®

TPE-E, Arnite®

PBT and PET

polyesters, Xantar® polycarbonate, Yparex®

extrudable adhesive

resins. These materials are used in technical components for

electrical appliances, electronic equipment and cars, in barrier

packaging films as well as in many mechanical and extrusion

applications. With Stanyl®, it is the global market leader

in high heat polyamides.

DSM and NCPC sign

contracts to establish nutrition and anti-infectives joint

ventures in China

Royal DSM N.V., the global Life Sciences and Materials Sciences

company headquartered in the Netherlands, North China

Pharmaceutical Group Corporation Ltd. (NCPC GroupCo) of

Shijiazhuang, Hebei Province, People’s Republic of China, NCPC ListCo,

the listed affiliate of NCPC and the State-owned Assets

Supervision and Administration Commission of the State Council

(SASAC) of Hebei Province today announce that they have signed

the contracts regarding investment by DSM in NCPC GroupCo and the

establishment of three joint ventures in the areas of nutritional

products and anti-infectives.

These contracts are the follow-up to the announcements made at

the end of 2004 and the further detailing of the agreement in

late 2005. DSM will make a strategic investment in NCPC by

obtaining a minority share (9.77%) in NCPC

GroupCo.

Parties will establish one nutrition production joint venture

(Vitamin C) and two anti-infectives抗感染薬 business joint ventures

(anti-infectives active pharmaceutical ingredients and

intermediates). In the two anti-infectives joint ventures

DSM will have a 51%

interest. In the Nutrition production joint

venture, DSM will hold a minority share of 30%.

The total cash investment by DSM following completion, will

amount to approximately USD 110 million. In addition, DSM will with this

investment leverage its technology and management capabilities.

NCPC

North China Pharmaceutical Group Corporation (NCPC) is one of the

largest vitamin and antibiotics manufacturers in People’s Republic of China. NCPC is

originally started in 1953 in the Hebei Province and now has

eight production technology platforms including microbian

pharmaceutical, chemical synthesis pharmaceutical, biochemical

pharmaceutical, modern biotech pharmaceutical, natural drug

extraction, nutritional healthcare products, bio-energy and

biochemicals. In 2007, NCPC achieved sales revenue of RMB 6.42

billion.

May 4, 2009 British Plastics & Rubber

Further investment by DSM

as it waits to sell its rubber businesses

Capacity for Sarlink, the thermoplastic vulcanisate(架橋型エラストマー:TPV) business which DSM currently has

up for sale alongside its EPDM business, has been doubled with

the official opening of a new production unit at Genk in Belgium.

According to Sarlink business unit director and president David

Huizing: "The TPV market is growing at rates beyond GDP

growth, and Sarlink is growing much faster than that."

Production capacity fell below demand in 2007, and since then the

business has invested steadily in new capacity and new

capabilities. The new Genk plant is fully automated and doubles

(undisclosed) global capacity ? Sarlink also has a plant in

Leominster, Massachusetts in the USA.

It was in 2007 that DSM announced that

its elastomers businesses were to be sold off as part of the group's Vision 2010

plan to convert from an industrial chemicals company to a

specialist in life science technologies. Despite its plans to get

rid of them, DSM is continuing to invest in the development of

its elastomer businesses and as well as this expansion of Sarlink

capacity, its has been putting money into a new breed of EPDM,

its Keltan ACE - Advanced Catalyst Elastomer. ACE has a high VNB

(5-vinyl-2-norbornene) content which gives the EPDM a greater

affinity for peroxide and so improves the curing process and the

quality of the final elastomer, or can lower the hydrocarbon

content of the compound and so improve oil resistance. ACE was

revealed in 2007 and the first grade has now gone into production

at Geleen in the Netherlands. The Keltan DE 8270C grade is

intended for peroxide curing applications where it can reduce the

level of peroxide needed, lowering costs and improving resistance

to ageing with lower levels of residual peroxide.

Sarlink

架硫ゴムと熱可塑性樹脂の特長を有するエラストマーです。 射出、押出、プロー成形などさまざまな成形加工が行えます。 広範囲の硬度のグレードがあり、お客様のニーズにお答えします。 サーリンクはDSM社が製造し、東洋紡が販売しております。 ..

DSM plans elastomers

sell-off

DSM is planning to dispose of its elastomers and thermosets

businesses as part of an accelerated move into life sciences and

performance materials. In a restatement today of its Vision 2010

strategy DSM outlined a plan to move 'non-core'

businesses into separate units for divestment.

In a strategy not unlike that pursued by Bayer over the past five

years DSM is positioning itself in the nutrition, pharmaceutical

and performance materials businesses in sectors where it has

market-leading positions, and where it can build on its strengths

in chemistry, process technology, biotechnology and materials

science.

'Those businesses which do not fit with the strategic thrust will

be carved out and divested, during the course of the Vision 2010

period, to new owners for whom there is a stronger strategic fit

and under whose ownership they can prosper further,' says the

company in today's announcement.

Initially these businesses will be grouped in a new Base

Chemicals & Materials cluster and include:

Melamine, urea, fertilisers and energy, currently within

Industrial Chemicals and with around Eur 700 million sales in

2007;

elastomers, currently within Performance Materials and with some

Eur 500 million sales this year;

special products (Nutrition, Eur 100 million);

and maleic anhydride and its derivatives (Pharma, Eur 75

million).

DSM Fibre Intermediates, currently within Industrial Chemicals

and which provides backward integration for DSM Engineering

Plastics, will join a new division Polymer Intermediates.

DSM's new structure from 2008 will be:

Life Sciences (nutrition and pharma),

Materials Sciences (performance materials and polymer

intermediates), and

Base Chemicals & Materials.

The company says it

expects its 'portfolio adjustments' to be completed during the

course of the Vision 2010 programme. The aim is to derive 60 per

cent of the company's total revenues from specialty businesses,

remaining only in those businesses formerly within the Industrial

Chemicals cluster where backward-integration provides a

competitive advantage.

Alongside its planned divestments DSM will seek acquisitions in

its core business areas to achieve external growth. Internally it

expects to achieve an additional 1 billion in sales from

innovation by 2010, and has raised its organic sales growth

target to more than 5 per cent annually and increased its

expectations from China by half to forecast sales in 2010 up from

a $1 billion target to $1・5 billion.

Sale of its non-core businesses will give DSM a reduced presence

at the Chemelot site at Geleen in the Netherlands and DSM says it

will review its options how it can best support the further

development of that site into a successful industrial park. In

addition, it will continue to invest in its R & D campus

infrastructure on the site.

DSM to sell DSM Energy to TAQA

Royal DSM N.V., the

global Life Sciences and Materials Sciences company headquartered

in the Netherlands, announces today that it has reached an

agreement with TAQA Abu Dhabi National Energy

Company PJSC

for the sale of DSM Energie Holding B.V. (DSM Energy) for an enterprise

value of EUR 285 million. The intended sale is expected to close

in Q3 2009, subject to regulatory approvals and notifications.

The disposal consists of the participations which DSM has in oil

and gas exploration and pipelines, including the 40%

participation in Noordgastransport.

DSM expects to realize a book profit of approximately EUR 275

million after tax on the sale. This profit will be reported as an

exceptional item in the income statement at closing. DSM Energy

realized net sales of EUR 161 million in 2008.

Rolf-Dieter Schwalb, Chief Financial Officer of Royal DSM gave

the following comment: “ The intended sale of the energy

business is another important step in DSM’s accelerated transformation

towards a Life Sciences and Materials Sciences company. As stated before, in such a

company there is no place for participations in oil and gas

exploration and pipelines. These participations have a much

better strategic fit with TAQA. I would like to thank all DSM

Energy employees for their continued support and substantial

contribution.”

.

DSM to sell

urea-licensing business to Maire Tecnimont

Royal DSM N.V., the global Life Sciences and Materials Sciences

company headquartered in the Netherlands, and Maire Tecnimont

S.p.A., a leading

international engineering and construction group headquartered in

Italy, announce today that they have reached an agreement for the

sale of DSM’s urea-licensing subsidiary

Stamicarbon B.V. to Maire Tecnimont for a total consideration of EUR

38 million on a cash and debt-free basis. The intended sale is

expected to close by Q4 2009, subject to regulatory and other

customary approvals and notifications.

Stamicarbon, founded in 1947, is the world market leader in

licensing urea technology with over 250 licensed urea plants

located in over eighty different countries and a leading market

share in new capacity. Urea, mainly used as a fertilizer, is

produced from ammonia and carbon dioxide. Stamicarbon realized

net sales of EUR 57 million in 2008 and an operating profit of

EUR 25 million. In 2008 Stamicarbon’s operating profit was

exceptionally high as a result of a number of large contracts

closed during the year. The average operating profit for

Stamicarbon has been approximately EUR 10 million per year over

the past four years.

DSM acquires full ownership of NPC PA6 polymer facility

Royal DSM N.V., the global Life Sciences and Materials Sciences company headquartered in the Netherlands, and Shaw Industries Group, Inc. announce today that DSM has acquired full control of the PA6 polymerization facility of Nylon Polymer Company LLC (NPC) in Augusta (Georgia, United States). Shaw Industries and DSM Chemicals North America were previously joint venture partners in NPC.

As a result of the transaction, which has been closed, NPC is fully integrated into DSM Engineering Plastics’ activities as of 1 January 2010. Financial details and terms of the transaction will not be disclosed.

For DSM Engineering Plastics the acquisition of the full ownership of the PA6 polymerization facility is an important step in its strategy to increase its geographical footprint, including expansion into South America. It also allows the company full integration in the PA6 chain, including caprolactam, polymer and compounded products, in North America, supporting its strong commitment to key customers in the Americas. Last year, DSM opened its first PA6 polymerization plant in China, making it the only company to produce the entire PA6 chain in China. DSM inaugurates Akulon® PA6 polymer plant in China

Koen Devits, President of DSM Engineering Plastics Americas, says: "This acquisition represents a major expansion of our polymerization capabilities in the Americas. It helps us to fully exploit our strong backward integration at the Augusta site, where DSM also produces caprolactam, a key raw material for Akulon®. The acquisition is also needed to support the additional sales opportunities we have generated, especially in the automotive, furniture and packaging industries, and it illustrates DSM’s strong commitment to the Americas market."

Richard Pieters, Global Business Director Akulon® PA6, comments: “We are very excited about this acquisition as it will further reinforce our commitment to global customers who want local supply and global support. North America will remain a key specification and innovation area for DSM Engineering Plastics.”

Akulon® Polyamide 6 (PA6) is a thermoplastic with outstanding mechanical properties over a wide temperature range used in various everyday applications such as automotive, luggage, sports, electronics, packaging films, lighting and furniture. Caprolactam, produced by DSM Fibre Intermediates, is the raw material for PA6, which gives DSM a unique position as an integrated producer of the material. As a replacement of metal in various applications, Akulon® PA6 can offer weight reduction to for instance the automotive industry, resulting in lower CO2 emissions.

DSM Engineering Plastics

DSM Engineering Plastics is one of the world's leading suppliers

of quality engineering thermoplastics providing customer value

through sustainable solutions that reflect the DSM People, Planet

and Profit strategy. DSM Engineering Plastics delivers innovative

opportunities for customers who design or produce electrical

applications, electronic equipment, cars, barrier packaging films

as well as many mechanical and extrusion applications. These

markets are served with a broad portfolio of high-performance

materials including Akulon® 6 and 66 polyamides, Arnitel®

TPC, Arnite®

PBT and PET

polyesters, Yparex® extrudable adhesive resins, and

Stanyl® high heat 46 polyamides. Most

recently, DSM Engineering Plastics introduced the first new

polymer of the 21st century: Stanyl® ForTii™. DSM Engineering Plastics had

sales in 2008 of EUR 761 million with 1500 employees worldwide.

More on: www.dsmep.com.

DSM and Novomer to develop first CO2-based resin for coatings

Royal DSM N.V., the global Life Sciences and Materials Sciences company headquartered in the Netherlands, and Novomer Inc., based in Waltham (Massachusetts, United States), today announce that they have signed an agreement to jointly develop a revolutionary coating resin using carbon dioxide (CO2) as a raw material.

This development agreement follows a cooperation agreement and an investment by DSM Venturing in Novomer in 2007. The joint development project will benefit from the broad variety of DSM’s technologies and market access, in combination with the unique, efficient CO2 polymerization technology of Novomer.

The chemistry and process technology for producing polymers from CO2 and propylene oxide (PO) will be developed by Novomer, while DSM will convert the polymers into resins and formulate them for target applications such as coatings, adhesives and graphic arts. Initial results are encouraging and suggest that this project might lead to completely new and improved application properties in coatings.

Given the fact that up to 50% by weight of CO2 is used as raw material, the production of these resins will result in an improved carbon footprint. The process is also expected to be highly efficient, enabling the replacement of conventional resins in a number of coating applications.

Polycarbonate resins are widely known because of their superior performance and resistances and theoretically could find use in many types of coatings. Commercial use of conventional types has however always been limited due to their cost position and some weaknesses that are inherent in these products. The new CO2-based aliphatic 脂肪族 polycarbonates to be developed by DSM and Novomer could potentially resolve these weaknesses.

Rob van Leen, Chief Innovation Officer of DSM, comments: “DSM and Novomer are looking to develop the first polymer in more than a decade to enter the mainstream of the coating industry. This exciting development can lead to a breakthrough that could change the coating industry. Besides cost issues, these innovative coating resins also address environmental and performance issues. They therefore fit in perfectly within DSM’s People, Planet and Profit approach.”

Peter Shepard, Vice President of Business Development of Novomer, adds: “We are very enthusiastic about our relationship with DSM as they bring a wealth of skills and industry knowledge to help drive the commercialization of our technology in the coatings industry. In addition, this product development relationship with DSM leverages our ongoing technical development work that has been supported by the New York State Energy Research and Development Authority.”

About Novomer

Novomer (www.novomer.com) is a revolutionary new materials

company pioneering a family of low-cost, high-performance,

sustainable plastics, polymers and other chemicals. Based on the

pioneering catalyst work of Dr. Geoff Coates at Cornell

University, Novomer's groundbreaking technology allows carbon

dioxide and other renewable feedstocks to be cost-effectively

transformed into polymers, plastics and other chemicals for a

wide variety of industrial markets. Novomer’s products combine environmental

benefits with improved performance and can be used in a range of

applications, from injection molded parts, specialty binders for

electronics, polymeric packaging materials to paper coatings and

medical implants.

IT SOUNDS TOO GOOD to be true. Ithaca, N.Y.-based start-up Novomer has a technology that reacts carbon dioxide with other molecules, locking it into a polymer backbone and putting it to better use than as an atmosphere warming gas. The company says the anti-greenhouse-gas bonus of its chemistry has drawn attention, but it would rather focus its efforts on making polymers that people want to buy.

At the heart of Novomer's technology are catalysts developed by Geoffrey W. Coates, a chemistry professor at Cornell University. The catalysts are based on transition metals and can break open the highly stable CO2 molecule, enabling it to polymerize with epoxide groups. For example, CO2 combines with ethylene oxide to make the polymer polyethylene carbonate and with propylene oxide to make polypropylene carbonate. These polymers have about 50% and 43% CO2 content by weight, respectively.

カーボネート基 -O-(C=O)-O-

CO2からの高分子合成は、井上祥平・東京理科大学教授が1968年に発見した。

---

Novomer is bringing multiple products to market based on our platform of CO2 and CO catalysis technology. As our first commercial product NB-180 utilizes CO2 feedstocks to produce an ultra-performance material for specific high-tech markets.

Through cutting-edge green chemistry initiated at Cornell University, Novomer's first product NB-180 has been developed specifically for high performance industrial and commercial applications requiring a binder that decomposes rapidly, cleanly and is environmentally friendly.

NB-180 is an amorphous, colorless thermoplastic polymer (polypropylene carbonate) which decomposes into environmentally benign products making it the perfect solution for broad applications in the electronics, brazing and ceramics industries.

Due to a recently-patented catalytic process, NB-180 binders burn more uniformly and at lower temperatures than currently available sacrificial binders. Thus shorter binder burnout times and higher precision results in multiple applications can be achieved simultaneously.

2007年12月25日DSMは、同社コーポレートベンチャリング部門であるDSM Venturingが本日、Novomer社に資本投資したことを発表しました。両社は、提携協定に署名することも計画しています。投資の財務上の詳細については、開示されない予定です。

Novomer社は、機能ポリマー、プラスチックス、その他の化学物質を生産するために、二酸化炭素やその他の再生可能物質を活用する技術基盤を開発して います。Novomer社の製品は、環境保全上の利点と改良材の性能とを兼ね備えており、その適用範囲は、電子機器向けの射出成形部品から紙塗工や医療移植片にまでおよんでいます。

DSM to sell Sarlink unit

to Teknor Apex

Royal DSM N.V., the global Life Sciences and Materials Sciences

company headquartered in the Netherlands, today announces that it

has reached an agreement regarding the sale of the business unit Thermoplastic

Elastomers

(Sarlink), part of the business group DSM Elastomers, to Teknor Apex

Company. The

intended sale is expected to close in Q4 2010, subject to

regulatory and other customary approvals and notifications.

The intended sale of the business unit is a result of DSM’s ambitions to focus on Life

Sciences and Materials Sciences. As announced in September 2007,

DSM Elastomers (Sarlink and Keltan) does not fit with this focus.

DSM Elastomers

With a market share of around 16%, DSM Elastomers is one of the global market leaders in EPDM (Ethylene Propylene Diene Monomer) rubber under the brand name Keltan®. It is also the number two player in the market for EPDM-based - fully vulcanized 加硫処理- thermoplastic elastomers (TPVs). DSM sells these TPVs under the brand name Sarlink®.

Keltan® EPDM is used in cars and other transportation vehicles, white goods, various industrial products and construction materials and as a motor-oil additive. It is also used as a waterproof covering for roofs.

Sarlink® TPVs are used in a wide variety of applications including automotive, consumer electronics, electrical, food, building, medical and industrial applications.

Production plants for Keltan® are based in Sittard-Geleen (Netherlands) and Triunfo (Brazil). Plants for Sarlink® are found in Genk (Belgium) and Leominster (Massachusetts, United States).

A new EPDM unit with annual production capacity of 80,000 tonnes was opened by DSM Elastomers in Geleen, the Netherlands, in 2003.

「出光DSM」解散へ、EPDM事業から撤退

オランダ・DSM社と出光興産の合弁会社「出光DSM」は、このほどDSM側の意向で日本でのEPDM事業から撤退することを決めた。出光興産・千葉工場内にあるEPDM年産4万トン・プラントは2004年9月末から操業を停止しており、合弁会社も解散する方向で両社協議中という。

「出光DSM」は、EPDMを共同事業化するため、1989年1月に出光石油化学(当時)と、DSM社の折半出資(現在資本金112億円)で設立、同3年に設備が完成して営業開始したが、同11年からはDSMが販売を担当し、合弁会社はDSMの製造委託会社となっていた。ーーー

2010/3/3 三菱化学、DSMとの高機能樹脂事業における事業交換契約に合意

三菱化学は2月26日、Royal DSMとの間で事業の交換(ポリカーボネート事業の買収及びナイロン事業の売却)で合意したと発表した。

DSM は、ナイロン事業を主力事業の1つと位置づけ

---

2010/6/1

DSM completes sale of DSM Agro and DSM Melamine to OCI

Royal DSM N.V., the global Life Sciences and Materials Sciences company headquartered in the Netherlands, today announces that it has completed the sale of DSM Agro and DSM Melamine to Orascom Construction Industries (OCI), as announced on 30 March 2010.

With the closing of the sale, OCI will start integrating the businesses as of 1 June 2010.

DSM Agro is a producer of ammonia and high-nitrogen fertilizers for grasslands and agricultural crops and the market leader in the Netherlands. It also ranks among the market leaders in Germany, France and Belgium. DSM Agro, which operates a production site in Sittard-Geleen, produces about 1.6 million tons of fertilizers per year. DSM Agro realized net sales of EUR 338 million in 2009.

DSM Melamine is the world’s largest producer of melamine. The main application of melamine is in wood-based panels and laminates used for furniture and flooring. DSM Melamine has a plant in the Netherlands and also produces melamine in joint ventures in China (DSM 49%) and Indonesia (DSM 60%). In 2009 DSM Melamine realized net sales of EUR 151 million.Orascom Construction Industries

Over the last 50 years, OCI has grown into one of Egypt’s largest corporations with projects and investments across Europe, the Middle East and North Africa. The company directly employs more than 86,000 people.

OCI currently has two core business activities. The OCI Construction Group is a leading construction contractor active in emerging markets with a backlog of US$ 6.6 billion as at 31 December 2009. It primarily focuses on infrastructure projects in Europe, the Middle East and Africa in addition to industrial and high-end commercial projects.

The OCI Fertilizer Group is a strategic owner and operator of nitrogen fertilizer plants in Egypt and Algeria with an international distribution platform spanning Latin America, the United States, Europe and Africa.

Both parties have agreed

not to disclose financial details at this time. DSM expects to

report a small book profit as a result of the transaction upon

closing. Approximately 90 employees will transfer to the new

owner upon closing.

Sarlink(R) has compounding operations in Leominster

(Massachusetts, United States) and Genk (Belgium). While the

business unit will operate as an integral part of Teknor Apex, it

will continue to sell its TPVs (thermoplastic vulcanizate) under

the Sarlink(R) name. In 2009 Sarlink realized net sales of over

EUR 50 million.

Nico Gerardu, Member of the DSM Managing Board and responsible

for the Base Chemicals and Materials cluster, commented: “The sale of Sarlink is another

important step for DSM in its ongoing transformation towards a

Life Sciences and Materials Sciences company. As there is a

natural fit with Teknor Apex, we see a bright future ahead for

Sarlink under new ownership. I would like to thank all Sarlink

employees for their ongoing support and substantial contribution

to DSM.”

Bertram M. Lederer,

executive vice president of Teknor Apex said: “Teknor Apex is a good home for the

Sarlink group, and the enhanced potential from our combined

people and resources will benefit customers. The addition of the

Sarlink TPV business strengthens the position of Teknor Apex as

the world’s most diversified independent

compounder of TPEs and expands our portfolio at the

high-performance end, particularly for automotive applications.”

Sarlink is one of

the two business units of the business group DSM Elastomers. The

selling process for Keltan (EPDM), the other business unit of DSM

Elastomers, as well as most of the remaining other businesses in

Base Chemicals and Materials is ongoing.

| 2009 | 2008 | ||||||

| Sales | EBIT | Net Profit |

Sales | EBIT | Net Profit |

||

| Core business | Nutrition | 2,824 | 521 | 2,710 | 447 | ||

| Pharma | 721 | 32 | 863 | 89 | |||

| Performance Materials |

1,823 | 68 | 2,297 | 175 | |||

| Polymer Intermediates |

849 | 6 | 1,201 | 19 | |||

| Others | 381 | -189 | 436 | -135 | |||

| subtotal | 6,598 | 438 | 7,507 | 595 | |||

| Base Chemicals and Materials |

Agro Melamine Elastomers |

1,134 | -68 | 1,572 | 174 | ||

| Total | 7,732 | 370 | 337 | 9,079 | 769 | 577 | |

Teknor Apex Company

A privately held firm founded in 1924. Teknor Apex Company is an

international polymer technology company and one of the world’s leading custom compounders of

plastics. For U.S. markets, the company also manufactures

chemicals such as plasticizers and the nationally branded

consumer product, Apex garden hose. Teknor Apex is headquartered

in Pawtucket, RI, U.S.A., operates manufacturing facilities

around the world, and sells in 90 countries. Six of the eight

Teknor Apex business units focus on plastics compounding,

including bioplastics; color concentrates; nylon, PET, and other

engineering thermoplastics; thermoplastic elastomers; toll and

specialty compounds; and vinyl. The company’s operations in the U.S. serve

customers throughout the Americas. Subsidiaries in China,

Singapore, and the United Kingdom serve customers in Asia,

Africa, the Mideast, and Europe. Visit www.teknorapex.com.

2007/5/12 米コンパウンド会社

Teknor

Apex、中国進出

1949年に塩ビコンパウンド生産、塩ビホース生産から Lawn and Garden 事業

1959年に着色料の販売を開始

蘇州でコンパウンドの生産

シンガポールのSingapore Polymer Corporation (SPC)を買収

英国と米国でエンジニアリング樹脂コンパウンドを供給する英国のChem Polymer を買収

DSM to acquire Martek to add new Nutrition growth platform

| * | DSM to offer US$31.50 for each share of Martek Biosciences Corporation in an all-cash transaction (through a tender offer) |

| * | Total consideration of US$1,087 million (about Euro829 million) |

| * | Offer price represents 35% premium to Martek’s closing share price on December 20, 2010 |

| * | Martek Board of Directors recommends the offer |

| * | Acquisition adds new growth platform for natural, healthy Polyunsaturated Fatty Acids (PUFAs 多価不飽和脂肪酸) nutrition ingredients (Omega-3 DHA and Omega-6 ARA) |

| * | PUFAs are clinically proven to have important human health benefits. Martek is a leader in this field with strong positions, especially in Infant Formula Nutrition applications |

| * | Acquisition positions DSM as a leader in PUFAs and in Infant Nutrition, greatly strengthens DSM’s presence in the United States and expands DSM’s complementary technology platform in the field of algal and other microbial fermentations |

| * | Martek’s growth will be accelerated by DSM’s global market reach, technology base and application skill capabilities, its insights in the food, beverage and global dietary supplements markets and its strength in industrial biotechnology and related applications |

| * | Acquisition is immediately EPS(EPS accretive) accretive |

Royal DSM N.V., the global Life Sciences and Materials Sciences company, and Martek Biosciences Corporation today announce that they have entered into a definitive agreement under which DSM will acquire all the outstanding shares of common stock of Martek for US$31.50 in cash per share for total consideration of US$1,087 million. The transaction has been approved by DSM’s Supervisory Board and is recommended by Martek’s Board of Directors. Subject to customary conditions, the tender process is expected to close in February 2011, and the transaction is expected to close in the first or second quarter of 2011.

The agreed price

represents a premium of 35% to Martek’s closing share price of US$23.36

on December 20, 2010, and 39% to the volume weighted average

closing price of Martek’s common stock over the last 90

days.

The Transaction

The acquisition is structured as an all-cash tender offer for all

the outstanding shares of Martek common stock to be followed by a

merger in which each remaining share of Martek common stock would

be converted into the same cash per share price paid in the

tender offer. The tender offer is expected to commence between 10

January 2011 and 25 January 2011. The Martek Board of Directors

has recommended that Martek stockholders accept the offer and

tender their shares into the offer when it is made. The

acquisition is subject to the satisfaction of customary

conditions, including the tender of a majority of the outstanding

shares of Martek common stock on a fully-diluted basis and the

expiration or earlier termination of the Hart-Scott-Rodino

antitrust waiting period and other regulatory approvals. The

tender process is expected to close in February 2011, and the

transaction is expected to close in the first or second quarter

of 2011.

The transaction is not subject to a financing condition, and DSM

intends to finance the acquisition from existing cash.

Strategic rationale

The purchase by DSM of Martek, a U.S. based producer of high

value products from microbial sources that promote health and

wellness through nutrition, will be the first major acquisition

by DSM after its successful transformation into a Life Sciences

and Materials Sciences company. This transaction is fully in line

with DSM’s strategy for its Nutrition

cluster “continued value growth”

and adds a new

growth platform for healthy and natural food ingredients for

infant formula and other food and beverage applications,

especially focused on Polyunsaturated Fatty Acids (PUFAs) such as

microbial Omega-3 DHA (docosahexaenoic acid) and Omega-6 ARA

(arachidonic acid).

There is significant, broad based scientific evidence about the

link between health and nutrition. PUFAs have been clinically

proven to have a positive impact on human health and Martek is a

leader in this field. Martek therefore represents an attractive

strategic acquisition for DSM. It will provide DSM with new

opportunities in the infant nutrition segment as well as food and

beverage and dietary supplements and create a strong platform for

DSM to enter the fast growing Omega-3 and Omega-6 market through

Martek’s microbial DHA and ARA products.

DSM will be able to leverage DSM’s global nutritional

infrastructure (global market reach, application skills, R&D

and manufacturing technology base) to channel and accelerate the

growth of these products into other regions, applications and

market segments beyond Martek’s current strong US-based position

in infant formula ingredients and growing position in food and

beverage and dietary supplement applications. As a result of the

scale and resources that DSM can bring to the already solid

businesses of Martek, DSM instantly becomes a leading player in

the field of microbial PUFAs and through this attractive growth

segment expects to drive compelling financial performance for its

shareholders. The acquisition is immediately EPS accretive for

DSM by 15 to 20 euro cents per ordinary share on a full year

basis.

The two companies already have a longstanding relationship as DSM

supplies Martek with the key base material for its ARA product.

DSM has complementary intellectual property to the broad range of

patents and intellectual property Martek owns, which will further

extend the competitiveness of the combined company’s proprietary products.

DSM will also benefit from Martek’s recent acquisition of Amerifit,

an attractive consumer business for branded dietary supplements

with very specific health benefits, which it will be able to use

as an additional marketing channel for both Martek as well as DSM

ingredients.

Furthermore, Martek’s algal and other microbial-based

biotechnology platform and its robust algal technology pipeline

which complements DSM’s own biotechnology portfolio, is

expected to deliver new nutritional and non-nutritional

(industrial) growth opportunities.

The acquisition is expected to realize material revenue synergies

through expanded distribution, marketing and product development

as well as other operational efficiencies, and will accelerate

DSM’s revenue growth.

Martek is headquartered in Columbia Maryland USA and had annual

net sales of US$ 450 million for its fiscal year which ended

October 31, 2010. Martek has five principal locations and some

600 employees.

Feike Sijbesma, CEO/ Chairman of the DSM Managing Board, said:

“Martek

is a great company and a leader in the innovation, development,

production and sale of high-value products from microbial sources

that promote health and wellness through nutrition. DSM has

enormous respect for Martek’s products, organization and

people. We look forward to working with their highly skilled

team.

“This

acquisition is an attractive and logical next step for DSM.

Martek’s leading position in healthy,

natural ingredients and algal technology will add a new growth

platform to our Nutrition business. DSM is a unique partner for

Martek and, with our strong track record of growing businesses in

competitive environments, we believe we can help to lift Martek

to the next level.”

Martek’s Chairman, Robert J. Flanagan,

said:

"We are proud of the achievements of our company and are

pleased to see the company's value recognized by DSM. Following

thorough analysis by our board of directors, we have determined

that this transaction offers the best value for our stockholders.”

Martek’s CEO, Steve Dubin, said:

“We

are pleased to announce this transaction, and we believe that it

is in the best interest of Martek and our stockholders. After

careful analysis, our board of directors unanimously approved

this transaction with DSM, which has a strong reputation and

global operations. We are pleased that this transaction

appropriately recognizes the value of Martek’s nutritional ingredients,

technology platform, market position and skilled workforce, while

providing significant value to our stockholders. We have worked

collaboratively with DSM for many years, and we are confident

that they share our vision for Martek’s future.”

Martek

Martek is a leader in the innovation, development, production and

sale of high-value products from microbial sources that promote

health and wellness through nutrition. The Company’s technology platform consists of

its core expertise, broad experience and proprietary technology

in areas such as microbial biology, algal genomics, fermentation

and downstream processing. This technology platform has resulted

in Martek’s development of a number of

products, including the company’s flagship product, life’sDHA?, a sustainable and

vegetarian source of algal DHA (docosahexaenoic acid) important

for brain, heart and eye health throughout life for use in infant

formula, pregnancy and nursing products, foods and beverages,

dietary supplements and animal feeds. The Company also produces

life’sARA (arachidonic acid), an

omega-6 fatty acid, for use in infant formula and growing-up

milks. Martek’s subsidiary, Amerifit Brands,

develops, markets and distributes branded consumer health and

wellness products and holds leading brand positions in all of its

key product categories. Amerifit products are sold in most major

mass, club, drug, grocery and specialty stores and include:

CulturelleR, a leading probiotic supplement; AZO, the leading OTC

brand addressing symptom relief and detection of urinary tract

infections; and EstrovenR, the leading all-natural nutritional

supplement brand addressing the symptoms of menopause.

Columbia, Md.-based Martek produces polyunsaturated fatty acids - a family of nutritional supplements - via algal fermentation. Its flagship product, docosahexaenoic acid, is added to almost all major brands of infant formula, as well as to foods, beverages, and dietary supplements. Martek’s fiscal 2010 sales were $450 million, up 30% over the previous year.

In addition to fast growth, Martek brings an algal technology platform that complements DSM’s own expertise in yeast fermentation, enzymes, and advanced chemistry. In fact, Martek’s number two product, the fatty acid arachidonic acid, is manufactured under contract by DSM via fungal fermentation.

Formation of an Asian anti-infectives joint venture, meanwhile, is a long-held goal of the Dutch company, which is one of just a few remaining Western producers of penicillin. DSM had held sporadic talks with North China Pharmaceutical Group about such a venture since 2004 but finally abandoned them in 2009.

Under the new deal, Sinochem becomes half owner of a business with $425 million in annual sales and about 2,000 employees. In a presentation to investors, DSM executives said they believe Sinochem’s position as one of China’s biggest state-owned enterprises will help expand the business to more than $750 million in sales by 2015.

“Anti-infectives has been a problem child for years,” observed Andreas Heine, a stock analyst with UniCredit, in a note to investors. “The agreed move with Sinochem seems to be a very good solution.”

DSM and KuibyshevAzot

announce strategic cooperation in Russia

Royal DSM N.V., the global Life Sciences and Materials Sciences

company headquartered in the Netherlands, and KuibyshevAzot OJSC (KA) today announce a strategic

cooperation. As a result of this strategic cooperation, DSM

Engineering Plastics will enter into two joint ventures

with KA. In

both joint ventures DSM Engineering Plastics will hold a majority

share. In addition, KA will be granted a license under DSM Fibre

Intermediates’ technology for the production of

cyclohexanone.

The two joint ventures of DSM Engineering Plastics and KA relate

to marketing

and sales of engineering plastics in Russia and other members of

the Commonwealth of Independent States (CIS) and secondly for the production of

engineering plastics compounds in a plant located in Togliatti

(Russia). The strategic cooperation between DSM and KA will also

result in a license grant under DSM’s proprietary cyclohexanone

technology to

be applied at KA’s Togliatti caprolactam plant,

resulting into a further increase of its capacity to meet the

growing demand for this polyamide 6 intermediate.

Nico Gerardu, Member of the DSM Managing Board and responsible

for the Performance Materials cluster, commented: “This strategic cooperation with KA

is another example of DSM’s commitment to expansion in High

Growth Economies through Acquisitions & Partnerships, two of

the four growth drivers of our corporate strategy DSM in motion:

driving focused growth. We are excited to be able to partner with

KA, one of Russia’s leading companies in the

intermediates industry. Russia is an increasingly important

market for engineering plastics and it is expected that the

market for PA6 will double in the next five years. With our

partnership with KA I expect that DSM Engineering Plastics will

be in an excellent position to capitalize on this anticipated

growth. Furthermore, I see the license agreement for

cyclohexanone as further recognition of our technology

leadership.”

Victor Gerasimenko,

General Director of KuibyshevAzot OJSC, said: “Cooperation with DSM will promote

the realization of our strategic plans to strengthen our leading

positions in the markets for caprolactam and polyamide and to

increase the processing of these products within Russia. The use

of technology from leading global licensors will allow us to

increase operational performance and long-term competitiveness.”

DSM Engineering

Plastics and KA are joining forces in a marketing and sales joint

venture to better capture opportunities in the growing market for

engineering plastics in Russia and other countries in the region.

The joint venture will concentrate on polyamide 6 (PA6), both compounds and high viscosity

applications including film. DSM Engineering

Plastics will hold a 51% stake in the joint venture.

DSM Engineering Plastics also intends to acquire 80% in the

engineering plastics compounding plant located on KA’s manufacturing site in Togliatti.

As such, DSM will be the first western PA6 supplier with its own

manufacturing presence in Russia and the CIS. Financial details

and capacity of the plant will not be disclosed.

As a result of the license agreement between DSM and KA, DSM will

realize royalty income over 15 years. DSM Fibre Intermediates

will also participate via drawing rights in part of the increased

production capacity of KA.

DSM has proprietary world-class cyclohexanone and caprolactam

technologies with multiple licensees worldwide.

The establishment of the joint ventures and related agreements is

subject to regulatory approval. Closing of the intended

acquisition of the compounding plant is expected in Q1 2011.

KuibyshevAzot OJSC

KuibyshevAzot OJSC is one of the leading companies of the Russian

chemical industry. The company located in Togliatti, Samara

region, conducts its business in two areas: production of

caprolactam and its derived products (PA-6, high tenacity yarns,

cord fabric, engineering plastics) ;production of ammonia and

nitrogen fertilizers.

KuibyshevAzot takes a leading position in output of caprolactam

and polyamide in Russia and CIS and is among the top ten major

global producers of these products. The company consistently

builds up the proportion of higher added value product, by

realization from 2003 projects for further caprolactam

processing. In 2009 the company realized net sales of RUB 16,039

million ($ 505.2 million with 5,300 employees. The official web

site www.kuazot.ru.

化学工業日報

DSMはロシアでポリアミド(PA)6事業の本格展開に乗り出す。このためク イビシェフアゾドOJSC(KA)社と提携、販売とコンパウンドの生産に関する2社の合弁会社を設立する。同時にDSMがシクロヘキサノンの生産技術を KAに供与、KAはカプロラクタム事業の強化につなげる。両社の計画では、DSMが51%を出資するPA6のコンパウンドとフィルムのマーケティングと販 売を手掛ける合弁会社を設立する。またコンパウンドの生産については、KAがサマラ州トリアッティに持つ設備を合弁で運用する。DSMが80%を出資する 予定。生産能力は明らかにしていない。KAはカプロラクタム、PA6、肥料などの事業を展開している。DSMと手を組むことによってコンパウンドの販売体 制を強化する一方、DSMからシクロヘキサノンの生産技術を導入することで、カプロラクタムとPA6の競争力を高める。

“KuibyshevAzot” OJSC is one of the leading companies of the Russian chemical industry.

The company conducts its

business in two areas:

- production of caprolactam and its derived products (PA-6, high

tenacity yarns, cord fabric, engineering plastics);

- production of ammonia and nitrogen fertilizers.

Besides, “KuibyshevAzot” produces process gases which meet requirements of the main business-directions and at the same time are independent commodity products.

A full

range of products

accounts about 30 iterns.

The key figures

| 2000 | 2009 | Grow | |

| Sales, RUR million | 4473 | 16039 | 259% |

| Caprolactam, '000 tons | 105 | 175,3 | 67% Russiaでのシェア 50% |

| Polyamide, '000 tons | 0 | 86.6 | New product |

| Technical yarn, '000 tons | 0 | 6,3 | New product |

| Tire cord fabric, '000 tons | 0 | 5,1 | New product |

| Ammonium nitrate, '000 tons | 299.8 | 500,5 | 60% |

| Urea, '000 tons | 193.0 | 312.6 | 63% |

| Ammonium sulphate, '000 tons | 307.9 | 448,4 | 46 % |

| Ammonia, '000 tons | 530.6 | 556,9 | 5 % |

| Freight turn-over, '000 tons | 1353 | 2055,4 | 51.9% |

DSM acquires majority share in UHMWPE fiber manufacturer in China