Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@ÉgÉbÉvÉyĀ[ÉW

2005/9/18Ā@Asia Chemical Weekly Ā@Ā@Ā@Ā@Ā@ĖůĀēČūźŗ

Investors planned CTO

projects in China

Currently, the historic high oil prices add much cost to the

petrochemical producers. In China, some investors, particularly

those holds the coal resources, have planned a few

Coal-to-Olefins (CTO) projects.

On August, Shenhua Group (ź_ČōŹWíc) - the largest coal producer in

China- received preliminary nod from government for its coal-to-olefins

project,

which will be located at Baotou (ēÔď™), Inner Mongolia. And Shenhua is waiting the

finally approval for the project.

The proposed CTO project includes:

1.8 million tonne

coal-based methanol

600,000 tonne methanol-to-olefins

100MW thermal power station

300,000 tonne of PE

310,000

tonne of PP

94,000 tonne of butane

37,000 tonne of heavy alkanes

19,000 tonne of sulfur and

14,000 tonne of ethane and propane

224,000 cbm/hour (oxygen)air separation

Earlier, Shenhua has

signed an agreement with Dow Chemical in December 2004 to initiate

jointly a feasibility study for a CTO project in Yulin (ěĺó—), Shaanxi Province (ŤüźľŹ»).

Besides the above projects, recently, India's Gail has also signed a memorandum of

understanding (MoU) with Shaanxi Huashan Chemical Industry

(ŤüźľČōéRČĽćH) to build a

coal-to-methanol-to-petrochemicals facility in Shaanxi

province.

Two investors will conduct a joint feasibility study on the

production of polyolefins and other products.

Both Shaanxi and Inner Mongolia are the coal rich areas in China.

2007/6/6 Dow

Dow Technology Licensing Wins UNIPOL PP Technology

Contract in China

Shenhua Baotou Coal Chemicals to Build 300KTA

Polypropylene Plant

Dow Technology Licensing (DTL), a business unit of

The Dow Chemical Company and its consolidated

affiliates (Dow), today announced that Shenhua Baotou

Coal Chemicals Company, a leader among Chinese

manufacturers pioneering the coal-based production of

chemicals and plastics, has selected UNIPOL? PP

Technology from Dow for a new 300 KTA polypropylene

(PP) facility. The plant will be constructed within

the Shenhua Baotou Coal-to-Olefin complex in Inner

Mongolia Autonomous Region, The PeopleĀfs Republic of China,

and is expected to come on line in 2010. Aker

Kvaerner, an engineering and construction firm that

has collaborated with DTL on numerous UNIPOL? PP

Technology lines around the world, will prepare the

basic engineering design and provide technical

advisory services.

|

2005/11/4 Asia

Chemical Weekly

Shenhua kicks off the construction for CTO project in Baotou

On 28 Oct., Shenhua Group started the construction for the Coal-to-Olefins

(CTO) project in Baotou( (ēÔď™), Inner Mongalia.

Total investment for this integrated CTO project is USD 1.53

billion (RMB 12.4 billion). Besides Shenhua, there are two

other partners - Hongkong based Kerry Group

and Shanghai-listed Baotou Tomorrow Technology Co

(ēÔď™ĖĺďVČ»čZ), and Shenhua is the dominant

shareholder for the project.

The key technology for the project comes from UOP. This CTO

project would consume 4.73 million tonne coal per year,

wherein 3.45 million tonne coal for feedstock and 1.28 tonne

coal for fuel.

íÜćĎāŇźőíYČĽäwĆvČśĎĪŹo

Ā@źőĖŻČŅäiāŐćāďęāūéůāĮĀAíÜćĎāŇāÕďŃā…źőíYéĎĆĻāūóLā∑āťäťč∆āŐä‘āŇāŐźőíYČĽäwĆvČśā™ĎĪŹoāĶāńāĘāťĀB

Ā@Ė{ĒN8ĆéĀAíÜćĎćĎóLźőíYćŇĎŚéŤāŐź_ČōŹWícā™ź≠ē{ā©āÁďŗĖ÷Ć√é©é°čśāŐēÔď™āŇāŐCoal-to-Olefins

(CTO)ĆvČśāŐąÍéüĒFȬāūéůāĮĀAćŇŹIĒFȬāūĎ“āŃāńāĘāťĀBĆvČśāÕźőíYā©āÁÉĀÉ^ÉmĀ[Éčāūź∂éYāĶĀAÉĀÉ^ÉmĀ[Éčā©āÁÉIÉĆÉtÉBÉďāūź∂éYā∑āťāŗāŐāŇĀAĒ\óÕāÕą»ČļāŐí āŤĀB

Ā@Ā@Ā@ČőóÕĒ≠ďdĀ@Ā@100MW

Ā@Ā@Ā@źőíYÉxĀ[ÉXāŐÉĀÉ^ÉmĀ[ÉčĀ@180ĖúÉgÉď

Ā@Ā@Ā@ÉĀÉ^ÉmĀ[Éčā©āÁāŐÉIÉĆÉtÉBÉďĀ@60ĖúÉgÉď

Ā@Ā@Ā@āoādĀ@30ĖúÉgÉď

Ā@Ā@Ā@āoāoĀ@31ĖúÉgÉď

Ā@Ā@Ā@ÉuÉ^ÉďĀ@94źÁÉgÉďĀ@āŔā©

Ā@ź_ČōŹWícāÕäýā…ćūĒN8ĆéĀAďĮā∂ā≠ďŗĖ÷Ć√é©é°čśÁĹéĘĎĹézĀiÉIÉčÉhÉXĀjésāŇźĘäEāŇŹČāŖāńźőíYāūíľźŕČtČĽāĶāńćžāťźőíYČtČĽĖŻāŐÉvÉČÉďÉgāŐĆöź›āūénāŖāńāĘāťĀBÉAÉĀÉäÉJāŐHITčZŹpāūégópāĶĀAĎś1äķćHéĖā∆āĶāń970ĖúÉgÉďāŐźőíYā©āÁĀAÉKÉ\ÉäÉď50ĖúÉgÉďĀAÉfÉBĀ[É[ÉčĖŻ215ĖúÉgÉďĀAČtČĽÉKÉX31ĖúÉgÉďĀAÉxÉďÉ[Éďā‚ć¨ćáÉLÉVÉĆÉďā»ā«24ĖúÉgÉďāūź∂éYā∑āťĆvČśĀB

Ā@ź_ČōŹWícāÕā‹āĹĀAćūĒN12Ćéā…É_ÉEā∆āŐä‘āŇĀAźőíYā©āÁÉIÉĆÉtÉBÉďāūź∂éYā∑āťĆvČśāŐāeārāūč§ďĮāŇéņé{ā∑āťĆ_ĖŮāūĆčāŮāĺĀBĎŚčKĖÕā»ÉIÉĆÉtÉBÉďÉvÉČÉďÉgĆöź›āŐāĹāŖāŐĆoćŌźęĀAésŹÍē™źÕĀAē®ó¨ĀAčZŹpďôāūĆüďĘā∑āťĀBóßínāÕŤĚźľŹ»ěĺó—ésāŐčŖē”āŇĀA2005ĒNĎśāPélĒľäķā…ĆüďĘāūäJénāĶĀAĒNĖĖā…ŹIā¶āťó\íŤĀB

Ā@ź_ČōŹWícāÕ1995ĒNā…ź›óßā≥āÍāĹćĎóLäťč∆āŇĀAźĘäEāWĎŚíYďcāŐąÍā¬ā∆ā≥āÍāńāĘāťź_ē{ďĆŹüćzčśĀiďŗĖ÷Ć√é©é°čśā∆ŤüźľŹ»ā…ā‹āĹā™āťĀjāŐäJĒ≠ĀEČ^ČcāūíSďĖāĶāńā®āŤĀAä÷ėAéĖč∆ā∆āĶāńďSďĻĀAĒ≠ďdĀAíôíYź›ĒűĀAóAĎóź›ĒűāūČ^ČcāĶāńāĘāťĀB

Ā@ā»ā®āmādācānĀiźVÉGÉlÉčÉMĀ[ĀEéYč∆čZŹpĎććáäJĒ≠č@ć\ĀjāÕź_ČōŹWícāŐóvźŅā…āśāŤĀAāPāXāXāXĒNāTĆéāŐďķíÜćāčČéĖĖĪÉĆÉxÉčČÔčcāūĆoāńź_ČōŹWícā∆äÓĖ{č¶íŤŹĎāūíųĆčāĶĀAāmādācānākÉvÉćÉZÉXā…äÓā√ā≠ź_ČōíYČtČĽÉvÉČÉďÉg(5,000t/d)āŐāeārāūéņé{āĶāńāĘāťĀB

Ā@ā‹āĹÉCÉďÉhāŐāfāĀāČāĆĀiGas

Authority of India Ltd ĀjāÕćŇčŖĀAŤüźľČōéRČĽćHā∆āŐä‘āŇŤüźľŹ»āŇźőíYĀ[ÉĀÉ^ÉmĀ[ÉčĀ[źőĖŻČĽäwāŐź›ĒűāūĆöź›ā∑āťäoŹĎāūíųĆčāĶāĹĀBć°Ć„É|ÉäÉIÉĆÉtÉBÉďďôāŐź∂éYāŐāeārāūéņé{ā∑āťĀB

Ā@ć°Ćé1ďķĀACoal Research Institute

āŐĖkčěéxēĒā∆ĒJČńČŮĎįé©é°čśāŐćĎČcĒJČńźőíYŹWícā™č§ďĮāŇĒJČńźőíYŹWícĀEźőíYČĽäwÉäÉTĀ[É`ÉZÉďÉ^Ā[āūź›óßāĶāĹĀBāQāWāWČ≠źlĖĮĆ≥āūďäā∂āńďžÉAāŐÉTÉ\Ā[Éčé–āŐźőíYä‘źŕČtČĽčZŹpāŇźőíYČtČĽāūćsā§ĆvČśāŇĀA320ĖúÉgÉďāŐźőĖŻźĽēiāūź∂éYā∑āťĀBĆĽć›FSāŐéņé{íÜāŇĀA2008ĒNā…Ćöź›āūäJénāĶĀA2011ĒNā‹āŇā…ÉXÉ^Ā[Égā≥āĻāťć\ĎzĀB

Ā@Ė{ĒN4Ćéā…āÕFoster Wheeler

ā™ÉTÉ\Ā[Éčé–čyā—íÜćĎϧÉpĀ[ÉgÉiĀ[ĀiŤüźľŹ»āŐź_ČōźőíYČtČĽé–ā∆ĒJČńČŮĎįé©é°čśāŐLuneng

Energy and High Chemistry Investment GroupĀjā∆āŐä‘āŇĀA

ŤüźľŹ»ā∆ĒJČńČŮĎįé©é°čśāŇēvĀXĀAďķó āWĖúÉoÉĆÉčāŐCoal-to-Liquids

(CTL)ź›ĒűĆöź›āŐąÍéüāeāréņé{āŐĆ_ĖŮāūíųĆčāĶāńāĘāťĀB

Ā@ďŗĖ÷Ć√é©é°čśĀAŤüźľŹ»ĀAĒJČńČŮĎįé©é°čśāÕźőíYāŐĖLēxā»ínąśĀB

China Coal Research

Institute http://www.cari.com.cn/en/units.htm

It was founded in 1957

and is a unique and comprehensive research and developing

organization in the coal industry of our country. With over 40

years' development, it has become the national coal science and

technology research center with complete courses and categories,

serialized professional settings, excellent scientific research

stuffs, self-contained scientific research facilities. Till the

end of 1999 the whole institute has 5586 in-service employees

including 3765 specialized technical personnels which

constituting 67.4% of the total, 3 academicians of China

Engineering Institute, 1 consultant of the state council and 1477

personnels having senior title of professional post. The Coal

Research Institute has ever been directly under the domination of

the former Coal Industry Ministry, Fuel Chemistry Industry

Ministry, China Unified Distribution Coal Mine Corporation and

the National Coal Industry Bureau successively. On July 1, 1999,

the Coal Research Institute was restructured into a large-scaled

science and technology enterprise directly under the central

government and become one of large-scaled state backbone

enterprises under the industrial committee of central government

according to No. 18[1999], No.143[1999] and No.38[1999] files

promulgated by the general office of the State Council.

Now the Coal Research Institute has 15 branch institutes

spreading in 11 medium/large cities of our country and its head

office is in Beijing. 7 national inspecting quality centers, 6

quality inspecting centers of ministry class and 1# national

metering station of mine safety are set in the institute. And the

state research center for coal mine safe technology and

engineering, the state research center for water, coal and slurry

engineering and technology and the research center of coal

industry for clean coal engineering and technology are also set

in the Institute.

The China Coal Research Institute mainly engages in the research

of major technology problems and coal basic science in production

and construction of coal industry, including technology

development and extending which is relative to coal production

such as coalfield geoexploration and mine surveying, mine

construction, coal exploitation, excavating mechanization and

coal mine automation, coal mine safety, explosive technology and

so on, also including clean coal technology research and

extending such as coal preparation, section coal process, coal

transportation by pipeline, coal liquefaction and gasification,

water, coal and slurry, coal mine environment protection. It also

engages in research and development, science and technology

service and project task of special construction technique and

equipment of underground construction such as coal mine, tunnel,

building's foundation, city underground and so on.

The China Coal Research Institute is the main unit of the

industry and state for taking key project in science and

technology and also of the industry for technology progress. For

40 years the Institute has obtained over 4000 scientific and

research achievements and has established the complete systematic

technology. Among these achievements, there are 5 invention

awards by state, 700 awards for science and technology progress

by province, ministry and state and 500 items of various patents.

In the period of "The Eighth Plan of Five Years" and

"The Ninth Plan of Five Years", the Coal Research

Institute undertook 74% of key items of coal industry of the

states. These achievements, which have been widely used in the

coal industry, have mades great change in the technology

situation, and put forward the technical progress and industrial

upgrade, and supported the important technical reform in each

development period of the coal industry.

After the reform of scientific and technological system, the

Institute marches into the market with sustainable growth of

economic benefit. At the end of 1999, the Institute had total

assets 14.4 hundred million yuan and gross income 5.12 hundred

million yuan.

In recent years in the achievement order of 4871 natural science

research agencies all over the country which publicized by the

State Science and Technology Ministry. The China Coal Research

Institute keeps ahead of 300 industrial research units for

compositive strength and operation performance.

September 5, 2005 Ā@Sarkaritel.com News and

Features-Corporate News

GAIL Ventures Into

Coal Gasification In China

http://www.sarkaritel.com/news_and_features/sep2005/05gailcoalgas.htm

GAIL (India) Limited is

set to venture into the coal gasification activities in

China. The

company plans to invest in Coal - to Methanol - to

Petrochemical plant in the Shaanxi province.

During his recent

visit to China, Shri Proshanto Banerjee, Chairman and Managing

Director, GAIL along with the GAIL team has agreed to enter into

a Memorandum of Understanding with Shaanxi Huashan

Chemical Industry group.

The two companies

will subsequently consider setting up of a joint venture for

implementation of the proposed project and to set up distribution

and marketing network in China. Shaanxi Chemical is already

operating a fertilizer plant based on old coal gasification

technology and is willing to adopt the modern Shell coal

gasification technology to upgrade their plant. It may be

mentioned that the Shaanxi province is endowed with large

deposits of coal as well as oil and gas reserves.

GAIL will

be using domestic coal to produce synthesis gas or ĀesyngasĀf by using Shell Coal Gasification

Process (SCGP),

which will used for the first time in India. SCGP has an inherent

capacity of handling high ash content and hence is suitable for

Indian coals.

China Chemical Reporter

2005/9/21

CCP Builds PBT Resin Project in Zhangzhou

Ā@Ďšėpí∑ŹtÉOÉčĀ[ÉvĀ@ēüĆöŹ»ŹÕŹB

Recently the

positive ion coordination PBT (polybutylene terephthalate)

project, located at Longchi Development Zone, Zhangzhou city,

Fujian province, southeastern China, invested by China Taiwanese

Chang Chun Group (CCP) started construction in Chang Chun

Chemical (Zhangzhou) Co., Ltd.

The new facility will mainly manufacture phenolic plastics and

PBT resin and is scheduled to come on stream by the end of 2005

with a capacity of 200 t/d. The PBT resin the new facility will

produce is main raw materials for PBT engineering plastics with

the features of heat-resistant, solvent-resistant, high

dielectric strength, easy to mould, and is widely applied in

electronics, automobile sectors.

í∑ŹtÉOÉčĀ[Év

http://www.ccp.com.tw/japanese/nonflash/index.htm

China Chemical Reporter

2005/9/22

10 000 t/a Furfuryl Alcohol Project Puts on Stream Ā@

On September 13,

the 10 000 t/a furfuryl alcohol (ÉtÉčÉtÉäĀ[ÉčÉAÉčÉRĀ[Éč) project completed by Shandong Zhangdian Dongfang

Chemical Stock Co., Ltd. put on stream, with an investment

of RMB30 million.

Adopting the intermittent process and using new catalyst which is

applying the state patent, the yield of products reaches 98%, the

production cost is reduced by 30%, and the furfuryl alcohol

content is more than 99% while furfuraldehyde residue is lower

than 0.3%. Besides, no pollution is discharged, and the used

catalyst can be recovered and reused, cutting down the cost as

well as protecting environment. After the completion of 10 000

t/a furfuryl alcohol project, the sales revenue and net profit in

this company can be added by RMB80 million and RMB4 million per

year respectively.

Zhangdian Dongfang Chemical Factory, founded in 1984, specializes

in homopolymerization , copolymerization, and modification of

acrylamide. Our company was converted into a joint stock company

in 1993. The company also includes two factories and a scientific

institute.

http://www.orientchem.com/

ĀuźlĖĮĖ‘ďķĖ{ĆÍĒŇĀvĀ@2005ĒN9Ćé26ďķ

íÜćĎą„ĖÚāūíÜćĎāŐźŪó™ďIéYč∆ā…

íÜćĎź≠ē{āÕāĪāŐāŔā«ĀAíÜćĎą„ĖÚāŐĒ≠ďWā…ä÷ā∑āťĎSĎŐďIā»ć\ĎzāūämíŤāĶāĹĀBíÜćĎą„ĖÚāŐĆĽĎ„ČĽā…ĆŁāĮāĹĒ≠ďWāÕĀAí∑äķďIā»źŪó™ďIĒCĖĪāŇā†āŤĀAíÜćĎą„ĖÚéYč∆āÕíÜćĎā™źŪó™ďIā…ąÁź¨ā∑āťéYč∆ā∆ā»āťĀB

25ďķā…äJā©āÍāĹĀuĎś2ČŮíÜćĎą„ĖÚĆĽĎ„ČĽćĎćŘČ»äwčZŹpĎŚČÔĀvāŇĀAČ»äwčZŹpēĒāŐŹôä•ČōēĒí∑āÕĀAĀuíÜćĎź≠ē{āÕíÜćĎą„ĖÚāŐĆĽĎ„ČĽāūĀAČ»äwčZŹpāŐĒ≠ďWāŐóDźśóŐąśā∆āĶāńĀAā∑āŇā…ćĎČ∆íÜí∑äķČ»äwčZŹpĒ≠ďWĆvČśā…ź∑āŤćěāŮāĺĀvā∆Źqā◊āĹĀBČ»äwčZŹpēĒāŐóęČćČōēõēĒí∑āÕĀAĎŚČÔāŇäÓí≤ēŮćźāūćsāĘĀAĀučŖĒNĀAíÜćĎą„ĖÚéYč∆āūźŪó™ďIéYč∆ā∆āĶāńĒ≠ďWā≥āĻĀAĒ≠ďWāŐä¬čęā√ā≠āŤĀAČ»äwƧčÜāŐč≠ČĽĀAéYč∆āŐĒ≠ďWĎ£źiĀAčZŹpāŐÉOÉĆĀ[ÉhÉAÉbÉvāŐČŃϨā∆āĘāŃāĹäeēŻĖ āŇĎŚāęā»ź¨Č āūŹ„āįāńāĘāťĀvā∆Źqā◊āĹĀB

ďķĖ{ĆoćŌźVē∑Ā@2005/10/7

íÜćĎćĎóLźőĖŻāQé–Ā@ÉGÉNÉAÉhÉčĖŻďcāŗĒÉéŻĀ@í≤íBąņíŤČĽāūĎ_ā§

Ā@íÜćĎāŐćĎóLźőĖŻĎŚéŤāQé–ĀAíÜćĎźőĖŻďVĎRčCŹWíc(CNPC)ā∆íÜćĎźőĖŻČĽćHŹWíc(ÉVÉmÉyÉbÉN)āÕč§ďĮāŇÉJÉiÉ_āŐźőĖŻČÔé–ÉGÉďÉJÉiā™ēŘóLā∑āťďžēńÉGÉNÉAÉhÉčāŐĖŻďcƆČvāūĒÉéŻā∑āťāĪā∆āūĆąāŖāĹĀBĒÉéŻäzāÕāPāSČ≠āQźÁĖúÉhÉč(ĖŮāPāTāVāOČ≠Č~)ĀBíÜćĎāŐźőĖŻĎŚéŤā…ā∆āŃāńÉJÉUÉtÉXÉ^ÉďāŇāŐĖŻďcƆČvā…ĎĪā≠äCäOāŇāŐĎŚĆ^ĒÉéŻĀBÉGÉlÉčÉMĀ[éĎĆĻāŐąņíŤämēŘā÷ĆŁāĮāĹí≤íBźśāŐĎĹólČĽā™ČŃϨāĶāńāęāĹĀB

Ā@CNPCā∆ÉVÉmÉyÉcÉNāŐč§ďĮŹoéĎČÔé–āŇäCäOāŐĖŻďcäJĒ≠éĖč∆āūéŤä|āĮāťÉAÉďÉfÉXźőĖŻā™ÉGÉďÉJÉiāŐēŘóLā∑āťÉGÉNÉAÉhÉčāŐĖŻďcƆČvāūĒÉéŻā∑āťĀBíÜćĎϧā∆ÉGÉďÉJÉiā™āĪāŐāŔā«ćáą”āĶāĹĀBĒNďŗā…ĒÉéŻāūäģóĻā∑āťĆvČśāĺĀB

Ā@ĒÉéŻāŐĎőŹŘā…ā»āťāŐāÕĆīĖŻĖĄĎ†ó ā™ĖŮāPČ≠āSźÁĖúÉoÉĆÉčāŇďķó āVĖúāTźÁÉoÉĆÉčāūź∂éYā∑āťĖŻďcā‚ÉpÉCÉvÉČÉCÉďā»ā«ĀBÉGÉďÉJÉiā…āśāťā∆ÉGÉNÉAÉhÉčéĎéYāŐĒĄčpāÕíÜäjē™Ėžā÷éĖč∆āūŹWíÜā≥āĻāťźŪó™āŐąÍä—ĀB

íÜćĎāŐźőĖŻČÔé–ā…āśāťäCäOƆČvéśďĺāŐďģāę

| éěäķ |

íÜćĎźőĖŻČÔé– |

ĒÉéŻĀAŹoéĎźś |

| 4Ćé |

CNOOC |

ČŃMEGÉGÉiÉWĀ[āŐäĒéģéśďĺ |

| 8Ćé |

CNOOC |

ēńÉÜÉmÉJÉčĒÉéŻāūífĒO |

| CNPC |

ČŃÉyÉgÉćÉJÉUÉtÉXÉ^ÉďĒÉéŻāūĆąíŤ |

| 9Ćé |

CNPCā»ā« |

ČŃé–ā©āÁÉGÉNÉAÉhÉčĖŻďcƆČvĒÉéŻĆąíŤ |

| ĆüďĘíÜ |

CNOOC |

ćčÉEÉbÉhÉTÉCÉhĒÉéŻāūĆüďĘ |

| ÉVÉmÉyÉbÉN |

ČŃÉnÉXÉLĀ[ĀEÉGÉiÉWĀ[ĒÉéŻĖŕéwā∑ |

Platts 2005/10/11

China's Donghao commissions SM plant, commercial

sales from H2 Oct ć]ĎhŹ»ŹŪŹB

China's Donghao Chemical ďĆĚ› is in the process of commissioning

its 150,000

mt/yr styrene

monomer plant in Changzhou(ŹŪŹB), and hopes to start commercial

sales in late October, a source close to the firm said Tuesday.

Donghao

plans to sell all its styrene in the merchant market.

íćāPĀDPlattsčLéĖāŐé–ĖľĀAésĖľāÕĆŽāŤ

China's Do How

Chemical

is in the process of commissioning its styrene monomer plant

in CangzhouĀ@ĀiüťŹBĀj

āQĀD

Changzhou

Donghao Chemical is located in Changzhou,

Jiangsu Province. Changzhou is neighboured to Jiangyin Cityć]ČA, these areas are the famous

packaging base in China, even the worldwide. The demands for

EPS is huge.

2007/6 Ā@Ē\óÕ200źÁÉgÉď

Ā@Ewing Management buys China's

SM maker Donghao Chemical

Ā@Ā@Āę

Do How Chemical owns

a 210,000 mt/year SM plant at Changzhou. That plant is

currently being expanded with the addition of a new 200,000 mt/year line. Construction is scheduled for

completion by the end of 2008.

Platts 2006/4/10

China's construction

sector will absorb new SM capacity: Do How

Poor styrene monomer cash margins have not deterred China's

Do How Chemical (Donghao) from a planned expansion of its

plant in Changzhou as the firm expected the construction

sector in China's northern provinces to absorb its additional

output, a company source said Monday. Do How will take down

its SM plant later this month for debottlenecking. Sources

close to the firm gave varied accounts of the plant's

proposed new capacity, ranging between

180,000 mt/year to 216,000 mt/year.

The plant currently has the capacity to produce 150,000

mt/year,

but has rarely operated beyond 80% of its capacity since it

started commercial production in December 2005.

Asia Chemical weekly

2003/3/17

Changzhou Donghao

plans to up styrene

Changzhou Donghao

Chemical plans to double its styrene output to 300 000 tonne/

year in Changzhou, Jiangsu, China, at end- 2004 or early

2005, said a company official.

The company plans to start up a 150 000 tonne/year facility

in December 2003 or January 2004. The extra 150,000

tonne/year capacity would start up in the second phase.

The plant, which will use local technology, is to be built in

Changzhou Yangtze Riverside Chemical Park, in Changzhou New

District.

The Rmb300m (US$36.24m) 150,000 tonne/year project is a 50:50

joint venture between Donghao and China Railway United

Materials (Hong Kong). Seventy percent of the feedstock would

be imported.

Part of the styrene output will be used to feed a nearby

expandable PS (EPS) facility, which is due to come onstream

in July. Owned by local company Chengda Chemical, the 60 000

tonne/year plant is expected to be expanded to 120 000 tonne/

year in 2004.

Donghao also produces EPS - 165 000 tonne/year in Jiangying,

Jiangsu.

The company plans to add a new 190 000 tonne/year EPS line,

which is slated to start production in November this year.

The new line will raise the company's total EPS production to

355 000 tonne/year.

The official said the company expects China's imports of

styrene to soar to more than 2.5m tonne this year, up from

1.8m tonne last year. Jiangsu province accounted for about 1m

tonne of the imports last year.

Hong Kong-listed company Kingboard Chemical Holdings is also

planning to produce phenol, acetone and methanol in the park.

China Chemical

Reporter, February, 2003

China Railway

United and Changzhou Donghao launch styrene project.

China Railway United

Materials (Hong Kong) Co., Ltd. and Changzhou Donghao

Chemical Trade Co., Ltd. have recently signed an

agreement on the joint construction of a styrene project

in Xinbei District of Changzhou, Jiangsu Province. It is

another demonstrative project in Binjiang Chemical

Industry Zone, Changzhou City after the project funded by

Hong Kong Kingboard Chemical Industrial Group.

2005/10/13Ā@ďķĖ{ĆoćŌźVē∑ó[äß

ÉTÉnÉäÉďāRāŐąÍēĒƆČvéśďĺĀ@ÉVÉmÉyÉbÉN

íÜćĎāŐćĎóLźőĖŻĎŚéŤĀAíÜćĎźőĖŻČĽćHĀiÉVÉmÉyÉbÉNĀjāÕÉćÉVÉAćĎČcźőĖŻČÔé–āŐÉćÉXÉlÉtÉ`ā©āÁĀuÉTÉnÉäÉďāRĀvćzčśāŐąÍēĒčśČśā…ä÷āĶāńāQāTĀDāPĀďāŐƆČvāūéśďĺāĶāĹĀB

The Moscow Times Ā@March 30, 2007

Rosneft Takes Lead in

Sinopec Deal at Sakhalin

Rosneft has taken majority control of a large offshore field

near Sakhalin Island through a deal signed with China's

Sinopec, Rosneft announced Thursday.

Rosneft and Sinopec, China's No. 2 oil major, are jointly

developing the Veninsky oil project, a part of the Sakhalin-3

block, through Venin Holding.

A subsidiary of state-controlled Rosneft will

hold 74.9 percent

in the holding company, after buying 25.1 percent of

shares from the Sakhalin Oil Company, controlled by the regional

government.

Sinopec

maintained its holding at 25.1 percent in the deal signed Monday,

Rosneft said in a statement.

Venin Holding, in turn, is the sole shareholder in Venineft,

which owns the license to develop Veninsky and operates the

project, the statement said.

Division

of the project's expenditure is flipped, with Rosneft

providing 25 percent of funding and Sinopec 75 percent. Nearly $70 million has been

invested in the field so far.

The deal was signed on the first day of Chinese President Hu

Jintao's three-day trip to Russia.

President Vladimir Putin has said Rosneft and Gazprom would

retain majority control over all offshore projects. The

projects on Sakhalin, in the Far East, are being developed

mainly to feed energy-hungry markets in Asia.

Sakhalin-3's Veninsky block is estimated to hold nearly 170

million tons of oil and 258 billion cubic meters of gas.

Rosneft was awarded the Venineft license in 2003, and signed

a preliminary deal with Sinopec to develop the fields in

August 2005.

Sakhalin-3 comprises four blocks, and Veninsky is the only

one to have been licensed.

Deputy Natural Resources Minister Alexei Varlamov said last

month that the rest of the licenses would be awarded through

auctions by the end of the year.

July 04, 2005

Kommersant

Rosneft Opens

Sakhalin to the Chinese

Ā@Ā@Sinopec to

take part is development of Venin block

Ā@Ā@International

Cooperation

Ā@http://www.kommersant.com/page.asp?idr=1&id=588631

Rosneft signed an

agreement with the Chinese Sinopec petrochemical company on

Friday on the joint development of the Venin block oil and gas

field in the Sakhalin 3 project. Gazprom had also declared its

interest in working with Rosneft but had made no concrete

proposals. A partnership with Sinopec is likely to mean that

Rosneft will keep a share in the Venin block under any

circumstances.

On Friday, in the

course of Russian-Chinese negotiations, Roneft signed a framework

agreement on collaboration with CNPC, the Chinese national oil and gas

company, and a protocol on the foundation of a joint venture for geological

exploration and study of the Venin block field of the Sakhalin 3

project with the Chinese oil and gas company Sinopec.

The oil resources

in the Venin block are preliminarily estimated at 114 million

metric tons ad gas at 315 billion cubic meters. Rosneft received

a license for geological study of the block in April 2003. It is

assumed that the operator of the project will be a specially

founded OOO Veninneft. There are three other blocks besides Venin in the Sakhalin 3 shelf project.

They are the Eastern Odopinsky, Ayashsky and

Southern Kirinsky,

licenses for which are held in an indivisible fund.

China Chemical Reporter

2005/10/3

800 000 T/A Alumina Expansion Project Starts Production in ShanxiĀ@

éRźľŹ»Ā@

The 800 000 t/a

alumina expansion project in Shanxi Branch

China Aluminum Co., Ltd. and the 280 000 t/a electrolytic

aluminum and 2āė300MW power generation project in Shanxi Huaze

Aluminum Power Co., Ltd. were completed and put on stream

in Shanxi Hejin ČÕí√on Sept. 25.

When the existing capacity of 1.4 million t/a alumina in Shanxi

Branch China Aluminum Co., Ltd. is added, Shanxi Hejin will have

a capacity of 2.2 million t/a alumina, 280 000

t/a electrolytic aluminum and 160 000 t/a carbon and a 600MW

power station.

It will become the largest aluminum industry base in China with a

large integrated production chain of alumina and electrolytic

aluminum.

China Chemical Reporter

2005/10/14

SAWS and Dow Chemical Join Forces to Advance the Safe Management

of Chemicals

http://www.ccr.com.cn/news_view.asp?ID=764

On October 13, 2005, the

State Administration of Work Safety (SAWS) and the Dow Chemical

Company (Dow) signed a Letter of Intent for a joint, national

demonstration project on the safe management of hazardous

chemicals.

The 3-year project is aimed at fostering and promoting a better

understanding and awareness among small- and medium-sized

enterprises (SMEs) from various industries nationwide on the

importance of chemical safety management. SMEs will be selected

from the sectors of manufacturing, storage, transportation and

use of hazardous chemicals across China. Demonstrations will be

conducted jointly by SAWS and Dow to introduce best practices

regarding the safe management of hazardous chemicals. In

addition, auditing will also be carried out to gauge performance.

To support the project and as part of its on-going commitment to

supporting sustainable development in China, Dow will contribute

a total of RMB6 million in the next three years. The Chinese

Association of Technical Chemical Safety & Hygiene will be

responsible for the fund management. The National Registration

Center for Chemicals of SAWS will be responsible for the day to

day management and execution of the project which runs from

January 2006 to December 2008.

China Chemical Reporter

2005/10/18

500 000 T/A Ammonia Project of Yankuang Group Launched in Guizhou

čMŹBŹ»

A ceremony for

launching the 500 000 t/a ammonia project of Yankuang Group located was

held in Kaiyang, Guizhou province(čMŹBŹ»äJóz) on Sept. 28.

The 500 000 t/a ammonia project has a total investment of RMB2.0

billion. It is jointly funded by Yankuang Group and Guizhou Kailin

Group located

in Guiyang, Guizhou provinceĀičMŹBŹ»čMózĀj. It is a leading project in

Guiyang City Kaiyang Phosphorus, Coal and Chemical (National)

Ecological Industry Demonstrative Base. The project will be

completed and put on stream in 2008 and the supply shortage of

ammonia in Guizhou will be bridged at that time.

Yankugn

Group(http://www.yanzhoucoal.com.cn/) is located in Jining City,

Shandong Province.

Yankuang Croup Co., Ltd is an extra-large SOE with total

assets of RMB 22.844 billion and more than 50 subsidiaries.

Yankuang Croup is engaged in coal production and sales , coal

chemical, civil engineering, etc with annual total sales

income of RMB 11.258 billion. It is one of the 120

enterprises for experiment of large enterprise groups as

designated by the State Council. Its sub-company, Yangzhou

Coal Mining Company Limited, bas been successfully listed on

New York Stock exchange, Hong Kong Stock Exchange and

Shanghai securities Exchange respectively in 1998.Thanks to

the comprehensive mechanical top caving technique, the annual

raw coal output of the Group has reached 40 million tones and

annual export volumn reached 15 million tones. It is the

largest coal producer and trader in most prosperous eastern

China and one of the biggest coal exporter in China.

Guizhou

Kailin (Group) Corp., Ltd. (http://www.gzkl.com/) was founded in 1958,(formerly

named "Guizhou Kaiyang Phosphorous Mine Bureau")Ā@As a large state-owned mining

enterprise,Guizhou Kailin Group Ltd. was uniquely authorized

by the government to exploit phosphorous ore of Kaiyang

mineral Area in Guizhou Province.

Guizhou Kailin Group has been supplying phosphorous ore raw

material to the domestic large manufactures of DAP and high

density phosphorous compound fertilier all along since the

past 40 years. And meanwhile ,Kailin has also been devoting

to develop its own phosphoroue fertilier industry. So far

,Kailin has produced a variety of phosphorous fertilizers

such as DAP,TSP,MAP,NPK,etc....

Guizhou Kailin Group Import & Export Corp.,founded in

1995,fully represent Guizhou Kailin Group to conduct

international business,especially to export its own products

and import the raw material as well as related

equipments.Uptill now,Kailin has achieved to export its

phosporous products to South Korea,Japan,South-East

Asia,USA,South Africa,Oceania,etc...

A long -term and stable business relation has been

eatablished with DongBu Group,south Korea and Ravensdown

Fertilier, New Zealand.

2005/10/17 Asia Chemical

Weekly

China's boom spurs

foreign investment on Chemicals storages

Over the past years, the accelerated growth in China's chemicals

demand and projects investment, and the rising volume of liquid

chemicals transportation, has stimulated foreign investment on

the chemicals logistics services, particularly the liquid

chemicals storages.

Royal Dutch Vopak and Germany based Oiltanking are the top 2

worldwide independent storage operators for oils and chemicals,

both of them have investment activities in China market.

Vopak has five terminals in China,

which located in Tianjing (ďVí√), Lanshan, Shandong Province(éRďĆóíéR), Ningbo(ĒJĒg), Xiamen(õķĖŚ) and Caojing (ĎÜķŻ), Shanghai.

Vopak Caojing terminal is a 50:50 jv between Vopak and Shanghai

Chemical Industry Park Development Co. (SCIPDC). The jv has 225

000 cubic metres of chemicals storage capacity, and it would

expand to 700 000 cubic metres(cbm) in 2010. This terminals and

storage facilities are providing services for BASF and SECCO.

Currently, Vopak plans to build China's six terminal in

Zhangjiagang(í£Č∆ć`), Jiangsu Province. In the first

phase, Vopak would build 200 000 cbm chemicals storage capacity

in Zhangjiagang.

Also, Oiltanking has started the first phase

construction for the Chemicals storages facilities in Daya Bay,

Huizhou, Guangdong Province since July 2005. The first Phase will

comprise four tanks with a total capacity of 15 550 cbm.

OTDB near by the ethylene complex of CNOOC/Shell, It would

service for companies in Huizhou Daya Bay Petrochemical Park.

OTDB has signed a long-term agreement with Mitsubishi Rayon

(Huizhou) MMA Corporation, to cater for all their off-site

storage and handling requirements for the MMA plant.

Besides, another leading chemicals logistics services - Norway

based Odfjell - plans to associate with China's

EPS producer Jiangyin Garson(Č√ź∑) to build a chemical terminal in

Jiangyin(ć]ČA), Jiangsu Province. Both sides

have formed a jv named Odfjell Garson, which is 55% owned by

Odfjell and 45% by Garson.

The terminal will have about 80 000 cbm of chemical storage

capacity and two berths, both of which can accommodate ships up

to 50 000 deadweight tonne (dwt).

With the rapid development of chemical industry in China, the

demands for chemicals logistics and storages services would be

grown greatly in the coming future.

2005/10/23 Asia

Chemical Weekly

Odfjell started construction for chemical terminal in

Jiangyin

On 16 October, Norwegian based Logistics services provider

Odfjell started the construction for the chemical terminal in

Jiangyin Economic Development Zone, Jiangyin, Jiangsu

Province.

The chemical terminal is owned by the 55:45 jv between Odfjell and

Jiangyin Garson.

In the first phase, the total investment would be about USD

30 million; it will have two 50 000 dwt berths, and 100 000

cbm of chemical storage capacity. The construction is

expected to complete by the end of 2006 or early 2007.

The terminal is located on the south bank of the Yangtze

River. In the future, the chemical terminal would be expanded

according to the market demands.

Jiangyin Garson is a private EPS producer. Currently, it has

150 kt/a capacity of EPS in Jiangyin, Jiangsu province.

The under-building terminal would become Odfjell's chemical

logistics base in lower Yangtze River. After the terminal is

completed, it can store the SM feedstock for Garson's nearby

EPS plant, and provide chemical storage services for other

producers and traders.

ďķĖ{ĆoćŌźVē∑Ā@2005/10/25

äŘćgĀAéRďĆŹ»ā∆ēÔäáíŮĆgĀ@ā‹āłďķĖ{ā…éÜāŐĒŐé–ź›óß

Ā@äŘćgāÕíÜćĎĀEéRďĆŹ»ā∆ĆoćŌĀEĖfą’ē™ĖžāŇēÔäáíŮĆgā∑āťāĪā∆āŇćáą”āĶāĹĀBďĮŹ»āŇč@äBā‚ďdč@ĀAČĽäwēiā»ā«āŐźĽĎĘčíď_āūĆöź›ā∑āťéĖč∆ā…äŘćgā™źŌč…éQČŃĀAďĮŹ»ďŗāŐäťč∆ā™ďķĖ{ā»ā«āŇéĖč∆ďWäJā∑āťćŘā…āŗč¶óÕā∑āťĀBĎśąÍíeā∆āĶāńāPāPĆéā…éRďĆŹ»āŐźĽéÜÉĀĀ[ÉJĀ[ĀAéRďĆĚŪĖ¬(É`ÉFÉďÉ~Éď)éÜč∆ÉOÉčĀ[Évā∆č§ďĮāŇďķĖ{āŇéÜĀEĒ¬éÜāŐĒŐĒĄČÔé–ĀACMJ(ďĆčěĀEäĪĎ„ďc)āūź›óßā∑āťĀBāQāTďķā…ēÔäáďIč¶óÕč¶čcŹĎāūíųĆčā∑āťĀB

éRďĆĚŪĖ¬éÜč∆ŹWícĆ“ÉtÉFÉďóLĆņĆŲéi Shandong Chenming Paper

Holdings Limited

éŚóvč∆ĖĪāÕč@äBźĽéÜĀAĒ¬éÜčyā—éÜĆīóŅāŐź∂éYāŇĀA1995ĒNā©āÁ2001ĒNā…ā©āĮāńėAĎĪ7ĒNĀAĎSćĎč∆äEÉgÉbÉvā…óßā¬íÜćĎćŇĎŚčKĖÕāŐźĽéÜÉĀĀ[ÉJĀ[ĀBźVē∑éÜā‚É_ÉďÉ{Ā[Éčā™éŚóÕźĽēiĀBďdóÕāūíÜźSā∆āĶāĹÉGÉlÉčÉMĀ[āŗéŤä|āĮāťĀBĆīćřóŅāūóAďŁā…óäāŃāńā®āŤĀAóLĆÝďIā»ÉRÉXÉgÉRÉďÉgÉćĀ[Éčā™ČŘĎŤĀB

Ā@

Platts 2005/10/24

PetroChina's

Lanzhou revises upward planned No 2 cracker capacity

China's Lanzhou

Petrochemical has revised upward the planned capacity of its No 2

ethylene plant, currently under construction, to 450,000 mt/yr

from the original plan of 360,000 mt/yr, a source at the company

said Monday. The revision would allow Lanzhou, a subsidiary of

PetroChina, to reap greater economies of scale from a bigger

cracker.

2005/10/25Ā@Asia Chemical Weekly

Lanzhou hikes

ethylene expansion capacity and confirms derivatives projects

Lanzhou Petrochemical ĀNC a subsidiary of PetroChina - has

revised the ethylene expansion plan from the early declared

360 kt/a to current 450 kt/a, and confirmed the derivatives

projects and capacities.

The total investment for the 450 kt/a complex is about USD

770 million (RMB 6.3 billion). Construction for the project

was started on Q2 this year, and it is expected to be

completed by the end of 2006.

Lanzhou Petrochemical has a 240 kt/a ethylene cracker in

existence. The new added project is the No 2 ethylene plant.

After the project completed, Lanzhou petrochemical will have

total ethylene capacity of 690 kt/a.

Also, the derivatives projects of the complex were confirmed,

there are

-All density PE (HDPE/LLDPE swing) 300 kt/a (Univation

technology)

-LDPE 200 kt/a (Basell technology)

-PP 300 kt/a (Basell technology)

-Gasoline hydrogenation 340 kt/a, and

-Butadiene extraction 90 kt/a

PetroChina aims to sale the products from Lanzhou

petrochemical to midland and Southwest China market.

China Chemical

Reporter 2005/10/24

Yunan Launches DME

Project Ā@Ā@Č_»

The dimethyl ether (DME)

project will be launched in Yunnan province, southern China

recently. With the total investment of RMB970 million and the

production capacity of 150 000 tons/a, this project is

implemented by Yunan Jiehua Group Chem Co., Ltd and will be

completed in the end of 2007. When the project put into stream,

it is estimated that 1.1 million poor coal will be consumed per

year, and the additional value of poor coal will be quintupled

with annual sales revenue of RMB447 million.

ďķĖ{ĆoćŌźVē∑Ā@2005/11/1

íÜćĎźőĖŻĀ@āRéqČÔé–

Ź„ŹÍĒpé~Ā@ĎSäĒĀAāWāXāOČ≠Č~āŇĒÉéśāŤ

Ā@íÜćĎāŐźőĖŻĎŚéŤĀAíÜćĎźőĖŻďVĎRčC(ÉyÉgÉćÉ`ÉÉÉCÉi)āÕāRāPďķĀAíÜćĎĖ{ďyā‚ćĀć`ā»ā«ā…Ź„ŹÍā∑āťéqČÔé–āRé–āŐŹ„ŹÍāūĒpé~ā∑āťĆvČśāūĒ≠ē\āĶāĹĀBéqČÔé–āŐäĒéģāūā∑ā◊āńĒÉāĘŹ„āįĀAÉOÉčĀ[ÉvāŐĆoČcéĎĆĻāŐĆÝó¶óėópā»ā«āūĖŕéwā∑ĀBíÜćĎāŇźeČÔé–āŐäĒéģĒÉāĘéśāŤā…āśāťŹ„ŹÍĒpé~āÕŹČāŖāńā∆ā›āÁāÍāťĀB

Ā@ź[ÉZÉďŹōĆĒ霹ݏäā…Ź„ŹÍāĶāńāĘāťč—ŹBźőČĽā∆ó…ČÕčŗĒnĖŻďcāŐāQé–ĀAź[ÉZÉďā∆ćĀć`ĀAÉjÉÖĀ[ÉąĀ[ÉNā…óaĎűŹōĆĒāūĆŲäJāĶāńāĘāťčgó—ČĽäwćHč∆āŐäĒéģāūĆŲäJĒÉāĘētāĮā∑āťĀB

Platts 2005/11/14Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@PetroChina case

Sinopec to

privatize Zhenhai Refining & Chemical Co

Chinese oil company

Sinopec Corp plans to privatize Sinopec Zhenhai Refining &

Chemical Company Limited íŃäCóýĖŻČĽćHin a deal worth HK$7.672-bil

($989-mil), the company said Monday. The "merger by

absorption" is to be effected by a wholly-owned subsidiary

of Sinopec, Ningbo Yonglian.

Sinopec already

owns 1.800-bil or 71.32% of ZRCC's 2.524-bil shares. Ningbo

Yonglian is to be set up to to pay a cancellation price of HK$10.60/share

in cash to the holders of ZRCC's 724-mil publicly-traded H

shares. The completion of the merger is subject to regulatory and

ZRCC shareholder approvals.

The company has a

crude oil processing capacity of 18.5-mil mt/yr.

Downstream Zhenhai

also has a 650,000 mt/yr paraxylene plant and a 200,000 mt/yr of

polypropylene unit. Zhenhai currently has plans to build a

naphtha cracker with an ethylene capacity of 800,000 mt/yr by

2010, according to industry sources.

2005/10/31 Qenos

Sale of Qenos to

ChemChina

http://www.qenos.com/internet/home.nsf/vwwebpages/aboutqenos-articles-news&informationsaleofqenostochemchina?opendocument

Qenos is pleased to announce that

international chemical group China National Chemical Corporation

(ChemChina) has signed a Heads of Agreement with the companyĀfs shareholders, Orica and

ExxonMobil, to purchase the Qenos business. The agreement is

subject to required regulatory approvals in Australia and China,

with settlement targeted to take place in early 2006.

ChemChinaāÕćūĒN5Ćéā…ćĎČcāŐChina National Blue Star

(Group) ĀióēźĮÉOÉčĀ[ÉvĀjā∆ China Haohua Chemical

Industrial (Group) (Ě›ČōČĽćHĀjā™ďĚćáāĶāĹāŗāŐĀB

āXāXĒNāPāOĆéĀ@ÉPÉmÉXé–ĀiQenosĀjź›óßĀiÉGÉNÉ\ÉďÉāĀ[ÉrÉčāTāRĀďĀAÉIÉäÉJāSāVĀďĀj

Ā@ÉIÉäÉJé–ĀiOricaĀ@čĆāhābāhÉIĀ[ÉXÉgÉČÉäÉAĀjā∆

Ā@ÉGÉNÉ\ÉďÉāĀ[ÉrÉčĀ@čĆÉPÉÄÉRÉAé–ĀiKemcorĀ@ÉGÉNÉ\ÉďÉPÉ~ÉJÉčā∆ÉāĀ[ÉrÉčÉPÉ~ÉJÉčāŐź‹ĒľŹoéĎĀjā™ĀA

Ā@óľé–āŐźőĖŻČĽäwéĖč∆ďĚćá

At Qenos we use

Australian oil and gas feedstocks from Bass Strait and the

Moomba Basin. We employ 900 people. Our plants in Sydney and

Melbourne produce olefins and a full range of polyethylene

products (HDPE, LDPE and LLDPE). We also supply a diverse

range of specialty polymers. That makes Qenos a vital link in

the Australian manufacturing chain, supplying industries that

employ hundreds of thousands of people.

źĽēiĀF

Olefins/Olefines:

Approximately 500,000 tonnes ethylene, 50,000 tonnes

propylene, 20,000 tonnes butadiene

Elastomers:

12,000 tonnes BR,

Polyethylene:

About 180,000 tonnes HDPE, 90,000 tonnes LDPE and 120,000

tonnes of LLDPE

Qenos Imported

Product Range

Qenos acts as

local agent for a wide range of imported polymers

manufactured by ExxonMobil Chemical, Dexco Polymers, Kuhmo

and BASF. These products include: EPDM; butyl and nitrile

rubber; metallocene PE; EVA; EMA; EAA/ionomer; PP; BOPP;

polyester resins; bitumen modifiers; tackifying resins;

polymer modifiers; styrenic thermoplastic rubbers,

thermoplastic elastomers, styrene butadiene rubbers and PIB.

Dexco Polymers LP, a limited

partnership of affiliates of the Dow Chemical Company and

ExxonMobil Chemical Company, produces both SIS and SBS products from its dedicated facilities

in Plaquemine, Louisiana.

ĀuźlĖĮĖ‘ďķĖ{ĆÍĒŇĀv2006ĒN4Ćé4ďķ

íÜćĎČĽćHĀAćčŹBćŇĎŚāŐÉGÉ`ÉĆÉďÉĀĀ[ÉJĀ[āūĒÉéŻ

ĎŚéŤČĽäwÉĀĀ[ÉJĀ[ĀEíÜćĎČĽćHŹWícĆŲéiāÕ3ďķĀAÉIĀ[ÉXÉgÉČÉäÉAćŇĎŚāŐÉGÉ`ÉĆÉďÉĀĀ[ÉJĀ[āŇā†āťQenosé–āŐäģĎSĒÉéŻā…ź¨ĆųāĶāĹĀBíÜćĎČĽćHāÕāĪāÍā…źśóßāŅĀAÉOÉčĀ[ÉvéPČļāŐóēźĮĆŲéiāūí ā∂āńĀAźĘäEĎś2āŐÉĀÉ`ÉIÉjÉďÉĀĀ[ÉJĀ[ĀEēßAdisseoé–āŐĒÉéŻā…āŗź¨ĆųāĶāńāĘāťĀB

China Chemical Reporter

2005/11/3Ā@Ā@Ā@Ā@800

000 t/a alumina expansion project in Shanxi Branch China Aluminum

Co

NDRC Approves

Aluminum Oxide Project of Jinbei Aluminum

1

million t/a aluminum oxide project of Shanxi Luneng Jinbei

Aluminum Industry Corp. (SLJAIC) has recently been

examined and approved by the National Development and Reform

Commission. Up till now, the construction for the project has

been accelerated further.

So far, SLJAICĀfs 1 million t/a aluminum oxide

project is the largest scale project of aluminum industry for

domestic preliminary construction.

In a bid to control

further exportation of electrolytic aluminum, starting on August

22nd the Central Government of China had decided to cancel the

preferential policy for trading processed aluminum oxide. In

2004, around 24.26% of imported aluminum oxide was used in

processing trade in China. (CCR 2005 No.2) It sounds not good for

SLJAIC.

2005/11/1

Interfax-ChinaĀ@Ā@Ā@Ā@Ā@Ā@

Construction of

Shanxi alumina project destroys Great Wall beacon tower and

ancient tombs

The Great Wall

is one of the best-known symbols of China and Chinese law

strictly protects it. However, in late 2004, despite

widespread criticism, the Shanxi Luneng

Jinbei Aluminum Industry Corp. (Luneng), leveled a beacon

tower of the Great Wall, which was built during the Ming

Dynasty, during the construction of a major project, a one mln tons

alumina production line.

The

600-year-old tower, in Yuanping Town within Yizhou City of

central Shanxi Province, was razed to the ground during the

three-day grading of the site. During the construction, about

30 ancient tombs of the Han Dynasty, nearly 2000 years old,

were also destroyed. An official who refused to reveal his

name with the Cultural Relics Bureau of Shanxi Province

confirmed their destruction to Interfax.

"The

beacon tower, which is now completely gone, was a provincial

ancient cultural relic unit in our province," the

official explained. He said because the administration and

Luneng were not able to agree on a specific figure for the

funding necessary to protect the cultural relics, the two

signs did not make any arrangement or deal to handle the

issue.

China Chemical Reporter

2005/11/8

Sichuan Ally Completes

Ethanol Project in Thailand

The 30 000 t/a

absolute(Ė≥źÖ) ethyl alcohol (ethanol) project

contracted by Sichuan Ally High-Tech Co., Ltd. headquartered in Chengdu, Sichuan

provinceélźžŹ»ź¨ďs, with Thailand Thaiyuan

Co., Ltd. conducted

the successful wet commissioning recently.

The 30 000 t/a

absolute ethanol project is one of the enriching engineering

projects promoted by the King of Thailand. It makes use of the

local abundant cassava (ÉLÉÉÉbÉTÉo=É^ÉsÉIÉJ) as raw material to directly

produce absolute ethanol with a purity of over 99.5% and cosmetic

ethanol with a purity of 99.9%. This is the first project of

producing absolute ethanol that Thailand introduced the complete

set of technology and equipment from China.

The success of the

Thailand Thaiyuan project is the third project that designed by

Sichuan Ally after the two projects of the 30 000 t/a absolute

ethanol plant of Tianjin Luyuan and 30 000 t/a absolute ethanol

plant in WeifangąŘĖV, Shandong province were

commissioned successfully. It is also a successful demonstration

that the company is developing from convention to innovation. Now

the company has accumulated a great deal of experiences in

design, technology, construction, running and investment return

of absolute ethanol plant.

China Chemical Reporter

2005/11/7

PVC Preservative

Film Prohibits DEHA

The General

Administration of Quality Supervision, Inspection and Quarantine

of China (GAQSIQ:ćĎČ∆éŅó äńď¬ĆüćłĆüČuĎćč«) released on October 25 the

special inspection results for polyvinyl chloride (PVC)

preservative film products from domestic and abroad, and released

the announcement of prohibiting the production, sales and

importation/exportation of PVC food preservative film that

contains what fall short of national compulsory standard such as

DEHA ÉAÉWÉsÉďé_ÉWÉGÉ`ÉčÉwÉLÉVÉč

or excess vinyl

chloride monomer (VCM).

GAQSIQ began to

strengthen the inspection of PVC food preservative film along the

ports and carry out special inspection to producers and products

involving in PVC food preservative film. The investigation

disclosed there are 47 local producers of food preservative film,

of which 41 producers manufacture polyethylene food preservative

film, and 4 producers make PVC preservative film.

GAQSIQ will take

four measures. Firstly, the importation and exportation of PVC

food preservative film that contains what fall short of national

compulsory standard such as DEHA or excess VCM are forbidden. The

use of DEHA in PVC food preservative film production is

forbidden. The sales of polyvinyl chloride food preservative film

that contains DEHA or excess VCM is forbidden. The direct package

for meat, cooked food or lipidic food with PVC preservative film

is forbidden. Secondly, GAQSIQ will strengthen the supervision of

importation/exportation, production, sales and use of food

preservative film. Thirdly, the product standard for food

preservative film will be designed. Fourthly, PVC food

preservative film will be listed in the importation/exportation

law catalog.

ďķĖ{āŇāÕĀCźHēiópďrā…ĀCācādāgā`ĀiÉAÉWÉsÉďé_ÉWÉGÉ`ÉčÉwÉLÉVÉčĀjāÕĎäďĖĎOā…č÷é~ā…ā»āŃāńāťĀB

écĎ∂VCMāÕďķĖ{āŇāÕĖ‚ĎŤā…ā»āťāśā§ā»āŗāŐāÕŹoČŮāŃāńāĘā»āĘĀB

2005/11/11 Asia Chemical

Weekly

Lucite started commercial

production for MMA project in SCIP

On 25 Oct, Lucite held an official ceremony for the

commercial production of 100,000 tonne/year MMA project in

Shanghai Chemical Industry Park (SCIP), Caojing, Shanghai.

Total cost for the

100,000 tonne/year MMA project is USD 110 million. The MMA unit

has started trial production since May with the operate rate

ranging from 20% to 70%. But according to industry source, the

trial production was unstable until Oct

The MMA unit is

neighboring with Secco, and the feedstock comes from Secco's

ethylene complex. Secco has started a 260,000 t/a

acrylonitrile (ACN) unit, and its by-product hydrogen cyanide

(HCN) is the raw material for Lucite to produce MMA through the

acetone cyanohydrin (ACH) process.

According to

Lucite, the plant's current capacity is 100,000 t/a and with

opportunities to expand to 150,000 t/a as demand grows.

Besides Lucite's

MMA unit, Mitsubishi Rayon Chemcial (MRC) is building a 90,000

t/a MMA plant in Daya Bay, Huizhou, Guangdong Province. The plant

is operated by Huizhou MMA Co., a wholly owned subsidiary of MRC.

It will ! cost USD 100 million and is scheduled for completion in

Apr. 2006.

Currently, the MMA

market in China for MMA is about 200,000 per year, and it is

expected to reach 260,000-270,000 per year by 2008.

éOēHÉĆÉCÉąÉďāŐ100%éqČÔé–āŐĆbŹBĆbēHČĽź¨ĀiHuizhou

ālālā`ĀjĀiābāSíľé_Ė@ĀjāÕÉČÉtÉBÉlĀ[ÉgĀ[āPāūíÜäCÉVÉFÉčźőĖŻČĽäwā©āÁčüččāūéůāĮĀAĆīóŅāŐÉCÉ\ÉuÉ`ÉĆÉďāūíäŹoāĶāĹĆ„ĀAécāŤāŐÉČÉtÉBÉlĀ[ÉgĀ|āQāūíÜäCÉVÉFÉčā…ē‘čpā∑āťĀB

ā»ā®ĀAíÜćĎāŇč£ćáā∑āťóľé–āÕĖ{ĒNāUĆéĀAďäéĎāūē™íSāĶāńĖkēńā∆ÉAÉZÉAÉďāŇāQāUĖúÉgÉďčKĖÕāŐālālā`ÉāÉmÉ}Ā[ÉvÉČÉďÉgāūĆöź›ā∑āťāĪā∆āŇćáą”āĶāĹĀBĖkēńāŇāÕéOēHÉĆÉCÉąÉďā™ābāSĖ@āŇāPāSĖúÉgÉďāūĀAÉčĀ[ÉTÉCÉgā™ÉVÉďÉKÉ|Ā[ÉčāŇÉAÉčÉtÉ@Ė@ĀiābāQĀjāŇāPāQĖúÉgÉďāūĆöź›āĶĀAĎäĆ›ā…čüččā∑āťĀBÉAÉWÉAāŐéýóvāÕćXā…ĎĚĎŚā∑āťā∆ā›āńĒ\óÕĎĚč≠āūćsā§āŗāŐĀBĀ@

China Chemical Reporter

2005/11/10

Methanol Project

Makes Successful Startup in Shaanxi

ŤĚźľź_ĖōČĽäw

The

first-phase 200 000 t/a methanol production line of the 600 000

t/a coal-based methanol project in Shaanxi

Shenmu Chemical Industry Co., Ltd. made successful startup and

entered the stage of trial production in October.

The project has a

total investment of RMB1.078 billion. Construction was started in

October 2003 and boiler ignition was made in June this year. The

construction period was only 18 months. The company uses its own

technical force and only a little more than 9 days was spent from

the start of wet commissioning to the production of refined

methanol, 2 days shorter than the highest record of similar units

in China.

Shaanxi Shenmu ChemicalĀ@ŤĚźľź_ĖōČĽäw

http://www.cnsmci.com/en/rssm-5.asp

Following the initiative

on accelerating the construction of YuLin heavy Chemical

Industrial and energy base promoted by Local government of

Shannxi province , Shaanxi Shenmu Chemical Industrial Co., Ltd.,

is founded by Shaanxi Qinlong electric Limited Company, West

Trust Investment Company, State Asserts Running Company of Shenmu

County, Shaaxi Zhonglian Investment Co. Ltd., XiĀfan Sea-Star Scien-tech Investment

Holding(Group) Company and Shaaxi Huafu Science Industry and

Trade Co., Ltd. The main product of this new company should be methanol

transfered from coal.

This new Company plan to produce 1200,000 ton

methanol per

year. The construction should divided into three stages: The

first construction stage, aiming to produce 200,000 ton methanol per year, already began

at March, 2003ĀCand is scheduled to put into use

in June 2005. Covering an area of 960 Mum, the company is located

in jinjie Industry zone Shenfu Economy Develop Zone Yulin city,

Shaanxi. The

prepare work of construction a coal mine, a partner project to

our coal-methanol-transfer project, has finished, and the

construction work of the coal mine should begin soon.

To produce methanol transfered from coal play a important role in

the coal chemical industrial chain. Development coal-methanol-

transfer has strategically meaning to optimize Chinese energy

supply structure and to improve the capability of anti-crisis on

energy supply. Thus, Our product has bright market future.

Shaanxi Shenmu Chemical Industrial Co., Ltd should utilize deeply

the unique advantage of rich ,cheap and high quality coal

resource. We would adopt the advanced techniques and technology

both home and abroadĀCdo our best to lower cost, improve

production capability, obtain larger market share, provide

customer high quality product, deliver great return on the

investment come from the investors.

http://www.cnsmci.com/en/rssm-2.asp

Shaanxi Shenmu Chemical

Industrial Co., Ltd. is aiming at producing 600,000 tons of

methanol a basic chemical material per year.(alias Shenmu

coal-methanol-transfer project). To achieve such capability, the

company obtain investment from seven companies. including Shaanxi

Province Investment Group (Limited) CompanyĀAShaanxi Qinlong electric Limited

Company Company of Shenmu County etc.

Shenmu

coal-methanol-transfer project is key construction project in

Shannxi province. In this project many advanced techniques and

technology abroad are adopted , such as the gasification

technology of TAXCO,Ā@NHD desulphurization and

decarbonization technology, synthesizing methanol under low

pressure, refinery distillation through the towers,

air-separation liquid oxygen compressure technique, heatproof and

pipe-shell compound type reactor etc. then this project possess

the characteristics of less energy consumption, low cost,

advanced processing technology, excellent product quality and

outstanding key competitiveness.

Covering an area of

960 Mum, the company is located in jinjie Industry zone Shenfu

Economy Develop Zone Yulin ěĺó— city, Shaanxi. Today the focus of

Chinese energy development stratagem is on western China, local

government in northern Shannxi starts to promote projects to

utilize the abundant resource of coal, nature gas and oil. Many

coal mine in there possess the extraordinary advantages of huge

amount, high quality and easy to exploitation. Soft coal

discovered in there can produce higher heat amount while contain

extra lower amount of ash ,phosphor, sulfur, it is famous

high-quality coal adopted in low-temperature distil, gasification

industry and chemical industry around world. In the location the

project funded, the large amount of high quality and un-viscosity

bright-flame coal resource could be abundant ,cheap and reliable

resource supply for Shenmu coal-methanol-transfer project.

Under the lead of

directorateĀCOur people make great efforts to

rapidly construct this project. Once this project begin to

produce methanolĀCOur Company should be the largest

coal-methanol-transfer base in China, the outcome should reach

1.2 billion yuan RMB each year.

źlĖĮĖ‘Ā@2005/11/15

íÜćĎĀA2010ĒNāŐźőíYď]ČĽźĽēiź∂éYćāā™500ĖúÉgÉďā…

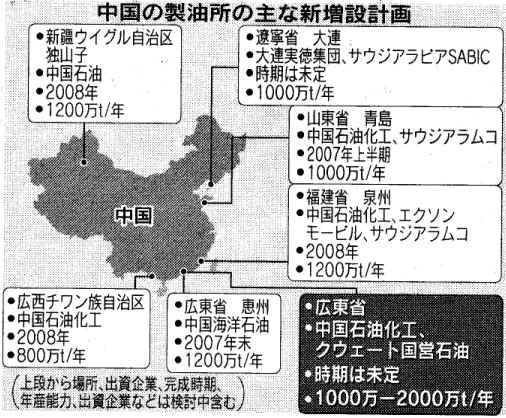

íÜćĎźőíYćHč∆č¶ČÔāŐĒÕąŘďāČÔí∑āÕ14ďķĀAíÜćĎāÕ2010ĒNā…āÕĀAźőíYāŐÉIÉCÉčā÷āŐď]ČĽĀAźőíYÉKÉXČĽāūä‹āŖāĹźőíYď]ČĽźĽēiāŐź∂éYćā500ĖúÉgÉďāŐéņĆĽāūĖŕéwāĶāńāĘāťāĪā∆āūĖĺāÁā©ā…āĶāĹĀB

āĪāÍāÕĒÕąŘďāČÔí∑ā™źśĒ äJć√ā≥āÍāĹĎś6ČŮĎSćĎźőíYćHč∆Č»äwčZŹpĎŚČÔāŐź»āŇŹqā◊āĹāŗāŐĀBĀuĎś11éüĆ‹ÉJĒNĆvČśĀväķā…ĀAíÜćĎāÕźőíYČ»äwčZŹpē™Ėžā…ā®āĘāńĀAíYĎwÉKÉXäJĒ≠ā®āśā—źőíYď]ČĽāŐĖ āŇĎŚāęā»źiēŗāūźčāįāťāŐāŇāÕā»āĘā©ā∆Ć©āÁāÍāńāĘāťĀB2010ĒNĀAíYćzÉKÉXäJĒ≠ā®āśā—źőíYď]ČĽāŐéYč∆ČĽā™éņĆĽāĶĀAíŠďßčCźęíYďcāŐíYĎwÉKÉXāŐćŐéśčZŹpāŐĖ āŇďňĒjďIā»źiďWā™Ć©āÁāÍĀAźőíYÉKÉXČĽĀAínČļāŇāŐÉKÉXČĽčZŹpāŐćHč∆ČĽÉeÉXÉgāūäģóĻā≥āĻāťāśā§č…óÕďwāŖāťēŻźjā∆ā»āŃāńāĘāťĀB

ĀuĎś11éüĆ‹ÉJĒNĆvČśĀväķā…ĀAíÜćĎāÕíYćzāŐč@äBČĽź∂éYāūĎSĖ ďIā…źĄāĶźiāŖāťāĪā∆ā…ā»āŃāńāĘāťĀBíÜćĎāÕźőíYä÷ėAāŐŹdóvź›ĒűāŐćĎéYČĽāūéņĆĽā∑āťāĪā∆ā…óÕāūďŁāÍĀAíYćzź›ĒűāŐÉĆÉxÉčāūíėāĶā≠ĆŁŹ„ā≥āĻāťĀB2010ĒNā…āÕĀAĎŚĀEíÜĆ^íYćzāŐč@äBČĽÉĆÉxÉčāū85Āďą»Ź„ā…ąÝāꏄāįāťĀBźVčKĆöź›ĀAčĆíYćzā…Ďőā∑āťčZŹpČŁĎĘāūí ā∂āńĀAíÜćĎā…300ą»Ź„āŐćāź∂éYó ĀAćāĆÝó¶āŐíYćzāūćžāŤŹ„āįĀAćāź∂éYó ĀAćāĆÝó¶íYćzāŐź∂éYćāāÕĎSćĎĎćź∂éYó āŐĖŮ50ĀďāūźŤāŖāťāĪā∆ā…ā»āťĀB

ĒÕąŘďāČÔí∑āÕā‹āĹĀAĀuĎś11éüĆ‹ÉJĒNĆvČśĀväķā…āÕĀAźőíYāŐĎććáóėópāŗā©ā»āŤĎ¨āĘÉXÉsĀ[ÉhāŇĒ≠ďWā∑āťā∆āĶāńāĘāťĀB2010ĒNā…ĀAĎSćĎā…ā®āĮāťĆīíYāŐĎIē ó¶ā™50Āďą»Ź„ā…íBāĶĀAźőíYä÷ėAéYč∆āŐčZŹpÉĆÉxÉčā™źőíYč∆äEāŐēĹčŌźÖŹÄā…íBāĶĀAéĎĆĻāŐäJĒ≠ā…ďKČěāĶāĹźőíYéYč∆É`ÉFĀ[Éďā™äÓĖ{ďIā…Ć`ź¨ā≥āÍĀAźőíYźĽēiāŐētČŃČŅílā™ĎŚēĚā…ĆŁŹ„ā∑āťā∆Ć©āÁāÍāńāĘāťĀB

2004/7/13Ā@ą…ď°íČ Ā@Ā@

Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Baosteel

jv with Yongcheng Coal, Brazil's CVRD approved

íÜćĎā…ā®āĮāťÉRĀ[ÉNÉXJVāŐĆŹĀ@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@startĀ@

http://www.itochu.co.jp/main/news/2004/news_040713.html

Ā@ą…ď°íČŹ§éĖäĒéģČÔé–āÕĀAíÜćĎéRďĆŹ»ćŌĒJésā…Ćöź›ā∑āťźĽďSópÉRĀ[ÉNÉXÉvÉČÉďÉgJVĀiź≥éģĖľŹŐĀFĀwéRďĆÉGÉćĎćŘŹŇČĽóLĆņź”ĒCĆŲéiĀxĀjā…ĎőāĶāńĀAíÜćĎĀEÉGÉŹWícóLĆņĆŲéiā∆ÉuÉČÉWÉčĀEÉäÉIÉhÉZé–ĀiCompanhia Vale do Rio DoceĀjā∆č§ā…ďäéĎā∑āťāĪā∆āūĆąāŖĀAĖ{ďķĀAĖkčěāŇćáéĎĆ_ĖŮŹĎā…í≤ąůívāĶā‹āĶāĹĀBĀiĀ¶ÉGÉāŐĀgÉGÉďĀhāÕíÜćĎäŅéöāŇĀuė≥ĀvČļā…Āuķ~ĀvĀj

Ā@ĎćďäéĎäzāÕ22.8Č≠Ć≥ĀiĖŮ301Č≠Č~ĀjĀAéĎĖ{čŗ8.8Č≠Ć≥āŇĀAą…ď°íČŹ§éĖāÕāĽāŐďŗ5ĀďāŐĖŮ5.8Č≠Č~āūďäéĎívāĶā‹ā∑ĀBĀiÉGÉŹWícāÕ70ĀďĀAÉäÉIÉhÉZé–āÕ

25ĀďāŐďäéĎĒšó¶ĀjJVāÕĀAÉhÉCÉcKaiserstuhlÉRĀ[ÉNÉXÉvÉČÉďÉgāŐź›ĒűāūíÜćĎéRďĆŹ»ā…ąŕź›ā∑āťāŗāŐāŇĀAĒNä‘200ĖútāŐźĽďSópÉRĀ[ÉNÉXāūź∂éYāĶĀAā‹āĹĀAÉRĀ[ÉNÉXėFÉKÉXāūČŮéŻāĶĒNä‘20ĖútāŐÉĀÉ^ÉmĀ[Éčāūź∂éYā∑āťÉvÉČÉďÉgāŗēĻź›ívāĶā‹ā∑ĀB

Ā@ÉGÉŹWícāÕJVā…ĎőāĶāńĆīóŅíYāŐčüččāūćsāĘĀAā‹āĹJVā™ź∂éYā∑āťÉRĀ[ÉNÉXĀAÉĀÉ^ÉmĀ[ÉčĀAāĽāŐĎľēõéYē®āŐíÜćĎćĎďŗĒŐĒĄā…ā¬āĘāńź”ĒCāūēČāĘā‹ā∑ĀBą…ď°íČŹ§éĖāÕĀAÉRĀ[ÉNÉXāŐĎőďķď∆źŤĒŐĒĄĆ†čyā—ÉuÉČÉWÉčą»äOāŐćĎäOÉ}Ā[ÉPÉbÉgāŐóDźśĒŐĒĄĆ†āūéĚāŅĀAóAŹoÉ}Ā[ÉPÉeÉBÉďÉOč∆ĖĪāūćsā§ĀBĀiÉäÉIÉhÉZé–āÕÉuÉČÉWÉčésŹÍāŐď∆źŤĒŐĒĄĆ†āūéĚāŅā‹ā∑ĀBĀj

Ā@ą…ď°íČŹ§éĖāÕĖ{JVāūí ā∂āńĀAíÜćĎóLźĒāŐźőíYź∂éYé“āŇā†āťÉGÉŹWícčyā—źĘäEćŇĎŚāŐďSćzźőź∂éYé“āŇā†āťÉäÉIÉhÉZé–ā∆āŐä÷ĆWāūź[āŖĀAíYćzäJĒ≠āūä‹āřēĚćLāĘéĎĆĻä÷ėAē™ĖžāŇóľé–ā∆āŐč¶óÕä÷ĆWāūč≠ČĽāĶāńāĘā≠ēŻźjāŇā∑ĀB

Ā@JVāÕ2004ĒNíÜā…é{ćHäJénĀA2006ĒNŹČŹ{ā…ÉRĀ[ÉNÉXčyā—ÉĀÉ^ÉmĀ[ÉčāŐź∂éYĀEĒŐĒĄāūäJénā∑āťó\íŤāŇā∑ĀB

č§ďĮí źMĀ@2004/5/25

íÜćĎāŇÉRĀ[ÉNÉXź∂éYā÷Ā@

ābāuāqācā™č¶íŤā…í≤ąů

Ā@źĘäEćŇĎŚāŐďSćzźőź∂éYé“ĀEóAŹoé“āŇā†āťÉRÉďÉpÉjÉAĀEÉoÉĆĀEÉhĀEÉäÉIĀEÉhÉZĀiCompanhia

Vale do Rio DoceĀFābāuāqācĀjāÕĀAíÜćĎćŇĎŚāŐźőíYź∂éYé“āŐāPā¬ĀAÉĄÉďÉNÉAÉďĀiŚŌćzĀjŹWícā∆íÜćĎāŇÉRĀ[ÉNÉXāūź∂éYā∑āťč¶íŤā…í≤ąůāĶāĹā∆Ē≠ē\āĶāĹĀB

Ā@č¶íŤā…äÓā√āęĀAĒNä‘āQāOāOĖúÉgÉďāŐÉRĀ[ÉNÉXā∆ĀAēõéYē®āŇā†āťÉĀÉ^ÉmĀ[Éčā™ĒNä‘āQāOĖúÉgÉďź∂éYā≥āÍāťĀBĎÄč∆āÕāQāOāOāUĒNā…äJénā≥āÍĀAź∂éYó āŐāQāTĀďāÕéŚā∆āĶāńÉuÉČÉWÉčā…óAŹoā≥āÍāťó\íŤĀB

Ā@ĎOŹqāŐćáą”āŐāŔā©ā…ĀAābāuāqācāÕéRďĆŹ»āŐś‚ėOésā…źVāĶāĘÉRĀ[ÉNÉXópíYāŐíYćzéĖč∆āūénāŖāťÉvÉćÉWÉFÉNÉgāŇÉĄÉďÉNÉAÉďā∆íŮĆgā∑āťČ¬Ē\źęāŗĆüďĘāĶāńāĘāťĀBäJĒ≠ā≥āÍāťĎśāPćÜíYćzāŐź∂éYó āÕĒNä‘ĀAāRāOāOĖúÉgÉďāŐó\íŤāŇĀAÉvÉćÉWÉFÉNÉgā™čÔĎŐČĽā≥āÍāÍāőĀAāQāOāOāVĒNā…ĎÄč∆ā™äJénā≥āÍāťĀB

Ā@óľé–āŐč¶íŤāÕābāuāqācā™ÉRĀ[ÉNÉXź∂éYéĖč∆ā…źiŹoā∑āťāĪā∆āūą”Ė°āĶĀAĆĽć›āÕďSćzźőĀAÉyÉĆÉbÉgĀAÉ}ÉďÉKÉďćzĀAćáčŗďSāŇć\ź¨ā≥āÍāńāĘāťďSć|č∆ĆŁāĮāŐźĽēiÉČÉCÉďāūē‚č≠ā∑āťĀBā≥āÁā…č¶íŤāÕíÜćĎćŇĎŚāŐźőíYź∂éYé“āŐāPā¬ā∆āŐä÷ĆWāūč≠ČĽā∑āťĀBā‹āĹÉuÉČÉWÉčā∆íÜćĎāŐä÷ĆWāŗąÍĎwĀAč≠ČĽā∑āťĀB

Rio Doce 2004/7

Production of

metallurgical coke in China Ā[

creation of

Shandong Yankuang International Coking Co., Ltd. (JV) joint

venture for production of metallurgical coke

http://www.cvrdlogistica.com.br/cvrd_us/cgi/cgilua.exe/sys/start.htm?sid=46&infoid=837

CVRD executed an

agreement with Yankuang Group Co., Ltd. (Yankuang), one of

the main coal producers in China, and Itochu Corporation

(Itochu), one of the leading trading companies in Japan, for

the Shandong Yankuang

International Coking Co., Ltd. (JV) joint venture for the

production of metallurgical coke.

The association

between these three companies brings together the expertise

in marketing, commercialization and funding of projects of

CVRD and Itochu, with the availability of mineral resources,

technology and infrastructure of Yankuang.

As described in

the agreement between the parties disclosed by CVRD on May 24

of this year, the industrial plant will be located in the

province of Shandong, in China, and will have an annual

production capacity of two million metric tons of coke and

200 thousand metric tons of methanol as a sub-product. The

operation startup is forecasted for 2006. The JV will use the

Kaiserstuhl coke plant, originally located in Germany, which

was purchased by Yankuang and will be reassembled in the

province of Shandong.

The investment

by CVRD will be about US$ 27 million, assuring a 25% share in

the capital of the JV. The total investment in the plant will

be US$ 275 millions.

Yankuang will

assure the stable supply of the coal necessary for the plant

operation and the production of high quality metallurgical

coke.

Simultaneously,

a contract was executed between CVRD and Yankuang for the

development of the coking coal mine of ZhaolouĀ@ś‚ėOés, also located in the province

of Shandong, with an estimated annual production capacity of

three million tons of coking coal. The participation of CVRD

in this project, which is subject to feasibility studies

under development, will also be 25%.

CVRD will have

the right to buy part of the production, both from the coke

plant and the future coal mine, proportional to its share in

the capital of the joint ventures, and may sell it to Brazil,

net importer of these raw materials for the steel industry.

Additionally, CVRD will be the exclusive representative for

the sale of coke of the JV in the Brazilian market.

The development

of both projects is subject to some previous conditions, such

as, for example, obtaining all the necessary approvals from

the Chinese Government, including a license for coke

exporting.

The executed

contracts are the first direct investment of CVRD in China,

and the Company entrance into the coke business,

complementing its product portfolio for the steel industry,

currently consisting of iron ore, pellets, manganese ore and

iron alloys.

China Chemical Reporter

2005/11/17Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@

Methanol Project

Based on Coke Oven Gas Ā@Ā@Ā@ÉRĀ[ÉNÉXėFÉKÉX

The ceremony for

launching the first phase of the 300 000 t/a

methanol project

in Shanxi Tianhao Chemical Co., Ltd. was held in Xiaoyi, Shanxi

province on Nov. 1. Ā@Ā@éRźľŹ»ćFč`és

The project is

funded by Shandong Yankuang GroupÉGÉŹWícóLĆņĆŲéi. The first phase has an

investment of RMB500 million. The world leading coke oven gas

conversion technology with the intellectual property right is

used in the methanol production. The process technology has the

features of simple process flow, little investment, high

production efficiency, high product added value, energy

conservation, environmental friendly, convenient operation and

good economic performance. The core technology is the process for

the production of synthetic gas through the pressurization,

catalysis and partial oxidation of coke oven gas in a way of heat

exchange.

2005ĒN11Ćé18ďķĀ@Chemnet Tokyo

íÜćĎāŇÉRĀ[ÉNÉXėFÉKÉXĆīóŅāŐ30ĖúÉgÉďÉĀÉ^ÉmĀ[Éčź›ĒűíÖćH

Ā@ć°Ćé1ďķĀAéRźľŹ»ćFč`ésāŇéRźľTianhao ČĽäwāŐ30ĖúÉgÉďÉĀÉ^ÉmĀ[ÉčÉvÉČÉďÉgāŐĆöź›čNćHéģā™ćsāŪāÍāĹĀBíÜćĎćŇĎŚāŐźőíYź∂éYé“āŐ1ā¬āŇĀAéRďĆŹ»ā…Ė{číāūíuā≠ÉGÉŹWícóLĆņĆŲéi(Yankuang Group Co., Ltd. )ā™ŹoéĎā∑āťāŗāŐāŇĀAÉRĀ[ÉNÉXėFÉKÉXāūĆīóŅā∆āĶāńāĘāťĀB

Ā@ÉGÉŹWícóLĆņĆŲéiāÕāĪāÍā∆āÕē ā…ĀAźĘäEćŇĎŚāŐďSćzźőź∂éYé“ĀEóAŹoé“āŇā†āťÉuÉČÉWÉčāŐÉäÉIĀEÉhÉZā∆ą…ď°íČā∆āŐćáēŔČÔé–ĀAéRďĆÉGÉćĎćŘŹŇČĽóLĆņź”ĒCĆŲéiāūź›óßāĶĀAÉhÉCÉc

KaiserstuhlāŐÉRĀ[ÉNÉXÉvÉČÉďÉgāŐź›ĒűāūíÜćĎéRďĆŹ»ā…ąŕź›āĶāńĀAĒNä‘200ĖúÉgÉďāŐźĽďSópÉRĀ[ÉNÉXā∆ĀAÉRĀ[ÉNÉXėFÉKÉXā©āÁ20ĖúÉgÉďāŐÉĀÉ^ÉmĀ[Éčāūź∂éYā∑āťÉvÉČÉďÉgāūĆöź›íÜāŇā†āťĀB

Ā@

Ā@óąĒNĎĀĀXā…āŗź∂éYäJénāŐó\íŤāŇĀAÉGÉŹWíc(70%ŹoéĎ)āÕJVā…ĎőāĶāńĆīóŅíYāŐčüččāūćsā§ā∆ā∆āŗā…źĽēiāŐíÜćĎćĎďŗĒŐĒĄāūíSďĖĀAÉäÉIÉhÉZ

(25%ŹoéĎ)āÕÉuÉČÉWÉčésŹÍāŐď∆źŤĒŐĒĄĆ†āūéĚāŅĀAą…ď°íČ(5%ŹoéĎ)āÕĀAÉRĀ[ÉNÉXāŐĎőďķď∆źŤĒŐĒĄĆ†čyā—ÉuÉČÉWÉčą»äOāŐćĎäOÉ}Ā[ÉPÉbÉgāŐóDźśĒŐĒĄĆ†āūéĚā¬ĀB

Ā@ÉäÉIÉhÉZāÕāĪāÍā…āśāŤÉRĀ[ÉNÉXź∂éYéĖč∆ā…źiŹoĀAďSćzźőĀAÉyÉĆÉbÉgĀAÉ}ÉďÉKÉďćzĀAćáčŗďSāŇć\ź¨ā≥āÍāńāĘāťďSć|č∆ĆŁāĮāŐźĽēiÉČÉCÉďāūē‚č≠ā∑āťā∆ā∆āŗā…ĀAÉuÉČÉWÉčā∆íÜćĎāŐä÷ĆWāŗąÍĎwč≠ČĽā∑āťĀB

Ā@íÜćĎāŇāÕĆĽć›ĀAźőíYéĎĆĻāūóLā∑āťäťč∆āŐä‘āŇźőíYČĽäwĆvČśā™ĎĪŹoāĶāńāĘāťĀB

Ā@

China Chemical

Reporter 2007/1/4 Ā@Ā@Ā@Ā@Ē≠ē\Ā@Ā@Ā@Ā@í≤ąů

Methanol Project

Based on Coke Oven Gas Starts up

Ā@Shandong

Yankuang International Coking Co., Ltd. held a ceremony for

the completion of its 2.0 million t/a coke and 200

000 t/a methanol project in Yanzhou of Shandong

province on December 16th, 2006. It is a project for the

reuse of coke oven gas.

The project is jointly

undertaken by Yankuang Group, CVRD of Brazil

and Itochu of Japan. The 3 parties have made a

joint investment of RMB2.284 billion and set up Shandong

Yankuang International Coking Co., Ltd. Yankuang Group holds

70% equity, CVRD holds 25% equity and Itochu holds 5% equity.

The second-hand equipment provided by a German company is

used.

The sales revenue is expected

to reach RMB2.3 billion a year after completion of the

project. Since the start of wet commissioning, the purity of

methanol product has reached 99.9%.

The purification and recovery

of coke oven gas is carried out through advanced high-effect

cooling, scrubbing, desulfurization and recovery process.

Technologies and equipment for environmental protection and

energy conservation are also used to convert coke oven gas

with low added value to methanol, a chemical product and raw

material with high added value.

2006/12/20Ā@Rio Doce

CVRD, Yankuang and

Itochu inaugurate joint venture to produce coke in China

Companhia Vale do Rio Doce (CVRD), the world-leading iron ore

producer and exporter, Yankuang Group Co., Ltd, one of the

biggest Chinese coal and coke producers, and Itochu

Corporation, one of the leading trading companies in Japan,

officially inaugurated on Saturday, December 16th, the joint

venture Shandong Yankuang International Coking Co. Ltd. to

produce coke in the Shandong Province, China.

The joint venture, which started production in the first half

of 2006, is the largest of its kind in China and has an

annual production capacity of 2.0 million tons of high

quality coke and 200,000 tons of methanol. CVRD has a 25%

stake in the JV's capital, while Yankuang and Itochu have

respectively 70% and 5%.

CVRD has invested US$ 26.6 million in the project and will

have the right to off-take a percentage of coke equivalent to

its equity stake in the joint venture as well as act as the

exclusive sales channel for the JV's products in Brazil.

The alliance between CVRD, Yankuang and Itochu combines the

expertise in global trading and project financing of CVRD and

Itochu, with the technology, infrastructure and experience in

China held by Yankuang.

This joint venture illustrates CVRD's confidence in the

future of China and of its steel industry.

Ā@

2005/6/24 AFXĀ@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@ą…ď°íČĀAÉGÉŹWícóLĆņĆŲéiĀAÉuÉČÉWÉčĀEÉäÉIÉhÉZJV

China's Baosteel jv with Yongcheng Coal, Brazil's CVRD approved

by government

Yongcheng

Coal & Electricity (Group) Co Ltd, ČiŹťĒ}ďdŹWíc one of the largest anthracite Ė≥ČĆíY

producers in China,

said its

planned coal joint venture with Shanghai Baosteel

Group Corp Ź„äCēůć|ŹWíc

and Brazil's

Companhia Vale do Rio Doce (CVRD) has been approved by the National

Development and Reform Commission.

Yongcheng Coal said in a statement that Baosteel and CVRD will

jointly inject a total of 1.66 bln yuan into the venture -- Henan Longyu

Energy Resources Co Ltd.

When the deal is completed, net assets of Henan Longyu will be

approximately three bln yuan.

Shanghai Baosteel will hold a 12.95 pct stake in the venture

while CVRD will have 25 pct. Yongcheng Coal will be the

controlling shareholder with a 45 pct stake.

State media reported today that Yongcheng Coal is also in talks

with Thailand-based Chia Tai Group to set up a coal chemical

joint venture in China.

Platts

2007/5/18

China's Longyu

Coal to complete Henan methanol plant by end-2007

China's Longyu Coal

Chemical

plans to launch a 500,000 mt/year coal-based methanol plant

in Henan province by the end of this year, a company official

said Thursday. The plant is expected to be expanded to a

capacity of 1.6 million mt ultimately, he added.

Using

production technology from Shell, the plant is scheduled to

come on stream in three stages.

(The final

stage) would also include a 500,000

mt/year propylene unit and a 300,000 mt/year polypropylene

unit.

Longyu Coal

Chemical is a subsidiary of Henan-based Yongcheng Coal and Electricity

Group,

a major coal and electricity producer. Longyu Coal Chemical

was formed in 2004 specifically for methanol and olefins

production.

ďķĖ{ĆoćŌźVē∑Ā@2005/11/23 Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@Ā@íÜćĎĀAćHŹÍĒöĒ≠ĎäéüāģĀ@ŹdĆcāŇāŗČÕźžČėźű

źÖĆĻŹ„ó¨āŇČĽäwćHŹÍĒöĒ≠Ā@ÉnÉčÉrÉďĀAāSďķä‘ífźÖĀ@ésĖĮĀAĒÉāĘŹoāĶéEďě

Ā@íÜćĎďĆĖkēĒāŐćēó≥ć]Ź»ÉnÉčÉrÉďésāÕāQāQďķā©āÁāSďķä‘ĀAźÖďĻźÖāŐčüččāūí‚é~ā∑āťā∆Ē≠ē\āĶāĹĀBźÖĆĻā∆ā»āťŹľČ‘ć]āŐŹ„ó¨ĀAčgó—Ź»čgó—ésāŇāPāRďķā…ČĽäwćHŹÍāŐĒöĒ≠éĖĆŐā™ā†āŤĀAźÖéŅā™Čėźűā≥āÍāĹčįāÍā™ā†āťāĹāŖĀBźlĆŻĖŮźÁĖúźlāŐĎŚďsésāŇífźÖā™źĒďķä‘ĎĪā≠āŐāÕíÜćĎāŇāŗąŔóŠĀBąýóŅźÖāŐĒÉāĘŹoāĶā…ĎĖāťésĖĮā™ąÍéěďIā…ÉpÉjÉbÉNŹůĎ‘ā…ä◊āŤĀAćHŹÍāŐź∂éYā…āŗéxŹŠā™Źoāťā∆āŐĆúĒOā™ćLā™āŃāńāĘāťĀB

Ā@ĒöĒ≠éĖĆŐāÕćĎóLźőĖŻĎŚéŤĀAíÜćĎźőĖŻďVĎRčCŹWíc(CNPC)ĆnāŐźőĖŻČĽäwćHŹÍāŇĒ≠ź∂ĀBāTźlā™éÄĖSāĶāPĖúźlą»Ź„ā™ĒūďÔāĶāĹĀBďĮćHŹÍāÕŹľČ‘ć]Ź„ó¨ā…ā†āŤĀAÉnÉčÉrÉďésāÕŹľČ‘ć]āŐźÖéŅāūí≤ćłāĶāńāĘāťĀBĀuēaČ@ā»ā«ā…āÕē āŐēŻĖ@āŇźÖāūčüččā∑āťĀvā∆āĶāńāĘāťā™ĀAŹZĖĮā…āśāťā∆Ź§ďXā…āÕźÖāūčĀāŖāťésĖĮā™éEďěĀAÉyÉbÉgÉ{ÉgÉčďŁāŤāŐźÖāūĒŐĒĄā∑āťí¬óŮíIāÕƨēņā›čůāŃāŘāŐŹůĎ‘ā∆āĘā§ĀBésďŗā…ā†āťźXČiďŻč∆āŐÉ~ÉčÉNćHŹÍāÕĀuínČļźÖāūégā§āĹāŖĎÄč∆āÕĆpĎĪāŇāęāťĀvā∆āĶāńāĘāťĀB

ŹľČ‘ć]āÕí∑ĒíéRĆnāŐćŇćāēŰĀAĒíď™éRāŐéRíłČőĆŻāŐÉJÉčÉfÉČĆőĀiďVírĀjā©āÁĒ≠āĶĀAĆīénó—ínĎ—āūä—í āĶõcć]ĀEČ≤íOć]ā»ā«āŐĎŚāęā»éxó¨āūā†āŪāĻāńÉćÉVÉAćĎčęāŐćēóīć]Ź»ďĮć]ésētčŖāŇÉAÉÄĀ[Éčźžā…ćáó¨āĶĀAÉćÉVÉAāŐÉnÉoÉćÉtÉXÉNētčŖāŇĖkďĆā…ó¨āÍāūēŌā¶ĀAÉIÉzĀ[ÉcÉNäCā…íćāģĀB

źVČōé–Ā@2005-11-22

Harbin moves to

ensure water quality after blast

The provincial health department of northeast China's

Heilongjiang province vowed Tuesday to step up inspection of

water quality as a chemical plant blast caused possible water

contamination in Harbin, capital of the province.

Harbin announced on MondayĀiNov.21) to stop water supply

for four days as of Tuesday evening for fears that a chemical

plant blast on November 13 may have caused a leakage of

poisonous substances into the Songhua River, a major water

source of the city.

Harbin is located at the middle reaches of the river, which

originates in the neighboring province of Jilin. The blast

took place in the chemical plant only a few hundred meters

upstream.

The announcement has sparked frenzied purchase of drinking

water in the city with a population of 3 million. Bottled

water, various beverages and even boxed milk were sold out by

Tuesday morning in some supermarkets and food stores.

The local health department ruled that drinking water in the

city has to be checked twice every day, to ensure the water

quality drinkable.

Severe measures will be taken simultaneously in all

water-related enterprises and companies to abide by the

standards of the safe water quality.

źVČōé–Ā@2005/11/24

Petrochemical

company blamed for river pollution

A chemical plant of Jilin Petrochemical Company under China

National Petroleum Corp. should be held responsible for the

pollution of Songhua River, said Zhang Lijun, deputy director

of the State Environmental Protection Administration, at a

press conference here Thursday.

The chemical plant experienced an explosion on Nov. 13.

Sino-Russia cooperation

China will keep Russia informed on the conditions of Songhua

River pollution after the polluted water passes Harbin, Zhang

said.

"The two sides are making specific arrangements for

opening a hotline for the matter," he said.

Zhang said the polluted water in the Songhua River is

expected to flow into the Heilongjiang River (called Amur

River in Russia) on the Sino-Russian border in around 14 days

judging from the current flow speed.

He said the Chinese government has already briefed the

Russian side on the pollution accident.

"During his meeting with the Russian ambassador to China

this morning, director of the administration Xie Zhenhua made

a detailed introduction of the entire incident," said

Zhang. Enditem

CNPC apologizes

HARBIN, Nov. 24 (Xinhuanet) -- Deputy general manager of

China National Petroleum Corp.(CNPC) Zeng Yukang expressed

his sincere sympathy and deep apologies to the residents of

northeast China's Heilongjiang province, for the pollution of

the Songhua River caused by the blast in a chemical plant

under the CNPC Jilin Petrochemical Company.

Zeng, who is also director of Daqing Petroleum Administration

Bureau, came to Harbin on Wednesday, heading a drilling crew

whichis to dig 100 deep groundwater wells for universities

and collegesas well as water and heat suppliers in the city.

He made an apology on behalf of the CNPC to residents along

the Songhua River on the pollution of the major city water

source, saying that it is CNPC's duty to help treat the

pollution, according to the city government of Harbin on

Thursday.

The blast took place at about 1:45 p.m. on Nov. 13 in a

workshop of the No. 101 Chemical Plant under the CNPC Jilin

Petrochemical Company based in Jilin City, some 100 km east

to Changchun, the provincial capital. Five people were killed

and about 70 people were injured. Enditem

Jilin Province apologizes

HARBIN, Nov. 24 (Xinhuanet) -- Vice-governor of Jilin

Province Jiao Zhengzhong expressed his sincere sympathy and

deep apologies to residents of Harbin, capital of neighboring

Heilongjiang Province, northeast China, for the pollution of

the Songhua River caused by blast in a chemical plant in

Jilin.

Jiao, who is also secretary of the Communist Party of China

(CPC) Committee of Jilin City, where the blast took place,

came to Harbin to discuss ways to treat the pollution on

Wednesday and make an apology to Harbin residents on the

pollution of the Songhua River, a major city water source,

according to the city government of Harbin on Thursday.

The blast took place at about 1:45 p.m. on Nov. 13 in a

workshop of the No. 101 Chemical Plant under the CNPC Jilin

Petrochemical Company based in Jilin City, some 100 km east

to Changchun, the provincial capital. Five people were killed

and about 70 people were injured.

Jilin provincial and Jilin city governments immediately

closed the pipelines that caused the pollution.

"People of Heilongjiang and Jilin provinces shared water

source from the same Songhua River and it was the obligatory

duty of the two provinces to safeguard the mother

river," said Shi Zhongxin, deputy secretary of the

Harbin city CPC committee and mayor of Harbin.

Shi said the Harbin city government had informed local

residents of the pollution situation and took emergency

measures to deal with the pollution. Enditem

Toxic water reaches Harbin

HARBIN, Nov. 24 (Xinhuanet) -- The front of the polluted

water of Songhua River in northeast China reached Harbin,

capital of Heilongjiang Province, on early Thursday morning,

local environment authority said.

The toxic benzene-contaminated water, flowing down from the

upper reaches of Songhua, arrived at the local water supply

inlet at about 5 a.m., and has now entered river sections

across the city's urban areas, according to the Heilongjiang

provincial environment protection bureau.

The front of the polluted water of Songhua River in northeast

China reached Harbin, capital of Heilongjiang Province, on

early Thursday morning, local environment authority said.

The State Environment Protection Administration confirmed

Wednesday that pollutants containing benzene and nitrobenzene

contaminated the Songhua River after a chemical-plant blast

at the upper reaches in Northeast China.

Since the river was contaminated in a chemical plant

explosion in the neighboring Jilin Province on November 13,

the benzene and nitrobenzene density in the water is

declining gradually after days of sedimentation and

adsorption, and the Harbin city government has added a large

amount of active carbon powders into the river to help clean

up the water.

Harbin, home to nine million population including 3.8 million

in the urban districts, has cut off water supply in the urban

areas since early Wednesday, an emergency action taken to

ensure public safety.

The operation of the city's water supply system was

temporarily resumed on Wednesday afternoon following a

forecast by China's State Environmental Protection

Administration (SEPA) that the polluted water will not reach

the city until Thursday.

The SEPA confirmed the "major pollution" of the

Songhua River on Wednesday. Chinese Foreign Ministry

spokesman Liu Jianchao said in Beijing on Thursday that China

has informed Russia of the water pollution situation in the

river, a tributary of the Heilong River (called Amur River in

Russia) on the border between the Russian far east and China.

2005ĒN11Ćé14ďķ Chemnet Tokyo

íÜćĎĀEčgó—Ź»āŇźőČĽÉvÉČÉďÉgā™ĒöĒ≠éĖĆŐ