トップページ

BASF 変遷図 能力

2003/7 BASF、MSAよりCallery Chemical事業部を買収

2003/5 BASF-YPC

社、中国・南京でのDMF生産能力を増強

2003/5 BASF、エクソンモービル・ケミカル社のポリイソブチレン事業を買収

2003/3 バイエル社の殺虫剤・殺菌剤の買収完了

2000/12/18 BASF, 医薬品事業をアボット・ラボラトリーズへ69億ドルで売却

2000/3/22 BASF、アメリカンホームプロダクツ社より農薬事業を買収

BASF

strengthens its plastics business

・BASF to acquire

Honeywell's worldwide engineering plastics business

・BASF to sell its nylon

fibers businesses to Honeywell

2003/9 BASF、DSMとの提携解消、飼料用酵素Natuphos®を独自に生産・販売

2003/11 BASF

、ビタミン事業拡張に向けて大きな一歩を踏み出す

2003/12 BASF、米ダイバーサ社からキラル中間体向け酵素の使用ライセンスを取得

2003/12 BASF、事業戦略に新たな要素を追加

2003/12 BASF to acquire

Ticona's nylon 6,6 engineering plastics business

2004/1 BASF divests

Phenoxy Business

2004/2 東レ・独BASF合弁 PBTを生産 マレーシアで2006年から

BASF(PolyTHF) : 日本 韓国 中国 米・独

2004/8 BASF officially

inaugurates its new citral plant in Ludwigshafen

2004/8 BASF plans to

invest in a polyurethanes specialties site in Shanghai

2004/8 Dow & BASF to construct a world-scale

PO, using HPPO technology

2004/12 BASF expands capacity of

its world-scale MDI plant in Antwerp by 25 percent

2004/12 Polyisocyanate plant to be

built in Shanghai Chemical Industry Park

2004/12 BASF、米国で高吸水性樹脂のS&B

2005/1 BASF acquires electronic

chemicals business of Merck KGaA

2005/2 BASF to strengthen

business with engineering plastics in Asia by new production

facilities

2005/3 BASF shifting Texas

plasticizers base from ethylene to butene

2006/9 BASF completes

conversion of Pasadena, Texas, unit to 2-PH

2005/4 BASF to sell U.S.,

Canadian polystyrene business to INEOS Americas, LLC

2005/4 BASF increases capacity

for biodegradable plastic Ecoflex®

2005/5 BASF and Shell to sell

their stakes in Basell to consortium led by Access Industries

2005/6 BASF、欧州での可塑剤事業体制を再編

2005/7 BASF

acquires Huntsman’s global TDI

business

BASF's

US Freeport petchem site cuts emissions by 58% on year

2005/8 BASF invests Euro 200 million in

expansion of cracker at Antwerp site

2005/9 独露3社でパイプライン 天然ガス直送調印

2005/9 BASF targets 10

percent of global chemical sales in China by 2010

BASF and SINOPEC Joint Venture

Officially Starts

2005/10 BASF increases

capacity for polyisobutene in Ludwigshafen

2005/10 Europe Strategy

2015

2005/10 BASF とダウ・ケミカル、プロピレンオキサイドの新生産プロセスを共同開発

2005/11 BASF commissions

amino resins plant in Shanghai, China

2005/11 BASF develops

biodegradable plastic based on renewable raw materials

2006/9 BASF, Dow, Solvay partnership

breaks new ground with innovative HPPO technology in Antwerp

2005/12 BASF、日本の中間体事業を再編

2006/1 BASF Makes

All-Cash Proposal To Acquire Engelhard

2006/4 エンゲルハード、BASFによる買収提案を拒否

2006/5 BASF、エンゲルハードの買収で再提案

2006/5 BASF と Engelhard、BASFによる買収で合意

2006/6 BASF receives majority of

Engelhard shares

BASF receives

over 90% of Engelhard shares

2006/8

BASF

renames Engelhard as BASF Catalysts LLC

2006/11 BASF announces full Engelhard

integration

2006/11 BASF set to become supplier

with the broadest pigment portfolio

2006/1 BASF

to open engineering plastics compounding unit at Altamira

2006/2 BASF and Diversa

Form Broad Alliance to Develop Innovative New Products

2006/3 BASF

reaches agreement to buy Degussa’s construction chemicals business

2006/12 BASF、独デグサ社建設用化学品事業の統合計画を発表

2006/3 Dow Signs HPPO Joint Venture

Agreement with BASF

2006/3 BASF

increases capacities of Acrylic monomers and superabsorbents to

meet growing demand

2006/4 BASF significantly

strengthens polyurethanes business in North America

2006/4 東レ/BASF、マレーシアにおけるPBTベースレジン合弁会社の稼働開始

2006/4 BASF

doubles production capacity for engineering plastic Ultrason(R)

in Ludwigshafen

2006/5 BASF

to acquire resins specialist Johnson Polymer

2006/5 BASF、エンプラ「Ultrason(R)」の生産能力を倍増

2006/5 BASF、ベルギーのバイオテクノロジー企業、クロップデザイン社を買収

2006/8 Opening ceremony marks successful

start-up of integrated isocyanates complex at Shanghai Chemical

Industry Park

BASF, Ciba

Specialty Chemicals, and Solvay invest in Pangaea Ventures Fund

II

2006/9 BASF and SINOPEC sign agreement on

feasibility study for the expansion of the Nanjing site

BASF

expands special amine manufacturing capacity

2006/10 BASF

demonstrates renewed strength in North America

2006/10 BASF

increases capacity of specialty plasticizer Hexamoll DINCH

2006/11 BASF set to become supplier with

the broadest pigment portfolio

2006/11 BASF

and Dow to Conduct Joint Feasibility Study for World-Class TDI

Facility in Europe

2006/12 BASF

to acquire motorcycle catalyst business in China

2007/2 BASF to build new DHDPS plant in

Ludwigshafen

2007/2 BASF、POMの製造能力を増強

2007/2 BASF

plans transformation into a European Company (SE)

2007/3 BASF Breaks Ground In China For

Two New Manufacturing Plants

BASF and Monsanto Announce R&D

and Commercialization Collaboration Agreement in Plant

Biotechnology

BASF

AG to shut down lysine factory in S. Korea

2007/4 BASF to debottleneck Antwerp

cracker mid Aug to end Sep

2007/5 BASF opens new engineering

plastics compounding plant in Shanghai

2007/6 BASF Agrees to Sell its Minority

Ownership Interest in Geismar Ethane Cracker

BASF rules itself out of ICI

acquisition

BASF and INVISTA enter into

ADN supply agreement

2007/7 BASF to Increase Capacity for

Neopentylglycol in China

BASF evaluates strategic options

for selected styrenics activities

2007/8 Basell : Leading contender for

BASF styrenics?

2007/8 BASF to increase propionic acid

capacity in Ludwigshafen and Nanjing

BASF Catalysts expands auto

catalyst plants in China and India

2007/9 BASF ready to take out 10 bln eur in

debt to finance acquisitions - CFO

BASF increases ethylene oxide

capacity in Europe for EO derivatives

200710 BASF inaugurates polyamide 6 and

superabsorbent plants at its Freeport, Texas, site

BASF: Official Partner of the “Germany and

China - Moving Ahead Together” initiative

2007/11 BASF acquires SABIC Innovative

Plastics'shares in the PBT joint venture

Nov 22, 2007

ReutersBASF CEO says not

impossible to be acquired

A takeover of

Germany's BASF AG is not impossible, the chief

executive of the world's largest chemicals company by

sales said.

"BASF is

not that big that it can't be taken over,"

Juergen Hambrecht told reporters in Stuttgart late on

Wednesday.

He

said he expected further consolidation in the

chemicals industry because the top 10 global

companies controlled only about 20 per cent of the

global market.

|

2007/12 BASF reorganizes

its businesses

2008/1 BASF expands plasticizers business

in Asia Pacific

2008/2 BASF interested in acquiring

Albemarle for 4.9 bln US$

2008/4 BASF ready for lawsuit against EU

on GMO potato

BASF May Abandon

Genetically Modified Crops for European Market

Dr Reddy's to buy BASF drug

contract manufact unit

2008/5 BASF Plant Science and Academia

Sinica (Taipei) to cooperate on gene discovery

2008/7 BASF delayed styrenics sale

because of low offers

BASF looking at takeover

targets

2008/8 BASF takes a further step in the

divestment of its styrenic activities

2008/9 BASF makes offer to acquire Ciba

2008/10 BASF offers a plastic that has the

property of killing microbes

2008/11 BASF looking to sell its shares in

PEC-Rhin

BASF reduces production worldwide

BASF Halts

Plan to Move Styrenics Business Into New Subsidiary

2009/1 BASF to change PolyTHF feedstock

supply in Korea

BASF got environmental approval

for MDI project in Chongqing

2009/2 BASF takes steps to optimize its

structures

2009/3 World's largest propylene oxide

plant of Dow and BASF finishes start-up phase

2009-4 BASF to sell China process

catalysts site to Sud-Chemie

2009/6 BASF to close the Styropor (EPS)

plant at its Tarragona site

BASF to reduce polystyrene

capacity in Europe by about 15 percent

BASF reorganizes its

Petrochemicals Division

2009/7 BASF in Greater China issues first

report on economic, environmental, and social performance 発表

2009/8 BASF sells styrene monomer plant

in Korea

2009/9 BASF aims to grow above market:

Asia Pacific sales to double by 2020

2009/10 BASF announces its intention to

cease activities in Feluy, Belgium and exits from MA production

2010/2 BASF Shown Styrene Escape Route by

Dow

2010/4 BASF Said to Prepare 3

Billion-Euro Bid for Germany's Cognis

2010/6

BASF reaches

agreement to purchase Cognis

2010/6 BASF starts up new plant to

increase polyisobutene (PIB) capacity

2010/8 BASF to build dispersions plant in

Huizhou 惠州

2010/10 BASF to establish STYROLUTION as a

leading company in styrenics

2010/11 BASF and INEOS to establish a new

leading global styrenics company called Styrolution

2010/12 PETRONAS and BASF sign MoU to

explore new joint investment

2010/12 BASF expands superabsorbent

polymer plants in Antwerp and Freeport

2010/12 BASF and SINOPEC

to further expand Nanjing joint venture

2011/1 BASF completes acquisition of

CRI/Criterion’s styrene

catalysts business

2011/2 BASF starts operations at expanded

Ecoflex plant

2011/3 BASF Chongqing MDI project

approved

BASF Plans Acrylic Acid, Butyl

Acrylate and Superabsorbents Complex in Brazil

2011/5 BASF to build world’s largest single-train TDI plant

in Europe

BASF and INEOS sign joint venture

contract for Styrolution

2011/6 BASF のBisomer monomer事業をGEO Specialty

Chemicals, Inc.が買収

2011/7 BASF Mulls GMO Crop Exit in

Germany

BASF to build world-scale

production site for customer specific antioxidant blends in

Middle East

BASF doubling plasticizer capacity

2011/8

BASF and CSM explore a bio-based succinic acid joint venture

BASF to invest in a world

scale acrylic acid complex in Brazil

2011/9 ダイムラーとBASF、先駆的な電気自動車プロジェクトで双方のノウハウを結集

BASF to sell fertilizer

activities to EuroChem of Russia

2011/10

BASF strengthens position

in superabsorbent polymers in emerging markets:Brazil、China、Malaysia

2012/2

BASF、メルクの電解液事業を買収

2012/4

BASF to invest in new chemical

production site in Dahej, India

2012/5

BASF purchases

polyamide polymer business in Barzil

BASF to build new formic

acid plant in the USA

2012/6

BASF and Oleon celebrate grand

opening of bio PG plant from glycerin

2012/7

BASF to build butadiene

extraction plant in Antwerp

2012/8

BASF, Cargill and

Novozymes target commercial bio-based acrylic acid process

BASF、PolyTHF®の製造能力を増強 185,000トン→250,000トン

2012/9

BASF and Total

merge two JVs in the USA

BASF

focuses global EPS business on strategic markets

Products

Cracker Products:

BASF operates its

steamcrackers, "heart" of verbund sites (Ludwigshafen, Germany 1965 and 1980; Antwerp, Belgium 1994; BASF, along

with FINA Port Arthur, Texas, 2001; Nanjing, China planned) mainly for

captive use. In addition BASF markets cracker products e.g.

within the chemical industry, refineries, plastic industry,

steel- and automotive industry.

Verbund a decisive factor for success

BASF has

significant expertise unequaled anywhere in the

world in the carefully planned

networking of factories, with efficient integration of

production and energy supply the Verbund.

The concept of Verbund began with integrated production,

which grew out of the history of the Ludwigshafen site.

Integrated production implies effective utilization of

resources and also reduced waste and emissions synergies, which cut costs and

increase cost-effectiveness.

Integrated systems are also used by BASF in relation to

its wide-ranging technical expertise. Combining knowledge

from different disciplines at one location maximizes the

benefits to be obtained. Examples of areas included are

research and development, toxicology, technical service

and engineering technology.

Plastics - a core

sector:

Plastics are a core

sector for BASF. The BASF Group is among the largest plastics

manufacturers in the world, with one of the most

comprehensive product ranges.

The BASF plastics product

range :

Styrene copolymers

Polystyrene/PPE blend

Styrene polymers

Engineering materials

Foam materials

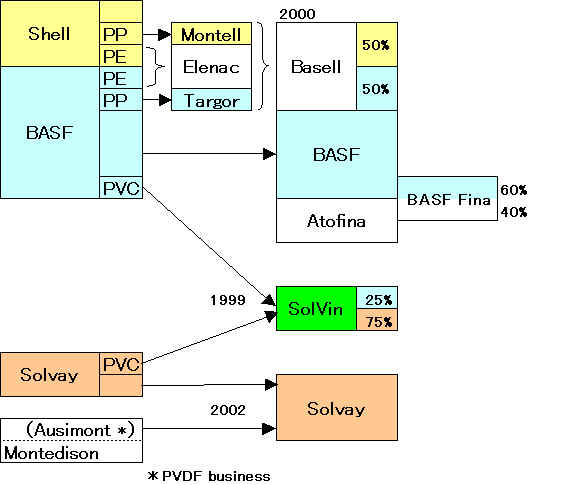

Vinyl chloride polymers → SOLVIN

modifiers Intumescent

Materials

Polyurethanes

BASF FINA Petrochemicals

Limited Partnership

is a venture between

BASF Corporation and ATOFINA Petrochemicals, Inc., a

subsidiary of TotalFinaElf SA. The limited partnership, in

which BASF holds a 60 percent share and ATOFINA holds a 40

percent share, was formed to manage the operations of the

steam cracker project and related facilities.

化学工業日報 2002/6/17

BASFフィナ、米でエチレン92万トン稼働

BASFとアトフィナの合弁会社であるBASFフィナがこのほど、米国テキサス州のポートアーサー工場で世界最大級のナフサクラッカーを建設、稼働に入った。新クラッカーのエチレン年産能力は92万トン。大規模生産により優れたコスト競争力が得られる。新プラントで生産された製品は、近隣にある両親会社の川下製品のプラントに原料として供給する。

1998/5/8 BASF

BASF Corporation (Mount

Olive, N.J.) and FINA, Inc. (Dallas, Texas) jointly

announced today that the boards of both BASF

Aktiengesellschaft (Ludwigshafen, Germany) and PetroFina

S.A. (Brussels, Belgium) have given final approval to

build the world's largest single-train steam cracker.

The facility will use a

special technology for enhanced propylene production,

thereby providing a nameplate capacity of 1.9 billion pounds

(860,000 metric tons) of ethylene and 1.9 billion pounds

(860,000 metric tons) of propylene.

2003/1/14 BASF BASF

completes transactions with Honeywell

BASF strengthens its plastics business

・BASF to acquire

Honeywell's worldwide engineering plastics business

・BASF to sell its nylon

fibers businesses to Honeywell

BASF will acquire the global engineering

plastics portfolio of Honeywell, which is primarily comprised of the

product line Capron®

nylon and

alloys (polyamide). These

products will complement BASF's engineering plastics

portfolio of Ultradur®

thermoplastic

polyester (PBT), Ultraform® acetal copolymer

(POM), Ultrason® E polyethersulfone

(PES) and Ultrason® S polysulfone (PSU),

and Ultramid® nylon-based

engineering plastics.

Honeywell release

Honeywell's global

engineering plastics portfolio includes nylon, polyester and

alloys offered in the Capron®

(nylon 6 and nylon 6,6),

Petra® (post-consumer recycled polyester) and

Nypel® (post-industrial nylon 6) product

lines.

The agreement covers polymerization and compounding

facilities, research and development assets and sales and

technical service locations in North America, Europe and

Asia. The Honeywell business currently employs about 500

people.

2003/5/1 BASF

BASF strengthens its plastics

business

BASF completes transactions with Honeywell

・BASF acquires engineering

plastics business from Honeywell

・BASF sells its nylon

fibers business to Honeywell

・Businesses transferred

on May 1, 2003

2003/03/24 BASF

BASF 農業製品部門、製品群を強化

背景

~ バイエル社の殺虫剤・殺菌剤の買収完了~

http://www.basf-japan.co.jp/news/pdf/030324.pdf

● バイエルの殺虫剤・殺菌剤製品の買収を完了

● 種子処理剤事業への重要な足がかり

● 拡大した事業活動でお客さまにさらなる価値を提供

このたびの買収を受けて、日本ではBASF アグロが原体と単剤(一部製品除く)独占で販売します。

2000年3月22日 BASFジャパン

BASF、アメリカンホームプロダクツ社より農薬事業を買収

http://www.basf-japan.co.jp/news/doc/000322.doc

BASF(本社

ドイツ・ルートヴィッヒスハーフェン)は、アメリカンホームプロダクツ社(米国・ニュージャージー州)の農薬事業を約38億ドルで買収することで合意し、両社は3月21日に契約に調印しました。

■

BASFのこれまでの主な農薬事業買収

過去4年間、BASFは農薬事業において意義深い事業買収を成功裡に進めてきました。

・1996年:とうもろこし用除草剤事業をスイスのサンド社より買収。

・1998年:米国のジェネリック農薬製品で第2位のマイクロフロー社の株式の過半数を取得。

・1999年:欧州の種苗会社大手であるスウェーデンのスバレフ・ベイブル社の株式の40%を取得。

2003/05/13 BASF

BASF、エクソンモービル・ケミカルのVistanex

LM ポリイソブチレン事業を買収

http://www.basf-japan.co.jp/news/pdf/030513.pdf

BASFは、エクソンモービル・ケミカル社のビスタネックスLM(Vistanex

LM)ポリイソブチレン(PIB)事業の買収を発表しました。

中分子量ならびに高分子量ポリイソブチレンの世界有数のサプライヤーであるBASFは、オパノール(Oppanol®)の商標で販売しています。BASFのPIB製品は、分子量の非常に小さいものから極めて大きなものまで、世界で最も広範囲の製品群を供給しています。

2003/5/22 BASF ジャパン

BASF-YPC

社、中国・南京でのDMF生産能力を増強

http://www.basf-japan.co.jp/news/html/030522.html

BASFと中国石油化工集団(SINOPEC

)の折半出資の合弁会社であるBASF-YPC

社は、ジメチルホルムアミド(DMF)プラントの年産能力を1万トンから4万トンに変更するとの決定を下しました。このプラントは現在中国・南京にある同社の統合石化拠点(IPS

)で建設が進んでいます。

■ BASF-YPC 社について

BASF-YPC 社はBASF とSINOPEC

の折半出資合弁会社です。同社は最先端の技術を駆使し、揚子江沿いの拠点(220

ヘクタール)にスチームクラッカー(エチレン年産能力60万トン)と9基の川下製品プラントを建設・操業する予定です。

2003/7/23 BASFジャパン

BASF、マイン・セーフティ・アプライアンシズ・カンパニー(MSA)よりCallery

Chemical 事業部を買収

―BASF は無機製品群を拡充、MSA

は、コアビジネスに特化―

http://www.basf-japan.co.jp/news/html/030723.html

米国ペンシルバニア州ピッツバーグを拠点とするマイン・セーフティ・アプライアンシズ・カンパニー(MSA)のCallery

Chemical(カレリー・ケミカル)事業部の買収で7月21日、合意に達しました。取引金額は約6,500万ドル(約5,800万ユーロ)となる予定です。

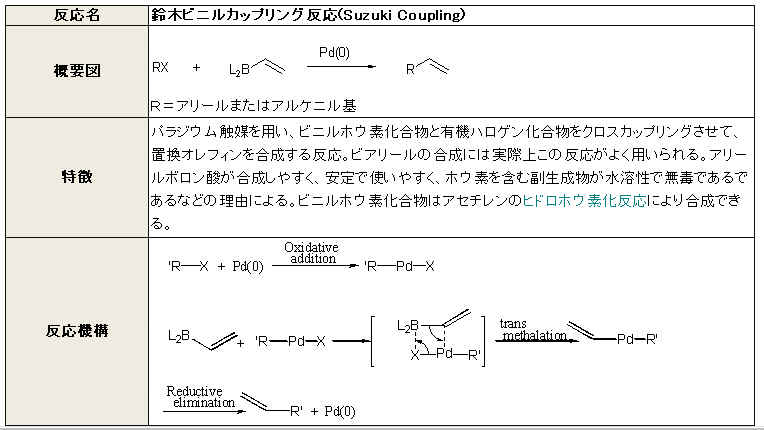

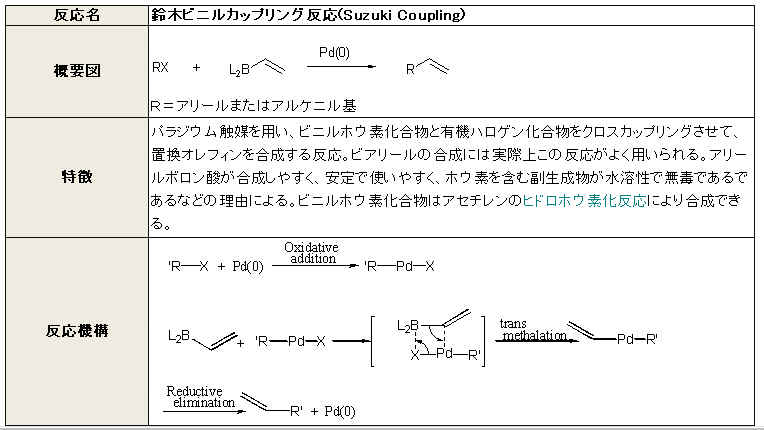

現在、Calleryにとって最大の市場は製薬業界ですが、同社の製品は農薬、界面活性剤、接着剤、ポリマー、電子工学、調味料、芳香剤、自動車などの分野でも幅広く使用されています。Calleryの製品群は、強塩基および触媒として使用されるアルカリ金属とアルコラートなどの有機合成用試薬、選択還元およびハイドロボレーションに使用されるボラン(水酸化ホウ素)類、そして急成長を遂げる化学技術である鈴木カップリング反応(Suzuki

Coupling)を支える最新のホウ素製品から構成されています。

2003/11/11 BASF ジャパン

BASF

、ビタミン事業拡張に向けて大きな一歩を踏み出す

http://www.chem-t.com/fax/images/031111basf.pdf

・ BASF

の韓国における世界規模のビタミンB2

工場、計画通り操業開始

・ 年産3,000

トンの新工場は顧客需要の増加を満たす

・ 新工場はビタミン事業に本格的に取り組むBASF

の姿勢を反映

2003/12/1 BASF

BASF、米ダイバーサ社からキラル中間体向け酵素の使用ライセンスを取得

~バイオ触媒プロセス技術のさらなる発展で広がるビジネスチャンス~

http://www.basf-japan.co.jp/news/html/031208.html

BASF (本社

ドイツ・ルートヴィッヒスハーフェン)はこのほど、ダイバーサ社(Diversa Corporation 本社:米国カリフォルニア州サンディエゴ)より、医薬中間体のバイオ触媒合成向け酵素を使用するライセンスを取得しました。この酵素を用いてBASF

はバイオ触媒を生産し、それを独自のバイオ触媒プロセスのひとつに応用してキラル中間体を合成します。この酵素は、さまざまな化学品向けに、バイオ触媒とバイオプロセスの開発を目指す両社の広範な提携関係のもとで、ライセンスされた初の商品となります。

http://diversa.com/corpinfo/corpover.asp

Diversa Corporation is a

leader in applying proprietary genomic technologies for the

rapid discovery and optimization of novel products from genes

and gene pathways. Diversa is directing its integrated

portfolio of technologies to the discovery, evolution, and

production of commercially valuable molecules with

pharmaceutical applications, such as optimized monoclonal

antibodies and orally active drugs, as well as enzymes and

small molecules with agricultural, chemical, and industrial

applications.

Diversa has formed alliances and joint ventures with market

leaders, such as The Dow Chemical Company, DuPont Bio-Based

Materials, GlaxoSmithKline plc, Invitrogen Corporation, and

affiliates of Syngenta AG.

2003年12月10日 BASF

BASF、事業戦略に新たな要素を追加

~収益性向上と顧客利益の拡大に向けた取組みをさらに強化~

http://www.basf-japan.co.jp/news/html/031211s.html

・世界最大の化学会社、事業戦略に新たな要素を追加

・新生コーポレート・ロゴは、パートナーシップを象徴

BASF(本社ドイツ・ルートヴィッヒスハーフェン)は、当社の基本戦略に新たな要素を加え、収益性の向上と顧客利益の拡大に向けた取組みをさらに強化していきます。これまでの戦略に加え、今後は以下の項目の実現も目指します。

| (1) |

将来性の高い分野に設備投資を集中させる |

| (2) |

顧客のニーズに照準を合わせたイノベーション(革新)、そしてビジネスモデルの構築 |

| (3) |

ナノテクノロジー、材料科学、エネルギー管理技術、バイオテクノロジーの分野における技術革新によるビジネスチャンスの発掘 |

【新コーポレート・ロゴの導入ついて】

新コーポレート・ロゴ:

2003/12/16 Celanese

BASF to acquire

Ticona's nylon 6,6 engineering plastics business

http://www.celanese.com/mr_news_business-fullpage?id=20115

BASF and Ticona, the

technical polymers business of Celanese AG, have reached an

agreement under which BASF will acquire the worldwide nylon 6,6

business of Ticona, effective December 31, 2003. Financial

details of the transaction were not disclosed. In 2002, the

business to be sold generated sales of around Euro 45 million.

01/14/04 BASF

BASF divests Phenoxy Business

http://www.basf.de/en/corporate/news/presse/-systemdoc_news.htm?doc_id=1226901&id=UDAoq4Mlrbsf3lP

・Focus

on higher growth products

・Nufarm to buy business

BASF

Aktiengesellschaft, Ludwigshafen, Germany will divest the

so-called phenoxy herbicide business (agrochemicals to

control weeds, globally known under the trade names U 46®

and Duplosan®

) to Nufarm Limited,

Melbourne, Australia. The sale comprises the six active

ingredients 2,4-D, MCPA, Mecoprop-P, Mecoprop, Dichlorprop-P

and Dichlorprop with sales of about Euro40 million in 2002.

The transaction includes registrations, trademarks,

intellectual property rights, customer lists and inventories.

CHINA CHEMICAL REPORTER

2004/3/31

Integrated Isocyanates Complex Kick off

http://www.ccr.com.cn/news_view.asp?ID=417

On March 29, the integrated isocyanates complex, jointly invested by BASF,

Huntsman, Shanghai Huayi (Group), Sinopec Shanghai Gaoqiao

Petrochemical and Shanghai Chlor-Alkali Chemical, kick off at the

Shanghai Chemical Industry Park. The startup was put off by

around three months than the planned schedule announced by Huayi

(CCR 2003 No.33 page 6). The US$1.5 billion project is expected

to complete in 2006.

After completion, it will supply annually 240 000 tons MDI

(diphenylmethane diisocyanate) and 160 000 tons TDI (toluene

diisocyanate) to the domestic booming polyurethane sector.

Bayer also has an

intention to set up an isocyanates project in Shanghai.

Yantai Wanhua, a

local MDI producer, is planning for the 160 000 t/a MDI unit in

Ningbo, south to Shanghai.

2004/8/24 BASF

BASF officially inaugurates its new citral plant in Ludwigshafen

Total of Euro300 million invested in

citral and its derivatives at the Ludwigshafen site

Citral becomes key building block for BASF’s fine

chemicals

http://www.corporate.basf.com/en/presse/mitteilungen/pm.htm?pmid=1537&id=YZlwC5UQVbcp1Hv

Today, August 24, 2004,

BASF will officially inaugurate a new production plant for the fine chemicals

intermediate citral at

its Ludwigshafen site. The world-scale plant, which has an annual

capacity of 40,000 metric tons, replaces an existing plant with a capacity

of 10,000 metric tons per year. As a result, citral will become

the key building block for BASF’s fine chemicals, forming the

starting point for the production of vitamins A and E, as well as

carotenoids and an extended range of aroma chemicals. Products based

on citral are used in animal and human nutrition and in the

health and cosmetics sectors.

BASF 2004/8/31

BASF plans to invest in a polyurethanes specialties site in

Shanghai

http://www.corporate.basf.com/en/presse/mitteilungen/pm.htm?pmid=1547&id=pc0h55Wi-bcp24f

・Site

in Pudong, Shanghai establishes a new level of closeness to

customers

・System house, product development and TPU

production at a single site

・Chinese polyurethanes market expected to

grow by about 10 percent per year in the next 10 years

BASF is expanding its polyurethanes activities in Asia with a

planned investment in a new specialties site in Pudong, Shanghai.

Polyurethanes specialties tailored to the requirements of Chinese

customers are to be produced in Pudong from early 2007 onward.

Approval for the project is currently being sought from the

authorities in Shanghai. Construction is planned to start next

year.

The project will comprise a polyurethane system house, a Technical Research &

Development Center

and a production plant for thermoplastic

polyurethanes (TPU).

These activities will be integrated in one company, BASF

Polyurethanes Specialties (China) Co. Ltd. The new site will use the cost advantages

provided by the regional Production Verbund for polyurethane: MDI

(diphenylmethane diisocyanate) and TDI (toluene diisocyanate) -

basic materials needed to produce specialties in Pudong - will be

supplied

from Caojing, Shanghai. Here, BASF and its partners are planning

to start up a world-scale production plant for these isocyanates

in 2006.

Basic products and specialties from a single source

TPU production benefits from global network

<参考>イソシアネート・コンプレックス

1)Shanghai Lianheng Isocyanate Co., Ltd.

アニリンとニトロベンゼンの製造施設を含む年産24万トンの粗MDI工場。

BASF、ハンツマン、上海クロールアルカリ、上海華誼公司、SINOPEC上海高橋石化のJV

2)Shanghai BASF Polyurethane Co., Ltd.

MDI精製工場と硝酸とジニトロトルエンを含む年産16万トンのTDI工場。

BASF、上海華誼公司、SINOPEC上海高橋石化のJV。

3)Huntsman Polyurethanes Shanghai Ltd.

MDI精製工場。

ハンツマンと上海クロールアルカリのJV。

2004/12/3 BASF

BASF expands capacity of its world-scale MDI plant in Antwerp by

25 percent

http://www.corporate.basf.com/en/presse/mitteilungen/pm.htm?pmid=1657&id=6XraD6*XLbcp26*

Extension to 450,000 metric tons

per year

Plant serves increasing demand in Europe and Asia

Polyurethanes market worldwide develops even more positively than

expected

BASF will expand the capacity of its world’s largest plant for MDI (diphenylmethane diisocyanate) in Antwerp,

Belgium, from a current figure of 360,000 metric tons per year to 450,000

metric tons per year. The

expansion will be completed in the second quarter of 2005.

The capacity expansion to 450,000 metric tons is the third

expansion within a short period. At the beginning of 2003, BASF

expanded the capacity of the plant, which originally had an

annual capacity of 230,000 metric tons, to 320,000 metric

tons per year. In the same

year, additional optimization measures were implemented to bring

the plant to its current annual capacity of 360,000 metric tons.

In addition to Antwerp, BASF also

operates world-scale MDI plants in Geismar, Texas, and Yeosu, Korea. Together with partners, the company is

also currently constructing an integrated world-scale production

complex for MDI and TDI in Caojing, Shanghai, which is scheduled

for completion in 2006.

2004/12/21 BASF

Polyisocyanate plant to be built

in Shanghai Chemical Industry Park

塗料原料用

Worldwide expansion of coatings raw

materials business continues

http://www.corporate.basf.com/en/presse/mitteilungen/pm.htm?pmid=1676&id=QOY5P63jDbcp.D4

BASF is investing in a new polyisocyanate plant in the Shanghai Chemical Industry Park in

Caojing near Shanghai, China. Construction of the plant, with an

annual capacity of around 8000 metric tons, is to begin mid-2005. It is scheduled to

go into operation at the end of 2006. The resulting

polyisocyanates, raw materials for the manufacture of

automotive, industrial and wood paints, will supply the entire Asian market. The

investment amounts to around $US30 million.

2005/2/23 BASF

BASF to strengthen business with

engineering plastics in Asia by new production facilities

http://www.corporate.basf.com/en/presse/mitteilungen/pm.htm?pmid=1722&id=felhl6OdUbcp2aL

- New compounding facility

in Shanghai, China

- Expansion of compounding

plant in Pasir Gudang, Malaysia

- Asia Pacific engineering

plastics market expected to grow by about 8 percent on

average per year

The company will build a new

compounding plant at its existing Pudong site in Shanghai, China.

Construction of the new facility will start in the first quarter

2005. The plant will have an annual capacity of about 45,000

metric tons. It is scheduled to come on stream by end of 2006.

In addition, BASF is expanding its compounding facility in Pasir

Gudang, Malaysia. The expansion from 30,000 metric tons to about

45,000 metric tons annual production capacity will be completed

by the second quarter of 2005. Together with the plant in Pudong,

the total investment will range in the double-digit million Euro

area. Both plants produce Ultramid® (polyamide PA) and Ultradur® (polybutylene perephthalate PBT)

compounds.

Raw materials for the plants in Pudong, Shanghai, and Pasir

Gudang, Malaysia, will be partially supplied from BASF´s 50-50 joint venture with Toray in

Kuantan, Malaysia. The joint venture is designed for an annual

production of 60,000 metric tons polybutylene terephthalate (PBT)

base resin.

Platts 2005/3/22

BASF shifting Texas plasticizers base from ethylene to butene

BASF announced late Monday $60-mil worth of plasticizer projects

in Texas for its planned transition from an ethylene-based

plasticizer producer to one which is based on butene.

| |

現状 |

投資後 |

| Pasadena

|

2-etyle hexanol

125,000t/y |

2-propyl heptanol

120,000t/y |

| ---- |

ester 125,000t/y |

| Freeport |

2-etyle hexanol

80,000t/y |

2-etyle hexanol

120,000t/y |

This is meant to

coincide with the expiration of an existing tolling agreement

with Sunoco, BASF added.

2006/9/1 BASF

BASF completes

conversion of Pasadena, Texas, unit to 2-PH

BASF has started

operation of its new 120,000 mt/year 2-propyl heptanol plant

at Pasadena, Texas, following the successful conversion of

its former 125,000 mt/year 2-ethyl hexanol plant, the company

said in a press statement Friday.

As the first

part of plasticizer platform restructuring effort at the

Pasadena site, BASF said this alcohol production unit is the

basis for the company's domestic production of DPHP

(di-propyl heptyl phthalate).

BASF also said

start-up of its DPHP and diisononyl phthalate (DINP) unit at

Pasadena was scheduled for Q1 2007.

2005/4/26 BASF

BASF to sell U.S., Canadian polystyrene business to INEOS

Americas, LLC

http://www.corporate.basf.com/en/presse/mitteilungen/pm.htm?pmid=1812&id=atOt_6iGpbcp3ds

Divestiture to include Joliet,

Ill., facility

Sale is part of ongoing NAFTA restructuring program

Transfer of approximately 140 employees to INEOS

The Joliet polystyrene facility has a total capacity of

approximately 385,000

metric tons per year and

produces general-purpose polystyrene (GPPS) and high-impact

polystyrene (HIPS).

The company has sold polystyrene

in the region continuously since 1992, when the company purchased the Joliet

facility from Mobil Chemical.

2005/4/26 BASF

BASF increases capacity for

biodegradable plastic Ecoflex®

http://www.corporate.basf.com/en/presse/mitteilungen/pm.htm?pmid=1809&id=atOt_6iGpbcp3ds

BASF starts up a new plant for

its biodegradable plastic Ecoflex®

BASF will start up in early 2006 a new plant for the production

of its biodegradable plastic Ecoflex® at its Schwarzheide site in Germany, thus

almost doubling its capacity for this product. The new plant will

have a total capacity

of 6,000 metric tons a year,

and complements

the 8,000 metric ton plant in Ludwigshafen. Ecoflex is a specialty plastic, which

belongs to BASF's Styrene Plastics operating division.

2005/6/20 BASF Japan

BASF、欧州での可塑剤事業体制を再編

BASF(本社:ドイツルートヴィッヒスハーフェン)は2005

年第3・四半期中に、欧州のジエチルヘキシルフタレート(DEHP)とその関連アルコール、2

エチルヘキサノール(2-EH)の生産を終了します。本社のルートヴィッヒスハーフェンにある2-EH

プラント(年産20 万トン)は停止し、2005 年10

月に解体します。

ベルギーのフェルイ拠点にあるいくつかの生産施設についても、無水フタル酸や可塑剤、フマル酸、ブタンジオール誘導体の製造では競争力を維持できないと判断したため、同時期に停止します。フェルイにおける無水マレイン酸の製造は継続します。こうした動きの背景には、欧州市場の停滞、世界的な設備過剰、フェルイ拠点のコスト構造が好ましくないことが挙げられます。

画期的なソリューションを模索する可塑剤業界

欧州の生産業者や顧客企業は、可塑剤として、DEHP

から他の製品、特にC9 フタレートやC10

フタレートに移行しつつあります。この結果、DEHP

市場は、2000 年対比で50%も縮小しました。

こうした変化を受け、BASF

でも、画期的な可塑剤を販売しています。一般的な用途には、Palatinol(R) N(DINP)および、BASF

のみが提供するC10 可塑剤、Palatinol(R) 10P(DPHP)です。玩具や医療機器、食品と接触するものなどのデリケートな用途向けには、Hexamoll(R) DINCH

という、人体との接触が多い用途向けに開発された画期的な特殊可塑剤も取り扱っています。

欧州における今回の事業再編は、NAFTA

やアジア地域でのBASF

可塑剤事業の展開に影響を及ぼすことは一切なく、両地域では今後も、2-EH

とDEHP の提供を継続します。

BASF 2005/7/6

BASF

acquires Huntsman’s global TDI

business

http://www.corporate.basf.com/en/presse/mitteilungen/pm.htm?pmid=1907&id=Nq0m372lnbcp18d

BASF has

acquired Huntsman’s global toluene

diisocyanate (TDI) business, effective July 6, 2005. Financial

terms for this agreement were not disclosed.

The

transaction involves Huntsman transferring its TDI customer list

and sales contracts to BASF. This agreement

does not include any transfer of manufacturing operations or

personnel. Huntsman and BASF will coordinate

efforts to facilitate an effective transition of supply

arrangements and support services for Huntsman’s TDI customers.

BASF

has TDI production facilities in Geismar,

Louisiana; Schwarzheide, Germany; Yeosu, Korea; and, commencing

in 2006, in Caojing, China (in cooperation with Chinese

partners).

BASFとHuntsmaは上海イソシアネート・コンプレックスで提携

1)Shanghai Lianheng Isocyanate Co., Ltd.

アニリンとニトロベンゼンの製造施設を含む年産24万トンの粗MDI工場。

BASF、ハンツマン、上海クロールアルカリ、上海華誼公司、SINOPEC上海高橋石化のJV

2)Shanghai BASF Polyurethane Co., Ltd.

MDI精製工場と硝酸とジニトロトルエンを含む年産16万トンのTDI工場。

BASF、上海華誼公司、SINOPEC上海高橋石化のJV。

3)Huntsman Polyurethanes Shanghai Ltd.

MDI精製工場。

ハンツマンと上海クロールアルカリのJV。

2005/7/6 Huntsman

HUNTSMAN

SELLS TDI BUSINESS TO BASF

http://www.huntsman.com/pu/index.cfm?PageID=3557&News_ID=1352&style=8

Huntsman

Corporation (NYSE: HUN) today announced the sale of its

toluene di-isocyanate (TDI) business to BASF, effective July

6, 2005.

The sale involves the transfer to BASF of Huntsman’s TDI customer

list and sales contracts. Huntsman’s Geismar,

Louisiana TDI manufacturing plant will not be transferred

pursuant to the transaction but will be

closed.

Commenting on the sale, Huntsman’s

polyurethanes U.S. Vice President, Greg Geaman, said,

"This sale represents a win-win-win situation for our

TDI customers, Huntsman and BASF. We are

focused on our MDI (diphenylmethane diisocyanate) business, with TDI

representing approximately 2% of our total polyurethanes

segment revenues in 2004.

Platts 2005/7/21

BASF's US Freeport petchem site cuts emissions by 58% on year

BASF's petrochemical hub in Freeport, Texas reduced its total

emissions in 2004 by 58% compared with the previous year, and by

84% since 2000, the firm said in a statement.

BASF reduced air emissions for 2004 by 9% on the year, and water

emissions by 85%. The improvements were made possible, in spite

of increased production, by an on-site waste water treatment

plant and an $8.5-mil nitric acid recovery process set up in

2001. The process extracts nitrates from by-product streams and

converts them into nitric acid, which is then sold or reused. The

recovery process reduces water consumption, eliminates waste and

generates annual cost savings of $1-mil, BASF said. The Freeport

site produces chemicals for a wide range of applications,

including the manufacture of adhesives, paints and coatings,

nylon and plastics. The firm employs about 600 employees and 300

contractors in Freeport.

2005/8/30 BASF

BASF invests Euro 200 million in expansion of cracker at Antwerp

site

http://www.corporate.basf.com/en/presse/mitteilungen/pm.htm?pmid=1948&id=fQlMe7Kwgbcp2Or

BASF will expand the

capacity of its naphtha steam cracker at its site in Antwerp,

Belgium. The expansion project will be conducted during the next

regular turnaround of the plant scheduled for the fall of 2007 to

avoid any additional shutdown. The investment of about Euro 200

million will raise ethylene capacity from 800,000

metric tons per year to 1.08 million metric tons per year - making the plant the largest

single-train steam cracker in Europe.

BASF operates other steam crackers in Ludwigshafen, Germany; Port

Arthur, Texas; and Nanjing, China.

2005/9/27 BASF

BASF targets 10 percent

of global chemical sales in China by 2010

http://www.corporate.basf.com/en/presse/mitteilungen/pm.htm?pmid=1989&id=SK-QV7UwJbcp2Gv

* Site in Nanjing will

make an important contribution to profitable growth in Asia

* Additional EUR1 billion budgeted for Asia until 2009

BASF aims to achieve 10 percent of its global sales and earnings

in the chemical business in China by 2010. The importance of the

company’s activities in China was stressed

in a press conference in Nanjing on the day before the opening

ceremony

of the company’s first Verbund site in China. The

site is the largest single investment in BASF’s 140-year history and an integral

part of BASF’s strategy in the Asia Pacific

region.

BASF has, therefore, commissioned the

German Society for Technical Cooperation (GTZ) to carry out a

study to analyze the economic, environmental, and social effects

of its investment in Nanjing.

2005/10/6 BASF

BASF increases capacity

for polyisobutene in Ludwigshafen

http://www.corporate.basf.com/en/presse/mitteilungen/pm.htm?pmid=2004&id=e2KYK7X_6bcp*8n

BASF is to increase its

production of medium molecular weight

polyisobutene

(MM PIB), which is marketed worldwide under the Oppanol(R)

trademark. It will increase capacity for MM Oppanol(R) at its

Ludwigshafen, Germany, site by 6 000 tonnes to a total of 18 000

tonnes per year. Work on extending the plant is expected to be

completed by the middle of 2007.

2005/10/6 BASF

BASF’s Strategy for Europe

http://www.corporate.basf.com/en/presse/mitteilungen/pm.htm?pmid=2005&id=e2KYK7X_6bcp*8n

* Growing faster than the

market

* Cooperating more closely with customers

* Systematically expanding market position

BASF is raising its European profile in order to be even more

successful in a fast and dramatically moving environment. The

company presented its new Europe Strategy 2015 at a press conference in

Ludwigshafen today. Over the next few years, BASF wants to

outperform the market, in this way winning market share,

cooperating more closely with its customers, and expanding its

market position even more systematically in certain countries.

2005/10/26 BASF

BASF とダウ・ケミカル、プロピレンオキサイドの新生産プロセスを共同開発

・ 2006

年初頭、アントワープBASF 生産拠点にHPPO プロセスのプラントを共同で建設

・

原料の過酸化水素の供給は、製造プラントをソルベイ社(ベルギー)と共同で建設中

・ 米国とアジアでもHPPO

プロセスのプラント建設を検討

BASF(本社:ドイツ

ルートヴィッヒスハーフェン)とザ・ダウ・ケミカル・カンパニー(本社:米国ミシガン州)

はこのほど、過酸化水素(HP)を使ってポリウレタン等の原料となるプロピレンオキサイド(PO)を生産するHPPOプロセス(過酸化水素法)と呼ばれる画期的な生産技術を共同で開発しました。

このPOプラントで使用する過酸化水素は、ソルベイ社との合弁企業により供給を確保します。ソルベイ社が開発した生産性の高い技術を用いて、年産23万トンのシングルトレイン過酸化水素工場を建設する予定です。ソルベイ社は、この高い技術を過酸化水素の生産拠点のすべてで採用しており、これまでに十分な実績を持っています。

2006/9/27 BASF

BASF, Dow, Solvay

partnership breaks new ground with innovative HPPO technology

in Antwerp

Environmentally friendly plant reduces waste water and energy

usage

The HPPO plant will be fed with hydrogen peroxide (HP) from a

second new plant at the Antwerp site.

The HP plant will have a capacity of 230,000 metric tons per

year and

will be constructed by Solvay, BASF and Dow.

The 300,000 metric tons per year HPPO plant, which is being built jointly

by

BASF and Dow,

is scheduled to start up in early 2008.

Platts 2005/11/14

BASF commissions amino

resins plant in Shanghai, China

BASF has started

commercial production at its new amino resins plant outside Shanghai, China, the

company announced Monday. The plant is located at BASF Auxiliary

Chemicals Co Ltd in Pudong, Shanghai. Amino resins are produced from

urea and formaldehyde, and are used commonly as adhesives for

plywood or as durable surface coatings.

Wholly Owned

Production Facilities

BASF

Auxiliary Chemicals Co. Ltd.(BACC)

BASF Auxiliary Chemicals Co. Ltd. (BACC) has a strategic role

in BASF's global Verbund network with the production of

colorants, leather and textile auxiliaries, acrylic

dispersions, acrylic copolymers, blending of fire resistant

hydraulic fluids and resin products. BACC is established in

1994 and became a wholly owned production facility of BASF in

2000. It has several hundreds employees .

BASF Chemicals Co.

Ltd. (BACH)

BASF Chemicals Co. Ltd. (BACH) was established in 2002 to

build and commission an integrated production facility for

polytetrahydrofuran (PolyTHF) and tetrahydrofuran (THF) at

the Shanghai Chemical Industry Park. The plants are planned

with an annual capacity of 60,000 metric tons of PolyTHF and

80,000 metric tons of THF, scheduled to start production in

2005.

BASF Polyurethanes

(China) Co. Ltd. (BAPC)

In 1998, BASF set up a polyurethane system house and

production lines for elastomer bumper (Cellasto) used in

automobile suspension system in Nansha, Guangzhou, Guangdong.

Current capacity for systems is 30,000 metric tons, while 3.2

million parts for elastomer bumpers, supplying customers from

the electrical appliance, construction, footwear, automotive,

furniture and other industries.

This wholly owned production facility of BASF has close to

100 employees

2005/11/28 BASF

BASF develops biodegradable plastic based on renewable raw

materials

http://www.corporate.basf.com/en/presse/mitteilungen/pm.htm?pmid=2071&id=o7JZE7nn6bcp01X

* Ecovio(R) consists of

45 percent polylactic acid obtained from corn ポリ乳酸

* Global launch

planned for 2006

* World market for biodegradable plastics expected to grow by

more than 20 percent per year

BASF has developed its first biodegradable plastic based on

renewable raw materials. The plastic Ecovio(R) consists of 45 percent

polylactic acid,

a material obtained from corn (maize). The other component is

BASF’s existing biodegradable plastic Ecoflex(R), which is derived from

petrochemicals. BASF plans to start marketing Ecovio(R) in Europe

next spring. The product is also to be launched in Asia and North

America in 2006.

エコフレックス―消費者と環境に利益をもたらす革新技術

http://www.basf-japan.co.jp/news/html/021206.html

BASF のエコフレックスは、石油化学品をベースとした完全な生分解性を持つプラスチックです。エコフレックスは、バクテリアや菌などの微生物によって、植物が分解されるのとほぼ同じ速さで、水、二酸化炭素、バイオマスに変換されます。現在、販売されたエコフレックスの約80%が再生可能な原材料の機能改善のために使用されています。このプラスチックは、澱粉や紙から作られる食品用パッケージに耐水性・耐油性を与えることによって汎用性が拡大します。さらにエコフレックスは、農業用シートにも使用されています。

エコフレックスは、1995 年にプラスチック見本市(K フェア)で初めて発表され、その3年後に商用販売が開始されました。生分解性プラスチックには数多くの利用用途が考えられていますが、エコフレックスは当初から特殊用途向けに開発されました。この革新的な製品は、消費者や環境に対する利益が最も重要となる分野において、従来の材料を補完します。例えば、BASF は2001 年に生分解性のラップフィルムを初めて開発しました。

ルートヴィッヒスハーフェンでは、現在年間8,000 トンのエコフレックスが生産されています。エコフレックスの販売開始から3年で、BASFは化学合成原料をベースとする生分解性材料の分野で・マーケットリーダーとしての地位を確立しました。2001年に売上は前年比35%増を達成し、今後2桁成長が期待されています。中期的には、生分解性材料の世界市場規模は10万トンを超えるとBASFは予想しています。エコフレックスの成功を受け、スチレン部門は生産能力の拡大を検討しています。

In the production of

Ecoflex, the chemists at BASF combine the constituents adipic acidアジピン酸, butanediol

and terephthalic acid to form the finished polymer. The length of

the molecular chains along with their branchings 分岐 and

interconnections affects the properties of the biodegradable

plastic.

This variable composition allows Ecoflex to be used as a

molecular construction kit for making customized products.

Regardless if they are formed as flexible films or sturdy

containers, they are always biodegradable. The fact that the

constituents are derived from petrochemicals has no effect on

the biodegradability.

2005年12月13日 BASFジャパン

BASF、日本の中間体事業を再編

http://www.basf-japan.co.jp/news/html/051213.html

* 日本の中間体事業はスペシャルティ製品に資源を集中

* 三重県四日市事業所でのTHF/PolyTHF(R)生産活動を終了

2006/1/3 BASF エンゲルハード、BASFによる買収提案を拒否

BASF Makes All-Cash

Proposal To Acquire Engelhard

http://www.corporate.basf.com/en/presse/mitteilungen/pm.htm?pmid=2112&id=E-nDT7zc4bcp0_K

* BASF Intends To Offer

US$37.00 Per Share For a Total of US$4.9 Billion

* Acquisition Would

Make BASF a Leading Provider in the Global Catalyst Business

BASF

Aktiengesellschaft, the world's leading chemical company, has

made an all-cash proposal to acquire all outstanding shares of

common stock of Engelhard Corporation, Iselin, New Jersey, USA, a

Fortune 500 company and leading supplier of goods for catalysis

and surface finishing, for US$37.00 per share or an aggregate of

US$4.9 billion. This price represents a 23% premium above the

December 20, 2005 closing price of Engelhard's stock of US$30.05

and a 30% premium over Engelhard's 90-day average share price

(VWAP) of US$28.42 as of December 20, 2005. This price also

represents a premium to Engelhard's 2005 year-end closing price

of US$30.15 and to the four-year-high closing price of US$32.49

achieved on July 14, 2004.

エンゲルハード社の概要について

社名 Engelhard

Corporation

本社 ニュージャージー州イセリン市

代表者 会長兼CEO ベリー

W. ペリー

売上高 5,096.9百万米ドル(2001年)

純利益 225.6百万米ドル(同上)

従業員数 6,540人

事業内容

貴金属精製・加工・販売、顔料・触媒の製造・販売

拠点 世界28ヶ国に研究・製造・販売拠点を有する。

上場 NY証券取引所上場 |

2006/4/26

Engelhard

Engelhard

Board Announces Recapitalization Plan Including $45 Per Share

Self-Tender Offer For 20% Of Company's Shares

Engelhard Corporation (NYSE:EC), one of the largest surface

and materials science companies in the world, today announced

that its Board of Directors has unanimously approved a

recapitalization plan consisting of a self-tender offer for 26

million shares for $45 per share in cash, continued execution

of the company's business strategy and incremental cost

savings the company expects will deliver $15 million annually

beginning in 2007. The 26 million shares represent

approximately 20% of the company's outstanding shares

including exercisable options.

Engelhard also announced that its board has unanimously rejected a

BASF proposal of $38 per share made in

response to the company's request for BASF to increase its

offer following BASF's access to non-public information.

Approval of the recapitalization plan completes a

value-maximization process Engelhard's board authorized in

January after determining BASF's unsolicited offer of $37 per

share was inadequate and not in the best interests of

Engelhard shareholders because it does not adequately

recognize the company's current performance or future

prospects. The board made the same determination with respect

to BASF's $38 per share proposal.

(当初:BASF Intends To Offer US$37.00

Per Share For a Total of US$4.9 Billion)

2006年05月02日 Chemnet Tokyo

BASF、エンゲルハードの買収で再提案

BASFは1日、エンゲルハードに対する買収について、買収価格を1株38ドルに引き上げ、買収期間を6月5日に延長すると発表した。

エンゲルハードでは既報の通りBASFによる買収価格の38ドルへの引き上げ提案を拒否し、株数の20%相当分の45ドルでの自社株買いを行うことを発表しているが、BASFでは38ドルで全株式を買収することを狙い、この方が株主にとって有利であるとしている。

BASFの当初の買収提案(37ドル)は4月28日までの期限で、1%以下しか応じていない。

2006/5/30 BASF

BASF and Engelhard

Reach Agreement

Engelhard

recommends that Engelhard’s shareholders accept BASF’s offer

BASF CEO

Hambrecht: “Crucial step towards

acquisition of Engelhard.”

BASF

Aktiengesellschaft announced today that it signed a

definitive agreement with Engelhard Corporation. According to

the agreement, Engelhard will recommend that Engelhard

shareholders tender their shares to BASF in exchange

for $39 per share in cash and will withdraw its

$45 per share self-tender offer for approximately 20 percent

of the company’s shares.

“We are very

pleased that BASF and Engelhard were able to reach agreement

on a negotiated transaction. This is a crucial step towards

our goal of acquiring Engelhard,” said Dr. Jurgen Hambrecht,

Chairman of the Board of Executive Directors of BASF

Aktiengesellschaft. “We are confident that

Engelhard’s shareholders will tender

their shares into our offer, following the recommendation of

Engelhard.”

BASF’s $39 per share all-cash offer

for all of the issued and outstanding shares of common stock

of Engelhard Corporation is scheduled to expire at midnight,

New York City time, on Monday, June 5, 2006.

BASFは5月30日、エンゲルハード買収について同社と合意したと発表した。

エンゲルハードが株主に対し、BASFによる1株39ドルでのTOBに応じるよう勧めるとともに、同社が出していた45ドルでの株式20%分の自社株買いのオファーを取り下げる。

BASFは昨年末にエンゲルハードの友好的買収を提案したが拒否されたため、本年1月3日に総額49億ドル(1株当たり37ドル)で買収する敵対的買収を発表した。

これに対してエンゲルハードはBASFに対してオファー価格を引き上げるよう要請し、BASFは38ドルを提案したが、エンゲルハードはこれを拒否したため、4月26日にBASFに対抗して株数の20%相当分について1株45ドルで自社株買いを行うことや、コスト削減策などを決めた。

BASFではこれを受け、5月1日にTOB価格を1株38ドルに引き上げると発表した。しかし、このTOBへの応募が少ないことから、エンゲルハードの大株主とも協議した結果、22日に買収価格を39ドルに引き上げるとともに、「これが最良の、最後のオファーであり、これ以上価格を引き上げる考えはなく、これが受け入れられないなら撤退する」と宣言した。

エンゲルハード側がこの案を評価し、今回の合意となったもので、TOBの締め切りは6月5日となっている。

Platts 2006/1/19

BASF to open engineering plastics compounding unit at Altamira

BASF will expand its North American engineering plastics

manufacturing operations with the installation of compounding

capacity at its Altamira, Mexico, site, the company said in a

press statement Thursday.

BASF 2003/6/3

Altamira site vital for BASF's commitment to North American

styrenics market

Global grades of ABS, ASA and new production for Styrolux SBC

are key highlights

http://www.basf.com/corporate/news2003/newsinfo_altamira_062303.html

2006/2/16

BASF/Diversa

BASF and Diversa Form Broad Alliance to Develop Innovative New

Products

http://www.diversa.com/presrele/2006/view_release.asp?id=20060216

Diversa Corporation and

BASF announced today that they have entered into a broad alliance

that will leverage Diversa's leadership position in novel enzyme

development and BASF's expertise in biotechnology, process

development, product applications, and global marketing and

distribution. Under the agreement, Diversa will be

responsible for discovery and optimization of new enzymes, and BASF will be

responsible for product and process development and all

commercialization matters.

About Diversa

Diversa Corporation is a leader in applying proprietary genomic

technologies for the rapid discovery and optimization of novel

protein-based products. Diversa is directing its integrated

portfolio of technologies to the discovery, evolution, and

production of commercially valuable molecules with agricultural,

chemical, industrial, and pharmaceutical applications. Diversa

has established alliances and joint ventures with market leaders,

such as BASF, Cargill Health and Food Technologies, DuPont

Bio-Based Materials, Medarex, Merck, and Xoma. In addition,

Diversa has formed a broad strategic relationship with Syngenta

AG, a world-leading agribusiness company. Diversa has

commercialized products both independently and in collaboration

with strategic partners and licensees. Additional information is

available at Diversa's website:

http://www.diversa.com/

2006/3/1 BASF

BASF reaches agreement to

buy Degussa’s construction chemicals business

http://corporate.basf.com/en/presse/mitteilungen/pm.htm?pmid=2175&id=IK9w28FQfbcp2-9

Transaction value Euro

2.7 billion for BASF

Attractive forward

integration for BASF

4 to 5 percent

annual growth in global construction chemicals market

BASF

Aktiengesellschaft, Ludwigshafen, reached an agreement with

Degussa AG, Dusseldorf, to acquire Degussa’s construction chemicals business. The purchase price for equity is

just under Euro2.2 billion. As a result, the transaction value

for BASF is Euro2.7 billion. The transaction, which still

requires approval from the relevant authorities, is expected to

close by the middle of 2006.

In fiscal 2004,

Degussa’s construction chemicals division

posted sales of approximately Euro1.8 billion and an EBIT of

Euro201 million, with a global workforce of about 7,400

employees. As the market and technology leader as well as the

largest supplier of construction chemical products, the division

markets about 40,000 products worldwide and is organized in two

segments - Admixture Systems and Construction

Systems.

デグサ ジャパン http://www.degussa.co.jp/japan/ja/company/structure/fine_industrial_chemicals.html

コンストラクション

ケミカルは建設業界の顧客を対象とした化学システムとフォーミュレーションから成り立ちます。デグサはグローバルマーケットリーダーとして、強固な流通ネットワークを築き、アプリケーション開発の豊富な経験を蓄えています。このセグメントに含まれるビジネスユニットは混和剤システム(北米)、混和剤システム(ヨーロッパ)、混和剤システム(アジア/パシフィック)、建材システム(アメリカ)、建材システム(ヨーロッパ)です。

株式会社エヌエムビー (デグサ AG 100%)

http://www.degussa.co.jp/japan/ja/company/degussa_japan_group/nmb.html

コンクリ-ト用化学混和剤、モルタル・グラウト用混和剤、コンクリ-ト製品用混和剤、吹付けコンクリ-ト用混和剤、コンクリ-ト用高性能床材、高性能無収縮材、コンクリ-ト用補修材、塗膜防水材

2006/3/22 BASF

BASF increases capacities of Acrylic monomers and superabsorbents

to meet growing demand

http://www.corporate.basf.com/en/presse/mitteilungen/pm.htm?pmid=2203&id=ahNGK8Mn-bcp44N

BASF plans to increase

its existing production capacities for acrylic acid and

superabsorbent polymers (SAP) in Antwerp and for butylacrylate in

Ludwigshafen.

The plans involve

increasing the capacity of the existing SAP plant at the

Antwerp site from the current figure of 115,000 metric tons to

175,000 metric tons annually. Capacity for the precursor

acrylic acid will be extended as a result. A second plant with a

capacity of 160,000 metric tons is to be built to back the

existing acrylic acid plant. The additional acrylic acid produced

will be needed for SAP production in Antwerp and will supply

additional volumes for Ludwigshafen as part of the European

integrated production system: Plans to expand the capacity of the

existing butylacrylate plant in Ludwigshafen will cause increased

demand for the precursor, acrylic acid. The new capacities will

be available by 2008 at the latest.

2006/4/5 BASF

BASF significantly strengthens polyurethanes business in North

America

http://www.corporate.basf.com/en/presse/mitteilungen/pm.htm?pmid=2227&id=JyVHp8R-Ebcp.6U

Expansion of polyol

production at Geismar site in United States

Acquisition of DNT plant from Air Products completed

BASF plans to increase the existing production capacities for polyols at its

Verbund site in Geismar, Louisiana.

In addition, BASF plans to transfer a major part of the polyol

production from its site in Wyandotte, Michigan, to Geismar. These measures will lead to an

increase in the annual capacity of polyols in the U.S. from

currently 250,000 metric tons (including external tolling

arrangements and purchases) to 350,000 metric

tons in

2008. BASF’s own capacity will better support

the existing business and replaces to a large extent external

tolling arrangements and purchases.

BASF has also successfully completed its acquisition of a

dinitrotoluene (DNT) manufacturing plant in Geismar from Air

Products and Chemicals Inc., Pennsylvania, for $155

million. The transaction has already received all necessary

regulatory approvals. DNT is an important raw material for the

production of toluene diisocyanate (TDI), a polyurethane basic

material used in various applications such as seat cushioning

foams for furniture and automobiles. The DNT plant will supply

BASF’s TDI plant in Geismar, which has

an annual capacity of 160,000 metric tons.

2006/4/25 BASF

BASF doubles production capacity for engineering plastic

Ultrason(R) in Ludwigshafen

http://www.corporate.basf.com/en/presse/mitteilungen/pm.htm?pmid=2245&id=alc2a8XiPbcp*tn

Expansion to 12,000

metric tons per year

23 new jobs created

Basis for global growth

Ultrason(R) is produced exclusively in Ludwigshafen. Global

marketing and application development are also managed from

Ludwigshafen.

* Ultrason S :polysulfone

Ultrason

E :polyethersulfone

2006/5/2 BASF

BASF to acquire resins

specialist Johnson Polymer

http://www.corporate.basf.com/en/presse/mitteilungen/pm.htm?pmid=2263&id=JeRSO8ZwPbcp45j

Acquisition of a

profitable and innovative business with high growth rates

Addition of water-based technology complements BASF's coating

resins portfolio

Strengthens global presence with focus on North America

BASF, Ludwigshafen, Germany, today announced an agreement to

acquire resins manufacturer Johnson Polymer, a subsidiary of

JohnsonDiversey Inc. of Sturtevant, Wisconsin, a U.S. cleaning

and hygiene products manufacturer. The respective agreement

signed on May 1, 2006 provides for a sale price of $470 million

on a cash and debt-free basis. Both companies have agreed not to

disclose additional financial details of the deal. The

transaction, which is still subject to approval by the relevant

authorities, is expected to close by the end of June 2006. The

parties are also seeking the advice of the Johnson Polymer B.V.

(Netherlands) works council prior to finalizing the transaction.

Johnson Polymer is one of the world's leading

producers and suppliers of water-based resins. Resins are important raw

materials for the production of coatings in the automotive, wood,

packaging and printing industries. Johnson Polymer's water-based

product range complements BASF's existing portfolio, which

concentrates mainly on high-solids and UV resins.

Johnson Polymer http://www.johnsonpolymer.com/johnsonpolymer/index?page=home

Johnson Polymer is a

member of the SC Johnson family of companies and has operations around the

world.

Johnson Polymer is a leading global innovator of polymers

that address environmental, health and safety issues such as

VOC reduction in inks and paints; food contact safety for

packaging materials; and recyclability for paper and plastic.

Printing & Packaging

Johnson Polymer produces polymers for use in film printing,

overprint varnishes, functional coatings and liquid inks for

the packaging and publishing markets.

Coatings

Johnson Polymer produces high solids, water-based polymers

used in the Industrial Coatings market to enhance coatings

for plastic, wood, metal, maintenance and auto refinish.

Johnson Polymer also offers a full line of water-based

polymers for the Architectural Coatings market, to improve

the performance of products such as exterior and interior

modifiers, interior varnishes, exterior and interior stains,

and concrete coatings.

Plastic Additives

Johnson Polymer offers flow additives, reactants and

compatibilizers, chain extenders and plasticizers into the

Plastic Additives market to aid in the recyclability and

overall performance of plastic products.

Functional Coatings and Active Packaging

Johnson Polymer offers a line of products for use on paper,

film and foil substrates. These products include barrier

coatings; heat seal additives; and metallization, foil and

film primers used in the food packaging (meat, dairy, and

snack), label and tobacco packaging markets.

----------

Johnson Polymer LLC has reached an amicable agreement with

its partner, Toyo Ink Mfg. Co. Ltd., to purchase its remaining

shares of the companies’ long standing joint venture,

Johnson Polymer Corporation (ジョンソンポリマー株式会社). On February 10, 2006, JPC

will become a wholly-owned subsidiary of Johnson Polymer.

2006/5/10 BASF

BASF、エンジニアリングプラスチック「Ultrason(R)(ウルトラゾーン)」の生産能力を倍増

生産能力を年産1 万2,000 トンに拡大

グローバル成長への基盤

BASFは、エンジニアリングプラスチックである「Ultrason(R)」の生産能力を倍増致します。本社ルートヴィッヒスハーフェンの施設の増強を2007

年末までに行い、生産能力を年産1

万2,000 トンに引き上げます。さらに、ウルトラゾーンの物流・梱包センターも新設致します。この2

つのプロジェクトの投資総額は約5,000 万ユーロ(約71億円)で、新たに23

人分の新規雇用を見込んでいます。

* Ultrason(R) ポリエーテルスルフォン/ポリスルフォン

( PES, PSU )

2006/5/25 BASF

BASF、ベルギーのバイオテクノロジー企業、クロップデザイン社を買収

http://www.basf-japan.co.jp/apw/Japan/Japan/ja_JP/function/conversions:/publish/Japan/upload/new/Press2006/2006-05-25.pdf

・バイオテクノロジーの研究開発をさらに強化

・農業的価値の高い形質の活用により、高収量のトウモロコシや大豆、ナタネを開発

BASF(本社:ドイツ

ルートヴィッヒスハーフェン)はこのほど、ベルギーのバイオテクノロジー企業、クロップデザイン社を買収致しました。クロップデザイン社は、BASF

グループ内で植物バイオテクノロジーを扱うBASFプラントサイエンス社に統合されます。買収額等の詳細については、両社の合意により非公開です。

クロップデザイン社の従業員は、ベルギーのヘントにある研究施設(買収後は、BASFプラントサイエンスに所属)に引き続き勤務致します。

■クロップデザイン社について

クロップデザイン社は世界の種子市場や植物由来の製品に各種形質を提供するバイオテクノロジー企業です。独自開発によるTraitMill(TM)プラットフォームを用いて遺伝形質を明らかにし、トウモロコシやコメなど、さまざまな植物の改良を進めています。1998

年に創立され、ベルギーのヘントにある研究所には70

人を超える職員を有しています。また、研究開発や商業的利用についても、広範なネットワークを築いています。

■BASF プラントサイエンス社について

BASF プラントサイエンス社はBASF

における植物バイオテクノロジー関連の活動を統括しています。同社は、欧州4

カ国と北米の7 拠点に500

人以上の従業員を擁し、国際的に研究開発・技術開発拠点をコーディネートしています。欧州および北米のさまざまな研究機関、大学、バイオテクノロジー企業との共同研究も数多く推進しています。研究活動では、農業活動の効率性向上や身体に良い栄養素、植物由来の再生可能原料の製造等の分野に注力しています。耐干ばつ性の強い植物の開発などが例として挙げられます。また、循環器系の疾病予

防に用いられるオメガ3

脂肪酸やビタミンを大量に含む植物の開発なども行っています。BASF

では、今後3 年間で2 億7,000 万ユーロを投資し、植物バイオテクノロジー関連事業を拡大する計画です。

2006/6/6 BASF

BASF receives

majority of Engelhard shares

・BASF-CEO

Hambrecht: “Special day for BASF and

Engelhard, more innovative solutions for customers.”

・Subsequent

offering period to expire on June 8, 2006

BASF

Aktiengesellschaft today announced the expiration of its initial

tender offer period to purchase all of the outstanding shares of

Engelhard Corporation and the commencement of a subsequent

offering period. The subsequent offering period will expire at

12:00 midnight, New York City time, on Thursday, June 8, 2006,

unless extended.

BASF has been

informed by The Bank of New York, the Depositary for the offer,

that, as of the expiration of the tender offer at midnight, New

York City time, on June 5, 2006, a total of 110,456,159 shares or

approximately 89% of Engelhard’s outstanding common stock had

been tendered into the offer and not withdrawn. Of those shares

tendered 18,464,174 shares, representing approximately 15% of

Engelhard’s outstanding common stock, were

tendered subject to guaranteed delivery. All shares validly

tendered and not properly withdrawn prior to the expiration of

the offer have been accepted for payment by BASF.

2006/06/09 BASF

BASF receives over

90% of Engelhard shares

BASF Announces Completion of Subsequent Offering Period

BASF Aktiengesellschaft (Frankfurt: BAS, NYSE: BF [ADR], LSE:

BFA, SWX: AN) today announced the completion of the

subsequent offering period for the outstanding shares of

Engelhard. As of 8:00 p.m. New York City time on June 8,

2006, a total of 113,489,680 shares, representing more than

90% of Engelhard’s (NYSE: EC) outstanding

common stock, had been tendered into BASF’s initial tender offer and

during the subsequent offering period.

BASF intends to complete the acquisition of Engelhard through

a merger of the acquisition vehicle, Iron Acquisition

Corporation, into Engelhard Corporation in which all

Engelhard shares not tendered into BASF’s offer or during the

subsequent offering period (other than shares held in the

treasury of Engelhard or held by BASF or any of its

subsidiaries) will be converted into the right to receive $39

per share. Following the merger, Engelhard will be a wholly

owned subsidiary of BASF. Under applicable law, the merger is

not subject to the approval of the remaining Engelhard

stockholders.

2006/8/1 BASF

BASF begins to rename Engelhard worldwide

Rebranding starts in United States with BASF Catalysts LLC

BASF today (August 1, 2006) announced that an important step in

the integration process of Engelhard into the BASF Group has been

accomplished with the registration of a new corporate name - BASF Catalysts LLC

-

in the United States. BASF will extend its brand to Engelhard

companies in other regions of the world within the next months

based on local registration requirements.

2006/8/18 BASF

Opening ceremony

marks successful start-up of integrated isocyanates complex at

Shanghai Chemical Industry Park

Joint ventures

between BASF, Huntsman and Chinese partners

Start-up of 240,000

metric tons per year of crude MDI, 160,000 metric tons of TDI

Second largest

investment by BASF in China

Shanghai Lianheng Isocyanate Co.,

Ltd.

BASF(35%)、ハンツマン、上海クロールアルカリ、

上海華誼公司、SINOPEC上海高橋石化のJV |

アニリン |

160 |

| ニトロベンゼン |

240 |

| MDI |

240 |

Shanghai BASF Polyurethane

Co., Ltd.

BASF(70%)、上海華誼公司、

SINOPEC上海高橋石化のJV。 |

硝酸 |

245 |

| ジニトロトルエン |

150 |

| TDI

|

160 |

Huntsman

Polyurethanes Shanghai Ltd.

ハンツマンと上海クロールアルカリのJV。 |

MDI精製 |

|

2006/9/14 BASF

Ludwigshafen Verbund site: BASF expands special amine

manufacturing capacity

BASF is going to expand its annual capacity for manufacturing the special amines

aminodiglycol (ADG) and morpholine, from the current 20,000 metric

tons to 30,000 metric tons, at its German Verbund site in

Ludwigshafen. The expansion of an existing production facility is

scheduled to come on stream in the first quarter of 2007. By

enhancing its special amines capacity, BASF is responding to the

increase in demand by the gas purification and electronics

industries. The company makes these products at its Ludwigshafen

plant only.

2006/10/5 BASF

BASF demonstrates renewed

strength in North America

Savings

goal of $400 million achieved ahead of schedule

Second

largest chemical company by sales in North America

Profitable

growth through acquisitions and capital expenditures

BASF today (October 5, 2006) announced that it had achieved in North America

annual fixed cost savings of $400 million ahead of its planned target of

mid-2007. The savings measures are part of a two-phase

restructuring program initiated in 2002 to increase

profitability. BASF is pursuing a course of profitable growth in

North America through investments and acquisitions and plans to spend over $500

million per year on capital expenditures in the region in 2006

and 2007.

Having largely completed its restructuring programs, BASF has

undertaken a number of capital expenditure projects in North

America that will allow it to further improve its manufacturing

base:

| ・ |

A

new superabsorbent

polymer

facility is under construction in Freeport and is

scheduled to start operations in 2007. Once completed,

this will allow less efficient sites in Aberdeen,

Mississippi, and Portsmouth, Virginia, to be closed.

BASF is constructing a nylon

intermediates unit at Freeport, also to be

up and running in 2007. This will enable the closure of a

smaller facility in Enka, North Carolina. |

| ・ |

At

the Pasadena, Texas, site $60 million is being invested

to expand production capabilities for plasticizers.

This

will enable BASF to introduce a new plasticizer into the

North American market. |

| ・ |

BASF is also

investing $125 million in an expansion of its polyol plant in Geismar, Louisiana,

which is scheduled to start up in 2008. A new

alkylethanolamines plant, also in Geismar, is scheduled

to start operations in 2007. |

| |

|

| Facts

and figures on BASF’s acquisitions in 2006: |

| ・ |

BASF

acquired Engelhard

Corporation

on

June 6, 2006. As a result of this acquisition, BASF will

become a leading supplier in the fast growing market for

catalysts. The acquisition involves 50 production sites

and 22 R&D centers in more than 20 countries.

Approximately 7,300 Engelhard employees have transferred

to BASF as a result of the acquisition. The purchase

price for Engelhard shares amounted to $4.8 billion or

approximately Euro 3.8 billion. Engelhard posted sales of

$4.6 billion in 2005. |

| ・ |

The

acquisition of the construction chemicals

business of Degussa AG by BASF was completed on

July 1. The acquisition includes production sites and

sales centers in over 50 countries as well as an R&D

center in Trostberg, Germany. Approximately 7,400

employees have transferred from Degussa to BASF. The

purchase price for equity was just under ?2.2 billion. In

addition, the transaction was associated with debt of

?0.5 billion. Degussa construction chemicals reported

sales of nearly Euro 2 billion in 2005. |

| ・ |

The

acquisition of Johnson

Polymer was completed on July 1,

2006. It provides BASF with a range of water-based resins

that complements its portfolio of high solids and UV

resins for the coatings and paints industry and will

strengthen the company’s market presence, in

particular in North America. The purchase price was $470

million on a cash and debt-free basis. In 2005, Johnson

Polymer posted sales of approximately $360 million and

had 430 employees worldwide. |

BASF Corporation,

headquartered in New Jersey, is the North American affiliate of

BASF Aktiengesellschaft, Ludwigshafen, Germany. BASF employs

about 16,000 people in North America and had sales of Euro 9.5

billion (approximately $11.3 billion) in 2005. For more

information about BASF’s North American operations, or to

sign up to receive news releases by e-mail, visit

www.basf.com/usa.

December 15, 2004

BASF to reshape SAP

manufacturing platform in North America

New plant another milestone in strategy to strengthen acrylic

acid value chain

BASF will reshape its superabsorbent polymer production

capabilities in North America by constructing a new

state-of-the-art production facility for superabsorbent polymers

at its manufacturing site in Freeport, Texas.

As a result, the company

will close

its Aberdeen, Miss., and Portsmouth, Va., production operations once the new plant is fully

operational. The new plant will begin operation in mid-2007.

Investment and capacity details were not disclosed.

2006/10/11 BASF

Hexamoll(R) DINCH (R) The

Success Story Continues

Capacity

in Ludwigshafen will be increased to 100,000 metric tons per year

European

Food Safety Authority (EFSA) approves Hexamoll(R) DINCH

BASF will increase the capacity for its specialty

plasticizer Hexamoll DINCH in Ludwigshafen to 100,000 metric

tons per year.

Hexamoll DINCH is an innovative plasticizer that was especially

developed for use in sensitive applications. Demand for Hexamoll

has continuously increased since the market introduction in 2002

leading to full utilization of the 25,000 metric tons

per year

production plant in Ludwigshafen. The additional capacity will be

ready for commercial production in the second quarter of 2007.

Up to now the main focus

has been on toys and medical applications, but in the future food contact

applications such

as cling film 食品包装用フィルムor sealants will also gain

importance. At the beginning of October, Hexamoll DINCH received

a positive review from the European Food Safety Authority (EFSA)

in addition to the existing recommendation from the German

Federal Institute for Risk Assessment (BfR). Hexamoll DINCH is

regulated under the global migration with 60 mg per kilogram

food. This makes Hexamoll DINCH suitable for a wide range of food

contact applications such as cling film, tubes or sealants.

Plasticizers are used to give flexibility to normally rigid and

brittle PVC, thus opening up a large number of applications in

consumer goods. Plasticizers are essential for a large number of

everyday-products like flooring, cable insulation, blood bags and

cling film. BASF is one of the leading global plasticizer

producers with a production capacity of more than

500,000 tons per

year, offering its customers the widest range of standard and

specialty products based on their individual requirements.

2006/11/2 BASF

BASF announces full Engelhard integration

Annual

synergies of Euro 160 million ($200 million)

Reduction

of approximately 800 positions

Catalysts

division to be located in Iselin, New Jersey

BASF’s North American headquarters to

remain in Florham Park, New Jersey

Following the acquisition of Engelhard Corporation on June 6,

2006, BASF today (November 2, 2006) announced the full

integration of Engelhard into its global operations. BASF expects

the integration to result in annual synergies of Euro160 million

($200 million) by 2010. Almost half of this amount will be

achieved by 2007 and more than 80 percent by 2008. Contributing

to the synergies will be a broader global reach, a stronger

business presence in certain regions such as North America, and

further extensions into key markets. The development positively

enhances BASF’s position as the supplier of

choice to its customers through an innovative and more

diversified product portfolio.

2006/11/2 BASF

BASF set to become supplier with the broadest pigment portfolio

BASF is set to significantly expand its pigment portfolio

through the integration of Engelhard Corporation, which it acquired in June. “We are now the supplier with the

broadest portfolio in our strategically important markets of the

coatings industry and the coloration of plastics”, said Reinhard Leppkes, Group

Vice President Performance Chemicals for Coatings, Plastics &

Specialties.

Effective November 1, Engelhard’s previous businesses for effect

pigments and films, colored pigments, pigment preparations as

well as the special mineral Attapulgite are part of BASF’s Performance Chemicals division.

The integration will be completed by mid-2007.

(アタパルジャイト:

粘土鉱物の一種。

懸濁剤、シックナーとして用いられる)

2006/11/21 BASF

BASF and Dow to Conduct Joint Feasibility Study for World-Class

TDI Facility in Europe

BASF Aktiengesellschaft (BASF) and The Dow Chemical Company (Dow)

today announced their decision to conduct a joint feasibility

study for the construction of a state-of-the-art production plant

for

toluene diisocyanate (TDI) and precursors at one of their integrated sites

in Europe. The plant would have an annual capacity of 300,000 metric

tons and

would be the world’s largest such facility ever

built. The study will take into consideration factors such as

location, technology and infrastructure. Should the project prove

viable, the facility would start operations in 2011.

Following the joint development of a process

to produce propylene oxide on the basis of hydrogen peroxide

(HPPO technology),

this current venture is the second recent cooperation between Dow

and BASF that focuses on the polyurethanes industry. In September

2006, Dow and BASF held a groundbreaking ceremony for their first

world-scale HPPO plant at BASF's site in Antwerp, Belgium. Dow

and BASF are considering the development of additional HPPO