トップページ

Asia Chemical Weekly

2003-12-12

China's Liaoning (遼寧) gets nod for C2

expansion, PVC project

Liaoning

United Chemical has received preliminary approval from the

Chinese government for its integrated cracker expansion and

polyvinyl chloride (PVC) project in Liaoning, China,

according to a Panjin government official.

The Chinese company has proposed expanding the cracker of one

of its shareholders, Panjin Ethylene Industry Corp (盤錦 Peic), to 400 000 tonne/year

from 160 000 tonne/year. The company will also double its polyethylene (PE)

capacity to 250 000 tonne/year, and build a 120 000

tonne/year polypropylene (PP) facility and a new 400 000

tonne/year PVC unit.

The integrated cracker-PVC project is one of 100 projects in northeast China

approved by the government recently in a move intended to

revitalise ageing industries in the area.

Liaoning

hopes to invite Sabic as a joint-venture partner. Sabic has confirmed

its interest in the project and plans to complete its due

diligence on the project by mid-2004.

The planned PVC unit in Huludao would be integrated with a 450 000 tonne/year

vinyl chloride monomer (VCM) plant. An ethylene dichloride

(EDC) unit will also be built and will obtain

ethylene feedstock from the expanded cracker in Panjin.

China

Chemical Reporter 2003 <ISSUE>: 34

400 000 T/A PVC Project in Liaoning Approved

The National Development and Reform Commission has recently

issued a circular concerning the first group of national-bond

renovation projects for 2003 in the Northeast China old

industrial base. 100 industrial fixed-asset

investment projects in the three provinces of Northeast China

are approved. 52 of them are in Liaoning Province and they

have an investment of RMB44.21 billion, accounting for 72.5%

of the total. They are the first group of projects to get the

biggest amount of national bonds in the province. It shows

that the Chinese government has started to implement the

policy of enforcing the readjustment and renovation to the

old industrial base with national bonds or special funds.

The 100 projects have been defined to be the first group of

national-bond renovation projects for 2003 in Northeast China

old industrial base. The total investment is around RMB61.0

billion. 52 projects are in Liaoning and 11 of them are

petroleum and chemical projects. These projects feature good

market prospect, great development advantage, high technical

content and satisfactory economic performance. The crude oil

processing project in CNPC Dalian Petrochemical Company has a

total investment of RMB9.2 billion. The 400 000 t/a ethylene

expansion project and the 400 000 t/a PVC construction

project in Liaoning United Petrochemical Co., Ltd. have a

total investment of RMB9.9 billion. These major projects will

become a pillar for the vigorous development of Liaoning

petroleum and chemical industry base.

Asia Chemical Weekly 2003/12/18

China's Shaanxi to triple methanol output to 600 kt/yr 陝西省楡林

Shaanxi Yulin

Natural Gas Chemical Co plans to increase its methanol

capacity to 600 000 tonne/year from 200 000 tonne/year, a

company source said.

Shaanxi Yulin plans to build a 200 000 tonne/year gas-based

methanol line which would come onstream at the end of 2004.

Another 200 000 tonne/year methanol line, using coal as

feedstock, will be built later, with startup targeted for

2006.

* This is invested by Shaanxi

Yulin Natural Gas Chemical Co. ( based on Shaanxi

Province). It will use

the Natural Gas to produce Methanol.

Personally, I think the

Methanol is over-invested now in China.

China Chemical

Reporter 2005/4/21

600 000 T/A Methanol Project Kicked off 陝西省楡林

On 13 April,

a ceremony of breaking ground was held in Shaanbei Energy

Chemical Base, 42 km far from Yulin city, Shaanxi province for

the 600 000 t/a methanol project, which is the first phase of 2.3

million t/a methanol production line, and the largest methanol

unit using coal gas as raw material in this base. It is invested

by Shandong Yanzhou山東エン州 Coal Mining Company Ltd.,

with the total investment of RMB2.5 billion.

It is reported that the project will be completed and put on

stream in 2007. The sales revenue and profit are expected to

reach separately RMB960 million and RMB240 million per year at

that time.

*This is invested by Shandong

Yanzhou Coal Mining Company Ltd. ( based on Shandong

Province). It will use the Coal

Gas to produce Methanol.

China

Chemical Reporter 2004/8/26

China's First MTO Project Launched

http://www.ccr.com.cn/news_view.asp?ID=501

On August 8,

a MTO (methanol to olefin) industrialization

experimental unit which consumes 10 000 t/a methanol starts

construction in Shaanxi Yulin Energy & Chemical Base,

indicating the launch of the first and the only MTO project

in China. 陝西楡林

Asia Chemical Weekly 2003-12-18

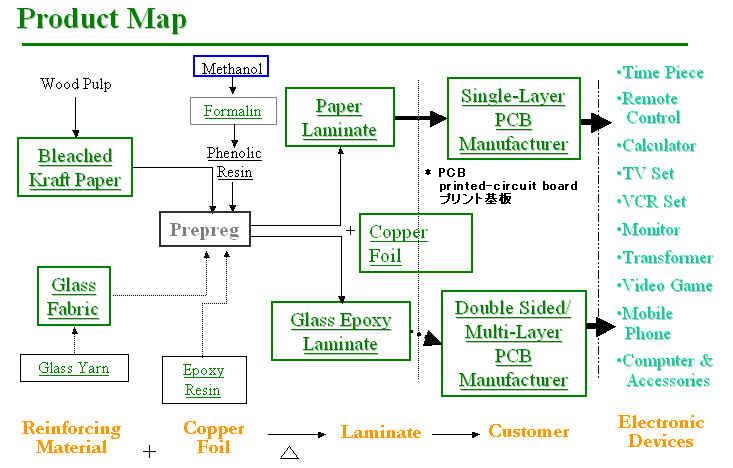

Hongkong's Kingboard to bring China phenol-acetone onstream in

'05-'06 江蘇省常州

Kingboard

Chemical Holdings is to bring its 200 000 tonne/year

phenol-acetone project in Changzhou, Jiangsu, China, onstream

at the end of 2005 or in early 2006, a company source said.

In Changzhou, Kingboard is also due to start up a 200 000

tonne/year formaldehyde plant later this month and a 60 000

tonne/year hydrogen peroxide plant in H1 2004.

Kingbaord

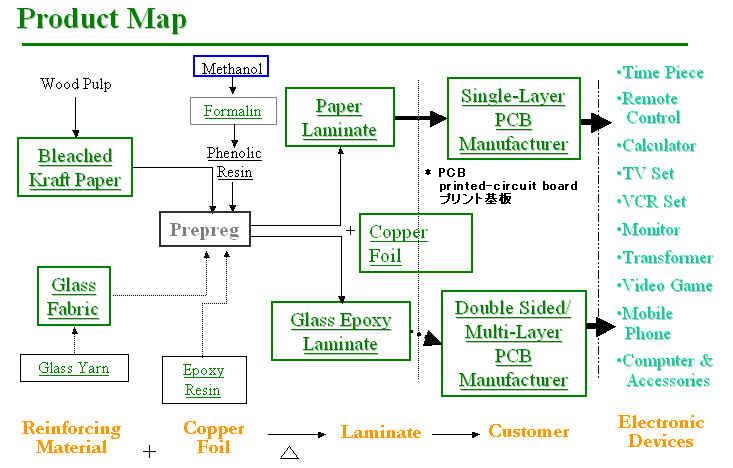

Chemical Holdings Limited 建滔化工集団 CNOOC-Kingboard Chemical Ltd.

http://www.kingboard.com/indexe.php

Established in

1988, Kingbaord Chemical Holdings Limited is principally

engaged in the manufacturing of Laminate and its related raw

materials. Since listed in 1993, Kingboard has formulated its

blueprint for vertical integration.

The group has set up over 30 factories, 9 of which are laminate facilities located in Shanghai,

Shenzhen, Shixing and Jiangmen, Qingyuan(Fogang) with monthly

production volume up to 4 million sheets. Major upstream

material such as copper foil, bleached kraft paper,

fabric glass and glass yarn are manufactured in Qingyuan,

Shenzhen, and Panyu(Nansha). In addition to the raw material

for producing laminate, the group also established a chemical complex in Panyu, Nansha Economic &

Technology Development Zone to produce a vast variety of

chemical material.

* PCB printed-circuit board プリント基板

SinoCast Dec 18, 2003

MPC to Upgrade

Ethylene Annual Output to 800,000 Tons 広東省茂名 → 1,000千トン

Guangdong

Maoming Petrochemical Co., Ltd. (MPC) will upgrade its

ethylene annual output from 380,000 tons to 800,000 tons.

The company will invest CNY 4.354 billion (USD 1 = CNY

8.2772) in this project that will be formally operated in

2006.

2004-1-22 Asia

Chemical Weekly

China's Fuling

Group planning 300 kt/yr PP in Zhejiang

The Zhejiang

Shaoxing Fuling Group plans to build two 300 000 tonne/year polypropylene (PP)

units,

company sources said sister publication Asian Chemical News. The

plants are to be built in Zhejiang, China. 浙江

The project,

which has been approved by the Chinese government, will be built

in the Shaoxing Paojiang Industrial Zone in two phases. The first

unit will be brought onstream in 2005 and the second in 2007.

Shaoxing Fuling is pursuing the Rmb2bn ($241.6m/Euro191.9)

project alone. It recently formed a subsidiary, Shaoxing Sanyuan

Petrochemical Co, to operate the project.

However, one of the company sources said that Shaoxing Fuling was

open to bringing in a joint-venture partner. Shaoxing Fuling

plans to use

Basell's Spheripol technology with propylene feedstock imported

from the Middle East and other countries.

Talks with lenders are still taking place.

Industry observers wonder whether there will be sufficient

propylene available in Asia to support the two PP plants. A

number of cracker projects were being planned and built in the

Middle East, but these gas-based crackers were not likely to

yield much propylene for export, they said.

Shaoxing Fuling sources said talks were being held with overseas

propylene suppliers and they were confident that feedstock

availability would not be a problem.

They added that the main reason for building the PP units was to

produce feedstock for the company's biaxially oriented PP

(BOPP) plants,

which are relying on imported PP feedstock. Surplus PP from the

new units would be sold locally.

A Shaoxing Fuling subsidiary, Zhejiang Shaoxing Fuling Plastic

and Textile Co, owns two BOPP lines in the same industrial zone

with a total capacity of 49 000 tonne/year. It plans to add two

BOPP lines, each of 35 000 tonne/year capacity. It aims to bring

both lines onstream at end-2005. Approval has been sought from

the government for this project.

The new BOPP lines are likely to employ technology from Bruckner,

which is the licensor for the existing BOPP units. Fuling Plastic

and Textile also produces 7000 tonne/year of clarified PP. Its

capacity is to be doubled in H2 2005.

2006/11/3 Asia

Chemical Weekly

Shaoxing Sanyuan

starts up 300kt PP project

Shaoxing Sanyuan (三圓) Petrochemical, a subsidiary

of Zhejiang Shaoxing Fuling (富陵) Group, has started up its

new 300 000 tonne/year PP project at Paojiang (袍江) Industry Park , Shaoxing

city, Zhejiang Province.

With total investment of the unit around USD 125 million (RMB

2 billion), the PP project use Spheripol technology of

Basell. It has started construction since Q1 2004.

Propylene feedstock will sourced from Asia Pacific or

Mid-East market; while the PP products, will partly captive

use for Fuling’s Biaxally Oriented PP (BOPP)

and Cast PP (CPP) line, and the remaining will sell to east

China market.

Fuling Group, Sanyuan's parent company, is a Shaoxing based

privated plastics film producer. It produces BOPP, CPP, POF,

etc, with total plastics film capacity of 80 000 tonne/year.

Sanyuan had also planned to build a second 300 000

tonnes/year PP project, to make total PP capacity to 600 000

tonne/year. However, this second phase plan maybe shelved, it

depend on the financing and the market condition,

particularly the supply and price of propylene.

Zhejiang Shaoxing

Fuling Plastic and Textile Co. has changed name to it is

still a subsidiary of Fuling Group, and the proposed new

7000 tonne/year of CPP project was shelved.

The company has built two new BOPP lines with total

capaty of 70 000 tonne/year (35 000 tonne/year each)

using Bruckner's technology. While the old two BOPP lines

should be stopped, which have total capacity of 49 000

tonne/year.

Currently, the company has 4 plastics film lines, 2 BOPP,

1 CPP and 1 POF, with total capacity of around 80 000

tonne/year.

(POF:Multi-layers

Co-extruded Polyolefin Film)

日本経済新聞 2004/1/24

中国の家電リサイクル 浙江省などで開始

中国はメーカーに使用済み電気製品の回収費用を負担させる、家電リサイクルの取り組みを始める。家電メーカーが集積する山東省青島市と浙江省をモデルに近く実施する。回収が順調なら、段階的に全国へ広げる方針だ。

2004/2/3 China

Chemical Reporter

Urumqi

Petrochemical Constructs Chemical Industry Base (新彊省ウルムチ)

http://www.sinocheminfo.com/asp/news/content.asp?id=11607

The petroleum and

petrochemical industry in Xinjiang is at the stage of rapid

development. Urumqi Petrochemical Co., Ltd. will fully use the

advantages in abundant resources such as coal, electricity, crude

oil and natural gas in Xinjiang to accelerate the development of

the chemical fertilizer sector with natural gas as feedstock. It

will also actively introduce capital and technology from outside

to extend the production chain of petrochemical downstream

products.

Urumqi

Petrochemical Co., Ltd. will make an investment of RMB5.1 billion

from 2004 to 2006 to expand the chemical fertilizer production

scale, construct a large-scale aromatic production base, use

olefin resources to launch chemical units and also construct a

world-class chemical industry base.

The sales

revenue accomplished by the company in 2003 was RMB8.0 billion

and the tax was expected to be RMB860 million, an increase of

21%. The operation tasks for 2003 were fulfilled.

February 6, 2004 Dow Jones

News Service

Sinopec Mulls Building Ethylene

Project In Wuhan, China 湖北省武漢

China Petroleum &

Chemical Corp. (SNP) is considering the construction of an 800,000

metric-ton-a-year ethylene cracker in Wuhan, Hubei province, as part of

its strategy to expand its petrochemical sector, a company

official said Thursday.

The company, better known as Sinopec, and local Wuhan

authorities have reached an initial agreement to begin a

feasibility study for the project, which is estimated to cost

30 billion yuan ($1=CNY8.28), he told Dow Jones Newswires.

2004-2-6 Asia Chemical

Weekly

Cabot finalises China silica jv, plans $30m plant for '05

US specialty chemicals producer Cabot formally announced the

creation Monday of a new Chinese silicas joint venture and plans

for a $30m (Euro23.8m) investment in a new plant to produce fumed

silica(乾式シリカ).

Boston, Massachusetts-based Cabot will own 90% of the new company

called Cabot Bluestar Chemical. Cabot's partner is Bluestar New

Chemical Materials, a part of China National Bluestar Group.

Cabot said the new plant will become China's first world class,

fumed silica manufacturing facility. Located near Nanchang in

Jiangxi Province, the plant should be operational by late 2005.

It will be Cabot's sixth fumed silica facility, complementing

other sites in the US and Europe.

| Jiangxi Xinghuo

Organic Silicone Plant |

organic silicone

monomers:200,000

t/a (to 300,000 t/a in 2010)

caustic soda :80,000

t/a

fumed silica:

5,000 t/a 〈JV

with Cabot(US)〉 |

2008/5/16 Cabot

Cabot Announces Joint

Venture With China National Bluestar Group To Build A Second

Fumed Silica Manufacturing Facility in China

Cabot Corporation

announced today that its subsidiary, Cabot (China) Ltd., has

signed a joint venture agreement with the China National

Bluestar Group

to build a facility for the manufacture of fumed silica in China.

The agreement was signed in Beijing on May 16, 2008 and

represents an expansion of the relationship between the two

companies, which began with the construction of China's first state of the art

fumed silica manufacturing facility in Jiangxi province in 2004.

To expand the

relationship, Cabot Bluestar Chemical (Tianjin) Co., Ltd, the new

joint venture company, will invest approximately US $40 million

to build Cabot's next world class fumed silica facility, with a

manufacturing capacity of approximately 7000 metric tons per year. The plant will be

located in Tianjin, China and will be commissioned in early 2010.

Chemical Week, Dec

18, 2002

China approves PTA project planned by local firm

China's State Council says it has approved a proposal by Sanxin Chemical (Shaoxing) to build a

500,000-m.t./year purified terephrhalic acid (PTA) plant at the

Shaoxing Binhai Industrial Zone, Zhejiang. Sanxin is a joint

venture of Guangzhou Group Co., Zhejiang Zhanwang Industrial

Group, and Zhejiang Jiaboli Textile Industrial. The plant will

cost Rmb2.46 billion ($282.8 million) and will be completed by

2004. It will use an undisclosed foreign technology. China

consumed about 53 million m.t. of PTA last year, more than 3

million m.t. of which was imported.

2005/12/22 Platts

China's Union

Holdings to double Sanxin PTA capacity in 2006

China Union Holdings plans to double the PTA capacity of its

subsidiary, Sanxin Petrochemical in Shaoxing紹興, from 600,000

mt/yr to 1.2-mil mt/yr by August 2006, an official at

the company said Thursday. The expansion project has received

official approval from the National Development and Reform

Commission, the source added.

Sanxin secures PTA feedstock paraxylene from both the

domestic and international markets. The company sells its PTA

output in Jiangsu, Zhejiang and Shanghai in eastern China.

China Union Holdings is listed on the Shenzhen stock

exchange.

China Union

Holdings Limited Formerly known as Union Holdings China

Company Limited. The Group's principal activities are the

manufacture and sale of branded garments, clothing

materials, cotton yarn, chemical fibres, and textile

machineries. It also sells and leases out real estate and

sells computer software.

Chemical Week, March 5,

2003

China Textile finn selects Lurgi,

Eastman technologies for PTA complex.

Textile maker Union

Developing Group of China (UDC; Shenzhen) has selected Lurgi to

build a previously announced purified terephthalic acid (PTA)

complex at Shaoxing, China, CW has learned. Eastman Chemical

is providing its EPTA technology for the PTA unit. Lurgi and

Eastman declined to comment, but sources say that signing of

the relevant contract is imminent. UDC has received

government approval to build the 500,000-m.t./year PTA unit

and a nearby 330,000mt/year polyester polymer plant, which

are due for completion in two years.

The Union Developing Group of

China

http://www.udcgroup.com/en/profile.asp

The Union Developing Group of

China Ltd. (hereinafter referred as "UDC"), based

on textile industry, has been a state-level large-scale

enterprise group directly under the Central Government and

has engaged in a diversified economy including Science &

Technology, Industry, Commerce, Trade, Finance, Real Estate

and so on. It ranks the 280th among the 1000 national largest

enterprise-Groups in China in the year of 2000. Among the

"Top 500 of World Textile Industry", it also ranks

the front and is appraised as No.1 Chinese selected

enterprise of the "Top 500 World Textile Industry".

Petro-chemical and developed new

material industry is becoming an important industry invested

and constructed by the Group in recent years. As the result,

UDC has invested and built in Zhejiang Province with two

extra large sizes of PTA and PET petro-chemical new material

projects. The total investment for this PTA project is around

2.4 billion yuan of RMB with annual production of 600,000

tons. This PTA project is currently of the grandest scale for

single line production and fastest for construction in the

world. In addition, a PET project, with 1 billion yuan of RMB

investment and with annual production of 330,000 tons, is

down stream complete set of product of PTA. The PET project

also holds the leading position in the projects of the same

kind in terms of its scale and its technology. The Group is

planning to form up, within the country, the largest, with

the most advanced technology petro-chemical industrial base

which also holds among the best of its occupied market share.

2004/3/16 China Chemical Reporter

4 Large Ethylene Plants to Be Constructed

SINOPEC has recently announced that it will make an investment of

US$10.0 billion in the construction of 4 new 1.0 million t/a

naphtha-cracking ethylene plants. These projects will be

completed during the period from 2007 to 2010. They will be

constructed respectively by Shanghai Petrochemical Co., Ltd. in

Shanghai Caojing, Tianjin Petrochemical Co., Ltd. in Tianjin,

Wuhan Petrochemical Co., Ltd. in Wuhan and Zhenhai Refining &

Chemical Co., Ltd.中国石化鎮海煉油化工 in Ningbo浙江省寧波市. These projects can be constructed either

in collaboration with joint venture partners or independently by

SINOPEC itself. Besides ethylene units, a series of downstream

production units will also be constructed in each ethylene plant.

It was originally planned to

construct the olefin project in Tianjin with Dow Chemical, but no progress has been made due to

various factors. It is reported that because of the rapid demand

increase of olefin products in China Dow Chemical will reconsider

its participation in the construction of the olefin project. The

sales revenue gained by Dow Chemical in China is US$1.5 - 1.8

billion and around one-third of the total is generated from

products made in China. Dow Chemical plans to double its sales

revenue in China within 3 years and also invest US$130 - 150

million in the construction of a comprehensive trichloromethane

plant in Zhangjiagang, Jiangsu.

2004/2/25 Sinopec

Sinopec and BP Will Invest Jointly In Striking Up a World-Class

Acetic Acid Project in Nanjing

http://www.sinopec.com.cn/english/en-newsevent/en-news/2744.html

China Petroleum & Chemical

Corporation (Sinopec) announced today that it has chosen BP as

its business partner, after comparing BP with another foreign

company, to work with for joint construction of an acetic acid

project on a world-class scale in Nanjing.

The project will be 500,000 ton acetic acid, jointly developed

with BP based on Yangtze Petrochemical’s existing facilities. Equity share of the

parties will be 50:50. This project will make full use of the

existing facilities of Yangtze Petrochemical Ltd., and is

expected to help meet acetic acid demands in domestic market,

adjust the structure of acetic acid industry in China, and

reinforce the competitiveness of Sinopec in the market as well.

In fact, Sinopec has already cooperated with BP successfully in

an acetic acid project in Chongqing(重慶).

This new project will further strengthen the two parties’

leadership in the acetic acid market

at home, and also facilitate the positive evolution of long-term

cooperative relationship between both parties”.

CHUANWEI ACETIC ACID

PLANT, CHINA

http://www.chemicals-technology.com/projects/chuanwei/

The project is an acetic acid plant in Chuanwei in Chongqing

province, southern China, located alongside Sinopec's Sichuan

Vinylon Works (SVW). In the first half of 2000, BP Amoco

announced that it was ambitious to extend the Chuanwei plant.

This would entail the expenditure of between $50 and $100

million, increasing the capacity by 150,000t/yr to

350,000t/yr. As part of the expansion, the company would also

build an 80,000t/yr acetyl acid resin unit at the complex in

Chongqing. This new project is expected to take approximately

two years to complete.

The Chuanwei plant is the result of a joint venture between

BP Amoco and Sinopec, called Yangtze River Acetyls Company.

BP Amoco holds a 51% share of the company, with the 44% being

held by Sinopec. Chongqing Investment and Construction

Company holds the remaining 5%.

2004-2-6 Worldeps

Runhua Chem. Will enlarge its EPS

Plant 江蘇省江陰

www.worldeps.com/CONTENT/highlightdetail.asp?hlid=2605

It is said that Jiangyin Runhua

Chem. has just make up an ambitious plan to build a new EPS resin

plant with a annual production capacity of 190 thousand tons,

which will be the second EPS plant for Runhua. When it is put

into production, the total annual capacity of the company will

reach 0.355 million tons.

Chemnet Tokyo 2004/5/20 中国、「産業構造調整指導リスト」を公表

中国政府、小規模石化計画を制限へ

中国の国家発展改革委員会(National

Development and Reform Commission :NDRC)、中国人民銀行、中国銀行監督管理委員会は4月30日、共同で通牒746号を出し、経済の過熱化を押さえ貸付リスクを管理するため産業政策と貸付政策の調和を強化する方針を明らかにした。

石油化学や繊維、鉄鋼、アルミ、建材、機械、医薬等の各業界が対象となるが、一定能力以下のプロジェクトや環境に悪影響を与えると見られる技術を使用するプロジェクトは審査の対象となり、計画中止に追い込まれる可能性も出ることになる。

この方針を実行するため、NDRCは金融組織を含む各レベルの関係組織に対し、既存の生産設備と新規プロジェクトを審査する組織をつくるよう指示した。

対象となるプロジェクトは、審査の間、建設工事が中断され、金融機関は融資を停止する。既に建設が完了した設備については、操業停止の最終期日が指定されることになる。

制限リストに載った石化製品(新設)には以下のものがある。

60万トン/年以下のエチレン

20万トン/年以下のPE

7万トン/年以下のPP

20万トン/年以下のSM

10万トン/年以下のPS

20万トン/年以下のPVC(EDC法)

8万トン/年以下のPVC(アセチレン法)

10万トン/年以下のクロルアルカリ

10万トン/年以下のアクリロニトリル

10万トン/年以下のABS

22.5万トン/年以下のPTA

20万トン/年以下のEO/MEG

20万トン/年以下の酢酸(エチレン法)

15万トン/年以下の酢酸(メタノール法)

10万トン/年以下のカプロラクタム

10万トン/年以下のPET

その他

詳細NDRCホームページ(中国語) http://www.sdpc.gov.cn/b/b200405141.htm

2004年07月15日 Chemnet

Tokyo

中国の設備投資規制、「PVCの新増設計画」に障害

中国では経済の成長に伴い、PVCの需要が年々増大している。これを受け、最近の集計では計画又は検討されている05年から08年の間の能力増は700万トンに達する。しかしながら、ここにきて、これらの新増設計画に障害が出てきた。

第1は国家発展改革委員会(NDRC)による規制で、NDRCは既報の通り、経済の過熱化を押さえるため、石油化学、繊維、鉄鋼、アルミ、建材、機械、医薬その他の産業で小規模設備の新設規制の通牒を出した。

塩ビ関連ではEDCベースPVCでは年産20万トン未満、アセチレン法PVCでは年産8万トン未満、クロルアルカリについても年産10万トン未満の設備の新設は認めないこととなった。

東ソーは、広州市南沙経済開発区で「東曹(広州)化工有限公司」のPVC年産11万トンのプロジェクト申請を行った。これは本通牒の対象(20万トン未満)となる唯一の海外からの投資だが、現地からの情報ではまだ認可が下りていない。

他の多くのメーカーは今のところ、この通牒がどのように適用されるのか様子待ちの状況だが、山東恒通化学のように、既に年産4万トンのアセチレン法PVCを稼動済みだが、この通牒が既存プラントにまで適用されるのを恐れて10万トンへの増設を急ぐ企業も出てきた。

場合によっては、以前の日本の30万トンエチレンのように、過熱化を押さえるための政策が逆に過熱化を促進する可能性もあるとの見方もある。

第2は電力不足で、特に南部及び東部で電力不足が深刻な状況だが、北京など北部にも広がってきた。経済の急速な発展で電力需要がこの10年間で2倍以上となったのに対して、供給がついていかないためで、産業界にも電力制限の影響が出てきた。6月には産業向けの電力料金が平均で約6%アップした。

塩ビの場合はプラント自体の停電停止の可能性に加え、原料のアセチレンや塩素をつくるカーバイドプラントや電解プラントが電力不足で減産を強いられ供給不足となり、また電力料金アップの影響も受けることとなる。黒龍江省のある企業は、アセチレンの調達が難しいとしてPVC新設を再検討していると報道されている。今後輸入VCMへの切り替えが増えるとVCM価格のアップのおそれがある。

電力不足は短期間に解消する見込みはなく、この問題はPVCプラントの新増設に影響を与えることとなる。中国経済の急速な発展の矛盾がいろいろなところに出てきた形で、今後の動向に注意が必要である。 (この項上海発=CNT特約)

Chemnet Tokyo 2004/5/21

中国政府、水銀法か性ソーダや毒性の強い農薬等も禁止対象

既報のとおり、中国の国家発展改革委員会、中国人民銀行、中国銀行監督管理委員会は産業政策と貸付政策の調和を強化する方針を明らかにしたが、経済の過熱化を押さえることのほか、環境に悪影響を与えると見られる技術の使用禁止も目的の一つとしている。

政府は環境汚染が深刻であるとみており、環境に悪影響を与える製品の禁止を通じて改善に乗り出したもの。通牒では禁止品目を列挙しているが、その中には水銀法か性ソーダや毒性の強い各種の農薬・殺鼠剤、シックハウスの原因となる塗料等が含まれている。

これらの動きには、わが国化学業界や商社、経産省なども強い関心を示している。

化学工業日報 2004/5/26

エチレン、中国で新たな新増設計画

大連に大型センター、蘭州などで相次ぎ増強も

大連でエチレンセンターの建設を計画しているのは大連実徳。現業はプラスチック加工でアップストリーム戦略のなかで基礎製品であるエチレンなどの生産に乗り出そうとしている。

一方、中国ではSINOPEC、ペトロチャイナグループを中心に既存プラントの能力増強が継続的に進められている。すでにこれまでの手直し増強によりエチレンの生産能力は年566万トンと2001年に比べて15%のアップが実現している。SRIなどによれば、この動きは今後も続き、すでにペトロチャイナグループの蘭州石油化学が年産24万トンから同54万トンヘの増強を計画しているほか、遼寧省の華錦化学集団も年産16万トンの設備を同36万トンに拡大しようとしている。

さらにSINOPECグループの茂名石油化学も、年産60万トンヘの増強を計画していると伝えられている。

中国・ASEANニュース速報 2004/5/26 影響 国際ルール

【台湾】石化業者、中国でのAN輸送費が倍増

http://www.e-plastics.gr.jp/japanese/nna_news/news/news0405_4/04052606.htm

中国の国家安全部門が24日、有毒化学品として6月1日から長江流域でのアクリロニトリル(AN)の運搬を全面的に禁止する新たな措置を発表したことで、長江沿岸に工場を持つ台湾のアクリロニトリル・スチレン(AS)、アクリロニトリル・ブタジェン・スチレン(АBS)メーカーは輸送コストの増大で大きな打撃を受ける見通しだ。

新措置実施以降はこれを陸運に切り替えねばならず、輸送コストは一挙に倍増する見通しだ。

2005/3 China's government

reassessing the ACN Ban in Yangtze River

2004/6/18 Platts

Chi Mei may shut China ABS

unit, China bans ACN up Yangzi River

Taiwan's Chi Mei was uncertain about the future of its

250,000 mt/yr ABS plant in Zhenjiang, China after the

Chinese government banned transportation of acrylonitrile

feedstock up the Yangzi River from Jun 1, a company source said

Friday.

Chemnet Tokyo 2004/6/4

2005/4改定

中国の化学繊維協会、「リスクを基準」に投資計画評価

中国の化学繊維協会は、世界の繊維業界が大きく動いている中で、業界の健全な発展を図るため、また投資家への手引きのため、化学繊維事業計画を投資リスクを基準にして評価した「早期警告システム」を作成、発表した。

( http://www.ccfa.com.cn/new-ccfa/warning.html )

各事業計画を「非常にリスキー」から「強く推奨」まで5段階のグループに分け、グループごとに、色分けして表示(○印)している。

赤色 非常にリスキー

オレンジ色 リスクが高い

黄色 リスクあり

緑色 推奨

緑色(○○) 強く推奨

化学繊維協会は1993年に設立され、メンバーは約400社で、SinopecやPetroChinaもメンバーとなっている。

品目別グループ色分け内容は以下の通り

【赤色】(非常にリスキー)

汎用グレードのPET繊維で日産300トン以下

包装用PETフィルム

汎用グレードのスパンデックス

【オレンジ色】(リスクが高い)

PET繊維で日産200-400トン

ボトルグレードのPETチップ

ビスコース繊維フィラメント

工業用ナイロン繊維ヤーン

PP繊維フィラメントヤーン

【黄色】(リスクあり)

PET繊維で日産400トン以上

特定のPETフィルム

ポリエステルステープルファイバーのチップ

ビスコース短繊維

特定のナイロンフィラメントヤーン

PP短繊維

PVA

【緑色】(推奨)

PTAで年産最低50万トン

PETで日産最低600トンでポリエステルフィラメントヤーン等の生産設備を含むもの

直接紡糸ポリエステルステープルファイバーで日産最低150トン

工業用PPファイバー

アクリルファイバー

特定のファイバー(例 超高分子量のポリエチレンファイバー、光ファイバー)

【緑色○○】(強く推奨)

パラキシレン、モノエチレングリコールのような繊維生産用の原料

特定の繊維

例:カーボンファイバー、ポリ乳酸ファイバー、

PBO(polyphenylenebenzobisoxazole)ファイバー

日本経済新聞 2004/6/4

三九企業集団 中国政府が資本注入 50億元で調整 外資導入、白紙に

中国政府は資金難に陥っている中国医薬品最大手の三九企業集団(広東省)に資本注入する方針だ。注入額は総額50億元(約650億円)前後で最終調整している。同社は外資導入で借入金返済を目指していたが、中央政府が支援し早期の経営健全化を目指す。中央政府が金融機関以外の一般企業に資本注入するのは珍しい。

日本経済新聞 2007/3/21

中国医薬大手の三九企業集団 華潤集団が買収

中国の大型国有企業の華潤集団は中国の医薬品大手、三九企業集団(広東省)を買収する。漢方薬を主力とする三九は自動車販売など多角化事業の失敗で負債が膨らみ、経営が悪化していた。華潤は三九を傘下に入れ、今後成長が確実な医薬品市場の開拓を急ぐ。

1985年設立の三九は2003年に日本の中堅医薬、東亜製薬(富山県)を買収するなど海外展開にも力を入れていた。多角化事業の失敗で負債総額が100億元まで膨らみ、04年に創業者を事実上解任、国資委主導で再建策を練っていた。

「人民網日本語版」2007年3月20日

薬品大手の三九集団を再編へ 華潤集団が出資

国務院の国有資産監督管理委員会(国資委

State-owned Assets Supervision and Administration Commission:SASAC

)は19日、華潤集団China

Resources Enterpriseを戦略投資家として三九企業集団999 Groupに対する資本再編を実施することを明らかにした。

三九集団は国資委の管轄下にある国有の大型医薬品企業で、上場企業の三九医薬やGMP認証(医薬品等の品質管理基準)を取得した医薬品製造企業を傘下に多数擁する。製品は漢方医薬・西洋医薬を合わせて約千種類に上り、全国をカバーする販売ネットワークをもつ。2003年末、同集団は債務超過に陥り、深刻な信用危機および債務危機に陥った。04年7月には国務院の認可を受けて債務再編をスタートし、06年12月には戦略投資家の導入作業を開始した。こうした動きを受けて、国資委はこのほど専門家による投票・審査に基づき、華潤集団を戦略投資家に選出した。

国資委の責任者によると、今回、戦略投資家が基本的に確定したことで、三九集団の債務危機および上場企業資金の占用問題を早期に解決し、上場企業の中小株主の権利を適切に保護し、各方面への損失を可能な限り軽減するのにプラスになる。

華潤集団 China

Resources http://www.crc.com.hk/

China Resources is

dedicated to enhancing people’s lives by bringing them

fundamental goods and services. Its name symbolizes “the great land of China,

endowed with abundant natural resources”.

China Resources

began its history in Hong Kong in 1938 as Liow & Company.

It was renamed China Resources Company in 1948 and

restructured and incorporated under China Resources

(Holdings) Co., Ltd. in 1983. In the same year, it relocated

to its current headquarters in the China Resources Building

on 26 Harbour Road, Wanchai.

In over half a

century’s business in Hong Kong, China

Resources has established a strong reputation based on its

proactive business strategies, an open corporate culture and

a commitment to fostering a better future. Today, it is one

of the leading conglomerates in Hong Kong and the Chinese

Mainland, with assets totalling around HK$100 billion.

China Resources’businesses touch every facet

of people’s lives. Its core businesses

cover three fields: the manufacture and distribution of daily

consumer goods, properties and related industries, plus

infrastructure and public utilities.

Moving forward,

the company will further develop its core businesses in the

Chinese Mainland, striving to become the market leader in

each industry. The success of its core businesses will

stimulate the further growth of the entire company and create

a broader development space.

化学工業日報 2004/6/8

上海華誼集団、C1化学大型投資を計画、メタ・酢酸、呉渥で100万トン

塩ビも、スペシャリティ拡充並行 10年売上高600億元めざす

中国の大手化学企業グループの上海華誼集団公司は上海化学工業団地で進む石油化学の投資を踏まえて今後、同拠点でスペシャリティケミカルの拡大に乗り出すと同時に、同じく華東地区の拠点である呉溢では年産100万トン級のメタノール、酢酸を中心としたC1ケミカルを本格的に展開、さらに年産100万トンの塩ビ樹脂事業化計画を推進していく意向だ。

上海華誼集団公司は上海クロールアルカリや上海コーキングなど旧化学工業部系化学企業を傘下に持つ集団公司で、上海市の委託を受け、広州湾北岸の上海化学工業団地の開発に携わってきた。

すでに同サイトでは年産90万トンのエチレンセンターの建設が進んでいるほか、BASF、ハンツマンが6社合弁でTDI、MDIの合弁事業を推進している。さらにバイエルがポリカーボネート樹脂プラントの建設に乗り出しているほか、華誼はBASF、ハンツマンの同計画やポリカーポネート樹脂事業計画にパートナーとして参画する一方、塩ビ、力性ソーダ事業に乗り出そうとしている。

China Chemical Reporter 2004/6/11

100 000 T/a Nylon 66 Project Starts Construction in Shenma

The 100 000 t/a nylon 66 project

has recently started construction in Nylon Chemical Industrial

Co., Ltd. of Shenma Group. The project has an investment of

RMB153.02 million and a construction period of one year. It can

expand the nylon 66 capacity by 100 000 t/a and the commodity

hexanediamine capacity by 700 t/a.

Shenma Group 神馬グループ

河南省平頂山市

http://www.shenma.com/introe.htm

China SHENMA Group, its former

body, Pingdingshan (平頂山)Nylon Tire Cord Fabric , is the first

modern nylon 66 dipped tire cord fabric enterprise to produce

tire backbone material in China, who imported whole set of

equipment and technology from Japan in 1981.

China Shenma Group could produce nylon 66 salt 85000 t/y, polymer

17000 t/y, nylon 66 dipped tire cord fabric (industrial yarn)

65000 t/y, rubber tire 80000 standard set. In addition, Shenma

Group also produces engineering plastics, alkali and chemical

fabric now.

China Shenma Group is the largest manufacturer and supplier of

nylon 66 salt, nylon 66 polymer, nylon 66 dipped tire cord fabric

(industrial yarn), among that, its main product enjoy high

reputation in domestic and international market. The output of

Shenma's tire cord fabric occupies 35% market share in domestic

market and 10% in international market. Meanwhile, Shenma brand

is the most reliable brand in our customers' heart.

China Shenma Group owns 5 share-controlled subsidiaries, 2

sub-company and more than one share holding companies, in which

one of the share-controlled subsidiary -Shenma Industrial Co.,

Ltd. is a stock company.

It gains more than 50 reward items such as national scientific

progress award, "Gold Horse Prize" in national business

management award, national perfect product award, etc.

China Shenma Group is going to follow the developing strategies

as "focus on the main industry, develop diversified economy,

strive for first class and enter into international market"

and to build itself into an international nylon and intermediates

manufacturer.

2004/06/23

Asia Chemical Weekly その後の記事

China's Dalian Shide, SABIC aim a

$5 billion petrochemical complex in Northeast China

There is bombing news on Jun 17,

2004 in China petrochemical industries. Dalian Shide(大連實德) Group associate with Saudi Basic

Industries Corp (SABIC) to build a 41.6 billion yuan ($5.03

billion) petrochemical complex in Northeast China, construction

of this project will be started in 2005 and finished by 2010.

This news confirmed by Shide Group on Jun 18.

The proposed world-scall complex will be in the Lvshun (旅順) port of Dalian(大連) City, and it would include a 1.3 million

tonne-per-year (tpy) ethylene plant and an 10 million tpy oil

refinery, sources familiar with the project said. Dalian Shide

and SABIC will hold this project as a 50:50 joint venture.

A proposal for the project had been submitted to the governmental

authority last November.

Yet there is no reply from SABIC about this project.

Dalian shide Group ( http://www.shide-global.com ) is a private firm in China. Its business

covered with chemical building materials, petrochemicals, home

appliances, sports, insurance, auto-manufacturing and so on. It

owned a famous Football club in China.

Some Hong Kong based Chinese medias reported that the president

of Dalian Shide Group, whose name is Xu Ming, is the son-in-law

of current China’s prime

minister Wen JiaBao, but have no China official media confirmed

this rumor.

http://www.shide-global.com

Dalian Shide Group Co. Ltd.

is a privately-owned company with diversified products and

services. It was founded in 1992 with its headquarters in

Dalian, China. Since its inception, Shide Group has

emphasized the importance of technology, marketing,

information and community. Due purely to hard work, efficient

management, community support and international cooperation

over almost a decade, Shide Group has quickly become one of

the most well known companies both in China and the world.

Shide Group originally started as Dalian Shide Machinery

Construction Corporation Ltd in 1992. Currently, Shide Group

is gaining renown primarily because of its high quality

chemical building materials and its expertise in the

petrochemical industry; home electrical appliances

manufacturing; sports; automobile manufacturing; health care

and insurance.

Dalian

Shide Plastics Industry Co., Ltd. is the cornerstone of Dalian Shide

Group. Originally, it was founded in August 1995 in the form

of a joint venture between Shide Group and Theysohn Company

(Germany). In that year, Dalian Shide Plastics Industry Co.,

Ltd imported the 12 most advanced automatic compounding

systems, high-speed profile extrusion lines, and door &

window assembly lines from Germany capable of maintaining a

12,000 ton capacity per year while producing highly qualified

windows and doors.

Because the PVC doors and windows were new building materials in China,

Shide proceeded to educate customers and cultivate the

potential market. Now Shide is proud of its comprehensive

marketing and sales network, which includes eight regional

sales center totally covering all areas of China. At the same

time, Shide has continued to cooperate with Reimelt Company

(Germany), Theysohn Company (Germany), Greiner Company

(Austria), Cincinnati Company (Austria), Chemson Company (U.

K.) in plastic profile processing technology. In addition to

importing the most advanced automatic compounding systems,

high-speed profile extrusion lines, as well as door &

window assembly lines from Germany, Shide has also imported

double-glazing production lines from the U. K. to produce

plastic profiles used for rigid plastic doors & windows.

Shide Group is one of the

biggest users of PVC and VCM. The price of the raw materials

has been the biggest cost of Shide chemical building

materials. In July 2000, Shide Group determined to establish

its own PVC and VCM production bases and founded Dalian Shide

Petrochemical Co. Ltd. In

the same year, Shide invested more than $1.2 billion to set

up an annual 500,000-ton PVC & VCM production base and auxiliary

facilities. The plant will be completed in 2003. Another PVC

and VCM production base will start the construction in

Jiaxing, Zhejiang, China.

Asia Chemical Weekly

2004/6/28

The impacts of

China's Yangtze ACN ban

For the environmental concerns, The Chinese government has banned

shipments of acrylonitrile (ACN) via the Yangtze River with

effect from 1 June,2004, and imposed a $10/tonne surcharge for

ground transportation of ACN. The authorities concern that marine

life would be affected by the ACN leakages, because ACN is

classified as a dangerous chemical.

For the sake of some of producers which use the ACN as a

feedstock imported ACN are often shipped through the river, with

this regulation, the producers based in the Yangtze Delta

(including Jiangsu Province 江蘇省and Shanghai City), will be affected

mostly. These potential affected producers including: Nantex

Industry台湾, which with

about 16000 tonne/year nitrile butadiene rubber(NBR) plant in

Zhenjiang鎮江, Jiangsu

Province; Shinho Changzhou新湖(常州)石化 韓国JV, which produces 50 000

tonne/year of ABS in Changzhou 常州, Jiangsu Province.

The worst affected firms are two Taiwan's ABS producers, Chi Mei

and Grand Pacific Petrochemical Corp (GPPC國喬石化). Chi Mei produces 250 000 tonne/year of

ABS in Zhenjiang while GPPC has a capacity of 180 000 tonne/year,

also in Zhenjiang, Jiangsu Province.

Platts have reported on 18 June that Chi Mei may shut China ABS

unit for the China's ACN ban.

Followed the GPPC, Taiwan's Chi Mei Group plans to negotiate with

Chinese government officials early July to discuss the

possibility of lifting the Yangtze ACN ban. GPPC is ongoing the

discussion with the Chinese government on the ban, source said.

Chi Mei had been

transporting ACN from Shanghai via the Yangzi River and through

about 600 kilometers Changjiang Canal to Zhenjiang. If the

negotiation failed, Chi Mei maybe alter the import site to

Lianyungang port, Jiangsu Province.

SHINHO(CHANGZHOU)PETROCHEMICAL

CO.,LTD was established with investment from Shinho

Petrochemical Co.,Ltd (SH Chemical) of Korea, Changzhou

Plastic Group常州塑料集団 and Changzhou Xingang Economic

Development Co.,Ltd, with an annual output of 100,000 tons of

ABS, for the first stage of which US$29.82 million has been

invested. The company has adopted the technology of Shinho

Petrochemical Co.,Ltd, specializing in the production of ABS

resin of various brands.

The Business

Times June 22, 2004

http://business-times.asia1.com.sg/story/0,4567,120349,00.html

---

Meanwhile, Chi Mei Group denied plans to close a plastics

plant in eastern China after the Chinese government banned

river shipments of a raw material.

China's decision this month to ban transport of acrylonitrile

on the Yangtze River and impose a US$10 per ton surcharge on

ground shipments will force the company to raise prices or

find ways to cut costs at the plant in Zhenjiang, said Huang

A-Rong, a section chief at Chi Mei. Acrylonitrile is a toxic

raw material used to make acrylic rubber and fibres.

'Chi Mei intends to continue the Zhenjiang operation even as

China's environmental protection measures will increase our

costs,' Mr Huang said, denying a report in Taiwan's Economic

Daily News that the plant may shut.

China's People's Daily in a May 31 commentary singled out Hsu

Wen-long, 76, founder of Chi Mei, as an example of the kind

of Taiwan businessman whose investment isn't welcome because

of his pro-independence views.

China's decision to adopt stiffer environmental protection

standards for the plastic industry isn't a political ploy

aimed at Chi Mei, Mr Huang said.

'Some people mistakenly think there might be some political

implications in China's decision,' he said.

China Chemical

Reporter 2004/7/2

Large PTA Project

Located in Shishi 福建省泉州市石獅

http://www.ccr.com.cn/news_view.asp?ID=462

The 1.2 million t/a

PTA project with a total investment of over RMB2.0 billion has

recently been evaluated by an expert team composed of experts

from China International Engineering Consultation Company and

relevant persons from Shishi,Quanzhou City Fujian Province.

Shishi municipal government hopes that after the evaluation by

experts the project can be launched in Shishi as soon as

possible.

The project was submitted to the National Development and Reform

Commission for approval in July 2003. After several consultations

between Shishi municipal government and investor Jialong

Investment Co., Ltd., the project site with a planned area of 20

square kilometer has been selected in Shihu Industry Park of

Quanzhou High-Tech Industrial Development Zone. A 600 000 t/a PTA

unit will be constructed in the first phase.

「人民網日本語版」2004年6月29日

医薬品企業1970社、7月から生産停止

国家食品薬品監督管理局は28日、全国の医薬品生産企業1970社と医薬品生産工場884社が医薬品生産に関する品質管理認証であるGMP認証に合格していなかったことから、7月1日に生産を停止することを明らかにした。

GMP認証を持つ医薬品生産企業は全国で累計3101社あり、全国の医薬品生産企業の60%を占める。生産停止する企業が7月1日以前に製造した合格薬品は、監督部門の許可を経て、規定の有効期限まで引き続き販売される。

国家食品薬品監督管理局薬品安全監督管理司の白慧良司長は、中国医薬品市場は現在全体的に供給が需要を上回っていると話す。GMP認証に合格した医医薬品生産企業は全体の60%を占めるが、国内市場で約90%のシェアを占め、臨床でよく使われるあらゆる医薬品を生産しており、市場需要を完全に満足させることができる。生産停止に追い込まれた企業は、大部分が実際にはすでに生産を停止している。まだ生産を続けている企業は、生産量も少なく、急病用や自社開発の医薬品は基本的に生産していない。

「人民網日本語版」2003年1月23日

5年間でニセ薬品事件28万件を摘発

開催中の全国薬品監督管理工作会議によると、1998年からの5年間に、ニセ薬品の製造・販売事件28万件以上が摘発された。額面18億元分のニセ薬品が没収され、製造販売拠点3088カ所が取り壊され、また違法薬品交易市場116カ所と無許可の小売店4万軒以上が取り締まりを受けた。こうした措置を通して、ニセ薬品の勢いが効果的に食い止められている。

国家薬品監督管理局の鄭篠ユ局長によると、この5年間、薬品経営許可証の発行と一般特恵関税(GSP)制度の監督・実施により、薬品卸売企業の営業活動の規範化が一層推進された。現在、許可証を取得した薬品卸売企業は全国に1万3265社ある。中薬(漢方薬)保健薬品はこれまで4627種類が登録されていたが、うち3312種が取り消され、中成薬(漢方製剤)は5915種類あったうちの2895種が取り消された。化学薬品は1700種類以上あったが、関連調査の第一段階作業の結果、700種以上が医学的、薬学的に評価できないとされた。2002年末時点で、1470余社の薬品製造企業がGMP(医薬品の製造管理と品質管理に関する基準)認証計1890を取得しており、同業企業全体に占める割合は26%となっている。

人民日報日本語版 2004/7/14

海南省、5年内に重要な石油・ガス・化学工業の基地に

海南省(海南島)は南中国海の豊富な石油・天然ガス資源と続々と流入する企業の投資をよりどころに、巨大な産業発展計画ーー2004年から5年ほどの期間をかけて大規模な開発と建設を行い、海南省を中国の重要な石油・天然ガス・化学工業の生産基地に築き上げる計画ーーを実施している。

地質調査によると、海南省所属の約210万平方㌔の海域には230~300億㌧の石油と約15兆立方㍍の天然ガスが埋蔵されているという。この巨大な資源は中国に新たなエネルギーの保障を提供することになるばかりでなく、農業と観光業がGDPの55%を占める省全体の経済構造の工業化への転換のために条件を整えることになった。

現在、石油・天然ガスの採掘と加工における中国のトップクラスの大手会社3社がすでに海南省の発展計画に参与し、アメリカ、ドイツ、オランダ、シンガポール、香港などの国や地域の多国籍企業が投資者として肩を並べている。

数多くの投資の流入につれて、生産規模が中国トップクラスにある化学工業プロジェクトがすでに建設工事が着工され、一部のプロジェクトが操業を開始した。海南島西部の沿海地域では洋浦経済開発区と東方市を中心とした石油・ガス化学工業ベルトが初歩的に形成されている。

海南省の衛留成省長はこのほど記者の取材を受けた際、次のように語った。海南省は今後南中国海の石油・ガスの探査、開発、加工を外資導入と対外経済協力の重点分野とし、石油、天然ガス、重化工業、ファインケミカルを優先的に発展させる計画である。具体策としては、「汎珠江デルタ(香港特別行政区、澳門特別行政区、広東省、福建省、江西省、広西チワン族自治区、海南省、湖南省、四川省、雲南省、貴州省によって構成される)」区域経済協力組織に参加し、当該組織のメンバーの資金を利用して、製品市場を開拓し、海南省の石油・天然ガス産業の発展を加速させ、特に香港の国際資金調達面での強みを十分に生かし、国際資本を誘致し、南中国海の石油・天然ガスの探査、採掘、深度加工に利用する計画である。

今日開かれる第1回汎珠江デルタ区域商談会において、海南省側は投資総額340億元を上回る、12の石油・天然ガス化工プロジェクトを新たに持ち出すことになっている。

2004/7/16 Platts

US affirms Asian plastic bag

imports detrimental to local trade

The US International Trade

Commission has determined that certain plastic bags imports from China, Malaysia, and

Thailand had been materially

detrimental to its domestic industry, given its sales at less

than fair value, the International Trade Administration said in a

press statement on Thursday, Jul 15. All six of its commissioners

had voted in the affirmative, based on the investigations which

were ongoing since end-June.

「人民網日本語版」 2004年1月22日

米商務省、中国産PE袋などに反ダンピング課税

米商務省は20日、中国、マレーシア、タイ産のPE袋製品(1億7500万ドル相当)に対し、反ダンピング税を課すことを決定した。

これによると、中国産製品に1~123%、マレーシア産に0.14~101.74%、タイ産に2.84~122.88%の課税措置を取る。最終的に課税措置を取るのは今年6月上旬という。

米国際貿易委員会はこの問題に関して今年8月に採決を行い、最終裁定を下す。

2004年07月21日 Chemnet Tokyo DSM release

中国海洋石油(CNOOC)とDSM、海南島に世界最大級メラミンJV

中国海洋石油(CNOOC)とDSMは、海南省東方市でメラミン年産12万トン製造のJVを設立する。投資額は1億ドルで、DSMが70%、CNOOCが30%を出資し、完成すれば世界最大級のメラミンプラントとなる。DSM技術を使用、2005年第1四半期に建設を開始し、2007年末完成を予定している。

CNOOCは現地に尿素132万トン、アンモニア70万トンのプラントを持ち、JVに原料を供給する。DSMはライセンス部門のスタミカーボンを通じてCNOOCに尿素技術を供与している。

現在の海南省の主席は元CNOOCのCEO。海南島はCNOOCの主要石化基地の一つで、2007年までに海南省・東方市に東方化工パークを建設する計画を明らかにしている。同社は香港のキングボードケミカルとの合弁で60万トンのメタノールプラントを建設中である。

中国では海南島を南中国海の豊富な石油・天然ガス資源と、続々と流入する企業の投資をよりどころに、巨大な産業発展計画を通じて、今後5年以内に同国の重要な石油・天然ガス・化学工業の生産基地に築き上げていく計画を進めている。 (この項上海発=特約)

CNOOC and DSM to form JV for

world scale melamine project

China National Offshore Oil

Corp(CNOOC) and Dutch Chemicals Group DSM are to form a JV to

build a 120kt/y melamine plant at Dongfang city, Hainan

province, China, a local government official told the media

and this news has been confirmed by DSM on Tuesday.

The final investment of the

project will be almost $100m, and after construction the

project will be one of the world's largest melamine plants.

DSM will hold the 70% stakes in the proposed JV while CNOOC

will hold the remaining 30%.

CNOOC owed an urea unit with

the capacity of 1.32m tonne/year and an ammonia unit with the

capacity of 700 000 tonne/year at the same site, and it would

provide feedstock to the planned plant.

Based on DSM technology, this

project is expected to get approval and start at Q1 of 2005,

and to be mechanically complete by the end of 2007. DSM also

provided technology for the CNOOC's urea plant through its

licensing unit Stamicarbon.

According to the DSM, the

output from the proposed melamine plant would be sold to

China domestic market as well as abroad; the new plant would

not impact the output from the company's existing plants in

Fortier, Louisiana, US; Geleen, the Netherlands; and Bontang,

Kalimantan, Indonesia, because the Chinese Marketing is

fast-growing.

Hainan island is a major

petrochemical base for CNOOC where the company is also

building a 600 000 tonne/year gas-based methanol project in a

joint venture with Hong Kong based Kingboard Chemical

Holdings.

China government plan that

Hainan province become a major petrochemical base in China

before 2009, with the advantages of Ocean oil and gas

competitiveness.

The current nomarch of Hainan

province--Wei Liucheng(衛留成)--was the former CEO of CNOOC. The

arrangement of Wei in the current position reflects the

strageties of China central government.

2005/5/8 Asia Chemical

Weekly

CNOOCC, DSM signed agreement for Hainan melamine project

China National Oil Offshore Corp Chemicals Ltd. (CNOOCC) has

signed an agreement with DSM in the early April for the 120 kt/a melamine project in Dongfang,

Hainan Province, according to the industry source.

In the Jul of 2004, DSM Melamine and CNOOCC signed a letter of intent

to study jointly the feasibility of building a new 120 kt

melamine plant on Hainan. It was originally agreed that the stake

holding between DSM and CNOOCC would be 70/30. The total

investment amount was expected to be approximately $100 million.

In the final agreement, however, the financial terms are changed,

the total investment amount is $170 million (1.4 billion Yuan),

and the stake holding is also changed with CNOOCC

now holding 40% and DSM holding 60%.

The project is expected to completed in early 2008, and the

engineering contractor for this project is Technip.

Also in Hainan, CNOOC owed an urea unit with the capacity of

1.32m tonne/year and an ammonia unit with the capacity of 700 000

tonne/year. It would provide feedstock to the planned plant.

DSM will provided technology for this project. DSM plans that the

output from the proposed melamine plant would be sold to China

domestic market as well as abroad market.

2004/7/20 DSM

DSM Melamine and China National Offshore Oil Corp. Chemical Ltd.

sign a letter of intent for building worldscale melamine plant in

China

http://www.dsm.com/en_US/html/media/press_releases/20_04_melamine_china.htm

Today DSM

Melamine and China National Offshore Oil Corp. Chemical Ltd.

(CNOOCC) signed a letter of intent to study jointly the

feasibility of building a new 120 kt melamine plant on Hainan

Island, China. The envisaged co-operation between DSM and CNOOCC

will be 70 / 30. The total investment amount is expected to be

approximately $100 million. The final investment decision by the

two companies is foreseen for Q1, 2005.

2004/7/22

中国・ASEANニュース速報

【中国】大型アクリル酸製品工場、天津に完成

http://www.e-plastics.gr.jp/japanese/nna_news/news/news0407_3/04072201.htm

国内最大規模のアクリル酸ポリマー生産・研究基地「天津亜科力化工科技有限公司」がこのほど、天津経済技術開発区に完成した。

同社の資本金は6,000万元。ハイテク企業の北京東方亜科力化工科技と、シンガポール系の福島企業投資による合弁で、福島企業投資が51%、北京東方亜科力化工科技が49%を出資している。稼働後の売上高は4億5,000万元、税引き前利益は6,000万元を見込んでいる。

Aug.8

2004 Asia Chemical Weekly

The

bullish Asian market of naphtha in 2005

China

will become a net naphtha importer from March 2005, once Secco

commissions its new cracker. As China's three crackers come on

stream as planned, the bullish Asian naphtha market can be

expected.

China to commision three big crackers in 2005. There are: Shanghai Secco's 900kt/y

cracker at SCIP (Shanghai Chemical Industry Park, Caojing of

Shanghai), which to come onstream in the March of 2005; the

following is BASF-YPC's new 600kt/y

cracker at Nanjing, which to come onstream in the middle of 2005;

the third cracker is Shell Chemicals' 800kt/y Daya Bay cracker, which to come

onstream in Nov. 2005.

Secco's 900kt/y cracker need 3 million t/y of naphtha for

feedstock, 75% of that total requirement will be sourced from two

Sinopec refineries in Zhenhai and Gaoqiao, while the remaining

25% will imported. BASF-YPC's cracker will need 2 million t/y

naphtha for feedstock, some of these will be sourced from Jinlin

refinery, and 10% of the total requirement will depend on

imports. Shell Chemicals' Daya Bay cracker need 2.65million t/y

naphtha, the total reuirement of this cracker will depend on

imports.

According to the statistic, China will have an extra naphtha

requirement of 7.65m tonne/year when three new crackers come

onstream as planned next year. Of the total new requirement, 3.6m

tonne is expected to be sourced from the international market.

Currently, all Chinese crackers are supplied by domestic

refineries. As a net exporter of naphtha, China exported 1131kt

naphtha in 2003, about 84%--950kt--is for Japan, and about

14%--156kt--is for S.Korea. West Pacific Petrochemical Co (WEPEC)

refinery at Dalian in northeastern China, which with the capacity

of 164 000 bbl/day, is the main naphtha exporter of China (it

exports two to three 30 000 tonne naphtha cargoes monthly). In

the same period, China imported 238kt naphtha, about half of it

is from Russia.

After 2005, China will compete with Japan and S.Korea in Asian

naphtha market. Most of the 3.6m tonne naphtha requirement, may

be sourced from India and Mideast market. That means India, which

is now exporting about 300 000 tonne/month of naphtha mostly to

Japan and South Korea, will boost its export volume for China

demand. And some industrial observers consider that Chinese

refineries must refine more lighter crude oil (like Saudi Light

crude) in order to meet the higher naphtha demand in 2005.

The stress of China domestic naphtha demand will not be relaxed

partly until the year of 2007. After 2007, two new Chinese

refineries planned by CNOOC and Sinopec are to come

on-stream, providing an additional 440,000 b/d of refining

capacity. CNOOC's feasibility study on a $2.1-bil, 240,000 b/d

[12-mil mt/year] refinery project in the southern Guangdong

province, was approved by government recently, this project is

scheduled to be completed in late 2007 or early 2008. Sinopec's

feasibility study on a 200,000 b/d [10-mil mt/year] plant in

eastern Shandong province, was also approved by government

recently. Sinopec aims to complete project development by

end-2006 and bring the refinery on stream during the first half

of 2007. The refinery, to be built in Shandong's coastal city of

Qingdao, will be designed to process Saudi Light crude.

Anyway,

with the on-stream of China's three crackers, the bullish picture

of Asian naphtha market can be expected in 2005.

August

9, 2004 Financial Times Information

China

plans 2 new refineries

China

will launch two refinery projects with a combined annual

capacity of 22 million tons of oil products to meet rising

demand and provide feedstock for new petrochemical plants,

industry officials and analysts said.

China

Petroleum & Chemical Corp (Sinopec), the country's top

refiner, plans to spend US$1.2 billion on a new refinery in

the eastern province of Shandong with annual capacity of 10

million tons, a Sinopec official said. Sinopec would

undertake the project on its own but no timetable has been

decided on yet, the official said. The project still requires

approval from the National Development and Reform Commission

(NDRC), the country's top economic planning agency, he said.

Meanwhile,

China National Offshore Oil Corp (CNOOC), the country's

dominant offshore oil producer, has also received permission

to build its first refinery with an annual capacity of 12

million tons of oil products, a company official said. The

project will be built in Huizhou in the southern province of

Guangdong where CNOOC and Royal Dutch/Shell are already

building a US$4.3 billion petrochemical complex. Issues such

as whether it will be a joint venture with Shell or solely

funded by CNOOC have yet to be decided, the official said.

"We'll make a formal announcement once everything is

finalized," she said.

Industry

analysts said the additional capacity of 22 million tons,

accounting roughly for 8 percent of China's current capacity

of 280 million tons, will help meet rising demand for

gasoline, diesel and fuel oil and provide feedstock for the

nation's expanding petrochemical capacity. The feedstock from

the new plants could be used in a number of new projects.

CNOOC's new petrochemical complex, scheduled for operation in

2005, has an annual capacity of 800,000 tons, while Sinopec

is expanding an ethylene cracker in Maoming in Guangdong

Province for 4.3 billion yuan (US$520 million). in 2006, its

annual capacity will rise to 800,000 tons from the current

380,000 tons, a Sinopec source said. Sinopec is also

considering expanding the capacity of other ethylene

facilities, including Sinopec Guangzhou, which is now

producing 150,000 tons of ethylene a year. There is ample

room for new ethylene plants in the country due to rising

demand, which will push up need for feedstock at the same

time, industry sources said. China's demand for ethylene has

been rising by about 10 percent a year in recent years, with

current domestic capacity only able to meet 50 percent of

domestic demand. Despite the expanding petrochemical

capacities, about 42 percent of China's ethylene needs will

still rely on imports by 2010, the industry source added.

August 13, 2004 Business

Wire

Borden Chemical Venture Opens New Production Facility in China

Asia Dekor Borden Chemical (Heyuan) Company Limited, a joint

venture between affiliates of Borden Chemical, Inc. and China's Asia

Dekor Group, has successfully completed the startup of

a formaldehyde and resin production facility in Heyuan, China. 河源市

Borden

Chemical is managing the formaldehyde and resin plant, which has

the capacity to annually deliver 55,000 metric tons of advanced

resins for the production of high and medium density fiberboard

and particleboard. The major customer for the facility is Asia

Dekor (Heyuan) Woods Company Limited, which operates an adjacent

new facility that produces fiberboard.

About Asia

Dekor

http://www.asiadekor.com.sg/

Asia Dekor

Holdings Limited is a company incorporated in Bermuda and its

shares have been listed on the main board of the Singapore

Exchange Securities Trading Limited since November 1999.

The Group was established in 1994 and is the leading producer

and distributor of laminated floor and related products in

China. The Group operates a 36,000 square meters factory

based in Shenzhen, China, with a current maximum capacity of

8 million square meters in production of laminated flooring

products. The capacity is expected to increase to 16 million

square meters by August 2002. In addition, the Group's

distribution network spans the entire country and up to 31

March 2002, there are 769 outlets in operation.

The Group's products are sold under three brands: “Power Dekor” targeted at the high-end market, “Mobifloor”

for the

middle-end market and “Borry” for the mass-end market. The Group's “Power Dekor” has been ranked by the China

Industrial Information Issuing Centre as the best selling

laminated flooring product in China for four consecutive

years from 1998 to 2001.

SearChina 2004/08/25

中国アルミ:ブラジルの工場は07年稼動開始

http://news.searchina.ne.jp/2004/0825/stockname_0825_007.shtml

アルミメーカー最大手の中国〓業股フェン有限公司[香港上場、中国アルミ(アルミニウムコーポ)、2600]の肖亜慶・董事長兼首席執行官は業績発表の記者会見で、ブラジルでのアルミナ工場建設プロジェクトは、2004年末には最終的な協議が合意に至ると述べた。24日付で香港・経済通が伝えた。(〓は金偏に呂)

同社は50%を出資する予定で、初期工事に対する投資総額は10億ドル程度の見込み。07年より稼動開始の予定となっている。

また、中国政府が05年にアルミナに対する輸出税還付を撤廃するとの情報が出ていることについては、正式な通知などは一切ないと説明した。

SearChina 2004/05/24

中国アルミ:ブラジルでアルミナ工場建設へ

http://news.searchina.ne.jp/2004/0524/stockname_0524_012.shtml

アルミメーカー最大手の中国〓業股フェン有限公司[香港上場、中国アルミ(アルミニウムコーポ)、2600]の親会社である中国〓業公司と、ブラジルのValedoRioDoce社が、ブラジル北部でアルミナ工場の建設を計画している。24日付の香港・財華網が外電の記事を引用して伝えた。(〓は金偏に呂)

同プロジェクトの投資総額は10億ドル(約78億香港ドル)。新工場での生産開始は2007年を計画しており、年産は180万トンに達する。

ValedoRioDoce社は、世界最大の鉄鉱石プロデューサーであるとともに資産規模でブラジル最大の企業。現在、ブラジルのルラ大統領をはじめとする企業経営者らの一行が中国に訪問中である。

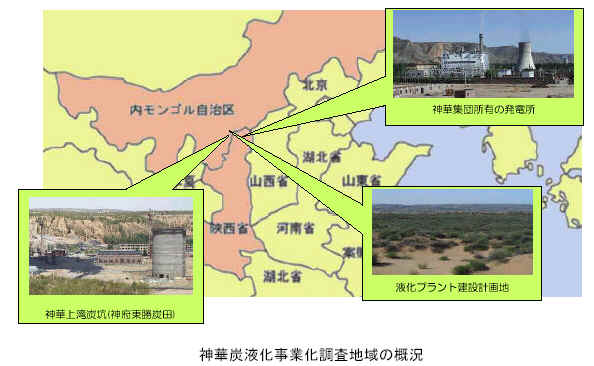

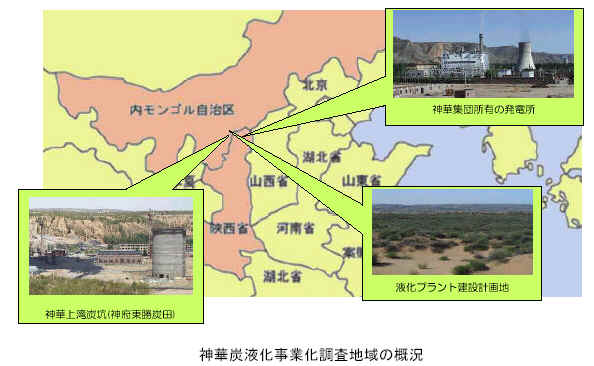

「人民網日本語版」2004年8月26日 NEDO協力 石炭液化 寧夏・山西省計画

神華計画(石炭輸送)

Shenhua and Dow Chemical

to study Coal-to-Olefins

神華石炭液化プロジェクトが始動 世界最大規模

http://j.peopledaily.com.cn/2004/08/26/jp20040826_42780.html

中国の石油代替資源戦略における重要プロジェクト「神華石炭直接液化プロジェクト」の生産拠点が25日、内蒙古自治区鄂爾多斯(オルドス)市で正式に着工した。同プロジェクトは神華集団公司が主導で実施。石炭を直接液化して作る石炭液化油のプラントを世界ではじめて建設する。製品油年産500万トンが目標だ。

プロジェクトは二期に分けて進められる。第1期工事の総投資額は245億元で、1年間で970万トンの石炭から製品油320万トンを生産する。製品の内訳はガソリンが50万トン、ディーゼル油が215万トン、液化ガスが31万トン、ベンゼンや混合キシレンなどが24万トンの予定。最初の生産ラインは2007年7月に完成し、2010年ごろに第2ラインが完成する見通しだ。

米国は現在、石炭の間接液化技術を使用した石炭液化油プラントを建設中だ。完成後は、1日当たり5千バレルの製品油を生産する。一方、神華集団のプロジェクトは、1日当たりの1万バレルの生産を目指す。

Shenhua and Dow Chemical agree to study

Coal-to-Olefins opportunity in China

「人民日報網絡中心」 2000年11月8日

内蒙古:中国最大の石炭液化プロジェクトを計画

情報によると、中国最大規模の石炭液化プロジェクト、神華石炭液化プロジェクトが、内蒙古(内モンゴル)自治区の伊金霍洛旗上湾炭鉱付近で実施されることが計画されている。

神華グループの石炭液化プロジェクトには、アメリカのHTI技術が導入され、石炭を化学的に加工することにより、石炭を液体油製品または化学製品へと転化させる技術が用いられる。計画によると、プロジェクト投資額250億元、年間の原炭消費量1500万トン、製品油の年間生産量500万トン、年間の水の消費量1800万トン、年間売上高100億元、納税額25億元、利益25億元。これまでで中国で計画された石炭液化プロジェクトの中でも最大規模。

このプロジェクトはまた西部大開発実施中行われる、同自治区のプロジェクトの中でも最大の投資規模を誇る。具体的には、自治区の「第10次五カ年計画」のプロジェクト投資総額の10分の1を占めている。

HTI Direct

Coal Liquefaction Technology

Conversion of Coal into Clean Transportation Fuels

http://www.htigrp.com/data/upfiles/pdf/DCL%20Technology%2023Feb05.pdf

Hydrocarbon

Technologies, Inc., a subsidiary of Headwaters Incorporated

(NASDAQ: HDWR), has a process license agreement with Shenhua

Group Corporation, Ltd., China’s largest coal

company, for a direct coal liquefaction plant to be built in

China. Under the license agreement, HTI has provided a

process design package for the first of the three reactor

trains of the world first commercial direct

coal-to-liquid-fuels plant.

The $2 billion facility will be located approximately 80

miles south of Baotou, at Majiata, Inner Mongolia in the

People’s Republic of China.

The plant will have an ultimate capacity of 50,000

barrels per

day of low-sulfur diesel fuel and gasoline produced from

indigenous coal.

After the startup of the first reactor train in late

2007,

Shenhua Group intends to construct three more coal

liquefaction plants in the general vicinity.

Coal is a solid organic material made up of large, complex

molecules containing mostly aromatic ring structures plus

small amounts of sulfur and nitrogen as contaminants. Raw

coal also contains moisture and solid particles of mineral

matter (ash). The aim of direct coal liquefaction is to break

down the complex coal structure into smaller component

molecules which then can be further refined into clean liquid

fuel products by reducing the contents of sulfur and

nitrogen.

The HTI COAL Process features:

・ HTI’s proprietary GelCatTM

Catalyst (dispersed, nano-scale, iron-based catalyst)

・ Two-stage,

back-mixed, slurry-phase reactors

・ Solvent de-ashing to

remove ash and unconverted coal and recover residual oils for

recycling

・ Mild hydrogenation to

replenish the hydrogen content of the recycle solvent and to

stabilize the raw distillate products

・ Resid recycle to

enhance net coal conversion

In the HTI COAL Process, pulverized coal is dissolved in

recycled coal-derived heavy process liquid under typical

hydrocracking temperature of 435 to 460oC in the presence of

elevated hydrogen overpressure (about 170 bars). Most of the

coal structure is broken down in the first-stage reactor.

Liquefaction is completed in the second-stage reactor. The

proprietary GelCat Catalyst is dispersed in the slurry for

both stages. The intermediate coal liquids from the mild

hydrogenation step will be further upgraded using

conventional refining techniques to produce gasoline, jet and

diesel fuels that will meet or exceed existing fuel

specifications.

Following the success of the Shenhua project, HTI is

undertaking two new pre-feasibility studies. One of these

studies is for Oil India Limited to evaluate the

viability of establishing a commercial facility in India

using Assam coal. This coal is one of the most reactive coals

tested so far and is expected to result in favorable

economics.

The other study is for the Department

of Energy of the Philippines. The objective of the study is

to assess the techno-economics of establishing a coal

liquefaction hub in the Philippines for countries in

Southeast. This study will also explore the benefits of

integrating direct and indirect coal liquefaction in the same

facility.

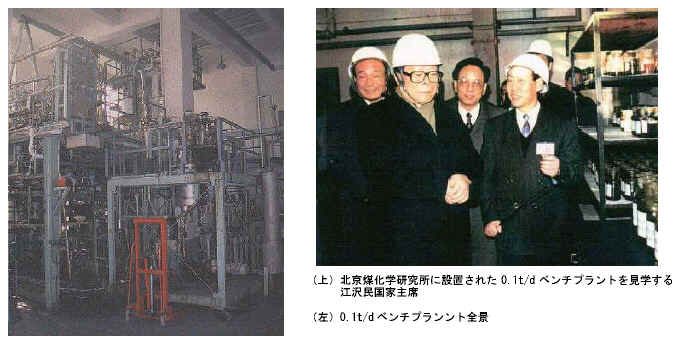

NEDO

http://www.nedo.go.jp/enekan/pdf/p1_a_sekitanekikakenkyu.pdf

中国における石炭液化協力

Collaboration on

Coal Liquefaction in China

石炭から石油代替燃料を得る石炭液化技術は、日本のみならず中国のエネルギー政策上重要な意味を持ち、両国にとって不可欠な技術といえます。

日中石炭液化技術開発

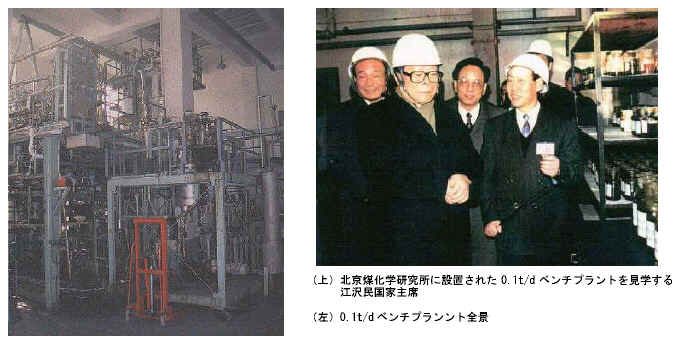

1981年11月、NEDOは中国煤炭工業局(現煤炭工業局)との間で「石炭液化技術共同開発に関する協議書」を締結し、共同研究をスタートしました。1983年、煤炭科学研究総院、北京煤化学研究所に石炭処理量0.1t/d

のベンチスケールプラントを設置し、多くの液化試験を実施し、多大な成果を上げました。

神華炭液化事業化検討(F/S)

1993年から石油の輸入国に転じた中国では、経済成長に伴い石油輸入量の大幅な増大が予想され、2000年には100万バーレル/日の輸入量に達するとの予測もあります。

中国、日本を含むアジア地域の石油輸入は中東地区に集中しており、現在でも既に中東依存度は75%にも達し、中国の輸入拡大により中東依存度はさらに上昇することが予想され、日本のエネルギー安全保障上重大な影響が懸念されます。

このような状況下、中国は自国に豊富に存在する石炭を原油並に扱うことのできる石炭液化に強い興味を持っており、2001年から始まる第10次5ヶ年計画での事業化を検討しています。

中国、内モンゴル自治区と陝西省にまたがる神府東勝炭田(神華炭)を開発している神華集団有限責任公司(略称:神華集団公司)の要請により、1999年5月の日中高級事務レベル会議を経てNEDOが神華集団公司と基本協定書を締結し、NEDOLプロセスに基づく神華炭液化プラント(5,000t/d)の立地可能性調査を実施しました。

神華炭は硫黄分や灰分が低く、採掘コストも安い等の石炭液化における種々のメリットを持っています。また、液化プラントの建設計画地は上湾炭坑に隣接し、電気や交通・住居などのインフラが整備されており、設備投資も最小限に抑えることが可能で、高い経済性が期待できます。

今後は、F/S結果をもとに、さらなる経済性向上のための各種検討、前述の北京0.1t/d

プラントによる神華炭の詳細な液化テストを行っています。

【神華集団公司】

中国の近代企業制度に基づいて創立された国営企業で傘下に17

の企業を有しています。資本金は25.8

億人民元(361 億円但し1 元=14 円)で、国務院大型試験企業集団の一つとなっています。主に神府東勝炭田(現在判明している石炭埋蔵量は2,236

億トン)の総合開発・経営とそれに付随する鉄道、発電所、港湾、輸送などの事業を行っています。

2004/8/26

中国・ASEANニュース速報

【中国】茂名石化、PE,PPを増産へ

広東省茂名市経済貿易局によると、中国石油化工集団傘下の茂名石油化工は、国内最大のポリプロピレン生産装置の建設を決定した。25日付民営経済報が伝えた。

建設されるのは生産能力35万トンの高密度ポリエチレン装置と25万トンの高圧ポリエチレン装置、30万トンのポリプロピレン装置。現在あるエチレン装置の改造工事を含め、総投資額は43億元に上る。新装置が稼働すれば同社のポリプロピレン年産能力は現在の15万トンから3倍の45万トンになるという。

2004/8/26

中国・ASEANニュース速報

【台湾】東聯、中国のEG工場建設を延期

東聯化学工業(OUCC)の郭佳輝総経理はこのほど、中国のマクロ経済引き締め政策を受けて現地の大手石油化学メーカーと共同で進めていたエチレングリコール(EG)工場建設を延期し、台湾での新工場建設を優先する方針に切り替えることを明らかにした。

台湾工場への投資額は108億台湾元で、第3四半期からの起工、2006年第4四半期の量産開始を見込む。年産量は50万トンで台湾第2位のEG工場となる見通しだ。

郭総経理は、中国は化学繊維メーカーの生産能力が拡大しておりEG需要も旺盛だが、生産過剰を懸念する政府による投資制限が設けられている。また、EGの石化原料も明らかに供給不足の状態であることから、工場建設を見合わせたとしている。計画再開は早くても2007年以降になるという。

しかし一方では、投資抑制策によって市場淘汰が進み良性の競争を促すことにつながるとし、業界にとって良い刺激となる点も指摘した。

25日付工商時報が伝えた。

2004/8/26

中国・ASEANニュース速報

【台湾】長春、揚州に年産6万トンPTMEG工場

台湾第2の石油化学メーカーである長春グループの林書鴻董事長は24日、中国・江蘇省揚州に1億1,000万米ドルを追加投資して年産能力6万トンのポリテトラメチレン・エーテル・グリコール(PTMEG)工場などを建設する投資意向書を、同市との間で調印したことを明らかにした。需要拡大が見込める中国のスパンデックス(ポリウレタン弾性繊維)の原料市場でシェア拡大を目指す。

同地にはPTMEGの原料となるポリプロピレングリコール(PPG)やブタンジオール(BDO)の生産工場も建設する予定。林董事長は、揚州市政府が原料となるエチレンの供給サプライヤー確保を約束しており、「原料供給の問題が解決され次第、投資計画を実行に移す」としている。

同社の推測では、中国は現在通年10万トン以上のPTMEGが不足している。長春グループは、昨年江蘇省儀征に設置した年産4万トンのPTMEG工場がフル稼働状態。今後、新規生産ラインと合わせて生産能力は年産10万トンに拡大し、台湾および中国メーカーの中ではトップとなるが、それでも供給が追いつかない状況という。

25日付工商時報が伝えた。

日本経済新聞 2004/9/1

エチレン生産 中国、日本抜き2位に

2010年能力2.3倍 米欧勢が工場

米欧の石油化学品大手が相次ぎ中国で化学製品の基礎原料であるエチレンの生産を始める。化学品世界最大手の米ダウ・ケミカルが中国最大規模の工場新設を決め、独BASFなどの設備も来年半ばに稼働する。2010年の中国のエチレン生産能力は日本を抜き米国に次ぐ世界第二位となる。自動車、家電、素材分野で中国生産を加速させている日本企業にとって原材料の安定確保につながる半面、汎用樹脂では世界的な価格競争激化も予想される。

欧米大手の中国での主なエチレン生産計画

| |

稼働時期

立地 |

年産能力

(万トン) |

総投資額

(億ドル) |

BASF

|

2005年半ば

江蘇省南京

|

60

|

29

|

BP

|

2005年半ば

上海 |

90

|

27

|

シェル

|

2005年11月

広東省恵州 |

80

|

43

|

エクソンモービル

|

2008年

福建省泉州 |

80

|

35

|

ダウ・ケミカル

|

2010年

沿海部

|

100

|

30

|

(注)中国側との折半出資。

エクソンモービルの出資比率は25%、サウジ・アラムコも25%を出資。

総投資額は化学品生産基地全体

Lurgi May 6, 2004

Lurgi is awarded order for a methanol plant in China

Formal Contract Signature at EU in Brussels

http://www.lurgi.de/english/nbsp/menu/media/news/lurgi_is_awarded_order_for_a_methanol_plant_in_china/

On the occasion of

the EU-China Business Forum in Brussels, Lurgi has signed the

contract for the construction of a methanol plant today in a

formal ceremony. Lurgi AG, a subsidiary of mg technologies ag,

Frankfurt am Main, is to build the plant on behalf of CNOOC - Kingboard Chemical

Ltd. and China National Technical Import and Export Corporation

(CNTIC).

The client, CNOOC-Kingboard

Chemical Ltd., is a joint venture between the state-owned Chinese

enterprise CNOOC (Chinese National Offshore Oil Corporation),

Beijing and the Hong Kong based Kingboard Chemical Holdings Ltd. CNOOC, incorporated in 1982 and authorized by

the Chinese State Council, took charge of the exploration and

development of China’s

offshore oil and natural gas resources and is developing into a

first-class international energy company.

Established in 1988, Kingboard Chemical

Holdings Limited is

principally engaged in the manufacture of laminate and its

related raw materials. Kingboard has been listed on the Hong Kong

Stock Exchange. Kingboard also operates several chemical plants

for the production of formaldehyde, using methanol as a

feedstock.

Lurgi is the world market leader in processes for methanol

production from natural gas and oilfield associated gases.

Already now and in the very near future, between 60 and 70

percent of world methanol output are originating from Lurgi-built

plants. Lurgi has developed specific proprietary technologies for

the production of petrochemicals from natural and associated

gases. The new 2,000-t/d plant will be erected in

Dongfang, Hainan island, in the extreme south of China. The plant is to go on

stream in 2007. It will be

the largest so far in China.

2006/9/7

China Chemical Reporter

CNOOC Methanol

Project Makes Successful Ignition

The converter of the

CNOOC 600 000 t/a methanol project, the most important control

point for the trial run progress, made successful ignition in

Hainan Dongfang Chemical City on August 28th, 2006. The train

test run of syngas compressors was completed. It shows that

the inlet and outlet system is basically put through and

production can be soon started.

2006/9/20 Asia

Chemical Weekly

CNOOC KingBoard start

up methanol project in Hainan

CNOOC Kingboard Chemical Co. has started commercial

production for the methanol project in Dongfang City, Hainan

Province.

Currently, production of this unit is not running at full

rates, it is expected to start mass production in January

2007.

It is a 60:40 methanol jv between China BlueChemical company

(中海石油化學) and Hong Kong based

Kingboard (建滔化工集団). China

BlueChemical is

the subsidiary of CNOOC. Earlier, it

was called as CNOOC Chemical.

With the investment of about USD 184 million (RMB 1.47

billion), the project has methanol capacity of 600,000

tonne/year. Using Lurgi technology, the methanol project

based on Natural gas, and feedstock will from source from the

CNOOC’s gas fields near Dongfang.

The methanol jv has signed a 20 years natural gas supply

contract with CNOOC.

CNOOC also planned another project with capacity of 1.13

million tonne/year in Dongfang city, It is expected to start

construction by the end of 2006 and start up by the end of

2008.

Hong

Kong's KingBoard plans large Methanol Project in Chongqing

2004年09月13日 Chemnet Tokyo

上海南部にエチレン300万トンのベルト地帯

奉賢区が隣接の金山区と協力し建設

中国の華東地区に石油化学工業の一大ベルト地帯が構築される見通しとなった。これは上海市の奉賢区(上海南部)が明らかにしたもので、来年4月に上海化学工業区(2010年まで1,500億元を投入)に完成するエチレン年産100万トン設備(BP、地元の合弁)に加え、さらに100万トン設備を建設、隣接している金山区の年産90万トンをあわせ、300万トンクラスの国際的な石油化学センターとする考え。来日中の黄祖光・上海化学工業区奉賢分区管理委員主任が明らかにしたもの。

年産300万トンクラスのエチレン・センターは、広東省恵州市のエチレン90万トン(英蘭シェル)、南京市の100万トン(独BASF)、福建省泉州市の80万トン(ExxonMobil)を大きく上回ることになる。

奉賢区は上海市工業総合開発区のA区とB区、化学工業区、海港総合経済開発区の大きな経済開発4計画を進めている。電子情報、バイオ医薬、精密化学、物流設備、送配電設備などの育成をねらっている。交通や港湾の利便性もあり、世界的な物流センターも構築したい考えで「ワンドア式」の輸出加工区の活用にも力を入れている。

同奉賢分区は市の中心から55キロ、浦東、虹橋両空港まで50キロ以内で高速道路、鉄道、海上輸送にも恵まれている。同区は外資企業に所得税を5年間免除するなどの優遇措置を講じている。

誘致する業種は、スチレン、ポリカーボネート、イソシアネートなどを利用するファインケミカル、製薬、化学繊維、プラスチック製品、包装資材、化学工業用機械など。黄主任は「杭州市とは60キロていどの距離なので、その周辺の石油化学産業とも提携して、国際化をめざしたい」としている。問い合わせは奉賢区駐日本事務所、TEL/03-3478-5618。

Chemnet Tokyo 2005年07月26日

中国石化が新たに上海にエチレン100万トン

上海SECCOの90万トンに続いて計画

中国石化(Sinopec)と上海石化、英BP3社の合弁会社、上海賽科石油化工(上海SECCO)の石油化学プロジェクト(エチレン年産90万トン)が今月から上海市の上海化学工業区(奉賢区)で操業を開始したが、Sinopecは引き続き同区にエチレン年産100万トン設備を増設する計画である。

同90万トン設備は現在、中国最大の規模だが、中国全体で石油化学製品の大幅な需要増が見込めるため、生産力の増強をはかることになったもの。

上海SECCOは、Sinopec30%、上海石化20%、BP50%の出資。これに対して次のエチレン100万トン計画では、中国資本100%の新会社による運営をめざしている。政府の発展計画委員会にプロジェクトの承認を申請中で、年内にも認められる見通しにあるといわれる。この計画には石油リファイナリー1,000万トン設備も含まれている。

(注 2005/7 時点では一次FSの段階)

中国のエチレン設備計画は01年から05年までの第10次5カ年計画として、上海のほか南京、広東(恵州)が認められ、南京はすでに年産70万トンまでの増設を完了している。恵州はことし11月中に年産80万トン設備の新設を終える予定。

中国のエチレン生産はことし800万トンと日本を抜く見通し。これに対し需要は1,500万トンに達すると見込まれ、供給不足が続くとみられている。さらに2010年には、生産能力1,300万トンに対して需要は2,500万トンと、いぜん国内での生産が間に合わないとされている。

上海化学工業区には英BP、独BASF、バイエル、米ハンツマン、独デグサなどが進出し、日本からも三井化学、三菱ガス化学などが参加している。エチレン100万トンプロジェクトでは三菱化学も調査をはじめているもようである。

なお、上海市には上海石化が金山区でエチレン年産65万トン設備を操業しており、上海市は向う数年で一挙に国際石油化学センターを保有することになる。

Platts

2005/12/13

Sinopec, Shanghai Chemical eye 10-mil mt/yr refinery in

Shanghai

Chinese state-owned integrated oil major Sinopec and Shanghai

Chemical Industry Park plan to jointly invest in a new 10-mil

mt/year (200,000 b/d) refinery and petrochemical complex in

the northern part of Hangzhou bay in Shanghai city, a senior

official said Monday.

The project will include a 1-mil mt/year ethylene cracker, Li

Guo Hua, technical director of Shanghai Chemical Industry

Park, told a conference of China/Asia Oil, Chemicals &

Petrochemicals Storage, Transportation & Terminals in the

southern Guangzhou city Monday.

The total investment in the refinery-cum-petrochemicals

project is expected to reach Yuan 30-40-bil ($3.7-4.9-bil),

which will be funded 60-70% by Sinopec and the remaining by

Shanghai Chemical Industry Park, Li said.

Both parties are currently carrying out a feasibility study,

and are scheduled to apply for approval from the National

Development and Reform Commission in early 2006, Li said.

"The new project is expected to be approved by NDRC by

the end of 2006 or early 2007," he said.

"Construction work can be started as soon as the project

gets approved and it can be finished within eighteen months,

so the new project is scheduled to come onstream by

2009," he added.

「人民網日本語版」2004年9月16日

中国―カザフ石油パイプライン 9月着工へ

中国新疆ウイグル自治区の阿拉山口とカザフスタンのアタスとを結ぶ石油パイプライン敷設工事が、今年9月に着工する。完成は来年末の予定で、使用開始後は、カザフスタンから中国に毎年1千万トンの原油が輸出される。駐中国カザフスタン大使が14日、北京の記者会見で明らかにした。

アタス-阿拉山口石油パイプラインは全長約1千キロメートル。カザフスタン西部から中国西部までを結ぶ「中国―カザフスタン石油パイプライン」(全長3千キロメートル)の重要な1区間となる。「中国―カザフスタン石油パイプライン」は、カスピ海沿岸の町アティラウからカザフスタンを横断し、中国・阿拉山口を経由して新疆ウイグル自治区独山子までを結ぶ予定。工事は3期に分けて行われる。中国-カザフ石油パイプラインは、中国西部に建設された製品油パイプラインとともに、西部から東部への石油輸送計画の一環だ。新疆ウイグル自治区と甘粛省を、東部や西南地方の石油輸送ラインや石油化学工場とつなぐことで、西部における石油パイプライン網を構築するとともに、市場に合わせたリソース調整を進める狙いがある。また、西部の石油資源の開発・利用とリソース配分の最適化を推進し、東部地域のエネルギーを確保する狙いもある。

専門家は、中国―カザフ石油パイプラインの建設により、新疆が「中国の石油タンク」になると指摘する。投資活動により現地製品へのニーズが刺激されると同時に、関連産業の発展が促されることで、中国の持続可能な発展に大きな意義をもたらすとみられる。

China Chemical Reporter 2004/9/16

800 000 t/a PTA in Liaoyang Startup 遼陽

PetroChina announced on September 10

that the 800 000 t/a PTA (purified terephthalic acid) in Liaoyang

Branch started construction.

The existing PTA capacity in Liaoyang Branch is 270 000 t/a. When